Professional Documents

Culture Documents

TDP Uk

TDP Uk

Uploaded by

SüleymanŞentürkCopyright:

Available Formats

You might also like

- Dosing ControlDocument288 pagesDosing ControlSüleymanŞentürkNo ratings yet

- Dosing ControlDocument288 pagesDosing ControlSüleymanŞentürkNo ratings yet

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- MANUALDocument690 pagesMANUALNaseer Hyden100% (6)

- Selecting JFET Bias Resistors For A Schoeps Type Microphone Circuit (Scope Method)Document1 pageSelecting JFET Bias Resistors For A Schoeps Type Microphone Circuit (Scope Method)Victor PastorNo ratings yet

- Solar Power Plant DesignDocument51 pagesSolar Power Plant Designswamychouhan100% (10)

- Vestavny Skrtici Ventil TDC Es Katalogove ListyDocument8 pagesVestavny Skrtici Ventil TDC Es Katalogove ListyIonut PanteaNo ratings yet

- Upc1851 JVC OmarDocument60 pagesUpc1851 JVC OmarAndres AlegriaNo ratings yet

- DatasheetDocument14 pagesDatasheetJonas NunesNo ratings yet

- I C Bus-Compatible Us Mts Processing Lsi: FeaturesDocument63 pagesI C Bus-Compatible Us Mts Processing Lsi: FeaturesLeonardo Scarpati de QueirozNo ratings yet

- 190 - Series K2A005Document1 page190 - Series K2A005helderfgmNo ratings yet

- Functional Description: Q Q Q Q QDocument6 pagesFunctional Description: Q Q Q Q QAgus YulfizarNo ratings yet

- 2-1. Structure and Function hx85x HyundaiDocument83 pages2-1. Structure and Function hx85x HyundaiAlfonso BerRamNo ratings yet

- New IHR IGBT TechnologyDocument4 pagesNew IHR IGBT TechnologyvittorioNo ratings yet

- GL358 GleamDocument8 pagesGL358 GleamLuis ColochoNo ratings yet

- BEI Encoder 3550035Document8 pagesBEI Encoder 3550035Debreceni PéterNo ratings yet

- External Pilot Type, Dual 2-Port Solenoid Valve and Manifold SY5A2R-X10 SS5Y5-20P-X688Document5 pagesExternal Pilot Type, Dual 2-Port Solenoid Valve and Manifold SY5A2R-X10 SS5Y5-20P-X688Ade AdeNo ratings yet

- RGB Encoder: This Is Not An Official Sony Document!Document5 pagesRGB Encoder: This Is Not An Official Sony Document!Rumen J.No ratings yet

- Series D 1FS Characteristics: Pilot Operated Proportional DC ValveDocument8 pagesSeries D 1FS Characteristics: Pilot Operated Proportional DC ValvesundyaNo ratings yet

- Cartridge Valve UDocument5 pagesCartridge Valve UcuervohenryNo ratings yet

- Cxa 1645Document14 pagesCxa 1645Wanderson PedreroNo ratings yet

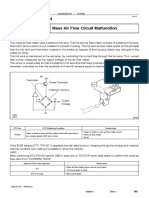

- Circuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionDocument4 pagesCircuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionJuanloNo ratings yet

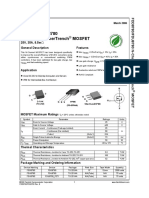

- FQB12P20 112073Document10 pagesFQB12P20 112073Beltazor HellboyNo ratings yet

- Tda 7343Document14 pagesTda 7343augustin cazanNo ratings yet

- Obsolete Product(s) - Obsolete Product(s)Document11 pagesObsolete Product(s) - Obsolete Product(s)Ignacio CardenasNo ratings yet

- Fdd8780 Mosfet Malo de Placa PC MariaDocument6 pagesFdd8780 Mosfet Malo de Placa PC MariadojiligNo ratings yet

- PM300DSA060: Mitsubishi Intelligent Power ModulesDocument6 pagesPM300DSA060: Mitsubishi Intelligent Power ModulesAlejandro Doza ChNo ratings yet

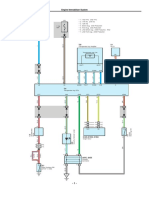

- LCD 1 DiagramDocument2 pagesLCD 1 DiagramEdu SantanaNo ratings yet

- Lu - Engine Lubrication SystemDocument4 pagesLu - Engine Lubrication SystemBRILLIANCE AUTO LIFENo ratings yet

- FQP7N65C/FQPF7N65C: 650V N-Channel MOSFETDocument10 pagesFQP7N65C/FQPF7N65C: 650V N-Channel MOSFETOneto Ayah KhayraNo ratings yet

- TB6500 PDFDocument18 pagesTB6500 PDFJavier CuraNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Document11 pagesObsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Ganapati SteelNo ratings yet

- CM200DU-24F: 200 Amperes/1200 VoltsDocument4 pagesCM200DU-24F: 200 Amperes/1200 VoltstrutleptNo ratings yet

- Catalogue Ventilateurs QPRBDocument20 pagesCatalogue Ventilateurs QPRBtallef001No ratings yet

- Catálogo de Convertidores de Frecuencia de La Serie HV390Document9 pagesCatálogo de Convertidores de Frecuencia de La Serie HV390Nancy GutiNo ratings yet

- Catalogo inversorHNC hv390 PolicompDocument8 pagesCatalogo inversorHNC hv390 PolicompRodrigo OrfeiNo ratings yet

- UPC1892Document43 pagesUPC1892Hari HaranNo ratings yet

- 3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument13 pages3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesKavinda Jayasinghege DonNo ratings yet

- RT9088ADocument11 pagesRT9088AБахтиёр БехбудовNo ratings yet

- GB 2457 ADocument16 pagesGB 2457 Ar_chulinNo ratings yet

- Proportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 BarDocument4 pagesProportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 Barbiomed2083No ratings yet

