Professional Documents

Culture Documents

Cgij Corp - Company Profile 2022 Updated

Cgij Corp - Company Profile 2022 Updated

Uploaded by

CHOTIEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cgij Corp - Company Profile 2022 Updated

Cgij Corp - Company Profile 2022 Updated

Uploaded by

CHOTIECopyright:

Available Formats

MANUFACTURER AND SUPPLIER OF PRECAST CONCRETE WALL FORM BLOCKS

A. Soriano Highway, Lontoc Timalan, Naic, Cavite

Contact Nos

Nos: 09053397558 – 09179691507 – 0919 877 4227 - (046) 527 9033

email us at cgijcorporation@gmail.com

CGIJ CORPORATION

CORPORATION, One of the country’s growing

supplier of quality precast concrete wall form blocks

History:

CGIJ CORPORATION is the successor of

Gilbert Crisologo and Imelda Jardin

Jardin’s 10

year company “CGIJCGIJ ENTERPRISE

ENTERPRISE”, and is

managed and operated by their children

headed by Mary Ann Crisologo, John

Crisologo, Heidi Crisologo, Albert Crisologo,

and the rest of the team.

CGIJ CORPORATION is still one of the

country’s growing manufacturers and supplier

of PRECAST CONCRETE WALL FORM

BLOCKS.. With the increasing demand the

company is looking forward to expanding its

reach and opening its doors to new business

partners in strategic locations.

CGIJ have started with a humble

beginning producing only fifty ((50) to one

hundred (100) sets of form blocks daily. The

company was initially located in Las Piñas and

has transferred to Naic Cavite to

accommodate increasing orders. The demand was indeed high; inquiries about the product

and customers’ request were continuously increasing. The need to produce more form

blocks was imperative. With good stewardship

stewardship,, management, and budgeting, the

production also increased to satisfy th the demand. Currently, we are producing and

providing our clients a good number of concrete precast wall form blocks, and we are now

moving closer in fulfilling the ccompany’s mission and vision.

We at CGIJ CORPORATION are looking forward to serve more clients and help more

contractors finish their project on time using our Precast Concrete Wall Form Blocks.

Blocks

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 1

Mission:

Our mission is to provide high--quality

quality precast concrete wall form blocks that maintain

efficient and cost-effective

effective standards on labor and materials.

Vision:

To become the number one leading supplier of high quality precast concrete wall form

blocks.

To meet and be able to increase customers satisfaction in the product that we deliver.

Product:

Precast

ast Concrete Wall Form Block is a concrete kind of form rm permanent in place. It has

variety of sizes, height, thickness, width and length. Diversity of design and strength as per

required by the users with different types and design for external and in internal

ternal applications.

Precast wall form

orm blocks are best for retaining wall, party wall ll (fencing), load and non-

non

load bearing wall, partition wall, insulation wall, fire wall, shear wall, low-cost low

housing projects, high-end end housing projects, high high-rise

rise building projects, etc.

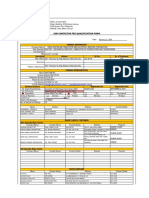

Specifications:

Two (2) Concrete precast panels joined

together with steel dowels to form a

set of blocks.

Smooth exterior face

Light weight

1190 psi concrete strength for five (5)

days curing

Size of one (1) set

Length: One (1) meter

Height: .25 meter

Width (Thickness): 4”, 5”, 6”

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 2

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 3

Designs:

Conventional

Ship-lap

V-cut

Advantages:

Smooth surface

Easier and faster installation

Variety of sizes available for

interlocking

Embedded with recesses for

water line, electrical,

sewerage, and

communication cables

Infill will be concrete mix and

not mortar mix

Aesthetic Value

Time Saving

Cost-effective

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 4

Projects/ Clients:

Buildings

The One Building, Jocson St. Esapaña

Lupacco Building, Makati City

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 5

Madison Gallery, Muntinlupa City

Bambang, Metro Manila

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 6

Condominium Project at España Manila

Residential

Marikina

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 7

Bauan, Batangas

Tanza, Cavite

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 8

Alaminos, Batangas

Perimeter Fence, Naic Cavite

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 9

METHODOLOGY

LAYOUT AND STACKING

Install batter boards only on corners initially at

right angles approximately .60 from

monuments, .60 width and at least .45 above

ground. Ensure that stakes are firm and strong to

resist any movement when lines are put under

tension.

EXCAVATION

Guidelines should be present on limits of excavation line. Invert elevation should be established

from level of guideline.

Cut and remove until desired depth is achieved. Use plumb line from guidelines to ensure depth

is correct and level. Do not overcut. Width of cut should not exceed 150mm of required

dimension. Bottom of excavation should be level. No backfilling is allowed. When cut exceeds

desired depth, level to cut depth.

