Professional Documents

Culture Documents

4.gas Welding Butt Joint Flat

4.gas Welding Butt Joint Flat

Uploaded by

Tayyab HussainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.gas Welding Butt Joint Flat

4.gas Welding Butt Joint Flat

Uploaded by

Tayyab HussainCopyright:

Available Formats

GOVT OF THE PUNJAB, TEVTA

GOVT.SWEDISH PAKISTANI COLLEGE OF TECHNOLOGY,GUJRAT

Technology/course/trade: Mechanical

Title of subject and code: Workshop practice I (Mech-127) Practical no: 13

Practical: Open Square butt joint , flat position ,Fore hand technique

Name of the Instructor: Muhammad Ali Raza

Technology: Mechanical Year: 1st

Specific Objectives: At the end of this practical a student will be able to

Define back hand technique

Make square butt joint

Define root gap

State importance of tacking

Set the oxy acetylene welding flame (neutral flame=6000 0F)

Introduction, Preparation, Motivation:

Different types of gas welding techniques.

Different types of welding flames.

Simple and square butt joints identification

Tools & Equipment/ Machines

Acetylene Cylinder, Oxygen Cylinder, Blow Pipe, Pressure regulator, hose pipe, welding torch, spark lighter,

Goggles, Safety shoes, leather apron, face shield, chipping hammer.

Material : 1-Mild steel 100X50X3 mm =2 pieces

2-M.S Filler wire Ø 2 mm

Safety Precautions:

1- Cylinder should be placed in vertical standing position.

2- Be careful, that there should be no leakage in cylinders.

3- Use safety Goggles while welding.

4- Material, which may catch fire, should away from welding station.

5- Use recommended equipment.

6- Having well-ventilated and open space.

7- Do not tilt or roll the gas cylinder.

8- Do not use acetylene gas pressure above 15psi.

9- Use proper size of nozzle for welding.

10-Use spark lighter for lighting the torch.

11-Protect your eyes by wearing goggles.

12-Close the valve of cylinder at the end of work.

13-Always apply first aid to burn and cut.

14-Use cylinder key to open or close the cylinder.

Procedure/Method

STEPS Key points/ Precautions for skillful

performance

1-Marking • Mark the piece according to specifications.

• Cut the piece on hydraulic shear cutter.

2-Cutting • Prepare edges of work pieces on grinder.

• Remove any dust, oil or rust from surface

3-Edge preparation of work pieces.

• Set the required gas welding flame.

4-Pre-cleaning • Place the pieces on welding table by

maintaining root gap and then tack the

5-Set welding flame.

pieces.

• Start the welding according to welding

6-Alligne/Tacking

technique.

7- Gas Welding • Cool & clean the job

8-Post cleaning

Blow pipe angle with job =45-

50 degree

Filler rod (dipped in molten pool)angle=20-

30 degree

Application & Try out:

Although gas welding is nearly finished in major steel industry (only used for cutting purposes), however in

small gauge metal works gas welding is being used successfully.

Testing & Follow up:

1- Differentiate between butt joint and square butt joint.

2- Define gas welding flames.

You might also like

- AWP-Dual ManualDocument23 pagesAWP-Dual ManualDanny ChenNo ratings yet

- Man Trans Overhaul PDFDocument30 pagesMan Trans Overhaul PDFDaniel OlariNo ratings yet

- Engineering Workshop PDFDocument55 pagesEngineering Workshop PDFIzax Afxal Khan100% (1)

- Welding Report.Document12 pagesWelding Report.Haikal SubriNo ratings yet

- Welding ReportDocument10 pagesWelding ReportEboyzZ81% (16)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Skoda Rapid Maintenance Workshop ManualDocument194 pagesSkoda Rapid Maintenance Workshop ManualOvidiu DuţăNo ratings yet

- Corner JointDocument2 pagesCorner JointTayyab HussainNo ratings yet

- 3.gas Welding Bead MakingDocument2 pages3.gas Welding Bead MakingTayyab HussainNo ratings yet

- 2.gas Welding Pool MakingDocument2 pages2.gas Welding Pool MakingTayyab HussainNo ratings yet