- Pd2e Ha4050 9-2010Document6 pagesPd2e Ha4050 9-2010nadmyrNo ratings yet

- RT7296AGJ8FDocument13 pagesRT7296AGJ8Ftu anhNo ratings yet

- Servo Amplifier VT 1600 Series 3X Data SheetDocument4 pagesServo Amplifier VT 1600 Series 3X Data SheetMagno SalgadoNo ratings yet

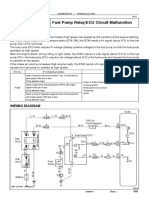

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocument4 pagesDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNo ratings yet

- Immobilizador PDFDocument3 pagesImmobilizador PDFjuan carlos diaz cardozoNo ratings yet

- Manual Air Band ReceiverDocument8 pagesManual Air Band Receiverdp500100% (1)

- Rt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1Document9 pagesRt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1laptophaianhNo ratings yet

- TA84007PQ, TA84007SG, TA84007FG: PreliminaryDocument16 pagesTA84007PQ, TA84007SG, TA84007FG: PreliminarywijakesumaNo ratings yet

- Zse Ise60Document9 pagesZse Ise60Ramon Cobos GuerreroNo ratings yet

- Datasheet TL082 PDFDocument11 pagesDatasheet TL082 PDFJavier RenanNo ratings yet

- Icl8038 PDFDocument12 pagesIcl8038 PDFmarcosNo ratings yet

- TV LG KCP 29C85Document18 pagesTV LG KCP 29C85Anonymous lQyR2IWNo ratings yet

- MAFDocument4 pagesMAFJonn Sim-One100% (1)

- It6430 0908 - BSV NDocument20 pagesIt6430 0908 - BSV NgunarxNo ratings yet

- Data SheetDocument19 pagesData SheetRobertoBarbosaNo ratings yet

- MP1038 r1.2Document11 pagesMP1038 r1.2Дмитрий ГаевскийNo ratings yet

- Digital Controlled Stereo Audio Processor: DescriptionDocument15 pagesDigital Controlled Stereo Audio Processor: DescriptionFelipe De Jesús JonapaNo ratings yet

- 500ma LNB-Power Supply & Control Voltage Regulator: Features General DescriptionDocument11 pages500ma LNB-Power Supply & Control Voltage Regulator: Features General DescriptioninfosolutionNo ratings yet

- Positive Voltage Regulator Ics: FeaturesDocument55 pagesPositive Voltage Regulator Ics: FeaturesshohratNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Alugard Ce-S - 25933Document2 pagesAlugard Ce-S - 25933SüleymanŞentürkNo ratings yet

- Coveral - 90 - 285703Document2 pagesCoveral - 90 - 285703SüleymanŞentürkNo ratings yet

- Ceramol 258g 2 - en TRDocument1 pageCeramol 258g 2 - en TRSüleymanŞentürkNo ratings yet

- Developing An Effective Die Cooling Technique For Casting SolidificationDocument173 pagesDeveloping An Effective Die Cooling Technique For Casting SolidificationSüleymanŞentürkNo ratings yet

- The Effect of Jet-Cooling Application On Microstructural Properties of The Overheating Areas in High Pressure Die Casting PartsDocument4 pagesThe Effect of Jet-Cooling Application On Microstructural Properties of The Overheating Areas in High Pressure Die Casting PartsSüleymanŞentürkNo ratings yet

- Study of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelDocument10 pagesStudy of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelSüleymanŞentürkNo ratings yet

- Porosity Formation in AlSi9Cu3 Alloy Castings - The Influence of Iron, Strontium, Sodium, Antimony and BismuthDocument240 pagesPorosity Formation in AlSi9Cu3 Alloy Castings - The Influence of Iron, Strontium, Sodium, Antimony and BismuthSüleymanŞentürkNo ratings yet

- Soğuk Kamara Basınçlı Dökümde Güncel Teknolojiler Ve Endüstri 4.0Document27 pagesSoğuk Kamara Basınçlı Dökümde Güncel Teknolojiler Ve Endüstri 4.0SüleymanŞentürkNo ratings yet

- A Speed Control Algorithm and Motion Stability Evaluation Method For Parallel Machine ToolsDocument2 pagesA Speed Control Algorithm and Motion Stability Evaluation Method For Parallel Machine ToolsSüleymanŞentürkNo ratings yet

- Dettaglio A Scala 1: 1 DIS. N°:: Cad Solidworks Effettuare Modifiche Esclusivamente Al CadDocument1 pageDettaglio A Scala 1: 1 DIS. N°:: Cad Solidworks Effettuare Modifiche Esclusivamente Al CadSüleymanŞentürkNo ratings yet

- DAG 1000 MCT - LeafletDocument2 pagesDAG 1000 MCT - LeafletSüleymanŞentürkNo ratings yet

- Powerspray: Systematic Spraying TechnologyDocument36 pagesPowerspray: Systematic Spraying TechnologySüleymanŞentürkNo ratings yet

- DC60012 TechData Evo-Carat en V02Document2 pagesDC60012 TechData Evo-Carat en V02SüleymanŞentürkNo ratings yet

- Catalogue RVVPDocument8 pagesCatalogue RVVPSüleymanŞentürkNo ratings yet

- Spray Head HDDocument2 pagesSpray Head HDSüleymanŞentürkNo ratings yet

- PR BAV1215 ASTM ReferenceImagesDocument62 pagesPR BAV1215 ASTM ReferenceImagesSüleymanŞentürkNo ratings yet

- Pinomatik Çift Kumanda Bloğu Operating InstructionDocument64 pagesPinomatik Çift Kumanda Bloğu Operating InstructionSüleymanŞentürkNo ratings yet

