Professional Documents

Culture Documents

Reviewed: by Nadiera at 11:45 Am, 5/17/22

Reviewed: by Nadiera at 11:45 Am, 5/17/22

Uploaded by

carlos farinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reviewed: by Nadiera at 11:45 Am, 5/17/22

Reviewed: by Nadiera at 11:45 Am, 5/17/22

Uploaded by

carlos farinaCopyright:

Available Formats

Format Rev.

REVIEWED

By Nadiera at 11:45 am, 5/17/22

A IFA ISSUED FOR APPROVAL - 13-05-2022 SNS VR AB

No. STATUS DESCRIPTION AC No. DATE BY CHECKED APPROVED

REVISIONES

Desalter System

UNIT: APS PROJECT:

Improvement Project

TÍTLE:

DISCIPLINE : Q

CONTRACTOR DOC. No.: PACKING & PRESERVATION PROCEDURE

SIZE: A4 FOR WASH WATER PUMPS

AXNAPQPRO101160000

CONTRACTOR PROJECT:

SCALE: N/A

621113

REPLACES: DOC.

REV.

LEAF: 1 of 16 AXNAPQPRO101160000

-- No. A

DOCUMENT TYPE Page 02 of 16

221000305-M06-MSSD-001 Valid from: 13-05-2022 IEC

Business: REF Expires end: N/A Status: IFA

Title: PACKING & PRESERVATION PROCEDURE FOR WASH WATER PUMPS

Author: SNS Checked: VR Approved: AB

TABLE OF CONTENTS

SR.NO DESCRIPTION PAGES

1. PACKING & PRESERVATION PROCEDURE FOR WASH WATER PUMPS 01 to 16

PROPERTY OF PAN AMERICAN ENERGY S.L. - ARGENTINE. IT CANNOT BE REPRODUCED.

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

1 of 14

CONTENTS

1. PURPOSE AND SCOPE OF APPLICATION .............................................................................. 2

2. CONSERVATION MEASURES ............................................................................................... 3

3. PACKAGING CATEGORIES ................................................................................................... 3

3.1 USE OF PACKAGING FOR CORROSION PROTECTION ....................................................... 5

3.2 PACKAGING FILMS ........................................................................................................... 5

3.3 HUMIDITY INDICATORS .................................................................................................... 5

4. LOAD ASSUMPTIONS.......................................................................................................... 7

5. WOODEN PACKAGING........................................................................................................ 7

5.1 WOOD QUALITY ............................................................................................................... 7

5.2 IPPC STANDARD ............................................................................................................... 8

5.2.1 Labeling ............................................................................................................... 8

5.3 EDGE PROTECTION FOR BOXES ....................................................................................... 8

6. MARKING AND PACKING LIST ............................................................................................. 9

6.1 MARKINGS........................................................................................................................ 9

6.2 PACKING LISTS................................................................................................................ 11

7. STANDARDIZED MARKING SYMBOLS (PURSUANT TO HPE, APPENDIX 1) ........................... 12

8. REVISION CONTROL ......................................................................................................... 14

© 2017 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

2 of 14

1. PURPOSE AND SCOPE OF APPLICATION

This standard applies to shipping and export packaging for pumps, decoking units and their respective spare

parts.

NOTE 1: Any special requirements can be set out in an order-specific procedure. The order-specific

procedure can refer back to this specification.

NOTE 2: This work order may be applied to other types of packaging and goods.

The values and load assumptions set out below represent indicative values and are not to be construed as

having universal applicability. They assume exposure to normal stresses throughout the transport chain,

meaning conditions encountered during transport by sea, air or overland given proper handling, storage and

cargo securing. Even the use of packaging that can withstand these stresses does not release the persons

involved in the logistics chain from their duty of care in handling the goods.

The technical design of wooden packaging is based on the following documentation:

HPE Packaging Guidelines (Bundesverband Holzpackmittel - Paletten - Exportverpackung

(HPSE) e.V.

ANSI/API 610 / ISO 13709 Centrifugal pumps for the petroleum, petrochemical and natural gas

industries (short: API).

To warrant proper packaging, it is imperative that the customer of RUHRPUMPEN furnishes the following

information within due time:

Modes of transport involved (truck, rail, ship, plane).

Type of transport, conventional or container FCL / LCL.

Routing and schedule.

Storage location, storage duration.

Temperatures and climate conditions (precipitation, humidity, exposure to light and UV, etc.)

expected during storage.

