Professional Documents

Culture Documents

Aluminum Vs Copper Lead

Aluminum Vs Copper Lead

Uploaded by

Cadeco ZamoraCopyright:

Available Formats

You might also like

- The Manufacture of Aluminium Alloy WheelsDocument18 pagesThe Manufacture of Aluminium Alloy WheelsGirish Shet67% (3)

- Engine Block Manufacturing ProcessDocument12 pagesEngine Block Manufacturing ProcessFadirul Ezwan100% (3)

- Weld Defect Wall ChartDocument1 pageWeld Defect Wall ChartRafiqKuNo ratings yet

- Tubing ComparisonsDocument2 pagesTubing ComparisonsBrummerNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Paint Manufacturing ProcessesDocument5 pagesPaint Manufacturing ProcessesKarthik HegdeNo ratings yet

- Compare For Yourself ... : We Find Solutions To Your Motor Problems ... ... As Your Partner Not Just Your SupplierDocument2 pagesCompare For Yourself ... : We Find Solutions To Your Motor Problems ... ... As Your Partner Not Just Your SupplierDennis RajNo ratings yet

- Report On Engine BlocksDocument7 pagesReport On Engine Blocksmanshulakesh59No ratings yet

- EngineDocument2 pagesEngineFuner AndrishNo ratings yet

- Operational Information Bearing Materials: Babbitt MetalDocument4 pagesOperational Information Bearing Materials: Babbitt Metalargentum19619692No ratings yet

- Aluminium AlloyDocument22 pagesAluminium AlloyAashish Gharde0% (1)

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument12 pagesAluminium Alloy - Wikipedia, The Free EncyclopediaAshishJoshi100% (1)

- Bicycle ProjectDocument4 pagesBicycle Projectgaming channelNo ratings yet

- Material Science - Selecting Materials and Processing For A Specified ProductDocument12 pagesMaterial Science - Selecting Materials and Processing For A Specified ProductSteven Goddard100% (3)

- Aluminum LithiumDocument3 pagesAluminum LithiumJohirul RumenNo ratings yet

- Build Up A BikeDocument5 pagesBuild Up A BikeNhel OclinariaNo ratings yet

- Unit 4-2-NonferrousDocument32 pagesUnit 4-2-NonferrousNisha JaiswalNo ratings yet

- Theories of Machine - S.s.rattanDocument16 pagesTheories of Machine - S.s.rattanRohitsingh JadaunNo ratings yet

- Shoeb 2Document26 pagesShoeb 2Naveen PipperaNo ratings yet

- Material Used in Engine Block CastingDocument1 pageMaterial Used in Engine Block CastingSapari VelNo ratings yet

- Affect of Elements On SteelDocument82 pagesAffect of Elements On SteelAditya PratapNo ratings yet

- Aluminium AlloyDocument17 pagesAluminium AlloyPrasanth PNo ratings yet

- Metallographic Properties: 1. Mild SteelsDocument4 pagesMetallographic Properties: 1. Mild SteelsmuralidharanNo ratings yet

- G2 DiscBrakeDocument33 pagesG2 DiscBrakesiddout2006No ratings yet

- Electrical Steel - WikipediaDocument5 pagesElectrical Steel - WikipediaBozidar KemicNo ratings yet

- Ceramic Ball BearingsDocument4 pagesCeramic Ball Bearingssuseelaparvathimsp100% (2)

- Mahle MaterialsDocument6 pagesMahle MaterialsAngel ZanottiNo ratings yet

- Steel or Aluminum, Which Material Is Better? Motorcycle Engine Block?Document2 pagesSteel or Aluminum, Which Material Is Better? Motorcycle Engine Block?Raizel DNo ratings yet

- Chapter 6, ALUMINIUM AND ITS ALLOYSDocument5 pagesChapter 6, ALUMINIUM AND ITS ALLOYSPAUL NDIRITUNo ratings yet

- Aluminium Matrix Composites in Automotive ApplicationsDocument3 pagesAluminium Matrix Composites in Automotive ApplicationsAminul Mehedi100% (1)

