Professional Documents

Culture Documents

3000 Titanium CRSLockring ABS 0920 2004-09 4

3000 Titanium CRSLockring ABS 0920 2004-09 4

Uploaded by

Konelek AeroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3000 Titanium CRSLockring ABS 0920 2004-09 4

3000 Titanium CRSLockring ABS 0920 2004-09 4

Uploaded by

Konelek AeroCopyright:

Available Formats

AIRBUS

ABS0920

Issue 4

Page 1 of 8

September 2004

Aerospace series

Adapter - Ring locked fitting -

Flareless end

“When this standard is applied, a careful check must be made as to whether any protective rights

exist. This standard issuer hereby disclaims any liability for infringement of patent or design rights

resulting from the use of this standard"

Published and distributed by :

AIRBUS

AIRBUS

INDUSTRIE

S.A.S.

ENGINEERING DIRECTORATE

31707 BLAGNAC Cedex

FRANCE

© Copyright AIRBUS S.A.S. 2004. All rights reserved

Ref. no. ABS0920

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 2

Issue 4

Contents

1 Scope

2 Normative references

3 Requirements

4 Designation

5 Marking

6 Technical specification

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 3

Issue 4

1 Scope

This standard specifies the dimensions, tolerances, required characteristics and the mass of an adapter, flareless

tube end AS33514 or AS4375, ring locked type, installed in a port as per ABS0919 for use in hydraulic and fluid

systems up to 3 000 psi from 04 to 16 and 1 000 psi for 20 and 24.

2 Normative references

This Airbus Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this Airbus

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

ISO 3161 UNJ threads, with controlled root radius for aerospace - Inch series.

ISO 7169 Separable tube fittings for fluid systems, 24 degrees cone - General specification.

1

EN 2424 Aerospace series - Marking of aerospace products.

ABS0919 Port - Ring locked fitting - Standard dimensions for.

ABS1376 Hydraulic plug-in unions - Technical specification.

2

AMS 2486 Conversion coating of titanium alloys fluoride - Phosphate type.

2

AMS 2488 Anodic treatment of titanium and titanium alloys.

2

AMS 4928 Titanium alloy bars, wire, forgings, and rings 6Al-4V annealed.

2

AMS 4965 Titanium alloy bars, wire, forgings, and rings 6.0Al - 4.0V - Solution and precipitation heat treated.

2

AMS 4967 Titanium alloy bars, forgings, and rings 6.0Al - 4.0V annealed, heat treatable.

AMS 5731 Steel bars, forgings, tubing, and rings, corrosion and heat resistant 15Cr - 25.5Ni - 1.3Mo - 2.1Ti -

2

0.006B - 0.30V consumable electrode melted, 1 800 °F (+980 °C) solution heat treated.

AMS 5732 Steel bars, wire, forgings, tubing, and rings, corrosion and heat resistant 15Cr - 25.5Ni - 1.2Mo -

2.1Ti - 0.006B - 0.30V consumable electrode melted, (+982 °C) solution and precipitation heat

2

treated.

AMS 5734 Steel bars, forgings, and tubing, corrosion and heat resistant 15Cr - 25.5Ni - 1.2Mo - 2.1Ti - 0.006B

2

- 0.30V consumable electrode melted, 1 650 °F (900 °C) solution heat treated.

AMS 5737 Steel bars, forgings, and tubing, corrosion and heat resistant 15Cr - 25.5Ni - 1.3Mo - 2.1Ti - 0.006B

2

- 0.30V consumable electrode melted, 1 650 °F (900 °C) solution and precipitation heat treated.

2

AMS QQ-P-35 Passivation treatments for corrosion-resistant steel.

2

AS568 Aerospace size standard for O-ring.

2

AS4375 Fitting end, flareless, design standard.

2

AS33514 Fitting end, standard dimensions for flareless tube connection and gasket seal.

NAS1611 Packing, ethylene propylene performed o-ring phosphate ester resistant (-65 DEG. F to +250/300

3

DEG. F).

