Professional Documents

Culture Documents

Inspection Testing Repair Form

Inspection Testing Repair Form

Uploaded by

Vajid MadathilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Testing Repair Form

Inspection Testing Repair Form

Uploaded by

Vajid MadathilCopyright:

Available Formats

PRV inspection Procedure

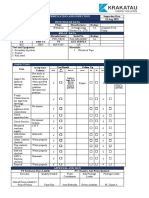

Inspection, Testing, & Repair Form

Inlet/Outlet Inspection Date

Tag # Unit

Size & Location

Basic Data

Set-Pressure

Leak Pressure Back Pressure Media

CDTP

Manufacturer Class Last Dismantle

Work Order

Type (C/BB/P/V) Interval Date PM CM

Inlet Piping Outlet Piping Atmospheric

Inspection

Weep Halls

Condition Condition Covers

Field

Support Condition Bolts Condition Flange / Thread Paint Condition

Pre-Test Done Waived Justification

Result

Actual Pop (As per Construction

(Shall not Exceed 150% CDTP)

Code)

Un-Satisfactory (If failed to open within acceptance criteria)

Leak Test Result Pass Failed Leakage Rate

(As per API 527)

A Good C Eroded E Broken G Plugged I Bent

As Found

Condition

B Corroded D Dirty F Fouled H Pitted J Stuck

Overhaul Adjustment

Overall Result

Yes No Yes No

Disc Spindle Cap Gasket

Broken / Damaged Nozzle Seat O-Rings Pilot Kit Tested By

Spring Bellow Guide Orifice

Pallets

Sticking Corroded Normal

Condition

Vacuum Breakers Notes

Flame

Fouled Plugged Normal

Arrestors

Flange Re-

Cleaned Lapped Machined

Faced

Parts Replaced

Repairs

Other Remarks

Additional Spares

Inspector Date Time Signature

Satisfactory

Final Test CDTP Result Justification

Un-Satisfactory

Final

Test

Satisfactory Spring

Leak Test Result Leakage Rate Adjustment

Un-Satisfactory

(±MM)

Previous Inspection Result

Interval

Change

Recommendatio

Additional

Next Recommendation

Current Inspection Interval

n

Inlet /

Tested By Signature Shipping Tagged Outlet Shipped On

Covered

Accepted By Signature By Signature

SAP Record Update Signature Calibration

Recor

(Area Planner)

Interval Change

ds

Signature

Meridium Update Signature Raised By

(Static Inspector)

C: Conventional BB: Balanced Bellow P: Pilot V: Breather Valve/Vacuum valve

Page 1 of 1

This Form is controlled document under PRD Management System.

You might also like

- Final Ace & Tate Research Book PDFDocument71 pagesFinal Ace & Tate Research Book PDFmorganNo ratings yet

- Pre-Concrete Inspection Checklist FormDocument1 pagePre-Concrete Inspection Checklist FormzainalNo ratings yet

- Practice Problem Set2 - Process Capacity AnalysisDocument4 pagesPractice Problem Set2 - Process Capacity AnalysisMayuresh GaikarNo ratings yet

- Root Cause Analysis For VRF System FailureDocument3 pagesRoot Cause Analysis For VRF System Failurelcatey1No ratings yet

- Stationary Equipment Inspection ScopeDocument2 pagesStationary Equipment Inspection ScopeVajid Madathil100% (1)

- Precast Segment ChecklistDocument1 pagePrecast Segment ChecklistRahul Chauhan100% (1)

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Chhattisgarh Swot AnalysisDocument5 pagesChhattisgarh Swot Analysisashwin_narayankarNo ratings yet

- Google Car Case Analysis ICLADocument5 pagesGoogle Car Case Analysis ICLASam DhuriNo ratings yet