- The New Generation Engine Bearings That Go The Distance: ... and Then Some!Document4 pagesThe New Generation Engine Bearings That Go The Distance: ... and Then Some!Troy BauerNo ratings yet

- Application of Aluminum Alloys For Combustion Engine BearingsDocument6 pagesApplication of Aluminum Alloys For Combustion Engine BearingsJoffre Lautaro Benavides SeminarioNo ratings yet

- Emec221 Research PaperDocument10 pagesEmec221 Research Paperapi-717199906No ratings yet

- Elements & Their Effects.Document81 pagesElements & Their Effects.vinay9560% (1)

- Materials of PropellerDocument2 pagesMaterials of PropellerSenthil Kumar PNo ratings yet

- Operational Information Bearing Materials: Babbitt MetalDocument11 pagesOperational Information Bearing Materials: Babbitt MetalMeghali BorleNo ratings yet

- Sheet Metal Stamping in Automotive Industry IgnoreDocument48 pagesSheet Metal Stamping in Automotive Industry IgnoreSalil GhateNo ratings yet

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDocument63 pagesCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNo ratings yet

- Ceramic Disc BrakesDocument14 pagesCeramic Disc Brakesmayur_bng75% (4)

- Piston: Parts, Types, Working, Piston Clearance, Shape and MoreDocument12 pagesPiston: Parts, Types, Working, Piston Clearance, Shape and MoreAndre RichardNo ratings yet

- Read More:: Prices - Htm#Multi - Walled - Nanotubes - Prices#Ixzz2PjcaipjtDocument3 pagesRead More:: Prices - Htm#Multi - Walled - Nanotubes - Prices#Ixzz2Pjcaipjtkr_padmavathiNo ratings yet

- Chapter-3 Cylinder Heads, Cylinders & LinersDocument18 pagesChapter-3 Cylinder Heads, Cylinders & LinersdearsaswatNo ratings yet

- Iml213 (2 Föy)Document65 pagesIml213 (2 Föy)HilalAldemirNo ratings yet

- Krydshoved WM AlSn40Document4 pagesKrydshoved WM AlSn40Jorge ArimanaNo ratings yet

- Operational Information Bearing MaterialsDocument2 pagesOperational Information Bearing MaterialsHim SatiNo ratings yet

- Differences Between Steel and Alloy WheelsDocument2 pagesDifferences Between Steel and Alloy Wheels16mariusNo ratings yet

- Challenge Yourself IIIDocument2 pagesChallenge Yourself IIIShaquille NaradaNo ratings yet

- Stratosphere Developments Assignment 2Document5 pagesStratosphere Developments Assignment 2micropig1234No ratings yet

- Welding Al CastingsDocument13 pagesWelding Al CastingsSmartNo ratings yet

- CHDX04 Module 1 MaterialsDocument18 pagesCHDX04 Module 1 Materialsargiun20No ratings yet

- Materials: 11.3 TitaniumDocument1 pageMaterials: 11.3 TitaniumAshutosh KumarNo ratings yet

- Zinc Alloy BearingsDocument6 pagesZinc Alloy BearingsJeff DunningNo ratings yet

- National Institute of TransportDocument9 pagesNational Institute of Transportfahad khalefNo ratings yet

- Aluminum GradesDocument2 pagesAluminum GradesdantoliniNo ratings yet

- New Perspectives in Automotive Construction: Cast Crankshafts As An Alternative To Forged CrankshaftsDocument3 pagesNew Perspectives in Automotive Construction: Cast Crankshafts As An Alternative To Forged CrankshaftsEmilce Bogado MartinezNo ratings yet

- Aerospace Materials Aluminum CompositesDocument5 pagesAerospace Materials Aluminum CompositesfrancescaNo ratings yet

- 2.doc Semi Process TechnicalsDocument2 pages2.doc Semi Process TechnicalsshreyeshNo ratings yet

- Materials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDocument8 pagesMaterials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDzaky ArizsaNo ratings yet

- Bevel Gears and Gear SetsDocument4 pagesBevel Gears and Gear SetsCadeco ZamoraNo ratings yet

- Bearings For John Deere®Document4 pagesBearings For John Deere®Cadeco Zamora100% (1)