- 1.gas Welding Flame MakingDocument2 pages1.gas Welding Flame MakingTayyab HussainNo ratings yet

- SMAW 9 - Q1 - W2 - Mod2Document29 pagesSMAW 9 - Q1 - W2 - Mod2Romeo Dela RosaNo ratings yet

- DJJ10022 Report (Sir Amri)Document6 pagesDJJ10022 Report (Sir Amri)Muhd Imran Kasyidi OmarNo ratings yet

- SMAW 9 - Q1 - W3 - Mod3Document19 pagesSMAW 9 - Q1 - W3 - Mod3Romeo Dela RosaNo ratings yet

- Plate 7.3 BASIC WELDING ANGADocument11 pagesPlate 7.3 BASIC WELDING ANGAjason.angaNo ratings yet

- Smaw Prepare Weld MaterialsDocument38 pagesSmaw Prepare Weld MaterialslildensixxNo ratings yet

- Chung Cheang Ping (20dkm18f2032)Document16 pagesChung Cheang Ping (20dkm18f2032)Syfull musicNo ratings yet

- Mig ReportDocument14 pagesMig ReportDhana KumaranNo ratings yet

- Workshop WeldingDocument10 pagesWorkshop WeldingakhilNo ratings yet

- M2 - U2 - Introduction To Oxy-Acetylene WeldingDocument26 pagesM2 - U2 - Introduction To Oxy-Acetylene WeldingAravind Phoenix100% (2)

- MS-II Lab ManualDocument18 pagesMS-II Lab ManualdibyenindusNo ratings yet

- LEARNING GUIDEperforming Cuting and Welding Using Oxy AcetyleneDocument75 pagesLEARNING GUIDEperforming Cuting and Welding Using Oxy AcetyleneG/michael AregayNo ratings yet

- Safe Work Procedure: Sep/12/2006 Hourly Auto Body Metal Tig Welder Teacher and or StudentsDocument2 pagesSafe Work Procedure: Sep/12/2006 Hourly Auto Body Metal Tig Welder Teacher and or StudentsGanga DaranNo ratings yet

- Department of Petrochemical Collage of Technical Engineering Duhok Polytechnic UniversityDocument13 pagesDepartment of Petrochemical Collage of Technical Engineering Duhok Polytechnic UniversityIbrahimNo ratings yet

- Welding ProjectDocument10 pagesWelding ProjectSean LimNo ratings yet

- Sogec - CP Cathodic Protection Training Manual-Module 6Document10 pagesSogec - CP Cathodic Protection Training Manual-Module 6Emre ErdemNo ratings yet

- Module 1 Week 4-6, TVE SMAW 10Document25 pagesModule 1 Week 4-6, TVE SMAW 10Daryl TesoroNo ratings yet

- WeldingDocument8 pagesWeldingmukesh201094No ratings yet

- Weld Carbon Steel PipeDocument14 pagesWeld Carbon Steel PipeAdrienne Bates100% (2)

- BasicGasWelding - Millwright - Without Crop MarksDocument25 pagesBasicGasWelding - Millwright - Without Crop MarkspikasNo ratings yet

- Shielded Metal Arc Welding: Mild Steel I (E7018)Document41 pagesShielded Metal Arc Welding: Mild Steel I (E7018)greatsteelNo ratings yet

- Basic ElectricalDocument133 pagesBasic ElectricalBk BhaiNo ratings yet

- Laboratory Manual: Chandigarh Engineering College, Landran (Mohali)Document9 pagesLaboratory Manual: Chandigarh Engineering College, Landran (Mohali)Jay PandeyNo ratings yet

- Gas and Electrical Welding (Nuetral Flame and Smaw) : Acetylene Valve About 1/6 TurnDocument3 pagesGas and Electrical Welding (Nuetral Flame and Smaw) : Acetylene Valve About 1/6 TurnAbuja sygNo ratings yet

- Requirements To Be AccomplishedDocument9 pagesRequirements To Be Accomplishedcheenee dela cruzNo ratings yet

- Chapter 1: Introduction: PKM Smts SPM 2010Document9 pagesChapter 1: Introduction: PKM Smts SPM 2010yeopsagorNo ratings yet

- Welding Report (Basic)Document15 pagesWelding Report (Basic)kurttaufiqhakimiNo ratings yet