3 Requirements

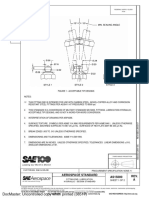

3.1 Configuration, dimensions, tolerances and mass

The configuration, dimensions, tolerances and mass shall conform with Figure 1 and Table 1.

Dimensions J and K are for design purposes only. Do not use as installation data.

Dimensions are expressed in inches (millimetres).

1

Published as AECMA Standard at the date of publication of this standard

2

Published by : Society of Automotive Engineers (SAE), 400 Commonwealth Drive, Warrendale, PA 15096-0001, USA

3

Published by : Aerospace Industries Association of America, Inc. (AIA), 1250 Eye Street, N.W., Washington, D.C. 20005-3924,

USA

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 4

Issue 4

3.2 Materials and finishes

Materials and finishes shall be in accordance with Table 2.

E F

See note 1 M

ØH

ØC

ØD

ØL

Thread B

Thread A G Lockring captivated 0 - .015 (0 - 0,381)

from A thread chamfer

See note 1

J

K

Lockring

O-Ring (see note 2)

Port as per ABS0919

(see table 1)

Note 1 : Dimensions meet the minimum requirements of specification AS33514 or AS4375 style E for pipe

connection.

Note 2 : O-ring size as per Table 1 and as per AS568 must be used. The O-ring compound shall be specified by

the using design activity and shall be selected based on system fluid and temperature (NAS1611 o-ring

for hydraulic systems).

Figure 1 : Configuration, dimensions and tolerances

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 5

Issue 4

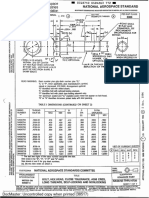

Table 1 : Dimensions, tolerances and mass

(continued)

ITEM TUBE THREAD A as THREAD B as ØC ØD E F G

CODE SIZE per ISO 3161 per ISO 3161 Ref. ± .005 0 ± .007

Min. Max.

No. CLASS 3A CLASS 3A (± 0,127) − .015 (± 0,178)

(see note 1) (see

0

note 3) − 0,381

.2500 .400 .355

04 .4375-20UNJF .3125-24UNJF See note 2

(6,3500) (10,160) .752 (9,017) .192

.3125 .231 .237 .491 (19,101) .381 (4,877)

05 .5000-20UNJF .3750-24UNJF

(7,9375) (5,867) (6,020) (12,471) (9,677)

.3750 .294 .300 .544 .789 .395

06 .5625-18UNJF .4375-20UNJF

(9,5250) (7,468) (7,620) (13,818) (20,041) (10,033)

.5000 .419 .425 .670 .882 .430 .210

08 .7500-16UNJF .5625-18UNJF

(12,7000) (10,643) (10,795) (17,018) (22,403) (10,922) (5,334)

.6250 .497 .503 .824 .945 .465

10 .8750-14UNJF .6875-24UNJEF

(15,8750) (12,624) (12,776) (20,930) (24,003) (11,811)

.7500 .653 .659 .981 .527

12 1.0625-12UNJ .8125-20UNJEF

(19,0500) (16,586) (16,739) (24,917) 1.018 (13,386) .220

1.0000 .872 .878 1.251 (25,857) .564 (5,588)

16 1.3125-12UNJ 1.1250-18UNJEF

(25,4000) (22,149) (22,301) (31,775) (14,326)

1.2500 1.090 1.096 1.466 .569

20 1.6250-12UNJ 1.3125-18UNJEF

(31,7500) (27,686) (27,838) (37,236) 1.045 (14,453) .240

1.5000 1.341 1.347 1.768 (26,543) .608 (6,096)

24 1.8750-12UNJ 1.6250-18UNJEF

(38,1000) (34,061) (34,214) (44,907) (15,443)

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 6

Issue 4

Table 1 : Dimensions, tolerances and mass (concluded)

ITEM TUBE ØL M ØH O-ring Port size J K Mass

CODE SIZE + .005 + .010 ± .005 dash No. No. ± .0175 max. approx.