- 3004 SideDocument2 pages3004 SideSüleymanŞentürkNo ratings yet

- Principal ltc4054Document16 pagesPrincipal ltc4054RobertNo ratings yet

- 236 4YZ Multi Terrain Electrical System (RENR4823-04)Document2 pages236 4YZ Multi Terrain Electrical System (RENR4823-04)Hdmq Parts100% (1)

- SSG STARTERS GUIDE-One PDFDocument18 pagesSSG STARTERS GUIDE-One PDFMihai Iulian CristeaNo ratings yet

- 34450A Multimeter 5.5 Digit Dual Display, Benchtop DMM: Data SheetDocument13 pages34450A Multimeter 5.5 Digit Dual Display, Benchtop DMM: Data SheetRefugio Hernandez ArceNo ratings yet

- NiceDocument112 pagesNiceJose Gabriel Marin CerezuelaNo ratings yet

- A PE4518R14v 06Document3 pagesA PE4518R14v 06itsafakeaccountNo ratings yet

- Beyer Dt300 HeadphonesDocument2 pagesBeyer Dt300 HeadphonesJames Joyce100% (1)

- Telwin Plasma 34 en-RUDocument27 pagesTelwin Plasma 34 en-RUAlex GerasimenkoNo ratings yet

- Service BulletinDocument4 pagesService BulletinMohammad yasinNo ratings yet

- Low Power Atpg For Path Delay FaultsDocument6 pagesLow Power Atpg For Path Delay Faultsemail2pr2639No ratings yet

- Weak InversionDocument33 pagesWeak Inversionrafael_santos_121No ratings yet

- Bul. 440R - Guardmaster® Safety Relays (DI, DIS, SI, CI, GLP, EM, and EMD)Document12 pagesBul. 440R - Guardmaster® Safety Relays (DI, DIS, SI, CI, GLP, EM, and EMD)Carlos AguirreNo ratings yet

- Schneider Installation Guide Pages N33-N48-N49Document3 pagesSchneider Installation Guide Pages N33-N48-N49josette_hajjarNo ratings yet

- Electricity QuestionsDocument5 pagesElectricity QuestionsShiv VathsNo ratings yet

- Protection and Control REX640: All-In-One Protection For Any Power Distribution ApplicationDocument2 pagesProtection and Control REX640: All-In-One Protection For Any Power Distribution Applicationricardo BuitronNo ratings yet

- Specification of Branch Connector (Y)Document5 pagesSpecification of Branch Connector (Y)Kalyanaraman RamakrishnanNo ratings yet

- Development of Hardware-in-the-Loop (HIL) and Fast Prototyping Tool (FPT) Using OPAL-RTDocument18 pagesDevelopment of Hardware-in-the-Loop (HIL) and Fast Prototyping Tool (FPT) Using OPAL-RTaboofazilNo ratings yet

- Datasheet Blue Solar Charge Controller Overview enDocument2 pagesDatasheet Blue Solar Charge Controller Overview enSemih Hürmeydan100% (1)

- A319 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsDocument204 pagesA319 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsArun ChaudharyNo ratings yet

- Li-MnO2 Batteries (Friwo)Document7 pagesLi-MnO2 Batteries (Friwo)MedSparkNo ratings yet

- OLTC TestDocument3 pagesOLTC TestmshahidshaukatNo ratings yet

- 2014 02 Beacon-Cat VitDocument12 pages2014 02 Beacon-Cat VitAyouvNo ratings yet

- Altronics DC-CPU IOM 06-1988 PDFDocument22 pagesAltronics DC-CPU IOM 06-1988 PDFSMcNo ratings yet

- Fulham 2010 CatalogDocument60 pagesFulham 2010 CatalogHoria DraganNo ratings yet

- Focus Tig 200 Ac/Dc PFCDocument2 pagesFocus Tig 200 Ac/Dc PFCsezai dağNo ratings yet

- Transmission Line Power Transfer Capability Improvement, Case StudyDocument5 pagesTransmission Line Power Transfer Capability Improvement, Case StudyMuhammad NawalNo ratings yet

- Chapter 3 ElectromagnetismDocument29 pagesChapter 3 ElectromagnetismAnonymous oW9OeJvEvNo ratings yet

- HMC 1001 and HMC 1002Document15 pagesHMC 1001 and HMC 1002Không Có GìNo ratings yet

TDP Uk

TDP Uk

Uploaded by

SüleymanŞentürkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDP Uk

TDP Uk

Uploaded by

SüleymanŞentürkCopyright:

Available Formats

Catalogue MSG11-3500/UK 2-Way Servo Prop.

Valve with VCD® Technology

Characteristics Series TDP

The 2-way servo proportional valves with VCD® techno-

logy valves series TDP are used in applications where

high flow has to be precisely controlled at maximum A Y

dynamics. Typical applications are die casting, injection

moulding and hydraulic presses.

U

G

Function B X

The 2-way servo proportional valves TDP have a 2-stage

design consisting of a DFplus pilot valve and a main stage

with poppet and LVDT. TDP040

With the DFplus pilot valve the TDP achieves extremely Features

fast response times: from 10.5 ms (NG25) up to 28 ms

• Active pilot operated 2-way servo proportional valve

(NG100) with an accuracy of <0.1 % of the nominal flow.

The pilot valve actively controls the poppet - independent • Cavity and mounting pattern according to ISO 7368

of the pressure conditions in the main ports. It is basi- • Fast step response

cally required that the pilot pressure is at the level of the • Flow direction B to A and A to B

system pressure. At low system pressure the pilot pres- • Completely mounted and adapted unit with integrated

sure should be min. 140 bar, when high valve dynamics electronics

are desired. • In order to ensure the closed position, pilot pressure

The integrated electronics in the pilot of the TDP has is required

two control loops for the main poppet and the pilot spool. • 7 sizes, NG25 up to NG100

TDP040

SP MY

Function symbol

SP MB1)

BTA

XX

U

G

SP 2)

X Y

U

G

A B

P T

B XX 1) MY1)

1)

B A MA X Y

1) NG25 and NG32 without accu port XX and without port MA, MB and MY.