- Module 9 Quarter II Week 3Document14 pagesModule 9 Quarter II Week 3WilmerNo ratings yet

- MST185 Manual SMLDocument44 pagesMST185 Manual SMLGreg MeyerNo ratings yet

- Railtech Aluminothermic Welding ManualDocument35 pagesRailtech Aluminothermic Welding ManualIrwan Joe100% (2)

- Ministry of Education, Malaysia Curriculum Development Division Vocational College Standard CurricullumDocument12 pagesMinistry of Education, Malaysia Curriculum Development Division Vocational College Standard CurricullumMohamad Nadzri YahayaNo ratings yet

- Die Casting Maintainance PDFDocument32 pagesDie Casting Maintainance PDFgksp100% (1)

- EWS ManualDocument85 pagesEWS Manualxena5356No ratings yet

- Shop Exercise 5Document16 pagesShop Exercise 5Athena GrotesqueNo ratings yet

- Weld RepireDocument91 pagesWeld RepireالGINIRAL FREE FIRENo ratings yet

- Welding ATWDocument62 pagesWelding ATWARPIT MATHURNo ratings yet

- Lesson Plan: Trade: Welder Module/Unit: 1Document2 pagesLesson Plan: Trade: Welder Module/Unit: 1Amar jit mohantyNo ratings yet

- Title: Arc Welding Project. Name of LecturerDocument9 pagesTitle: Arc Welding Project. Name of LecturerDaus FirdausNo ratings yet

- Welding Workshop ManualDocument16 pagesWelding Workshop ManualMuhammad FarooqNo ratings yet

- Adam Junid - Assignment Sheet DCS 1205 Rev1 23mar16Document29 pagesAdam Junid - Assignment Sheet DCS 1205 Rev1 23mar16yogapostNo ratings yet

- Soldering TechniqueDocument23 pagesSoldering TechniquemokongNo ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- Yoke Style Closure Double Single Bolt BrochureDocument14 pagesYoke Style Closure Double Single Bolt Brochureandreshuertascalderon02No ratings yet

- Sop Welding & Gas CuttingDocument9 pagesSop Welding & Gas CuttingvinodsnNo ratings yet

- Lab Report 5Document5 pagesLab Report 5mamoona noreenNo ratings yet

- 05 - WELD REPAIR PROCEDURES of BOILER COMPONENTS PDFDocument165 pages05 - WELD REPAIR PROCEDURES of BOILER COMPONENTS PDFLakshmi Narayan100% (2)

- EPAS 11 - Q1 - W7 - Mod5Document40 pagesEPAS 11 - Q1 - W7 - Mod5Alberto A. FugenNo ratings yet

- TestDocument10 pagesTestAnonymous BW1EW9beJqNo ratings yet

- Cathodic Protection ProcedureDocument3 pagesCathodic Protection Procedurewhah11100% (2)

- Phase IV Welder Module 1.2Document15 pagesPhase IV Welder Module 1.2Magdi SiamNo ratings yet

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Corner JointDocument2 pagesCorner JointTayyab HussainNo ratings yet

- 3.gas Welding Bead MakingDocument2 pages3.gas Welding Bead MakingTayyab HussainNo ratings yet

- 2.gas Welding Pool MakingDocument2 pages2.gas Welding Pool MakingTayyab HussainNo ratings yet

- 1.gas Welding Flame MakingDocument2 pages1.gas Welding Flame MakingTayyab HussainNo ratings yet

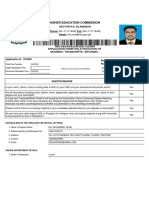

- Struck Off ApplicationsDocument9 pagesStruck Off ApplicationsTayyab HussainNo ratings yet

- The Effect of Learning Organization Organizational Climate and Work MotivationDocument12 pagesThe Effect of Learning Organization Organizational Climate and Work MotivationTayyab HussainNo ratings yet

- DAS AppFormDocument3 pagesDAS AppFormTayyab HussainNo ratings yet

- S.no. Description Part No. Qty/trDocument9 pagesS.no. Description Part No. Qty/trspdhimanNo ratings yet