Agreements on corrosion prevention.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

3 of 14

2. CONSERVATION MEASURES

The packaged goods are subject to intense stresses during transport, handling and storage -

particularly during overseas transport - for which the factory is responsible to provide protection

against corrosion. Specific anticorrosion measure employed by the factory must be set out as a

separate set of instructions.

None not to be stored without additional provisions

Type 1 Short Term up to 2 weeks

Protected from Rain/Wind/Direct Sun up to 6 months

Type 2

-20C(-4F) to 40C (104F)

Protected from Rain/Wind/Direct Sun up to 12 months

Type 3

-35C(-31F) to 70C (158F)

Protected from Rain/Wind/Direct Sun up to 24 months

Type 4

-35C(-31F) to 70C (158F)

Table 1 Storage and Conservation Types

3. PACKAGING CATEGORIES

This standard contains specifications for the packaging categories of pumps, decoking units and

their spare parts. These packaging categories serve the purpose of identifying the correct

packaging to be used for properly transporting the goods.

The packaging categories are composed of the combination of the packaging groups and

packaging code numbers. Based on the storage term and the customer required storage terms,

you can determine the appropriate packaging method. Please refer to following table:

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

4 of 14

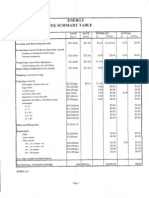

Acceptable

Desiccant

Indicator

Humidity

Storage

Lining /

Packaging

Export

Wrap

Term

Group # Uses

Spare/Small Parts

01 Cardboard Box YES NO N/A N/A Type 2

Low Weight

Spare/Small Parts

02 Wooden Box YES NO N/A N/A Type 2

Medium Weight

A Pump / Large Parts

03 Pallet NO NO NO N/A None

Short Overland

Pallet Pump / Large Parts

04 NO NO PE N/A Type 1

with Protection Short Overland

Plywood Box Pump / Large Parts

01 YES YES PE NO Type 2

Lined Low to Med Weight

Plywood Box Pump / Large Parts

02 YES YES AL NO Type 3

Wrapped Low to Med Weight

Plywood Box Pump / Large Parts

03 YES YES AL YES Type 4

Wrapped Low to Med Weight

C Wooden Box Pump / Large Parts

04 YES YES PE NO Type 2

Lined Med to large Weight

Wooden Box Pump / Large Parts

05 YES YES AL NO Type 3

Wrapped Med to large Weight

Wooden Box Pump / Large Parts

06 YES YES AL YES Type 4

Wrapped Med to large Weight

S 01 SPECIAL Per Project Specific Instructions

Table 2 Packaging Categories

PE = Polyethylene film.

AL = Laminated aluminum film

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

5 of 14

3.1 USE OF PACKAGING FOR CORROSION PROTECTION

Three methods are available for protecting packaged goods from corrosion:

Desiccant

Protective coating

VCI (Volatile Corrosion Inhibitor)

Further details are set out in the packaging guideline of the Bundesverband Holzpackmittel, Paletten,

Exportverpackung (HPE) e.V. (HPE).

The factory’s anticorrosion measures to conserve the packaged goods must be appropriate for the

respective duration of storage.

3.2 PACKAGING FILMS

For packaging purposes, two different types of film can be used:

1. Polyethylene films (PE films).

PE films, according to DIN 55530, ASTM D 2103 or approved equivalent, are made of low

density polyethylene (PE-LD).

These films are used in conditions ranging from -20°C (-4°F) to a maximum of 40°C (104°F).

2. Laminated Aluminum film according to DIN 55531 – 1 or approved equivalent.

This type of film is made from three (3) layers of different materials, specifically (12 µ PET / 12 µ

Alu / 75 µ PE).

The laminated aluminum film is impermeable to water and gases.

This film is used in conditions ranging from -35°C (-31°F) to a maximum of 70°C (158°F).

3.3 HUMIDITY INDICATORS

Humidity indicators are predominantly used for prolonged storage in combination with the desiccant method.

They change color to indicate if the relative humidity within the sealed packaging has exceeded a permitted

threshold.

Humidity indicators are calibrated at a temperature of 20°C (68°F).