2) NG25 without suction port SP.

TDP UK.indd 13.06.22

8-121 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Ordering Code / Performance Curves Series TDP

Ordering code

TDP E H 9 C 2 0

2-way servo Nominal Slip-in Closed loop, Flow Nominal Flow Pilot Seal Command Standard Design

proportional size cartridge VCD® per- charac- flow direction oil signal electronics series

valve with formance, teristic B → A (supply ex- (not required

LVDT integrated A → B ternal, drain for ordering)

external)

electronics

Code Nominal size Code Command signal

025 NG25 B 0...+10 V

032 NG32 E 0...+20 mA

040 NG40 S 4...+20 mA

050 NG50

063 NG63

Code Seal

080 NG80

100 NG100 N 1) NBR

V FPM

Code Flow characteristic

7 progressive

9 linear

1) HFC fluids suitable

The DFplus pilot valve is also available with EtherCAT Please order connector separately.

interface, see chapter 3, D*FP and D*1FP with EtherCAT. Angle female connector must be used for NG25 to NG50.

Characteristic flow/signal line, Dp = 5 bar

8 Linear (code 9)

10000

Progressive (code 7 for TDL replacement)

10000

Flow [l/min]

Flow [l/min]

8000 8000

NG100

6000 6000

NG100

NG80

4000 4000 NG80

NG63

NG63

2000 NG50 2000 NG50

NG40 NG40

NG32 NG32

NG25 NG25

0 0

0 20 40 60 80 100 0 20 40 60 80 100

Command signal [%] Command signal [%]

Opening point factory set to 3 % Flow at different ∆p Qactual = Qnominal • ∆ pactual / ∆ pnominal

Characteristic curve measured with HLP46 at 50 °C.

TDP UK.indd 13.06.22

8-122 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Technical Data Series TDP

General

Proportional throttle valve with LVDT and integrated electronics, slip-in cartridge according

Design

to ISO 7368

Nominal size DIN NG25 NG32 NG40 NG50 NG63 NG80 NG100

Mounting position unrestricted

Ambient temperature [°C] -20...+50

Weight [kg] 11 13 15 26 52 105 157

Vibration resistance [g] 10 sinus 5...2000 Hz acc. IEC 68-2-6

10 (RMS) random noise 20...2000 Hz acc. IEC 68-2-36

15 shock acc. IEC 68-2-27

Hydraulic

Max. operating pressure [bar] Ports A, B, X and SP up to 350, XX observe accumulator pressure rating;

port Y: max. 35

Fluid Hydraulic oil according to DIN 51524

Fluid temperature [°C] -20...+60 (NBR: -25...+60)

Viscosity recommended [cSt] / [mm²/s] 30 ... 80

permitted [cSt] / [mm²/s] 20 ... 400

Filtration ISO 4406; 18/16/13

Nominal flow at ∆p = 5 bar (linear) [l/min] 420 850 1500 1900 3600 4500 8000

Recommended max. flow (linear) [l/min] 800 2000 3000 4500 8000 13000 20000

Nominal flow at ∆p = 5 bar (progressive) [l/min] 380 750 1300 1700 3200 3900 6800

Recommended max. flow (progressive) [l/min] 700 1750 2600 4000 7000 11250 17000

Flow direction B to A / A to B

Pilot pressure [bar] must be as high as system pressure

Pilot oil supply external via X

drain external via Y

Leakage in pilot valve at 100 bar [ml/min] < 400

Pilot valve size NG06 NG10

Max. pilot flow at 140 bar pilot pr. [l/min] 23 30 40 40 70 80 100

Static/dynamic

(for optimal dynamics see installation recommendation)

Step response at pilot press. >140 bar [ms] 10.5 12 14 20 17 23 28

Frequency response at pilot press. >140 bar

Amplitude -3 dB; 10 % ±5 % [Hz] 95 80 74 66 52 46 41

Hysteresis

Phase -90°; 10 % ±5 % [Hz]

[%] < 0.1

85 63 59 52 56 51 47

8

Sensitivity [%] < 0.05

Temperature drift [%/K] < 0.025

Electrical

Duty ratio [%] 100

Protection class IP65 in accordance with EN 60529 (with correctly mounted plug-in connector)

Supply voltage / ripple [V] DC 22 ... 30, electric shut-off at < 19, ripple < 5 % eff., surge free

Current consumption max. [A] 3.5

Pre-fusing [A] 4.0 A medium lag

Input signal

Code B Voltage [V] 0...+10, ripple < 0,01 % eff., surge free

Impedance [kOhm] 100

Code E Current [mA] 0...+20, ripple < 0,01 % eff., surge free

Impedance [Ohm] < 250

Code S Current [mA] 4...20, ripple < 0,01 % eff., surge free

< 3,6 mA = disable, > 3,8 mA = enble on according to NAMUR NE43

Impedance [Ohm] < 250

Differential input max. [V] 30 for terminal D and E against PE (terminal G)

11 for terminal D and E against 0V (terminal B)

Enable signal [V] 5...30, Ri = > 8 kOhm

Diagnostic signal [V] 0...+10 / +12.5 error detection, rated max. 5 mA

EMC EN 61000-6-2, EN 61000-6-4

Electrical connection 6 + PE acc. EN 175201-804

Wiring min. [mm²] 7 x 1.0 (AWG16) overall braid shield

Wiring length max. [m] 50

TDP UK.indd 13.06.22

8-123 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Installation Recommendations / Electronics Series TDP

Installation recommendations

An insufficient pilot oil supply (e.g. due to long distances and/or small diameters) can negatively influence the dy-

namics of the TDP valve.