- Xerox: OrdinaryDocument1 pageXerox: Ordinaryvijay kumarNo ratings yet

- Xerox: OrdinaryDocument1 pageXerox: Ordinaryvijay kumarNo ratings yet

- TRN-334-DG SetDocument1 pageTRN-334-DG Setcontracts1.delhiNo ratings yet

- Mold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationDocument3 pagesMold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationUmang Srivastava100% (1)

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Document3 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Sasanka SekharNo ratings yet

- 6 Sigma SD Shaft Dia. VariationDocument32 pages6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- J-2441 Ci-Sg DRG-C2 Rev.0Document2 pagesJ-2441 Ci-Sg DRG-C2 Rev.0BINOY DASNo ratings yet

- Road Bitumen Work QAP No 02Document2 pagesRoad Bitumen Work QAP No 02Sasanka SekharNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- Qap - Structural Mechanical FabricationDocument8 pagesQap - Structural Mechanical Fabricationbharathi_pmNo ratings yet

- Protection Relay Verification and Inspection Switchgear DataDocument11 pagesProtection Relay Verification and Inspection Switchgear DatamomoNo ratings yet

- QAP N2 Generator & N2 VesselDocument2 pagesQAP N2 Generator & N2 VesselVijay - Spantech EngineersNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- 12.0.6 FQP Transformer R0 Aug08Document18 pages12.0.6 FQP Transformer R0 Aug08Zala PushprajNo ratings yet

- SEIP For 086-V-001: Amine Acid Gas KO DrumDocument6 pagesSEIP For 086-V-001: Amine Acid Gas KO DrumThinh NguyenNo ratings yet

- Om-03 Hose Handling Crane PDFDocument126 pagesOm-03 Hose Handling Crane PDFcpîndaruNo ratings yet

- GMs Drill Deep Read Across MatrixDocument10 pagesGMs Drill Deep Read Across MatrixJohn Oo100% (1)

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Method of Statement: Fit Up and ToolsDocument1 pageMethod of Statement: Fit Up and ToolsAmul PontingNo ratings yet

- RESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusDocument2 pagesRESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusSameer SaxenaNo ratings yet

- Mẫu báo cáo nghiệm thu khởi động máyDocument13 pagesMẫu báo cáo nghiệm thu khởi động máyduccanh98.hustNo ratings yet

- Precast Segment ChecklistDocument1 pagePrecast Segment ChecklistRahul ChauhanNo ratings yet

- Precast Segment ChecklistDocument1 pagePrecast Segment ChecklistRahul ChauhanNo ratings yet

- Crane 90 MeindoDocument11 pagesCrane 90 MeindoPrawiraNo ratings yet

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- L - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.Document1 pageL - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.NIEL TANEDONo ratings yet

- Nissan Magnite - Seat Cover Inspection ReportDocument19 pagesNissan Magnite - Seat Cover Inspection ReportQuality elegantNo ratings yet

- I2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCDocument3 pagesI2114-OPR-ITP-CHK-007A (01) Pour Inspection Checklist - RCCPrasant Kumar SahooNo ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- Daily Check List For EPGDocument2 pagesDaily Check List For EPGchilamparasanNo ratings yet

- Check List Grue A Tour Tower CraneDocument3 pagesCheck List Grue A Tour Tower Cranemed sarhanNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- Amc QapDocument8 pagesAmc QapSasanka SekharNo ratings yet

- Preparacion de SuperficieDocument5 pagesPreparacion de SuperficieJulio HuancaNo ratings yet

- Format For Information For Inspection of Ongoing /completed WordDocument13 pagesFormat For Information For Inspection of Ongoing /completed WordARTI PALEKARNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : PotentialDocument2 pagesFailure Mode and Effects Analysis (Process Fmea) : Potentialjavier ortizNo ratings yet

- New Supplier OrientationDocument92 pagesNew Supplier Orientationminhtam.angelaNo ratings yet

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- Motors Overhauling ChecklistDocument10 pagesMotors Overhauling ChecklistAdnan AhmedNo ratings yet