Humidity indicators are a simple and cheap solution, their measurement accuracy is however not on par

with expensive electronic equipment. Their permissible tolerance is of +/- 5% relative humidity at a test

temperature of 20°C (+/- 2°C) [68°F (+/- 3.6°F)]. When exporting to areas with extreme climate conditions, it

must be taken into account that the indicator’s color will take longer to change at temperatures warmer than

20°C (68°F) and will take less time to change color at temperatures colder than 20°C (68°F). The deviation is

approximately of +/- 2.5% relative humidity per 5°C (41°F) above/below 20°C (68°F).

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

6 of 14

For prolonged storage, it is recommended that the boxes be stored in an enclosed and covered warehouse.

After six (6) months, the humidity indicator must be inspected on a monthly basis.

A visual inspection may be performed via a viewing window (installed in a box), which is accessible by

opening the metal lid.

The color of the humidity indicator changes once the humidity has reached 40%. This is an indication that

the desiccant contained in the package must be replaced.

Figure 3.1 Metal Lid Figure 3.2 Humidity Indicator.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

7 of 14

4. LOAD ASSUMPTIONS

The following load assumptions are based on normal stresses experienced during transport. Extreme and/or

unusual stresses are unsuitable for the specification of standard packaging.

MEANS OF FORWARD BACKWARD LATERAL

TRANSPORTATION ACCELERATION ACCELERATION ACCELERATION

Road Transportation

Road Transport Vehicle 1.0 g 0.5 g 0.5 g

Railroad Vehicle

Shunting Traffic 4.0 g 4.0 g 0.5 g

Combined Traffic 1.0 g 1.0 g 0.5 g

Ocean-Going Vessel

Baltic Sea 0.3 g 0.3 g 0.5 g

North Sea 0.3 g 0.3 g 0.7 g

World-Wide Voyage 0.4 g 0.4 g 0.8 g

Aerial Transportation

Airplane 1.5 g 1.5 g Vertical +/- 3.0 g

Table 3 Transportation means and acceleration

5. WOODEN PACKAGING

5.1 WOOD QUALITY

Export packaging is usually made from wood or wood-based materials. Solid wood and plywood are

particularly suitable for prolonged transport and / or prolonged storage.

Wooden crates or wooden carriages used by RUHRPUMPEN must meet the following requirements:

MOISTURE CONTENT

GRADING CLASS

FOR PROCESSING

Planks S7, M7 or equivalent as available Semi-Dried

Slats

Sleepers

S10, M10 or equivalent as available Semi-Dried

Scantling

Beams

Table 4 Wood grading classes

*Plywood must be a minimum of 12 mm or .5 inch thick.

*Dimensional lumber must be a minimum of 24 mm or 1 inch thick.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

8 of 14

5.2 IPPC STANDARD

Export packaging whose destination is outside the originating country must comply with the requirements of

the IPPC standard (International Plant Protection Conventions) ISPM 15.

The wood used for ISPM 15 must be heat-treated.

Wooden packaging is designated as ISPM 15-compliant as per the statutory requirements, consisting of:

IPPC logo.

Country code as per ISO 3166 (i.e. “DE” for Germany).

Registration number of the company performing the treatment (including. region / federal state).

Treatment method (i.e. HT [heat treatment] or MB [methyl bromide]).

NOTE: In general, RUHRPUMPEN does not use the methyl bromide (MB) treatment method. If required,

check with the appropriate LOGISTICS or PACKAGING department.

5.2.1 Labeling

The labelling of ISPM 15-compliant wooden packaging must generally correspond to the following layout

(incl. frame and dividing line). The information may be contained in a single or multiple lines.

Figure 5.1 Example of a ISPM 15 compliant wooden packaging label.

NOTE: 0000 is the registration number including region / federal state. HT stands for “Heat Treatment”.

5.3 EDGE PROTECTION FOR BOXES

For loads of more than 5 tons (11,023 lbs), a metal edge protector will be fitted at the longitudinal skids as

well as on the upper edges of the box.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

9 of 14

Figure 5.2 Example of a metal edge protector.

6. MARKING AND PACKING LIST

6.1 MARKINGS

Markings are usually specified by the customer. If no marking is specified, it may be affixed according to DIN

55402 T2 or equivalent.

A compliant marking must include the following information:

Shipping mark

Information mark

The shipping mark must include the following information:

Identification mark including consignee or consignor.

Identification number including order number.

Address including place and port of destination.

Package number including the sequential number of consignment.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

10 of 14

The information mark must include the following information:

Origin details.

Weight (mandatory for packages whose gross weight is of 1,000 kg [2,204.62 lbs] or more).