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 10

FOUNDATION WORKS

Concrete must be according to desired strength. Use

correct pouring methodology. Drop no more than

1.5m. Pour desired height before moving forward.

Concrete must be properly tamped with rids the

correct elevation and made level. Ensure that pour is

monolithic. Where concrete stops are required, stops

shall be vertical or at a diagonal of not more than 45

degrees from the vertical.

FOUNDATION BLOCKS

Install storey poles at all corners of the building line. Measure height of blocks from highest

point of footing. Mark elevation on all other storey poles. Use concrete to level blocks.

Pour concrete filler to ½ - ¾ height of topmost layer of form blocks. Ensure concrete is tamped

by use of rods or mechanical vibrator. Use desired concrete mix.

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 11

BACKFILLING

Return back soil in 30cm layers and should be sprinkled with water to achieve better

compaction. Backfill materials should be as specified. Continue cycle until desired elevation

is achieved.

GROUND FLOOR WALLS

Lay-out succeeding layers to second floor elevation. Lay block tops aligned to the guide

lines. Check plumb and level of each block. Check joint spacing (max = 3mm). Face of blocks

should be aligned (max = 2mm).

Pour concrete filler to ½ – ¾ height of a block to ensure interlocking between blocks.

Recheck alignment and levelness and adjust concrete while still soft. Allow to set before

adding additional layers. Start pouring from one corner until desired height is achieved

moving forward until all walls are at desired height of concrete.

Check plumpness of each block and alignment to the 1st layer. Cut required embedment and

ensure it is properly positioned and fixed.

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 12

USE OF GRINDER APPLICATION OF SKIMCOAT

Grinder can be used to cut form Skim coat can be applied between form blocks.

blocks to desired size.

“The faster a construction project can be

built without compromising the quality, the

less time it sits not generating revenue.“

CGIJ CORPORATION . 09053397558–09179691507-09198774227 Page 13

You might also like

- Exodura CatalogDocument20 pagesExodura CatalogChad SoribelloNo ratings yet

- Company Profile 2020Document20 pagesCompany Profile 2020Edrian Louis Manalo TavasNo ratings yet

- NRRC SG 020Document51 pagesNRRC SG 020Ahmed shabanNo ratings yet

- ND-400 NDA API User GuideDocument30 pagesND-400 NDA API User GuideOtho Salazar Arenas100% (1)

- 12 PV System Util Scale BIPVDocument58 pages12 PV System Util Scale BIPVSachin SoniNo ratings yet

- Call List 1Document54 pagesCall List 1joliel gabasaNo ratings yet

- Adding Value To ConcreteDocument16 pagesAdding Value To ConcreteFrancois KokNo ratings yet

- Group No. 3 Strama ResearchDocument11 pagesGroup No. 3 Strama ResearchJoshua Pangilinan SalinNo ratings yet

- DuctDocument14 pagesDuctSalehAfadlehNo ratings yet

- 2022 Building Energy Efficiency StandardsDocument533 pages2022 Building Energy Efficiency Standardshellaspam888No ratings yet

- Konita WPC Board Brochure PDFDocument8 pagesKonita WPC Board Brochure PDFSusanta MaharanaNo ratings yet

- PVC Sheet BrochureDocument8 pagesPVC Sheet BrochureAnoop BalakrishnanNo ratings yet

- DATEM Pre Qualification FormDocument4 pagesDATEM Pre Qualification FormGilbert PinedaNo ratings yet

- FileDocument14 pagesFileiandegs2010No ratings yet

- 2 Mixer FlygtDocument8 pages2 Mixer FlygtHugo Miño Carrasco100% (1)

- Commissioning CertificateDocument1 pageCommissioning CertificateSiva GNo ratings yet

- D1000 Catalogue NEW MAY14Document34 pagesD1000 Catalogue NEW MAY14mssurajNo ratings yet

- Top 100 Firm - PHDocument1 pageTop 100 Firm - PHHershey GabiNo ratings yet

- Vertical Shaft Brick KIln Technology VSBDocument53 pagesVertical Shaft Brick KIln Technology VSBDragos NojeaNo ratings yet

- Power Xpert CX (Actualizado)Document20 pagesPower Xpert CX (Actualizado)GUSTAVO DUARTENo ratings yet

- Grace Solar Company Profile-2020 PDFDocument45 pagesGrace Solar Company Profile-2020 PDFLyndon AnduyanNo ratings yet

- Vaillant FlexoTHERM Tech Brochure 2.6 Web March 2018Document42 pagesVaillant FlexoTHERM Tech Brochure 2.6 Web March 2018Duncan StevenNo ratings yet

- Drawing Submssion Requirements - September - 2018Document66 pagesDrawing Submssion Requirements - September - 2018Suratman Blanck MandhoNo ratings yet