- Beert Bos: Affected ProductsDocument5 pagesBeert Bos: Affected ProductsRodolfo Alberto Muñoz CarcamoNo ratings yet

- Boeing CLEEN Projects BriefingDocument32 pagesBoeing CLEEN Projects BriefingVictor BettNo ratings yet

- Qap Eot CraneDocument5 pagesQap Eot CraneAmit KumarNo ratings yet

- 415 - Dexler - QAP - 800V, 2200ADocument4 pages415 - Dexler - QAP - 800V, 2200Asriram.5230No ratings yet

- Eye Bolt Inspection Report: Last of ExaminationDocument7 pagesEye Bolt Inspection Report: Last of ExaminationRonniNo ratings yet

- Inherent Risk Assessment - Ammonia Plant - 12032020Document6 pagesInherent Risk Assessment - Ammonia Plant - 12032020Anonymous gWKgdUBNo ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- 7 - HSE-SOP-007 Radiography Permit FormDocument2 pages7 - HSE-SOP-007 Radiography Permit FormEngr. Muhammad Hassan AzizNo ratings yet

- Incoming Goods Inspection ChecklistDocument4 pagesIncoming Goods Inspection ChecklistRiyu RathodNo ratings yet

- 8D Front Map Pocket Short MoldDocument10 pages8D Front Map Pocket Short MoldNirmal polyplastic100% (1)

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument2 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- A Review of Steel MicrostructuresDocument3 pagesA Review of Steel MicrostructuresVajid MadathilNo ratings yet

- Failure Analysis of 316L Seamless PipeDocument9 pagesFailure Analysis of 316L Seamless PipeVajid MadathilNo ratings yet

- Detail of Extension Cone-Rev-01Document1 pageDetail of Extension Cone-Rev-01Vajid MadathilNo ratings yet

- Jubcor 2019 Technical Program 1Document3 pagesJubcor 2019 Technical Program 1Vajid MadathilNo ratings yet

- Asset Intelligence Report - A Primer On High Temperature Hydrogen AttackDocument9 pagesAsset Intelligence Report - A Primer On High Temperature Hydrogen AttackVajid MadathilNo ratings yet

- ERNiCrCoMo 1Document1 pageERNiCrCoMo 1Vajid MadathilNo ratings yet

- DatasheetDocument1 pageDatasheetVajid MadathilNo ratings yet

- Equivalent ASME EN MaterialsDocument3 pagesEquivalent ASME EN MaterialsVajid MadathilNo ratings yet

- Detail of Extension ConeDocument1 pageDetail of Extension ConeVajid MadathilNo ratings yet

- Boiler Feed Water and Steam ChemistryDocument4 pagesBoiler Feed Water and Steam ChemistryVajid MadathilNo ratings yet

- PR-Request FormDocument2 pagesPR-Request FormVajid MadathilNo ratings yet

- Low Alloy SteelDocument6 pagesLow Alloy SteelVajid MadathilNo ratings yet

- Visitor Information RequirementsDocument1 pageVisitor Information RequirementsVajid MadathilNo ratings yet

- Welder Performance Card - DetailsDocument2 pagesWelder Performance Card - DetailsVajid MadathilNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument2 pagesPolythionic Acid Stress Corrosion CrackingVajid MadathilNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- Astm 112Document45 pagesAstm 112Vajid Madathil100% (1)

- Water Tube Boiler-Working PrincipleDocument3 pagesWater Tube Boiler-Working PrincipleVajid MadathilNo ratings yet

- Crack at Blower's NozzleDocument3 pagesCrack at Blower's NozzleVajid MadathilNo ratings yet

- Step 1: Identify Equipment Prone To CuiDocument7 pagesStep 1: Identify Equipment Prone To CuiVajid Madathil100% (1)

- SpiceJet AirlinesDocument2 pagesSpiceJet AirlinesVajid MadathilNo ratings yet

- Federal Bank Utsav Rewards - Debit Card Loyalty ProgramDocument2 pagesFederal Bank Utsav Rewards - Debit Card Loyalty ProgramVajid MadathilNo ratings yet