No. − .002 − .005 (± 0,127) as per as per (± 0,444) lb per part

+ 0,127 + 0,254 AS568 ABS0919 (see (kg per part)

− 0,051 − 0,127 note 3)

.2500 .239 .514 .014

04 010 04

(6,350) (6,071) (13,056) .587 .124 (0,00635)

.3125 .301 .624 (14,910) (3,150) .021

05 011 05

(7,9375) (7,645) (15,850) (0,00952)

.3750 .364 .125 .700 .609 .025

06 012 06

(9,525) (9,246) (3,175) (17,780) (15,469) (0,01134)

.5000 .482 .814 .702 .130 .038

08 014 08

(12,700) (12,243) (20,676) (17,831) (3,302) (0,01723)

.6250 .625 1.040 .765 .063

10 016 10

(15,875) (15,875) (26,416) (19,431) (0,02857)

.7500 .737 1.170 .083

12 116 12

(19,050) (18,720) (29,718) (0,03764)

1.0000 1.000 1.456 .128

16 120 16

(25,400) (25,400) .157 (36,982) .838 .140 (0,05806)

1.2500 1.225 (3,988) 1.782 (21,285) (3,556) .188

20 123 20

(31,750) (31,115) (45,263) (0,08527)

1.5000 1.502 2.031 .247

24 128 24

(38,100) (38,151) (51,587) (0,11203)

Note 1 : For information only, please refer to AS33514.

Note 2 : Dia. C for item code No. 04 is .184/.190 inch (4,674/4,826 mm) on AS33514 or AS4375 end and reduced

to .169/.175 inch (4,293/4,445 mm) diameter on opposite end.

Note 3 : Tolerance of E and J dimensions listed in table 1 shall be used from May 2004. Before this date,

tolerance of E and J dimensions were respectively + .010 + 0,254

− .005 inch − 0,127 mm and

± .020 inch (± 0,508 mm).

Table 2 : Materials and finishes

ELEMENT MATERIAL FINISH

Anodic treatment as per AMS2488, type 2

Titanium alloy 6Al-4V as per AMS 4928,

Adapter (tiodize TY II or equivalent) or

AMS 4965 or AMS 4967 (130 KSI UTS min.)

Fluoride-phosphate conversion as per AMS 2486

CRES A286 as per AMS 5731, AMS 5732,

Lockring Passivated as per AMS QQ-P-35

AMS 5734 or AMS 5737 (34-40 HRC)

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 7

Issue 4

4 Designation

EXAMPLE:

Description block Identity block

Adapter ring locked ABS0920 - 08

Number of this standard

Item code No. (see Table 1)

(tube size in 1/16 inch increments)

5 Marking

Parts shall be marked as per EN 2424, style G.

Manufacturer identification is stamped on the ring (either on the top or in the groove).

6 Technical specification

ISO 7169 and ABS1376 (except for -05 size).

DocMaster: Uncontrolled copy when printed (34473)

ABS0920 Page 8

Issue 4

RECORD OF REVISIONS

Clause

Issue Description of modification

modified

1 New Standard.

05/99

2 Values modified in column M of table 1.

09/99

3 Column "Port size No. as per ABS0919" added in table 1.

09/00 Detail Z added in figure 1.

4 Detail Z deleted in figure 1.

09/04 Item code Nos 03 and 32 deleted.

References EN 6079 deleted.

References AMS 2486, ABS1376 and NAS1611 added.

Reference ABS1376 : Title modified.

Note 1 and Note 3 added under table 1.

DocMaster: Uncontrolled copy when printed (34473)

You might also like

- Abs 5044 2009-07 8Document9 pagesAbs 5044 2009-07 8Bogdan Rusu100% (1)

- Aitm 1.0010 CaiDocument15 pagesAitm 1.0010 CaiJosé Mateus Rodrigues RangelNo ratings yet

- Airbus: Process and Material SpecificationDocument25 pagesAirbus: Process and Material SpecificationJorge OrtegaNo ratings yet

- ASNA2536-collars CortaduraDocument6 pagesASNA2536-collars CortaduraCurro Espadafor Fernandez AmigoNo ratings yet