To avoid this, an accumulator can be connected to port XX at the valve body of the TDP. A short-term undersupply

with pilot oil can be compensated via this accumulator.

Sizing data: see operation manual.

Please also consider the Parker accumulator product range and the Parker Accumulator Sizing Software.

Block circuit diagram electronics Connection diagrams electronics

Power supply

Parametrizing cable

3 m length Enable

Item no.: 40982923 + 24 V= 0V

+5...30 V

Diagnostics

C valve stroke V

A

Parametrizing 0...+10 V F B

interface G

Reference1) E C

D Enable

Command E

B: 0...10 V µC Reference1) 0V

E: 0...20 mA D B: 0...+10 V 5....30 V

S: 4...20 mA E: 0...20 mA

U I S: 4...20 mA

Diagnostic Command

spool stroke F U I

0...10 V

8

0V

G A B

Supply

PE voltage

22...30 V=

Female connector for NG63 to NG100 Angle female connector for NG25 to NG50

(EMC conform) (EMC conform)

7/8-20 7/8-20

max. 67 UNEF-2B 60.8 UNEF-2B

Ø28.6

47.3

PG13.5

ID no. 5004072

Please order plugs separately.

ID no. 5005160

1) Do not connect with the supply voltage zero.

TDP UK.indd 13.06.22

8-124 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Dimensions Series TDP

NG25

227

~13

202

P

100

69.3

76

5

x

Y X

71

Note:

Accu port XX and

153 85 Ø34 suction port SP

240 Ø45 non-existent

NG32

8

227

~5

203

SP Suction port

SP = G1/4"

P

100

72.5

69.3

68

5

X

Y X

84

Note:

153 102 Ø45 Accu port XX

259 Ø60 non-existent

Suction port SP: Contact Parker for installation recommendation.

NG Bolt kit -

NBR FPM

25 BK504 4 x M12x100 ISO 4762-12.9 108 Nm SK-TDP025EN30 SK-TDP025EV30

32 BK529 4 x M16x100 ISO 4762-12.9 264 Nm SK-TDP032EN30 SK-TDP032EV30

TDP UK.indd 13.06.22

8-125 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Dimensions Series TDP

NG40

Lifting eye bolt

M8-DIN 580

MY SP

226

216

SP

MB

110

P

85.5

76

69

XX

57.5

MA

5

Y X

17.5

104

Accu port

XX = G1/2"

Suction port

SP = G1/4"

153 125 Ø55 Ports

315 Ø75 MA and MB = G1/4"

NG50

Lifting eye bolt

M8-DIN 580

8 MY SP

238

227

SP

2

MB

132

XX

P

100

26

75

69

66.4

XX

57.5

20 MA

12

5

19

Y X

121

Suction port

SP = G3/8"

Accu port

XX = G1/2"

153 140 Ø68 Ports

330 Ø90 MA and MB = G1/4"

Lifting thread for disassembly M12

Suction port SP: Contact Parker for installation recommendation.

NG Bolt kit -

NBR FPM

40 BK481 4 x M20x110 ISO 4762-12.9 517 Nm SK-TDP040EN30 SK-TDP040EV30

50 BK481 4 x M20x110 ISO 4762-12.9 517 Nm SK-TDP050EN30 SK-TDP050EV30

TDP UK.indd 13.06.22

8-126 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Dimensions Series TDP

NG63

Lifting eye bolt

M8-DIN 580

MY SP

247.5

260

SP

10

MB XX

XX

154

TAPBT

118.5

105

90.3

25

71

MA

2.3

Y X

154

165 180 Ø90

382 Ø120

8

Suction port Accu port Ports

SP = G1/2" XX = G3/4" MA and MB = G1/4"

Lifting thread for disassembly M12

Suction port SP: Contact Parker for installation recommendation.

NG Bolt kit -

NBR FPM

63 BK518 4 x M30x160 ISO 4762-12.9 1775 Nm SK-TDP063EN30 SK-TDP063EV30

TDP UK.indd 13.06.22

8-127 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Dimensions Series TDP

NG80

Ø250

SP Accu port

MY XX = G3/4"

XX Suction port

SP = G1/2"

Ports

MA and MB = G1/4"

64 Lifting thread for disassembly M12

100

Lifting eye bolt

M8-DIN 580

272

247

166.5

TAPBT

MB

115

8

90

1.8

MA

X

Y X

204

165 119 Ø110

~411 Ø145

Suction port SP: Contact Parker for installation recommendation.

NG Bolt kit -

NBR FPM

80 BK530 8x M24x160 ISO 4762-12.9 890 Nm SK-TDP080EN30 SK-TDP080EV30

TDP UK.indd 13.06.22

8-128 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Dimensions Series TDP

NG100

Lifting thread for disassembly M12

Accu port

XX = G3/4"

Ø300

SP

MY Suction port

SP = G1/2"

XX

Ports

MA and MB = G1/4"

74

122.5

Lifting eye bolt

M8-DIN 580

272

247

176.5

MB MB

8

TAPBT

105

90

MA MA

1.8

Y X

244

165 144 Ø135

459 Ø180

Suction port SP: Contact Parker for installation recommendation.