Dimensions (L x W x H in cm or in).

On wooden boxes, the marking must be affixed on at least two adjacent sides of the package and easily

readable from a distance of 5 feet or 1.5 meters.

The surface bearing the marking must warrant satisfactory and consistent legibility. The information on the

markings must correspond with the information contained on the shipping documents.

Further details are set out in chapter “Markierungen” of the packaging guideline of the Bundesverband

Holzpackmittel, Paletten, Exportverpackung (HPE) e.V. (HPE).

Figure 6.1 Example of a correctly marked wooden crate.

When marking smaller packages (i.e. small plywood boxes, cartons / carton boxes on wooden pallets or

similar) the marking must be printed on a DIN-A4 size (or letter size) paper, laminated in transparent film and

affixed to the exterior of the package.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

11 of 14

6.2 PACKING LISTS

Packing lists are prepared by RUHRPUMPEN and contain information on the contents of the package,

including:

Quantity of packaged materials.

Description of materials.

Weights.

Details regarding markings, etc.

As a general rule, packing lists are attached to the exterior of the package. There might be some cases

where the packing list is sent by another means (i.e. courier, electronically, etc.). The package list will,

depending on the duration of transport and/or storage and the expected exterior conditions, be enclosed in a

weatherproof sleeve or affixed underneath a metal plate bearing the designation “PACKING LIST” or

alternatively in the appropriate local language.

Figure 6.2 Example of a packing list attached to the wooden crate.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

12 of 14

7. STANDARDIZED MARKING SYMBOLS (PURSUANT TO HPE, APPENDIX 1)

DESIGNATION SYMBOL EXPLANATION

The symbol should be applied to fragile cargo. Cargos

Fragile, Handle with Care marked with this symbol should be handled carefully and

should never be tipped over or slung.

Any other type of point load should also be avoided with

cargos marked with this symbol. The symbol does not

Use No Hooks

automatically prohibit the use of plate hooks used for

handling bagged cargo.

The package must be transported, handled and stored

with the arrows point upwards at all times. Rolling,

This Way Up swinging, severe tipping, tumbling or other ways of

handling must be avoided. The cargo does however not

necessarily have to be stored "on top".

Compliance with this symbol is best achieved if the cargo

is kept under the coolest possible conditions. It must in

any event be protected against additional sources of

heat. It may be appropriate to enquire whether the

Keep Away from Heat prevailing or anticipated temperatures may be harmful.

This label should also be used to prevent losses for

goods such as, for example, butter and chocolate, where

common knowledge dictates that they should not be

exposed to heat.

This symbol only indicates where the cargo should be

slung, but not the method of lifting. If the symbols are

applied equidistant from the middle or center of gravity,

Sling Here

the package will remain levelled when lifted if the slings

are of identical length. If this is not the case, the slinging

equipment must be shortened on one side.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

13 of 14

DESIGNATION SYMBOL EXPLANATION

Goods marked this way must be protected from

excessive humidity and must therefore be stored under

Keep Dry cover. If particularly large or bulky packages cannot be

stored in warehouses or sheds, they must be carefully

covered with tarpaulins.

This symbol is intended to provide a clear indication of

the position of the center of gravity. To be meaningful,

this symbol should only be used when the center of

Center of Gravity

gravity is not located in the precise central position of the

package. This symbol must be affixed on two upright

surfaces at right angles to each other.

The maximum stacking load must be stated as "... kg

max.". Since such marking is sensible only on packages

Stacking Limitation

with little loading capacity, cargo bearing this symbol

should be stowed in the uppermost layer.

A note stating that the package may be clamped at the

Clamp Here indicated point means that clamping at any other location

is prohibited.

According to regulations, the symbol must be followed by

the suffix "...°C" for a specific temperature or, in the case

of a temperature range, with an upper ("...°C max.") and

Temperature Limitations

lower ("...°C min.") temperature limit. The corresponding

temperatures or temperature limits should also be noted

on the consignment note.

This symbol should only be applied to the sides

prohibited from being lifted with a forklift. Absence of the

Do Not Use Forklift Truck symbol on other sides of the package means that it is

Here permitted to use forklift trucks on these sides.

© 2018 Ruhrpumpen Global

Doc. No. Rev.