- Beaded GasketsDocument1 pageBeaded GasketsCadeco ZamoraNo ratings yet

- 100R1 Hose AssemblyDocument3 pages100R1 Hose AssemblyCadeco ZamoraNo ratings yet

- 100R13 4 Layer Spiral Hydraulic HoseDocument1 page100R13 4 Layer Spiral Hydraulic HoseCadeco ZamoraNo ratings yet

- AnodesDocument1 pageAnodesCadeco ZamoraNo ratings yet

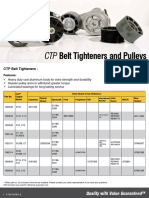

- Belt Tensioners and PulleysDocument2 pagesBelt Tensioners and PulleysCadeco ZamoraNo ratings yet

- Alarms & HornsDocument1 pageAlarms & HornsCadeco ZamoraNo ratings yet

- Air CompressorsDocument1 pageAir CompressorsCadeco ZamoraNo ratings yet

- 100R1 Single Wire Braid Hydraulic HoseDocument1 page100R1 Single Wire Braid Hydraulic HoseCadeco ZamoraNo ratings yet

- ActuatorsDocument1 pageActuatorsCadeco Zamora100% (1)

- Connecting Rod KitDocument1 pageConnecting Rod KitCadeco ZamoraNo ratings yet

- 100R5 Hose AssemblyDocument2 pages100R5 Hose AssemblyCadeco ZamoraNo ratings yet

- 100R4 Textile With Helical Hydraulic HoseDocument1 page100R4 Textile With Helical Hydraulic HoseCadeco ZamoraNo ratings yet

- 100R2 Double Wire Braid Hydraulic HoseDocument1 page100R2 Double Wire Braid Hydraulic HoseCadeco ZamoraNo ratings yet

- 100R5 One Wire Braid With Textile Cover Hydraulic HoseDocument1 page100R5 One Wire Braid With Textile Cover Hydraulic HoseCadeco ZamoraNo ratings yet

- BogiesDocument1 pageBogiesCadeco ZamoraNo ratings yet

- Cabin GlassDocument3 pagesCabin GlassCadeco ZamoraNo ratings yet

- Cadenas CTPDocument3 pagesCadenas CTPCadeco ZamoraNo ratings yet

- BrushesDocument1 pageBrushesCadeco ZamoraNo ratings yet

- Turbos Cruce Niitsu VS OEMDocument11 pagesTurbos Cruce Niitsu VS OEMCadeco ZamoraNo ratings yet

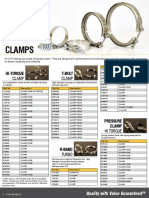

- ClampsDocument1 pageClampsCadeco ZamoraNo ratings yet

- ABC Gasket KitsDocument2 pagesABC Gasket KitsCadeco ZamoraNo ratings yet

- Air Filter Change IndicatorsDocument1 pageAir Filter Change IndicatorsCadeco ZamoraNo ratings yet

- Summative Test TleDocument18 pagesSummative Test TleGillyn Ruiz - AntonioNo ratings yet

- Haldor Topsoe PDFDocument28 pagesHaldor Topsoe PDFSlamet Purwadi S.TNo ratings yet

- Gear Hobbing SandvikDocument7 pagesGear Hobbing SandvikAndré Hemerly MaiaNo ratings yet

- Iso 5662 1978Document4 pagesIso 5662 1978muhammed hairieNo ratings yet

- MillingDocument76 pagesMillingAbduljebar SemuNo ratings yet

- R1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0ADocument3 pagesR1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0AAHMED AMIRANo ratings yet

- Ped Eam-0526-24-1-2006-03Document6 pagesPed Eam-0526-24-1-2006-03nathachaiNo ratings yet

- Stainless Steel 304 Round BarDocument3 pagesStainless Steel 304 Round Barevergrow solutions100% (1)

- Aluminum & Stainless Standards (Imperial) 2Document32 pagesAluminum & Stainless Standards (Imperial) 2Bradley GoldenNo ratings yet

- Atlas Copco Roto Inject Fluid JECDocument2 pagesAtlas Copco Roto Inject Fluid JECアラファト イスラム教No ratings yet