- Incremental Development Guidebook: Support Engineering Teams in The Frame of An Incremental DevelopmentDocument52 pagesIncremental Development Guidebook: Support Engineering Teams in The Frame of An Incremental Developmentcoralonso100% (3)

- prEN 6115Document15 pagesprEN 6115malotNo ratings yet

- FTI-8101 Revision G PDFDocument88 pagesFTI-8101 Revision G PDFJuan Carlos Omana Perez (LATAM)No ratings yet

- NSA CSS Supply Catalog Descriptive DataDocument567 pagesNSA CSS Supply Catalog Descriptive DataLion JudgeNo ratings yet

- BAMS 532-018 250 Degree Epoxy Prepreg Fiberglass ClothDocument22 pagesBAMS 532-018 250 Degree Epoxy Prepreg Fiberglass ClothJohn CollinsNo ratings yet

- Nce 003452Document939 pagesNce 003452Misbah ZaidiNo ratings yet

- BAMS 532-001 Rev NC 250 Degree Epoxy Resin Prepreg KevlarDocument18 pagesBAMS 532-001 Rev NC 250 Degree Epoxy Resin Prepreg KevlarJohn CollinsNo ratings yet

- Package of Airframe Preliminary Design and Analysis For Aerospace Engineering StudentsDocument22 pagesPackage of Airframe Preliminary Design and Analysis For Aerospace Engineering StudentsJonathan MooreNo ratings yet

- Asna2025: Docmaster: Uncontrolled Copy When PrintedDocument5 pagesAsna2025: Docmaster: Uncontrolled Copy When Printedpym31No ratings yet

- ATA - Spec2200 - Method of Presentation - p346-349Document4 pagesATA - Spec2200 - Method of Presentation - p346-349FredNo ratings yet

- B+G+2 Boq - (367-625)Document116 pagesB+G+2 Boq - (367-625)Amy Fitzpatrick100% (3)

- LustronDocument1 pageLustronOscar MiraNo ratings yet

- Doheny Pool PumpsDocument12 pagesDoheny Pool PumpsBenjamin DoverNo ratings yet

- Aips01-02-015 Installation of Blind Type ThreadedDocument22 pagesAips01-02-015 Installation of Blind Type ThreadedAlberto Biedma FernándezNo ratings yet

- Aerospace Material SpecificationDocument9 pagesAerospace Material SpecificationRoohi KatnoriaNo ratings yet

- Abs 0678Document11 pagesAbs 0678Jorge OrtegaNo ratings yet

- Published and Distributed By: Airbus S.A.S. Engineering Directorate 31707 BLAGNAC Cedex FranceDocument12 pagesPublished and Distributed By: Airbus S.A.S. Engineering Directorate 31707 BLAGNAC Cedex Francedarrow doriNo ratings yet

- FM300 Ips10-01-006-02Document9 pagesFM300 Ips10-01-006-02Danilo0% (1)

- ABS5377Document5 pagesABS5377BaCresNo ratings yet

- Aims03 08 007Document7 pagesAims03 08 007Jorge OrtegaNo ratings yet

- Rectification of Met Material by Shot PeeningDocument9 pagesRectification of Met Material by Shot Peeningolegprikhodko2809No ratings yet

- Abs 0973Document13 pagesAbs 0973AlejandroNo ratings yet

- Ips04 04 002 01 - 2Document7 pagesIps04 04 002 01 - 2Pedro Luis AceitunoNo ratings yet

- Pretreatment of Polyamide - APSDocument12 pagesPretreatment of Polyamide - APSolegprikhodko2809No ratings yet

- BAMS 551-007 - A Structural Foaming AdhesivesDocument17 pagesBAMS 551-007 - A Structural Foaming AdhesivesJohn Collins100% (1)

- ASNA2041Document18 pagesASNA2041BorjaNo ratings yet

- (Airbus) 51-70-10 Repair Design Guideline AirbusDocument110 pages(Airbus) 51-70-10 Repair Design Guideline AirbusMulya Azhari12No ratings yet