- Duct (HVAC) - Wikipedia, The Free EncyclopediaDocument4 pagesDuct (HVAC) - Wikipedia, The Free Encyclopediasaurabhjerps231221No ratings yet

- Case Study 3.4MW Toyota Building Thailand 30.5.21Document3 pagesCase Study 3.4MW Toyota Building Thailand 30.5.21Nguyen Trong TriNo ratings yet

- Artificial Intelligence For Energy Conservation in BuildingsDocument35 pagesArtificial Intelligence For Energy Conservation in BuildingsAbhijit KumarNo ratings yet

- R1000 CatalogueDocument24 pagesR1000 CataloguemssurajNo ratings yet

- PVCMC 0501 Us PDFDocument40 pagesPVCMC 0501 Us PDFAshok SureshNo ratings yet

- BrochureDocument18 pagesBrochureGideon Oyibo SmithNo ratings yet

- Smart Subcombiner US CEDocument2 pagesSmart Subcombiner US CEtalasubhanojiraogmaiNo ratings yet

- Preliminary Documents Design Report PDFDocument77 pagesPreliminary Documents Design Report PDFRamanNo ratings yet

- BollardsDocument51 pagesBollardsMohammed Wasiuddin100% (1)

- Heat Pump Report Final PDFDocument66 pagesHeat Pump Report Final PDFIna Rodica PricăNo ratings yet

- Air CasterDocument5 pagesAir CasterNitin Tembhurnikar0% (1)

- Mechanical and Electrical Services Capability StatementDocument4 pagesMechanical and Electrical Services Capability StatementTata Steel ProjectsNo ratings yet

- Modules BP 3230Q enDocument2 pagesModules BP 3230Q enJoaquim AlvesNo ratings yet

- Experiment No.:-3 TITLE: Study of Co-Generation Power Plant AIM: Study of Co-Generation Power Plant TheoryDocument10 pagesExperiment No.:-3 TITLE: Study of Co-Generation Power Plant AIM: Study of Co-Generation Power Plant Theory9527530909100% (1)

- Fire Extinguisher Manufacturing Project ReportDocument3 pagesFire Extinguisher Manufacturing Project ReportEMS CommerceNo ratings yet

- Pegler Commercial Valve Solutions Export BrochureDocument84 pagesPegler Commercial Valve Solutions Export BrochureRamadan RashadNo ratings yet

- LPG Piped Gas Systems For Residential FlatsDocument32 pagesLPG Piped Gas Systems For Residential Flatsnikita singhal0% (1)

- Sustainable FoundationsDocument4 pagesSustainable Foundationsk1l2d3No ratings yet

- PR20060419 enDocument2 pagesPR20060419 enscribidingyNo ratings yet

- FALAR IntroductionDocument18 pagesFALAR IntroductionjbonvierNo ratings yet

- Phase-Change Material - Wikipedia, The Free EncyclopediaDocument4 pagesPhase-Change Material - Wikipedia, The Free EncyclopediaBiswa Bikash SinghNo ratings yet

- Modular Prefabricated Housing Literature ScanDocument80 pagesModular Prefabricated Housing Literature ScangylNo ratings yet

- Manhole Brochure InteractiveDocument16 pagesManhole Brochure InteractiveIsmail IbrahimNo ratings yet

- Modular Coordination NotesDocument26 pagesModular Coordination NotesAbhishree Agrawal100% (1)

- 8TH Modular-C PDFDocument5 pages8TH Modular-C PDFAPRWSEA WG100% (1)

- Air CushionDocument20 pagesAir Cushionpegasus9428No ratings yet

- Alc CatalogDocument63 pagesAlc Catalogapi-274480886No ratings yet

- The Way of Saving Energy in The Traditional Houses of Iran's Arid Zone RegionsDocument3 pagesThe Way of Saving Energy in The Traditional Houses of Iran's Arid Zone RegionsEngineers Without Borders UKNo ratings yet

- Feasibility Study PDFDocument21 pagesFeasibility Study PDFShishan AhmadNo ratings yet

- PT 20200520 Sungrow ESS Business Introduction V10 enDocument22 pagesPT 20200520 Sungrow ESS Business Introduction V10 enHoàng ChungNo ratings yet

- Skeleton ProfileDocument69 pagesSkeleton Profileram_babu_59No ratings yet

- T05 3-4 2 PDFDocument201 pagesT05 3-4 2 PDFKhyss Ziah HerscheNo ratings yet

- CL Smartec Build SystemDocument24 pagesCL Smartec Build SystemSmartec Build System Pvt. Ltd.No ratings yet

- Villa in Bangalore CitrineDocument20 pagesVilla in Bangalore CitrineAdam SmithNo ratings yet