- Sewage TreatmentDocument22 pagesSewage TreatmentNelly Elias100% (1)

- Crimping Tools AssesmentDocument3 pagesCrimping Tools AssesmentAbhishekprasad royNo ratings yet

- 6082 t6 Aluminium Round BarDocument12 pages6082 t6 Aluminium Round Barben norwoodNo ratings yet

- Product CompatiblityDocument22 pagesProduct CompatiblityrahulchandokNo ratings yet

- Coil CoatingDocument5 pagesCoil CoatingNaveen RohiraNo ratings yet

- Mhanila Benedict H 2019-04-7090Document74 pagesMhanila Benedict H 2019-04-7090Maganghila SamwelNo ratings yet

- ANI Metal Hot Dip Galvanizing ChemicalsDocument2 pagesANI Metal Hot Dip Galvanizing ChemicalsEng-Ahmed AllamNo ratings yet

- Drilling: Bachelor of EngineeringDocument48 pagesDrilling: Bachelor of EngineeringramadanNo ratings yet

- Alloy 254 Technical InformationDocument3 pagesAlloy 254 Technical InformationIdehen KelvinNo ratings yet

- Work Method Statement For Painting Existing WallDocument11 pagesWork Method Statement For Painting Existing WallMohd Hafizi AzlanNo ratings yet

- 630 (17-4) Precipitation Hardening Stainless Steel BarDocument4 pages630 (17-4) Precipitation Hardening Stainless Steel Barehudingram6535No ratings yet

- Peco PGC SeriesDocument2 pagesPeco PGC SeriesReza PramataNo ratings yet

- Easywash: Technical Data SheetDocument2 pagesEasywash: Technical Data SheetCharm Der BardNo ratings yet

- Mrir 036Document17 pagesMrir 036Sam RajaNo ratings yet

- Wood Burning StoveDocument4 pagesWood Burning StoveAnthony SullivanNo ratings yet

- Mould Pin - Standard - Taha Associates - 2021Document21 pagesMould Pin - Standard - Taha Associates - 2021Taha AssociatesNo ratings yet

- fYP PROPOSED TOPICDocument2 pagesfYP PROPOSED TOPICUme HaniNo ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet

Aluminum Vs Copper Lead

Aluminum Vs Copper Lead

Uploaded by

Cadeco ZamoraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Vs Copper Lead

Aluminum Vs Copper Lead

Uploaded by

Cadeco ZamoraCopyright:

Available Formats

Engine

Bearings:

Aluminum vs

Copper/Lead.

Engine Bearings

In order to address this issue, some aluminum bearing

manufacturers bore the inside diameter of the bearings when the

Due to the fact that the bearings give a surface that allows the bearing are made rather than broach them. The boring procedure

parts to rotate without the friction of metal against metal, its leaves very small micro grooves in the surface that help flush out

importance can never be underestimated. They support the the contaminants, at the same time that improves oil retention

crankshaft and connecting rods and, in pushrod engines they and fatigue and seizure resistance.

also support the camshaft. Because of the high loads created by

combustion and the reciprocating mass of the pistons, bearings

have a very hard job to fulfill. High performance engines (subject The melting point of a regular aluminum bearing alloy is over

to even higher loads and rpms.) require even stronger bearing 1,100 degrees F, which is almost three times higher that Babbitt.

material and close oil clearances in order to maintain peak oil film The fact that aluminum has higher temperature rating gives an

strength thickness. additional protection against overheating that might be caused by

overloading, misalignment and detonation.

Over a period of time, main bearings and rod bearings will start to

wear out. The metal fatigue can form cracks that will later cause Aluminum bearings, though, are not the best choice for every

flaking and chipping that will cause the bearing to fail. Dirty oil and application, specially for engines that may not be remanufactured

loss of oil pressure as well as dryness of the bearing and acids to like-new tolerances under the cleanest conditions or for

in the crankcase will certainly cause irreversible damage to the engines that do not see regular oil changes. Although aluminum

bearing. is harder, it doesn’t have the fatigue resistance to loading that

copper/lead can provide. For example, for an A-600 (tough

aluminum alloy) the recommended limit is 100 hp per liter. For

Once bearings start to wear, oil clearances increase ending in a a 500-plus hp V8 we would need a copper/lead performance

loss of oil pressure. If rod bearings begin to make unusual noises bearing to be able to handle the load.