- Technical Notes (TN) : AirbusDocument76 pagesTechnical Notes (TN) : AirbusHossein RashediNo ratings yet

- Als Part 2 Variation 8.5Document5 pagesAls Part 2 Variation 8.5mnoorebsNo ratings yet

- ABS10021Document11 pagesABS10021darrow dori100% (1)

- Process Specification: Sairbus IhdustrieDocument10 pagesProcess Specification: Sairbus Ihdustriebrains26No ratings yet

- Asna 2531 2006-09 K 2Document7 pagesAsna 2531 2006-09 K 2Speeder JohnNo ratings yet

- 80 T 30 4010 - BBL - 05 - 2004 08Document1 page80 T 30 4010 - BBL - 05 - 2004 08Jacob Jack YoshaNo ratings yet

- NASM3Document4 pagesNASM3GFS ConsultoriaNo ratings yet

- Finish F 69: Aerospace CoatingsDocument2 pagesFinish F 69: Aerospace CoatingsKentNo ratings yet

- Nas451 3Document3 pagesNas451 3joeNo ratings yet

- Asb As350-52.00.53Document11 pagesAsb As350-52.00.53anon_847285754No ratings yet

- Tds0002 Illustration Style Standards Issue eDocument149 pagesTds0002 Illustration Style Standards Issue eZack MansorNo ratings yet

- Aims04 04 024Document11 pagesAims04 04 024arthur ballueNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument23 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- AA SM 028 Fastener FlexibilityDocument20 pagesAA SM 028 Fastener Flexibilitykrishbalu17No ratings yet

- Non-Conformities of Insulation Blankets - Airbus ManualDocument19 pagesNon-Conformities of Insulation Blankets - Airbus Manualolegprikhodko2809100% (1)

- ASNA2180Document29 pagesASNA2180Felix FloresNo ratings yet

- SAE AS 15000A Grease Nipple TipsDocument2 pagesSAE AS 15000A Grease Nipple TipsAndr EkmeNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document423 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)andres orjuelaNo ratings yet

- ILA06 Praesentat AIRBUS Juergen PleitnerDocument18 pagesILA06 Praesentat AIRBUS Juergen PleitnerFernando Olmedo0% (1)

- Ancra Aircraft-Catalog403Document28 pagesAncra Aircraft-Catalog403Robert FlorezNo ratings yet

- Abs 0059Document14 pagesAbs 0059darrow doriNo ratings yet

- Mil PRF 85285DDocument21 pagesMil PRF 85285DmmdominicNo ratings yet

- Paint - PRF 85285 DDocument21 pagesPaint - PRF 85285 Dsachinjoshi_2006No ratings yet

- Gif2008 Workshop Composites HellardDocument26 pagesGif2008 Workshop Composites HellardAlejandroPoloLlanaNo ratings yet

- AFS Europe Tooling CatalogDocument74 pagesAFS Europe Tooling CatalogANBU100% (1)

- 51-49-00 - Description - Standard Torque ValuesDocument14 pages51-49-00 - Description - Standard Torque ValuesMarijaNo ratings yet

- 01 TCT-Stress FamiliarizationDocument30 pages01 TCT-Stress FamiliarizationAviationaddictNo ratings yet

- AMM - VTI - A318/A319/A320/A321 REV DATE: Feb 01/2022 Tail Number - MSN - FSN: ALLDocument3 pagesAMM - VTI - A318/A319/A320/A321 REV DATE: Feb 01/2022 Tail Number - MSN - FSN: ALLkamal virkNo ratings yet

- N Fastener 0000000005 03Document169 pagesN Fastener 0000000005 03Alejandro MontealegreNo ratings yet

- Airbus Reference Language Glossary of Airbus Terms and Expressions (GATE)Document113 pagesAirbus Reference Language Glossary of Airbus Terms and Expressions (GATE)coralonsoNo ratings yet

- F-7.2.1.5 Specification Revision ListDocument11 pagesF-7.2.1.5 Specification Revision ListRam Parimalam0% (1)