NG Bolt kit -

NBR FPM

100 BK531 8x M30x150 ISO 4762-12.9 1775 Nm SK-TDP100EN30 SK-TDP100EV30

TDP UK.indd 13.06.22

8-129 Parker Hannifin Corporation

Catalogue MSG11-3500/UK 2-Way Servo Prop. Valve with VCD® Technology

Dimensions Series TDP

Code: ISO 7368-B*-*-2-A/B Code: ISO 7368-B*-*-2-A

NG25 to NG63 NG80 to NG100

Location pin t10 Thread depth t6 Location pin t10 Thread depth t6

m4

35°

45

°

d7

d6

d7

m3

22,5°

d5

X Y X Y

m1

b1

b1

d5

m1

d6

m1

m2 m2

b1

d1

15° W Required surface finish:

1 2

t7

1 = √ Rmax16, 2 = √ Rmax8

t5

2

t4

t1

t2

8

d4

d2 15°

1

t8

t3

t3 and t5 Deviating from ISO 7368 it is advisable to

d3 min. length of fit increase the diameters d3, d4 and d5.

d3 max.

Size b1 d1 H7 d2 H7 d3 d3 max d4 max1) d5 max d6 d7 H13 m1±0.2 m2±0.2 m3±0.2

25 85 45 34 25 27 32 6 M12 4 58 33 29

32 102 60 45 32 44 50 8 M 16 6 70 41 35

40 125 75 55 40 54 63 10 M 20 6 85 50 42.5

50 140 90 68 50 67 80 10 M 20 8 100 58 50

63 180 120 90 63 89 100 12 M 30 8 125 75 62.5

80 250 145 110 80 109 110 16 M 24 10 200 — —

100 300 180 135 100 134 150 20 M 30 10 245 — —

Size m4±0.2 t1+0.5 t2+1 t3 t4 t4 max1) t5 t6 t7 t8 t10 U W

25 16 58 72 12 44 40.5 30 35 25 25 10 0.03 0.05

32 17 70 85 13 52 44 15 35 2.5 2.5 10 0.03 0.1

40 23 87 105 15 64 54 15 45 3 3 10 0.05 0.1

50 30 100 122 17 72 59 17 45 4 3 10 0.05 0.1

63 38 130 155 20 95 78 19 65 4 4 10 0.05 0.2

80 — 175 205 25 130 115 32 50 5 5 10 0.05 0.2

100 — 210 245 29 155 133 32 53 5 5 10 0.05 0.2

1) Only in combination with d4max and t4max.

TDP UK.indd 13.06.22

8-130 Parker Hannifin Corporation

You might also like

- Dosing ControlDocument288 pagesDosing ControlSüleymanŞentürkNo ratings yet

- Dosing ControlDocument288 pagesDosing ControlSüleymanŞentürkNo ratings yet

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- MANUALDocument690 pagesMANUALNaseer Hyden100% (6)

- Selecting JFET Bias Resistors For A Schoeps Type Microphone Circuit (Scope Method)Document1 pageSelecting JFET Bias Resistors For A Schoeps Type Microphone Circuit (Scope Method)Victor PastorNo ratings yet

- Solar Power Plant DesignDocument51 pagesSolar Power Plant Designswamychouhan100% (10)

- Vestavny Skrtici Ventil TDC Es Katalogove ListyDocument8 pagesVestavny Skrtici Ventil TDC Es Katalogove ListyIonut PanteaNo ratings yet

- Upc1851 JVC OmarDocument60 pagesUpc1851 JVC OmarAndres AlegriaNo ratings yet

- DatasheetDocument14 pagesDatasheetJonas NunesNo ratings yet

- I C Bus-Compatible Us Mts Processing Lsi: FeaturesDocument63 pagesI C Bus-Compatible Us Mts Processing Lsi: FeaturesLeonardo Scarpati de QueirozNo ratings yet

- 190 - Series K2A005Document1 page190 - Series K2A005helderfgmNo ratings yet

- Functional Description: Q Q Q Q QDocument6 pagesFunctional Description: Q Q Q Q QAgus YulfizarNo ratings yet

- 2-1. Structure and Function hx85x HyundaiDocument83 pages2-1. Structure and Function hx85x HyundaiAlfonso BerRamNo ratings yet

- New IHR IGBT TechnologyDocument4 pagesNew IHR IGBT TechnologyvittorioNo ratings yet

- GL358 GleamDocument8 pagesGL358 GleamLuis ColochoNo ratings yet

- BEI Encoder 3550035Document8 pagesBEI Encoder 3550035Debreceni PéterNo ratings yet

- External Pilot Type, Dual 2-Port Solenoid Valve and Manifold SY5A2R-X10 SS5Y5-20P-X688Document5 pagesExternal Pilot Type, Dual 2-Port Solenoid Valve and Manifold SY5A2R-X10 SS5Y5-20P-X688Ade AdeNo ratings yet

- RGB Encoder: This Is Not An Official Sony Document!Document5 pagesRGB Encoder: This Is Not An Official Sony Document!Rumen J.No ratings yet

- Series D 1FS Characteristics: Pilot Operated Proportional DC ValveDocument8 pagesSeries D 1FS Characteristics: Pilot Operated Proportional DC ValvesundyaNo ratings yet

- Cartridge Valve UDocument5 pagesCartridge Valve UcuervohenryNo ratings yet

- Cxa 1645Document14 pagesCxa 1645Wanderson PedreroNo ratings yet

- Circuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionDocument4 pagesCircuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionJuanloNo ratings yet

- FQB12P20 112073Document10 pagesFQB12P20 112073Beltazor HellboyNo ratings yet

- Tda 7343Document14 pagesTda 7343augustin cazanNo ratings yet

- Obsolete Product(s) - Obsolete Product(s)Document11 pagesObsolete Product(s) - Obsolete Product(s)Ignacio CardenasNo ratings yet

- Fdd8780 Mosfet Malo de Placa PC MariaDocument6 pagesFdd8780 Mosfet Malo de Placa PC MariadojiligNo ratings yet

- PM300DSA060: Mitsubishi Intelligent Power ModulesDocument6 pagesPM300DSA060: Mitsubishi Intelligent Power ModulesAlejandro Doza ChNo ratings yet