that beat at the same rhythm as the engine speed, they may

cause computer problems with the knock sensor. All of these

symptoms indicate that it is time to replace a set of bearings. A regular trimetal copper/lead engine bearing is constituted by

three layers. The steel backing plate is covered with a layer of

copper/lead overlaid with a thin coating of Babbitt. The bearing

Aluminum Vs. Copper/Lead could also have a thin flash plating of tin for cosmetic purposes.

These three layers help achieve a combination of strength,

embedability and surface action. Cast/copper/lead can carry in

The question of which is the best material has been going on for a excess of 14,000 lbs per square inch of load versus about 7,000

while and is, apparently, far from being over. for an aluminum bearing.

Some US and Asian OEMs prefer aluminum bearings. An Currently at CTP, we carry bearings made with the F780 bearing

A-500 aluminum alloy, which is commonly used since 1994 to material. It is a sintered trimetal bearing with a base alloy of

make aluminum bearings, contains 8% tin, 3% silicon and 2% copper, lead and tin with a nickel dam and Babbitt top layer. The

lead. Aluminum bearings contain little or no lead, making them F780 alloy has a higher load carrying capacity than aluminum or

environmentally friendly. other copper/lead alloy. As a result of this advanced technology

material, F780 will provide longer life in normal operation and

Aluminum bearings have also a low cost of production and are significantly improve fatigue resistance under extreme operating

made of a hard material that withstands wear better that copper/ conditions. It costs more to manufacture but it is worth it because

lead bearings. Unfortunately, aluminum doesn’t have much of its improved durability, conformability and embedability. Using

embedability which suggests that any hard abrasive particles this premium bearing with a higher load carrying capacity

that make their way between the journal and bearing could get provides added insurance against detonation failure. In addition to

trapped and mark the surface. The softer copper/lead bearings this, CTP has just recently added aluminum alloy bearings to our

will embed the hard particles in the bearing surface, decreasing stock.

the probability of causing a score.

You might also like

- The Manufacture of Aluminium Alloy WheelsDocument18 pagesThe Manufacture of Aluminium Alloy WheelsGirish Shet67% (3)

- Engine Block Manufacturing ProcessDocument12 pagesEngine Block Manufacturing ProcessFadirul Ezwan100% (3)

- Weld Defect Wall ChartDocument1 pageWeld Defect Wall ChartRafiqKuNo ratings yet

- Tubing ComparisonsDocument2 pagesTubing ComparisonsBrummerNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Paint Manufacturing ProcessesDocument5 pagesPaint Manufacturing ProcessesKarthik HegdeNo ratings yet

- Compare For Yourself ... : We Find Solutions To Your Motor Problems ... ... As Your Partner Not Just Your SupplierDocument2 pagesCompare For Yourself ... : We Find Solutions To Your Motor Problems ... ... As Your Partner Not Just Your SupplierDennis RajNo ratings yet

- Report On Engine BlocksDocument7 pagesReport On Engine Blocksmanshulakesh59No ratings yet

- EngineDocument2 pagesEngineFuner AndrishNo ratings yet

- Operational Information Bearing Materials: Babbitt MetalDocument4 pagesOperational Information Bearing Materials: Babbitt Metalargentum19619692No ratings yet

- Aluminium AlloyDocument22 pagesAluminium AlloyAashish Gharde0% (1)

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument12 pagesAluminium Alloy - Wikipedia, The Free EncyclopediaAshishJoshi100% (1)

- Bicycle ProjectDocument4 pagesBicycle Projectgaming channelNo ratings yet

- Material Science - Selecting Materials and Processing For A Specified ProductDocument12 pagesMaterial Science - Selecting Materials and Processing For A Specified ProductSteven Goddard100% (3)

- Aluminum LithiumDocument3 pagesAluminum LithiumJohirul RumenNo ratings yet

- Build Up A BikeDocument5 pagesBuild Up A BikeNhel OclinariaNo ratings yet

- Unit 4-2-NonferrousDocument32 pagesUnit 4-2-NonferrousNisha JaiswalNo ratings yet