- DAN169Document8 pagesDAN169BorjaNo ratings yet

- NAS1149Document6 pagesNAS1149Konelek AeroNo ratings yet

- NASM21043Document3 pagesNASM21043Konelek AeroNo ratings yet

- Nas 6704Document7 pagesNas 6704Konelek AeroNo ratings yet

- NASM20426Document6 pagesNASM20426Konelek AeroNo ratings yet

- ACI - 201.2R-08 - Guide To Durable ConcreteDocument2 pagesACI - 201.2R-08 - Guide To Durable ConcreteJuanNo ratings yet

- Mirapox 4122 ABDocument3 pagesMirapox 4122 ABEjah SharNo ratings yet

- The Unique Challenges of Planning A New Town: The Gandhinagar ExperienceDocument17 pagesThe Unique Challenges of Planning A New Town: The Gandhinagar ExperienceAnushka AnandNo ratings yet

- MST Installation of Pressurization UnitDocument10 pagesMST Installation of Pressurization Unitvictor100% (1)

- FST Aerospace Parts Cross Reference BrochureDocument6 pagesFST Aerospace Parts Cross Reference Brochurechampyjm6532No ratings yet

- Catalogo Danfuss IntercambiadoresDocument20 pagesCatalogo Danfuss Intercambiadoresjuan10703032No ratings yet

- Design Brief - IX Sem - 2021Document4 pagesDesign Brief - IX Sem - 2021V.K.Jeevan KumarNo ratings yet

- 83027443667Document3 pages83027443667Bikram BhusalNo ratings yet

- Arif (2020)Document9 pagesArif (2020)JOHN ORELLE MANGAHASNo ratings yet

- Reaffirmed 1996Document36 pagesReaffirmed 1996jaianit89No ratings yet

- A5 Stockist GuideDocument48 pagesA5 Stockist Guideantonio gliattaNo ratings yet

- My Dream Job Is ArchitectureDocument3 pagesMy Dream Job Is ArchitectureKarla MarinNo ratings yet

- 04-Type 4-Con99-Sambungan Rafter Ke Rafter (Posisi Mid)Document80 pages04-Type 4-Con99-Sambungan Rafter Ke Rafter (Posisi Mid)Guntur SuwantoroNo ratings yet

- Composite Beam ExampleDocument4 pagesComposite Beam Examplexxazninvasionxx2697100% (1)

- Ktu Gte 1 Question CombinedDocument11 pagesKtu Gte 1 Question CombinedAshok Mathew0% (1)

- 施工设计服务合同 Construction Design ContractDocument7 pages施工设计服务合同 Construction Design ContractRebi HamzaNo ratings yet

- Boq Batang-Weleri Section 1Document26 pagesBoq Batang-Weleri Section 1Kiky HendrawanNo ratings yet

- Fluid Power Graphic Symbols User's Guide: General Service InformationDocument17 pagesFluid Power Graphic Symbols User's Guide: General Service Informationjorge william ramirezNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Every 1000M3 MixtureDocument3 pagesEvery 1000M3 Mixturedana setiawanNo ratings yet

- Topic 2: Building SystemsDocument12 pagesTopic 2: Building SystemsRochelleNo ratings yet

- Chapter 1introduction To Transport System and PlanningDocument20 pagesChapter 1introduction To Transport System and PlanningKefene GurmessaNo ratings yet

- Dimension Stone Cladding Design - Dowel Anchorage Design: Conference PaperDocument15 pagesDimension Stone Cladding Design - Dowel Anchorage Design: Conference PaperYusuf TrunkwalaNo ratings yet

- c19 Standard Operating ProceduresDocument36 pagesc19 Standard Operating ProceduresahsNo ratings yet

- Fiberglass Piping Engineering Design ManualDocument36 pagesFiberglass Piping Engineering Design ManualdestresscallNo ratings yet

- Smoke Control TraneDocument156 pagesSmoke Control Traneeselcosac100% (1)

- Kilsaran 15.0N 100mm Solid Block DOP&CE (Castletown) Rev01Document2 pagesKilsaran 15.0N 100mm Solid Block DOP&CE (Castletown) Rev01Reda SadNo ratings yet