- LCD 1 DiagramDocument2 pagesLCD 1 DiagramEdu SantanaNo ratings yet

- Lu - Engine Lubrication SystemDocument4 pagesLu - Engine Lubrication SystemBRILLIANCE AUTO LIFENo ratings yet

- FQP7N65C/FQPF7N65C: 650V N-Channel MOSFETDocument10 pagesFQP7N65C/FQPF7N65C: 650V N-Channel MOSFETOneto Ayah KhayraNo ratings yet

- TB6500 PDFDocument18 pagesTB6500 PDFJavier CuraNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Document11 pagesObsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Ganapati SteelNo ratings yet

- CM200DU-24F: 200 Amperes/1200 VoltsDocument4 pagesCM200DU-24F: 200 Amperes/1200 VoltstrutleptNo ratings yet

- Catalogue Ventilateurs QPRBDocument20 pagesCatalogue Ventilateurs QPRBtallef001No ratings yet

- Catálogo de Convertidores de Frecuencia de La Serie HV390Document9 pagesCatálogo de Convertidores de Frecuencia de La Serie HV390Nancy GutiNo ratings yet

- Catalogo inversorHNC hv390 PolicompDocument8 pagesCatalogo inversorHNC hv390 PolicompRodrigo OrfeiNo ratings yet

- UPC1892Document43 pagesUPC1892Hari HaranNo ratings yet

- 3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument13 pages3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesKavinda Jayasinghege DonNo ratings yet

- RT9088ADocument11 pagesRT9088AБахтиёр БехбудовNo ratings yet

- GB 2457 ADocument16 pagesGB 2457 Ar_chulinNo ratings yet

- Proportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 BarDocument4 pagesProportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 Barbiomed2083No ratings yet

- Pd2e Ha4050 9-2010Document6 pagesPd2e Ha4050 9-2010nadmyrNo ratings yet

- RT7296AGJ8FDocument13 pagesRT7296AGJ8Ftu anhNo ratings yet

- Servo Amplifier VT 1600 Series 3X Data SheetDocument4 pagesServo Amplifier VT 1600 Series 3X Data SheetMagno SalgadoNo ratings yet

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocument4 pagesDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNo ratings yet

- Immobilizador PDFDocument3 pagesImmobilizador PDFjuan carlos diaz cardozoNo ratings yet

- Manual Air Band ReceiverDocument8 pagesManual Air Band Receiverdp500100% (1)

- Rt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1Document9 pagesRt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1laptophaianhNo ratings yet

- TA84007PQ, TA84007SG, TA84007FG: PreliminaryDocument16 pagesTA84007PQ, TA84007SG, TA84007FG: PreliminarywijakesumaNo ratings yet

- Zse Ise60Document9 pagesZse Ise60Ramon Cobos GuerreroNo ratings yet

- Datasheet TL082 PDFDocument11 pagesDatasheet TL082 PDFJavier RenanNo ratings yet

- Icl8038 PDFDocument12 pagesIcl8038 PDFmarcosNo ratings yet

- TV LG KCP 29C85Document18 pagesTV LG KCP 29C85Anonymous lQyR2IWNo ratings yet

- MAFDocument4 pagesMAFJonn Sim-One100% (1)

- It6430 0908 - BSV NDocument20 pagesIt6430 0908 - BSV NgunarxNo ratings yet

- Data SheetDocument19 pagesData SheetRobertoBarbosaNo ratings yet

- MP1038 r1.2Document11 pagesMP1038 r1.2Дмитрий ГаевскийNo ratings yet

- Digital Controlled Stereo Audio Processor: DescriptionDocument15 pagesDigital Controlled Stereo Audio Processor: DescriptionFelipe De Jesús JonapaNo ratings yet

- 500ma LNB-Power Supply & Control Voltage Regulator: Features General DescriptionDocument11 pages500ma LNB-Power Supply & Control Voltage Regulator: Features General DescriptioninfosolutionNo ratings yet

- Positive Voltage Regulator Ics: FeaturesDocument55 pagesPositive Voltage Regulator Ics: FeaturesshohratNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Alugard Ce-S - 25933Document2 pagesAlugard Ce-S - 25933SüleymanŞentürkNo ratings yet

- Coveral - 90 - 285703Document2 pagesCoveral - 90 - 285703SüleymanŞentürkNo ratings yet

- Ceramol 258g 2 - en TRDocument1 pageCeramol 258g 2 - en TRSüleymanŞentürkNo ratings yet

- Developing An Effective Die Cooling Technique For Casting SolidificationDocument173 pagesDeveloping An Effective Die Cooling Technique For Casting SolidificationSüleymanŞentürkNo ratings yet

- The Effect of Jet-Cooling Application On Microstructural Properties of The Overheating Areas in High Pressure Die Casting PartsDocument4 pagesThe Effect of Jet-Cooling Application On Microstructural Properties of The Overheating Areas in High Pressure Die Casting PartsSüleymanŞentürkNo ratings yet

- Study of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelDocument10 pagesStudy of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelSüleymanŞentürkNo ratings yet

- Porosity Formation in AlSi9Cu3 Alloy Castings - The Influence of Iron, Strontium, Sodium, Antimony and BismuthDocument240 pagesPorosity Formation in AlSi9Cu3 Alloy Castings - The Influence of Iron, Strontium, Sodium, Antimony and BismuthSüleymanŞentürkNo ratings yet

- Soğuk Kamara Basınçlı Dökümde Güncel Teknolojiler Ve Endüstri 4.0Document27 pagesSoğuk Kamara Basınçlı Dökümde Güncel Teknolojiler Ve Endüstri 4.0SüleymanŞentürkNo ratings yet

- A Speed Control Algorithm and Motion Stability Evaluation Method For Parallel Machine ToolsDocument2 pagesA Speed Control Algorithm and Motion Stability Evaluation Method For Parallel Machine ToolsSüleymanŞentürkNo ratings yet