- Theories of Machine - S.s.rattanDocument16 pagesTheories of Machine - S.s.rattanRohitsingh JadaunNo ratings yet

- Shoeb 2Document26 pagesShoeb 2Naveen PipperaNo ratings yet

- Material Used in Engine Block CastingDocument1 pageMaterial Used in Engine Block CastingSapari VelNo ratings yet

- Affect of Elements On SteelDocument82 pagesAffect of Elements On SteelAditya PratapNo ratings yet

- Aluminium AlloyDocument17 pagesAluminium AlloyPrasanth PNo ratings yet

- Metallographic Properties: 1. Mild SteelsDocument4 pagesMetallographic Properties: 1. Mild SteelsmuralidharanNo ratings yet

- G2 DiscBrakeDocument33 pagesG2 DiscBrakesiddout2006No ratings yet

- Electrical Steel - WikipediaDocument5 pagesElectrical Steel - WikipediaBozidar KemicNo ratings yet

- Ceramic Ball BearingsDocument4 pagesCeramic Ball Bearingssuseelaparvathimsp100% (2)

- Mahle MaterialsDocument6 pagesMahle MaterialsAngel ZanottiNo ratings yet

- Steel or Aluminum, Which Material Is Better? Motorcycle Engine Block?Document2 pagesSteel or Aluminum, Which Material Is Better? Motorcycle Engine Block?Raizel DNo ratings yet

- Chapter 6, ALUMINIUM AND ITS ALLOYSDocument5 pagesChapter 6, ALUMINIUM AND ITS ALLOYSPAUL NDIRITUNo ratings yet

- Aluminium Matrix Composites in Automotive ApplicationsDocument3 pagesAluminium Matrix Composites in Automotive ApplicationsAminul Mehedi100% (1)

- The New Generation Engine Bearings That Go The Distance: ... and Then Some!Document4 pagesThe New Generation Engine Bearings That Go The Distance: ... and Then Some!Troy BauerNo ratings yet

- Application of Aluminum Alloys For Combustion Engine BearingsDocument6 pagesApplication of Aluminum Alloys For Combustion Engine BearingsJoffre Lautaro Benavides SeminarioNo ratings yet

- Emec221 Research PaperDocument10 pagesEmec221 Research Paperapi-717199906No ratings yet

- Elements & Their Effects.Document81 pagesElements & Their Effects.vinay9560% (1)

- Materials of PropellerDocument2 pagesMaterials of PropellerSenthil Kumar PNo ratings yet

- Operational Information Bearing Materials: Babbitt MetalDocument11 pagesOperational Information Bearing Materials: Babbitt MetalMeghali BorleNo ratings yet

- Sheet Metal Stamping in Automotive Industry IgnoreDocument48 pagesSheet Metal Stamping in Automotive Industry IgnoreSalil GhateNo ratings yet

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDocument63 pagesCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNo ratings yet

- Ceramic Disc BrakesDocument14 pagesCeramic Disc Brakesmayur_bng75% (4)

- Piston: Parts, Types, Working, Piston Clearance, Shape and MoreDocument12 pagesPiston: Parts, Types, Working, Piston Clearance, Shape and MoreAndre RichardNo ratings yet

- Read More:: Prices - Htm#Multi - Walled - Nanotubes - Prices#Ixzz2PjcaipjtDocument3 pagesRead More:: Prices - Htm#Multi - Walled - Nanotubes - Prices#Ixzz2Pjcaipjtkr_padmavathiNo ratings yet

- Chapter-3 Cylinder Heads, Cylinders & LinersDocument18 pagesChapter-3 Cylinder Heads, Cylinders & LinersdearsaswatNo ratings yet

- Iml213 (2 Föy)Document65 pagesIml213 (2 Föy)HilalAldemirNo ratings yet

- Krydshoved WM AlSn40Document4 pagesKrydshoved WM AlSn40Jorge ArimanaNo ratings yet

- Operational Information Bearing MaterialsDocument2 pagesOperational Information Bearing MaterialsHim SatiNo ratings yet