SPECIFICATION S470001 00

Packaging and Conservation Standards and Documentation Page

Ruhrpumpen Global

14 of 14

8. REVISION CONTROL

Created Checked Approved Release

Rev. Designation

By By By Date

00 Original release A.Ashoff, Ben Wood Víctor 05.17.18

José Luis Meléndez

Martínez

Tables.xlsx

© 2018 Ruhrpumpen Global

You might also like

- RFCC PDFDocument324 pagesRFCC PDFMohamed AdelNo ratings yet

- Measurement of Line Impedances and Mutual Coupling of Parallel LinesDocument8 pagesMeasurement of Line Impedances and Mutual Coupling of Parallel LinesKhandai SeenananNo ratings yet

- Transfer PricingDocument8 pagesTransfer PricingAnamir Bello Carillo50% (2)

- Final Report of SIPDocument56 pagesFinal Report of SIPRahul Parashar100% (1)

- The Challenges of Managerial Accounting 2Document5 pagesThe Challenges of Managerial Accounting 2therhine100% (2)

- An Assignment On Business Ethics..Document11 pagesAn Assignment On Business Ethics..Rahul Dhurka100% (1)

- Hydraulic Analysis - Segment C and D Gathering SystemDocument41 pagesHydraulic Analysis - Segment C and D Gathering SystemEmad El GebesyNo ratings yet

- Equipo Mayor (Major Equipment List)Document4 pagesEquipo Mayor (Major Equipment List)rondonjjNo ratings yet

- SNBP-EPC-20-PRO-PID-008 PID Open Drain Header - RRDocument2 pagesSNBP-EPC-20-PRO-PID-008 PID Open Drain Header - RRsugeng wahyudiNo ratings yet

- 6817 PR CN 0601 RevA (ReviewCheck)Document1 page6817 PR CN 0601 RevA (ReviewCheck)Nhật Quang PhạmNo ratings yet

- Parameters Symbol Unit Values: Input DataDocument10 pagesParameters Symbol Unit Values: Input DataAsad KhanNo ratings yet

- IONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 TransmittalDocument10 pagesIONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 Transmittalyusuf.yuzuakNo ratings yet

- Valve SizingDocument1 pageValve SizingfitobNo ratings yet

- Restriction Orifice-FKDocument2 pagesRestriction Orifice-FKdilip matalNo ratings yet

- SPD D0015ERN N: PR Rocess D Design M ManualDocument34 pagesSPD D0015ERN N: PR Rocess D Design M Manualchuntao fengNo ratings yet

- P 192.629 Purging of Pipeline RevisionsDocument7 pagesP 192.629 Purging of Pipeline RevisionscartarNo ratings yet

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- Desalting Dehydration Crude Oil K7LHDDocument18 pagesDesalting Dehydration Crude Oil K7LHDNguyễn Duy TânNo ratings yet

- Design Basis: Supply of Condensate Stabilization Unit For Mehar GPF Project No. 7005Document22 pagesDesign Basis: Supply of Condensate Stabilization Unit For Mehar GPF Project No. 7005Muhammad.SaimNo ratings yet

- 140 V 023Document4 pages140 V 023Goutam GiriNo ratings yet

- Kvaerner John Brown: Leff (Hor.) /H (Vert.)Document1 pageKvaerner John Brown: Leff (Hor.) /H (Vert.)bharathscdsNo ratings yet

- Process Group Spreadsheet-Based SoftwareDocument10 pagesProcess Group Spreadsheet-Based SoftwareAnonymous iCFJ73OMpDNo ratings yet

- Flare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectDocument20 pagesFlare Network Calculation Report Hammar Mishrif DGS: Eni - Iraq Zubair Oil Field Development ProjectEslam ShiblNo ratings yet

- Gas Liquid Seperation by VesselsDocument2 pagesGas Liquid Seperation by VesselszapspazNo ratings yet

- EPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 ApprovedDocument15 pagesEPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 Approvedboy telerNo ratings yet

- K PR 00 DSC 001 1 Process DescriptionDocument14 pagesK PR 00 DSC 001 1 Process DescriptionvahidforoughiNo ratings yet

- 31-MBD-127 Inlet Separator-Rev.0 (On Pile)Document53 pages31-MBD-127 Inlet Separator-Rev.0 (On Pile)Didi Hadi RiantoNo ratings yet

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsDocument62 pagesAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaNo ratings yet

- Process Engineer - PSV Installation-GuideDocument3 pagesProcess Engineer - PSV Installation-GuideMannu SatPuteNo ratings yet