- Dettaglio A Scala 1: 1 DIS. N°:: Cad Solidworks Effettuare Modifiche Esclusivamente Al CadDocument1 pageDettaglio A Scala 1: 1 DIS. N°:: Cad Solidworks Effettuare Modifiche Esclusivamente Al CadSüleymanŞentürkNo ratings yet

- DAG 1000 MCT - LeafletDocument2 pagesDAG 1000 MCT - LeafletSüleymanŞentürkNo ratings yet

- Powerspray: Systematic Spraying TechnologyDocument36 pagesPowerspray: Systematic Spraying TechnologySüleymanŞentürkNo ratings yet

- DC60012 TechData Evo-Carat en V02Document2 pagesDC60012 TechData Evo-Carat en V02SüleymanŞentürkNo ratings yet

- Catalogue RVVPDocument8 pagesCatalogue RVVPSüleymanŞentürkNo ratings yet

- Spray Head HDDocument2 pagesSpray Head HDSüleymanŞentürkNo ratings yet

- PR BAV1215 ASTM ReferenceImagesDocument62 pagesPR BAV1215 ASTM ReferenceImagesSüleymanŞentürkNo ratings yet

- Pinomatik Çift Kumanda Bloğu Operating InstructionDocument64 pagesPinomatik Çift Kumanda Bloğu Operating InstructionSüleymanŞentürkNo ratings yet

- 3004 SideDocument2 pages3004 SideSüleymanŞentürkNo ratings yet

- Principal ltc4054Document16 pagesPrincipal ltc4054RobertNo ratings yet

- 236 4YZ Multi Terrain Electrical System (RENR4823-04)Document2 pages236 4YZ Multi Terrain Electrical System (RENR4823-04)Hdmq Parts100% (1)

- SSG STARTERS GUIDE-One PDFDocument18 pagesSSG STARTERS GUIDE-One PDFMihai Iulian CristeaNo ratings yet

- 34450A Multimeter 5.5 Digit Dual Display, Benchtop DMM: Data SheetDocument13 pages34450A Multimeter 5.5 Digit Dual Display, Benchtop DMM: Data SheetRefugio Hernandez ArceNo ratings yet

- NiceDocument112 pagesNiceJose Gabriel Marin CerezuelaNo ratings yet

- A PE4518R14v 06Document3 pagesA PE4518R14v 06itsafakeaccountNo ratings yet

- Beyer Dt300 HeadphonesDocument2 pagesBeyer Dt300 HeadphonesJames Joyce100% (1)

- Telwin Plasma 34 en-RUDocument27 pagesTelwin Plasma 34 en-RUAlex GerasimenkoNo ratings yet

- Service BulletinDocument4 pagesService BulletinMohammad yasinNo ratings yet

- Low Power Atpg For Path Delay FaultsDocument6 pagesLow Power Atpg For Path Delay Faultsemail2pr2639No ratings yet

- Weak InversionDocument33 pagesWeak Inversionrafael_santos_121No ratings yet

- Bul. 440R - Guardmaster® Safety Relays (DI, DIS, SI, CI, GLP, EM, and EMD)Document12 pagesBul. 440R - Guardmaster® Safety Relays (DI, DIS, SI, CI, GLP, EM, and EMD)Carlos AguirreNo ratings yet

- Schneider Installation Guide Pages N33-N48-N49Document3 pagesSchneider Installation Guide Pages N33-N48-N49josette_hajjarNo ratings yet

- Electricity QuestionsDocument5 pagesElectricity QuestionsShiv VathsNo ratings yet

- Protection and Control REX640: All-In-One Protection For Any Power Distribution ApplicationDocument2 pagesProtection and Control REX640: All-In-One Protection For Any Power Distribution Applicationricardo BuitronNo ratings yet

- Specification of Branch Connector (Y)Document5 pagesSpecification of Branch Connector (Y)Kalyanaraman RamakrishnanNo ratings yet

- Development of Hardware-in-the-Loop (HIL) and Fast Prototyping Tool (FPT) Using OPAL-RTDocument18 pagesDevelopment of Hardware-in-the-Loop (HIL) and Fast Prototyping Tool (FPT) Using OPAL-RTaboofazilNo ratings yet

- Datasheet Blue Solar Charge Controller Overview enDocument2 pagesDatasheet Blue Solar Charge Controller Overview enSemih Hürmeydan100% (1)

- A319 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsDocument204 pagesA319 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsArun ChaudharyNo ratings yet

- Li-MnO2 Batteries (Friwo)Document7 pagesLi-MnO2 Batteries (Friwo)MedSparkNo ratings yet

- OLTC TestDocument3 pagesOLTC TestmshahidshaukatNo ratings yet

- 2014 02 Beacon-Cat VitDocument12 pages2014 02 Beacon-Cat VitAyouvNo ratings yet

- Altronics DC-CPU IOM 06-1988 PDFDocument22 pagesAltronics DC-CPU IOM 06-1988 PDFSMcNo ratings yet

- Fulham 2010 CatalogDocument60 pagesFulham 2010 CatalogHoria DraganNo ratings yet

- Focus Tig 200 Ac/Dc PFCDocument2 pagesFocus Tig 200 Ac/Dc PFCsezai dağNo ratings yet

- Transmission Line Power Transfer Capability Improvement, Case StudyDocument5 pagesTransmission Line Power Transfer Capability Improvement, Case StudyMuhammad NawalNo ratings yet

- Chapter 3 ElectromagnetismDocument29 pagesChapter 3 ElectromagnetismAnonymous oW9OeJvEvNo ratings yet

- HMC 1001 and HMC 1002Document15 pagesHMC 1001 and HMC 1002Không Có GìNo ratings yet