- SK330 Trouble Shoot (By Trouble)Document36 pagesSK330 Trouble Shoot (By Trouble)ferdyak1No ratings yet

- Catalog Maxi 5 2016Document128 pagesCatalog Maxi 5 2016Radu BarbaNo ratings yet

- Cars Pricelist Jan 2022Document16 pagesCars Pricelist Jan 2022Edenjoy Palacay Macugay Estabillo-CallanganNo ratings yet

- PC-203-3 - O-320-E1a,-E2aDocument82 pagesPC-203-3 - O-320-E1a,-E2aNathaniel LuraNo ratings yet

- Service Manual: Issued: March 2017 Pub. No. 292T2-00120Document287 pagesService Manual: Issued: March 2017 Pub. No. 292T2-00120Yeesvaran NarayanasamyNo ratings yet

- Bob's Card Models: Gippsland Airvan GA8 1:36Document12 pagesBob's Card Models: Gippsland Airvan GA8 1:36Luiz Fernando MibachNo ratings yet

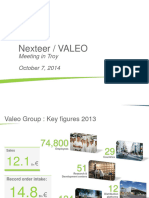

- 2014 10 07 Nexteer Valeo MeetingDocument29 pages2014 10 07 Nexteer Valeo Meetingmonutilisation0No ratings yet

- 2021 Nissan Kicks Owner ManualDocument556 pages2021 Nissan Kicks Owner ManualNoel HermidaNo ratings yet

- World Standard Automatic Transmission FluidDocument3 pagesWorld Standard Automatic Transmission Fluidida fariyantiNo ratings yet

- Mpierce Mmatic BenchDocument16 pagesMpierce Mmatic Benchhesparza0% (1)

- kIJANG INOVA DIESELDocument109 pageskIJANG INOVA DIESELIqbal ATNo ratings yet

- M-22 Swing Up ThrusterDocument199 pagesM-22 Swing Up ThrusterSergei Kurpish100% (2)

- Specification Cylinder Block Caterpillar 3412 Serial Number Prefix 38SDocument2 pagesSpecification Cylinder Block Caterpillar 3412 Serial Number Prefix 38SAmir J.No ratings yet

- CDM818D Spare Parts Manual 2021.12.23Document167 pagesCDM818D Spare Parts Manual 2021.12.23Angelo KuibidaNo ratings yet

- GUAGE LEVEL FUEL TANK - CRAWLER EXCAVATOR Doosan SOLAR 340LC-7 - BODY PARTS - 777partsDocument2 pagesGUAGE LEVEL FUEL TANK - CRAWLER EXCAVATOR Doosan SOLAR 340LC-7 - BODY PARTS - 777partsSRINIVASA RAO MARTURINo ratings yet

- 2017 2018 NGK CatalogDocument469 pages2017 2018 NGK CatalogJoseph Tchagou PoumoNo ratings yet

- IN Mahindra Cruzio Grande Buses 20221124Document13 pagesIN Mahindra Cruzio Grande Buses 20221124Psychedelic TranscendenceNo ratings yet

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument11 pagesBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan Sundararaj100% (1)

- Mergermarket Deals Export 20230404 04f1939bDocument22 pagesMergermarket Deals Export 20230404 04f1939bEmanuele TattaNo ratings yet

- S 831 - Parts - 2006Document50 pagesS 831 - Parts - 2006Centrifugal SeparatorNo ratings yet

- Gate Valve FLG WCB 125Document1 pageGate Valve FLG WCB 125rawalepushkar123No ratings yet

- P5k PMS PartlistDocument30 pagesP5k PMS PartlistuserfileNo ratings yet

- Servis DataDocument4 pagesServis DatamxNo ratings yet

- Ez Series: Specifications Ez Atv Ez Utv Ez Maxim Ez HDDocument1 pageEz Series: Specifications Ez Atv Ez Utv Ez Maxim Ez HDDarko GrujevskiNo ratings yet

- Arme de Transmision D6MDocument19 pagesArme de Transmision D6MLeonardo PerezNo ratings yet

- 21-17 - Standby Diesel Generator Set QCS 2014Document19 pages21-17 - Standby Diesel Generator Set QCS 2014Jegadeshwaran RNo ratings yet