- NOLTA US Catalog CompleteDocument16 pagesNOLTA US Catalog CompleteFelix BonnNo ratings yet

- Company ProfileDocument16 pagesCompany ProfileazimkhtrNo ratings yet

- Catalogue of Roof SheetDocument8 pagesCatalogue of Roof Sheetcvsatheeh1No ratings yet

- Slurry W Alls: Design, Construction, and Quality Contro/: Ichard - SoDocument4 pagesSlurry W Alls: Design, Construction, and Quality Contro/: Ichard - SoAyman SobhyNo ratings yet

- Design General Specification: Abu Dhabi Gas Company (Atheer) MasonryDocument11 pagesDesign General Specification: Abu Dhabi Gas Company (Atheer) MasonryJose Manjooran0% (1)

- Consultation StructuralAssessmentGuideline PDFDocument33 pagesConsultation StructuralAssessmentGuideline PDFinferno_bs100% (2)

- ROSTEK - Facade and Roof Access PDFDocument61 pagesROSTEK - Facade and Roof Access PDFptorice100% (2)

- Klima Ormar 15 KW Data SheetDocument2 pagesKlima Ormar 15 KW Data SheetCallany AnycallNo ratings yet

- PROJECT A Consists of Two (2) Contiguous Residential Serviced Apartment Buildings One of Forty - TwoDocument1 pagePROJECT A Consists of Two (2) Contiguous Residential Serviced Apartment Buildings One of Forty - TwoAB AgostoNo ratings yet

- CE-515: Design of Steel StructuresDocument15 pagesCE-515: Design of Steel StructuresZiaullahNo ratings yet

- Preliminary Design 1Document3 pagesPreliminary Design 1MakAsifNo ratings yet

- Structural PlansDocument23 pagesStructural PlansDiane de OcampoNo ratings yet

- Fatma Mohamed Mohamed - Research 2Document1 pageFatma Mohamed Mohamed - Research 2Fatma MHNo ratings yet

- Brgy Health CTRDocument4 pagesBrgy Health CTRCharles SiaNo ratings yet

- Defects in Building PDFDocument39 pagesDefects in Building PDFDevendra KumarNo ratings yet

- Building Code Vocabulary 1Document9 pagesBuilding Code Vocabulary 1Josua MenisNo ratings yet

- Building Drawing Midterm ExamDocument6 pagesBuilding Drawing Midterm ExamRahul SinhaNo ratings yet

- Final QCP Punta MirayDocument7 pagesFinal QCP Punta MirayDJabNo ratings yet

- CordwoodDocument3 pagesCordwoodpapawelNo ratings yet

- CivilDAR 2019 Vol 1Document2 pagesCivilDAR 2019 Vol 1Manish MishraNo ratings yet

- Vistabrik Solid Glass Block Details Miscellaneous Interior DetailsDocument4 pagesVistabrik Solid Glass Block Details Miscellaneous Interior DetailsAJBAJB BAJBAJNo ratings yet

- Combined Wall: Equivalent Elastic Section ModulusDocument0 pagesCombined Wall: Equivalent Elastic Section Modulusmdkml2No ratings yet

- Micropile Bearing Plates PDFDocument11 pagesMicropile Bearing Plates PDFrowatersNo ratings yet

- Stress Ribbon Bridge Vandanapu LohitDocument17 pagesStress Ribbon Bridge Vandanapu LohitLohitNo ratings yet

- Updates On Revision To ASHRAE Standard 90.2: Including Roof Reflectivity For Residential BuildingsDocument11 pagesUpdates On Revision To ASHRAE Standard 90.2: Including Roof Reflectivity For Residential BuildingsnubazNo ratings yet

- Architectural Space PDFDocument26 pagesArchitectural Space PDFPallavi SaxenaNo ratings yet

- General Seminar Report PDFDocument21 pagesGeneral Seminar Report PDFabuzarNo ratings yet

- DBC - Handbook On Development & Building Works in RPZ PDFDocument108 pagesDBC - Handbook On Development & Building Works in RPZ PDFNic LeeNo ratings yet

- Parameters (7000 Psi) - TANDEMDocument5 pagesParameters (7000 Psi) - TANDEMJes Arvin Ocampo ZapantaNo ratings yet

- 1562-2 Design and Installation of Sheet Roof and Wall CladdingDocument25 pages1562-2 Design and Installation of Sheet Roof and Wall CladdingVasko DrogriskiNo ratings yet

- Flexural Strength Masonry PrismsDocument10 pagesFlexural Strength Masonry PrismsMuhammadAboubakarFarooqNo ratings yet

- A S-1 C S-1: Foundation Plan Roof Deck Framing PlanDocument3 pagesA S-1 C S-1: Foundation Plan Roof Deck Framing PlanMelloween Bernardo BarnacheaNo ratings yet