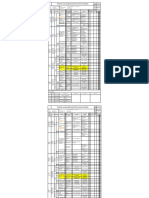

- Stationary Equipment List From SAPDocument132 pagesStationary Equipment List From SAPVajid MadathilNo ratings yet

- 1PSV 208008 BSDocument3 pages1PSV 208008 BSVajid MadathilNo ratings yet

- Caresoft - Wolfe Conference - 15-Feb-23Document46 pagesCaresoft - Wolfe Conference - 15-Feb-23Sadi HamutNo ratings yet

- Brochure Detector Family 202002Document4 pagesBrochure Detector Family 202002JaimeNo ratings yet

- Integrate Java and Angular Webapp in One JARDocument3 pagesIntegrate Java and Angular Webapp in One JARMahadi Hasan JoyNo ratings yet

- Loot Bits Money MethodDocument4 pagesLoot Bits Money Methoddann josue kouameNo ratings yet

- Catalog Motor ABBDocument36 pagesCatalog Motor ABBPhạm Hoài AnhNo ratings yet

- Bureau of Indian Standards: 10 Steps To BIS Licence For ToysDocument5 pagesBureau of Indian Standards: 10 Steps To BIS Licence For ToysLekshminarayanan SNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Survey On LLMDocument9 pagesSurvey On LLMRanger LosNo ratings yet

- Buku Manual Mesin Kisar UniversalDocument26 pagesBuku Manual Mesin Kisar Universalhill_me87No ratings yet

- Hysys 7.3Document1 pageHysys 7.3Alfian FathonyNo ratings yet

- ConclusionDocument1 pageConclusionRajeshYosuvaNo ratings yet

- Single Button Game Console With Arduino and PCBDocument23 pagesSingle Button Game Console With Arduino and PCBRusiu SieradzNo ratings yet

- Wi-Fi Smart Wall SwitchDocument26 pagesWi-Fi Smart Wall SwitchMyhome TowenNo ratings yet

- Technology Enhanced Learning Environments - HealeyDocument6 pagesTechnology Enhanced Learning Environments - HealeyPenny100% (1)

- Integrity Poster - Google SearchDocument1 pageIntegrity Poster - Google SearchDreamyNight UwUNo ratings yet

- Nyse Orcl 2019Document149 pagesNyse Orcl 2019ulsafarNo ratings yet

- Lifetec LCD Monitor TransistorDocument9 pagesLifetec LCD Monitor TransistornegrusrlNo ratings yet

- Effective Information Security: A Summary of General Instructions On Information Security ManagementDocument88 pagesEffective Information Security: A Summary of General Instructions On Information Security Managementmakarand1988No ratings yet

- Balanced Three Phase System v8Document56 pagesBalanced Three Phase System v8Pao CastillonNo ratings yet

- Carol of The Bells (3, 4 or 5 Octaves) - Arr. Cathy MoklebustDocument2 pagesCarol of The Bells (3, 4 or 5 Octaves) - Arr. Cathy MoklebustKelvinn Music AcademyNo ratings yet

- HCL Sap Means in Self Declaration FormDocument13 pagesHCL Sap Means in Self Declaration FormdrdomarkNo ratings yet

- High Capacity Microwave Solution BriefDocument12 pagesHigh Capacity Microwave Solution BriefabdullahNo ratings yet

- Receptor NE602 DCDocument1 pageReceptor NE602 DCMiguel OyarzabalNo ratings yet

- What Is Tungsten DisulfideDocument3 pagesWhat Is Tungsten DisulfidePrathyusha RamadurgamNo ratings yet

- Syllabus Disability StatementDocument2 pagesSyllabus Disability StatementCinthya LinianNo ratings yet

- Schedule For Ordinary Hazard OccupanciesDocument1 pageSchedule For Ordinary Hazard OccupanciesMostafa El-BalashonyNo ratings yet