- Differences Between Steel and Alloy WheelsDocument2 pagesDifferences Between Steel and Alloy Wheels16mariusNo ratings yet

- Challenge Yourself IIIDocument2 pagesChallenge Yourself IIIShaquille NaradaNo ratings yet

- Stratosphere Developments Assignment 2Document5 pagesStratosphere Developments Assignment 2micropig1234No ratings yet

- Welding Al CastingsDocument13 pagesWelding Al CastingsSmartNo ratings yet

- CHDX04 Module 1 MaterialsDocument18 pagesCHDX04 Module 1 Materialsargiun20No ratings yet

- Materials: 11.3 TitaniumDocument1 pageMaterials: 11.3 TitaniumAshutosh KumarNo ratings yet

- Zinc Alloy BearingsDocument6 pagesZinc Alloy BearingsJeff DunningNo ratings yet

- National Institute of TransportDocument9 pagesNational Institute of Transportfahad khalefNo ratings yet

- Aluminum GradesDocument2 pagesAluminum GradesdantoliniNo ratings yet

- New Perspectives in Automotive Construction: Cast Crankshafts As An Alternative To Forged CrankshaftsDocument3 pagesNew Perspectives in Automotive Construction: Cast Crankshafts As An Alternative To Forged CrankshaftsEmilce Bogado MartinezNo ratings yet

- Aerospace Materials Aluminum CompositesDocument5 pagesAerospace Materials Aluminum CompositesfrancescaNo ratings yet

- 2.doc Semi Process TechnicalsDocument2 pages2.doc Semi Process TechnicalsshreyeshNo ratings yet

- Materials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDocument8 pagesMaterials For Engine: © 2016 Scrivener Publishing LLC. Published 2016 by John Wiley & Sons, IncDzaky ArizsaNo ratings yet

- Bevel Gears and Gear SetsDocument4 pagesBevel Gears and Gear SetsCadeco ZamoraNo ratings yet

- Bearings For John Deere®Document4 pagesBearings For John Deere®Cadeco Zamora100% (1)

- Beaded GasketsDocument1 pageBeaded GasketsCadeco ZamoraNo ratings yet

- 100R1 Hose AssemblyDocument3 pages100R1 Hose AssemblyCadeco ZamoraNo ratings yet

- 100R13 4 Layer Spiral Hydraulic HoseDocument1 page100R13 4 Layer Spiral Hydraulic HoseCadeco ZamoraNo ratings yet

- AnodesDocument1 pageAnodesCadeco ZamoraNo ratings yet

- Belt Tensioners and PulleysDocument2 pagesBelt Tensioners and PulleysCadeco ZamoraNo ratings yet

- Alarms & HornsDocument1 pageAlarms & HornsCadeco ZamoraNo ratings yet

- Air CompressorsDocument1 pageAir CompressorsCadeco ZamoraNo ratings yet

- 100R1 Single Wire Braid Hydraulic HoseDocument1 page100R1 Single Wire Braid Hydraulic HoseCadeco ZamoraNo ratings yet

- ActuatorsDocument1 pageActuatorsCadeco Zamora100% (1)

- Connecting Rod KitDocument1 pageConnecting Rod KitCadeco ZamoraNo ratings yet

- 100R5 Hose AssemblyDocument2 pages100R5 Hose AssemblyCadeco ZamoraNo ratings yet

- 100R4 Textile With Helical Hydraulic HoseDocument1 page100R4 Textile With Helical Hydraulic HoseCadeco ZamoraNo ratings yet

- 100R2 Double Wire Braid Hydraulic HoseDocument1 page100R2 Double Wire Braid Hydraulic HoseCadeco ZamoraNo ratings yet

- 100R5 One Wire Braid With Textile Cover Hydraulic HoseDocument1 page100R5 One Wire Braid With Textile Cover Hydraulic HoseCadeco ZamoraNo ratings yet