- Eni 10009E04 PDFDocument64 pagesEni 10009E04 PDFSammyNo ratings yet

- PEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ADocument30 pagesPEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ARokan PipelineNo ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Relief and Blowdown Report: Page 1 of 21Document21 pagesRelief and Blowdown Report: Page 1 of 21TarekNo ratings yet

- DDG-T-P-03310 Condensate StripperDocument11 pagesDDG-T-P-03310 Condensate StripperCristinaNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- 01 P&ID Nitrogen System - Building 2,3,5Document1 page01 P&ID Nitrogen System - Building 2,3,5MTT VIETPRONo ratings yet

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- 140 V 009 PDFDocument4 pages140 V 009 PDFGoutam GiriNo ratings yet

- Zohr Development Project: Zohr Onshore - Sulphur Recovery UnitDocument25 pagesZohr Development Project: Zohr Onshore - Sulphur Recovery UnitMohamedNo ratings yet

- Guide Document GE P312 4.1.2 I General ConsiderationsDocument31 pagesGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraNo ratings yet

- Energy Optimization Using Pinch AnalysisDocument6 pagesEnergy Optimization Using Pinch Analysishwang2No ratings yet

- IPS MBD20031 in 523 Data Sheet of Thermal Relief Valve ADocument9 pagesIPS MBD20031 in 523 Data Sheet of Thermal Relief Valve ANikhil KarkeraNo ratings yet

- Line SizingDocument13 pagesLine Sizingadil alameenNo ratings yet

- PSV Load Calculation For Gas Expantion Fire Case PDFDocument2 pagesPSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaNo ratings yet

- Pipe Distributor Sizing Calculations - 07-08-2013Document26 pagesPipe Distributor Sizing Calculations - 07-08-2013pelotoNo ratings yet

- Calculation Note: XXXXX-F-MC-XXXDocument42 pagesCalculation Note: XXXXX-F-MC-XXXaalejandro251108No ratings yet

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- Appendix 5 - Control and Alarm SetpointsDocument20 pagesAppendix 5 - Control and Alarm SetpointsCù Xuân HuyNo ratings yet

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocument3 pagesDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTORONo ratings yet

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavNo ratings yet

- Ruwais Refinery Expansion Feed Project Feed: PhaseDocument9 pagesRuwais Refinery Expansion Feed Project Feed: PhaseAjit ParanjpeNo ratings yet

- Sensors & Gauges Legend: C175-16 Genset Skid LimitDocument5 pagesSensors & Gauges Legend: C175-16 Genset Skid LimitTrungSon NguyenNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument21 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- 2002 Foster Wheeler Energy Limited. All Rights ReservedDocument4 pages2002 Foster Wheeler Energy Limited. All Rights Reservedhwang2No ratings yet

- Att. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Document6 pagesAtt. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Ranjith Kumar100% (1)

- DatasheetDocument1 pageDatasheetDeni HermawanNo ratings yet

- PP Aaa PP1 123Document20 pagesPP Aaa PP1 123Rabah AmidiNo ratings yet

- Naimat West - 4 Compression Phase II - P&IDs AFCDocument13 pagesNaimat West - 4 Compression Phase II - P&IDs AFCSaqib LaeeqNo ratings yet

- Level Setting Diagrams: JOB No. 25635 25635-220-J6-0410-00001Document7 pagesLevel Setting Diagrams: JOB No. 25635 25635-220-J6-0410-00001Aldo QuispeNo ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Lubricated Plug Valves - Inverted TypeDocument16 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Lubricated Plug Valves - Inverted TypeXmanyeyNo ratings yet

- Reviewed: by Nadiera at 11:45 Am, 5/17/22Document3 pagesReviewed: by Nadiera at 11:45 Am, 5/17/22carlos farinaNo ratings yet

- Emergency PlanDocument39 pagesEmergency PlanSubbu Abu100% (2)

- Ni 1501Document7 pagesNi 1501Danilo CardosoNo ratings yet

- VPC Erection, Installation, Comm., Operation and Maint. Procedures For Triple Ecc. Butterfly ValvesDocument16 pagesVPC Erection, Installation, Comm., Operation and Maint. Procedures For Triple Ecc. Butterfly ValvesXmanyeyNo ratings yet

- Comentarios Mencionar/Confirmar en El Documento Si El Recipiente Viene Con Protección de Nitrógeno y Manómetros para Su PreservaciónDocument7 pagesComentarios Mencionar/Confirmar en El Documento Si El Recipiente Viene Con Protección de Nitrógeno y Manómetros para Su Preservacióncarlos farinaNo ratings yet

- Reviewed: by Nadiera at 11:45 Am, 5/17/22Document3 pagesReviewed: by Nadiera at 11:45 Am, 5/17/22carlos farinaNo ratings yet

- Reviewed: by Nadiera at 5:50 PM, 5/18/22Document5 pagesReviewed: by Nadiera at 5:50 PM, 5/18/22carlos farinaNo ratings yet

- Axn Ap Q Pro 10115 0000 0 ADocument16 pagesAxn Ap Q Pro 10115 0000 0 Acarlos farinaNo ratings yet

- Module 3 Notes (1) - 1Document18 pagesModule 3 Notes (1) - 1PARZIVAL GAMINGNo ratings yet

- Corona Rakshak Policy - Oriental Insurance Policy Schedule UIN: OICHLIP21064V012021Document4 pagesCorona Rakshak Policy - Oriental Insurance Policy Schedule UIN: OICHLIP21064V012021raghuNo ratings yet

- Franchise Application Form: (I) APPLICANT INFORMATION (For Individuals, Please Fill in Applicable Fields)Document2 pagesFranchise Application Form: (I) APPLICANT INFORMATION (For Individuals, Please Fill in Applicable Fields)Nha Nguyen HoangNo ratings yet

- Saudi Indian Embassy ContactDocument4 pagesSaudi Indian Embassy ContactjagateesanNo ratings yet

- Blueberry Jam Export Plan-1Document22 pagesBlueberry Jam Export Plan-1Nicole PortalNo ratings yet

- HELIOSOFT Presentation Webinar EMEADocument24 pagesHELIOSOFT Presentation Webinar EMEASvetlana ChiganovaNo ratings yet

- Full Chapter Blockchain and Smart Contract Technologies For Innovative Applications 1St Edition Nour El Madhoun PDFDocument54 pagesFull Chapter Blockchain and Smart Contract Technologies For Innovative Applications 1St Edition Nour El Madhoun PDFjames.harrington239100% (4)

- Adaptive Multi RateDocument16 pagesAdaptive Multi RateRogelio HernandezNo ratings yet

- ML Admin GuideDocument343 pagesML Admin GuidekarthiknehaNo ratings yet

- 9601/DM9601 Retriggerable One Shot: General Description FeaturesDocument6 pages9601/DM9601 Retriggerable One Shot: General Description FeaturesMiguel Angel Pinto SanhuezaNo ratings yet

- Lecture Notes-Basic Electrical and Electronics Engineering Notes PDFDocument30 pagesLecture Notes-Basic Electrical and Electronics Engineering Notes PDFMDR PRAPHU100% (1)

- KW950E Course RecorderDocument1 pageKW950E Course RecorderСКБ ФИОЛЕНТNo ratings yet

- Fusing Concurrent Orthogonal Wide-Aperture Sonar Images For Dense Underwater 3D ReconstructionDocument8 pagesFusing Concurrent Orthogonal Wide-Aperture Sonar Images For Dense Underwater 3D ReconstructionVincent WenNo ratings yet

- Criminal Law II - Quasi OffensesDocument2 pagesCriminal Law II - Quasi OffensesJanine Prelle DacanayNo ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

- NOC Video Walls Solutions - 4!10!2021 Rالبريد1Document2 pagesNOC Video Walls Solutions - 4!10!2021 Rالبريد1Sayed HamedNo ratings yet

- Yongcao 2008Document15 pagesYongcao 2008madebyNo ratings yet

- Specific PerformanceDocument3 pagesSpecific PerformanceAye AlexaNo ratings yet

- Shah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfDocument311 pagesShah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfTri4alNo ratings yet

- 3 Odometer DisclosureDocument1 page3 Odometer DisclosureJuan Carlos MartinezNo ratings yet

- TRIDENT - Request For ProposalDocument81 pagesTRIDENT - Request For ProposalPrince Mittal0% (1)

- AmbaniDocument14 pagesAmbaniShimoni ShahNo ratings yet

- BiodiversityR PDFDocument128 pagesBiodiversityR PDFEsteban VegaNo ratings yet

- Radio MirchiDocument7 pagesRadio MirchiRahul KasliwalNo ratings yet

- READMEDocument25 pagesREADMENate ClarkNo ratings yet