- BogiesDocument1 pageBogiesCadeco ZamoraNo ratings yet

- Cabin GlassDocument3 pagesCabin GlassCadeco ZamoraNo ratings yet

- Cadenas CTPDocument3 pagesCadenas CTPCadeco ZamoraNo ratings yet

- BrushesDocument1 pageBrushesCadeco ZamoraNo ratings yet

- Turbos Cruce Niitsu VS OEMDocument11 pagesTurbos Cruce Niitsu VS OEMCadeco ZamoraNo ratings yet

- ClampsDocument1 pageClampsCadeco ZamoraNo ratings yet

- ABC Gasket KitsDocument2 pagesABC Gasket KitsCadeco ZamoraNo ratings yet

- Air Filter Change IndicatorsDocument1 pageAir Filter Change IndicatorsCadeco ZamoraNo ratings yet

- Summative Test TleDocument18 pagesSummative Test TleGillyn Ruiz - AntonioNo ratings yet

- Haldor Topsoe PDFDocument28 pagesHaldor Topsoe PDFSlamet Purwadi S.TNo ratings yet

- Gear Hobbing SandvikDocument7 pagesGear Hobbing SandvikAndré Hemerly MaiaNo ratings yet

- Iso 5662 1978Document4 pagesIso 5662 1978muhammed hairieNo ratings yet

- MillingDocument76 pagesMillingAbduljebar SemuNo ratings yet

- R1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0ADocument3 pagesR1111-DSH-PL-00-006-DATA SHEET FOR INDUCTION BENDS - Rev 0AAHMED AMIRANo ratings yet

- Ped Eam-0526-24-1-2006-03Document6 pagesPed Eam-0526-24-1-2006-03nathachaiNo ratings yet

- Stainless Steel 304 Round BarDocument3 pagesStainless Steel 304 Round Barevergrow solutions100% (1)

- Aluminum & Stainless Standards (Imperial) 2Document32 pagesAluminum & Stainless Standards (Imperial) 2Bradley GoldenNo ratings yet

- Atlas Copco Roto Inject Fluid JECDocument2 pagesAtlas Copco Roto Inject Fluid JECアラファト イスラム教No ratings yet

- Sewage TreatmentDocument22 pagesSewage TreatmentNelly Elias100% (1)

- Crimping Tools AssesmentDocument3 pagesCrimping Tools AssesmentAbhishekprasad royNo ratings yet

- 6082 t6 Aluminium Round BarDocument12 pages6082 t6 Aluminium Round Barben norwoodNo ratings yet

- Product CompatiblityDocument22 pagesProduct CompatiblityrahulchandokNo ratings yet

- Coil CoatingDocument5 pagesCoil CoatingNaveen RohiraNo ratings yet

- Mhanila Benedict H 2019-04-7090Document74 pagesMhanila Benedict H 2019-04-7090Maganghila SamwelNo ratings yet

- ANI Metal Hot Dip Galvanizing ChemicalsDocument2 pagesANI Metal Hot Dip Galvanizing ChemicalsEng-Ahmed AllamNo ratings yet

- Drilling: Bachelor of EngineeringDocument48 pagesDrilling: Bachelor of EngineeringramadanNo ratings yet

- Alloy 254 Technical InformationDocument3 pagesAlloy 254 Technical InformationIdehen KelvinNo ratings yet

- Work Method Statement For Painting Existing WallDocument11 pagesWork Method Statement For Painting Existing WallMohd Hafizi AzlanNo ratings yet

- 630 (17-4) Precipitation Hardening Stainless Steel BarDocument4 pages630 (17-4) Precipitation Hardening Stainless Steel Barehudingram6535No ratings yet

- Peco PGC SeriesDocument2 pagesPeco PGC SeriesReza PramataNo ratings yet

- Easywash: Technical Data SheetDocument2 pagesEasywash: Technical Data SheetCharm Der BardNo ratings yet

- Mrir 036Document17 pagesMrir 036Sam RajaNo ratings yet

- Wood Burning StoveDocument4 pagesWood Burning StoveAnthony SullivanNo ratings yet

- Mould Pin - Standard - Taha Associates - 2021Document21 pagesMould Pin - Standard - Taha Associates - 2021Taha AssociatesNo ratings yet

- fYP PROPOSED TOPICDocument2 pagesfYP PROPOSED TOPICUme HaniNo ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet