Professional Documents

Culture Documents

Water Systems

Water Systems

Uploaded by

Ehab NashyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Systems

Water Systems

Uploaded by

Ehab NashyCopyright:

Available Formats

WATER SYSTEMS

Dr. Ahmed Farouk Elsafty

Associate Prof. – Mechanical & Marine Engineering Dept.

College of Engineering & Technology

Arab Academy for Science, Technology and Maritime

Transport – AASTMT

www.drelsafty.com

E-mail: elsafty@hotmail.com

Introduction

• Purpose of air

conditioning

▪ Luxury:

Residential

Commercial

▪ Necessary

Pharmaceuticals

industry

Laboratories

IT Industry

Dr. Ahmed F. Elsafty

Air Conditioning

Central Unitary

Dr. Ahmed F. Elsafty

AC systems

• All Air Systems

• All water systems

• Air-Water Systems

• Special Systems

Dr. Ahmed F. Elsafty

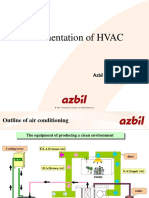

Air Conditioning Central System:

Hot water return Exhaust air Return air

Flue gases Steam

Prefilter

H.Ex.

Hot water supply Air damper Main filter Return air fan

Fuel&air Cooling coil

Steam generator Condensate Heating coil

Outside air Supply air

Hot water pump

Boiler pump

Alternative hot water system Air Handling Unit (AHU) Air humidifier

Supply air fan

Air cooled condenser Flue gases

Hot water return

Cold water return

Fuel&air

Cold water supply Hot water supply To other AHU

Hot water boiler

Cold water pump

Cold water pump

Chilling unit Alternative Chilling unit

Chilling unit

Condensing water to cooling tower

Cold water return

Condensing water from tower

Cooling tower Cold water supply To other AHU

Condensing water pump Chilled water pump

Dr. Ahmed F. Elsafty

There are four basic system categories:

1 Central chilled water air conditioning systems - All Air Systems

1.1 Single zone 1.4 Dual Duct

1.2 Reheat 1.5 Multizone

1.3 Variable Air Volume

2 Central chilled water air conditioning systems - Air-and Water Systems

2.1 Induction 2.3 Two-pipe

2.2 Fan Coil 2.4 Three-pipe

3 Central chilled water air conditioning systems - All Water Systems,

including cooling towers which can also be applied to systems 1, 2 above

3.1 Fan-coil units

3.2 Central chilled water air conditioning system with fan coils and

other devices

3.3 Water cooling tower

4 Direct expansion Systems [i.e. direct expansion of refrigerant, without the

chilled water cooling medium ]

4.1 Window air conditioners

4.3 Split type and package air conditioning systems

4.2 Unitary and Rooftop Air Conditioners

4.4 Heat pumps

Dr. Ahmed F. Elsafty

1. ALL AIR SYSTEM

• An all-air system provides complete sensible

and latent cooling capacity in the cold air

supplied by the system.

• Heating can be accomplished by the same air

stream, either in the central system or at a

particular zone.

• All-air systems can be classified into 2

categories:

– Single duct systems

– Dual duct systems

Dr. Ahmed F. Elsafty

All Air Systems

Dr. Ahmed F. Elsafty

Multiple zone system schematic

(courtesy of E-source, Boulder, CO).

Dr. Ahmed F. Elsafty

Components of an All-Air System

Outdoor air Equipment may be packaged or separated

Heat source

Fan Supply air

Humidifier

duct

Air filter

cooling

source

To other

rooms

Exhaust

air Air diffuser Room

Relurn air duct

Return air fan (optional) From other

rooms

Dr. Ahmed F. Elsafty

Distribution systems important components:

1. The Air Handling Unit is a cabinet that includes or houses

the central furnace, air conditioner, or heat pump and the

plenum and blower assembly that forces air through the

ductwork.

2. The Supply Ductwork carries air from the air handler to the

rooms in a house. Typically each room has at least one

supply duct and larger rooms may have several.

3. The Return Ductwork carries air from the conditioned

space back to the air handler. Most houses have only one or

two main return ducts located in a central area.

4. Supply and Return Plenums are boxes made of duct

board, metal, drywall or wood that distribute air to individual

ducts or registers.

Dr. Ahmed F. Elsafty

Distribution systems important components:

5.The Ductwork is a branching network of round or

rectangular tubes generally constructed of sheet metal,

fiberglass board, or a flexible plastic and wire composite

material located within the walls, floors, and ceilings. The

three most common types of duct material used in home

construction are metal, fiberglass duct board, and flex-duct.

6. Flex-duct is installed between the register and plenum box,

or plenum box and air handler, usually in a single,

continuous piece. While flex-duct has fewer seams, the

inner lining and outer insulated covering can tear or be

pinched closed. Also longer flex-duct runs can restrict the

flow of air; proper design and installation is very important.

7. Both metal and fiberglass duct board are rigid and

installed in pieces. Fiberglass duct board, like flex-duct, is

made of an insulation material. Ducts are built of sections of

the duct board. The seams in the duct board should be

carefully sealed with mastic or high quality duct tape.

Dr. Ahmed F. Elsafty

Distribution systems important components:

8. Rectangular metal duct, especially the kind used for plenums and

larger trunk runs, is often insulated on the inside with fiberglass duct

liner. If it is not insulated on the inside, metal ducts should be insulated

on the outside using a fiberglass matt with an attached metal foil vapor

retarder. The insulation should be at least two inches thick, and the

vapor barrier installed on the outside of the insulation facing away

from the duct.

The seams in the insulation are usually stapled together around the

duct and then taped. All of the seams should be sealed before

insulation is installed. All return and supply ducts located outside the

conditioned space, in attics, crawlspaces, or basements, for example,

should be sealed and insulated.

9. Ductwork Joints join pieces of ductwork.

10. Elbows are manufactured pieces of duct used for turns.

11. Boots connect ductwork to registers.

12. Registers and Grilles are the coverings for duct openings into the

conditioned

Dr. Ahmed F. Elsafty

1. ALL AIR SYSTEM

Advantages of All Air Systems

• The central plant is located in central room,

hence facilitating operating and maintenance,

noise control and choice of suitable equipment.

• No piping, electrical wiring and filters are

located inside the conditioned space.

Dr. Ahmed F. Elsafty

1. ALL AIR SYSTEM

Advantages of All Air Systems

• Gives a wide choice of zone-ability, flexibility, and

humidity control under all operating conditions.

• Allows good design flexibility for optimum air

distribution, draft control, and local requirements.

• Adapts to winter humidification

Dr. Ahmed F. Elsafty

Disadvantages of All Air Systems

• Requires additional duct clearance which can

reduce the usable floor space.

• It requires a close cooperation between

architectural mechanical and structural engineers.

• Air balancing in large systems, can be difficult.

Dr. Ahmed F. Elsafty

All Air System Classified to

All Air

System

Single- Reheat Variable Dual Multi-

Zone Air system Duct zone

Dr. Ahmed F. Elsafty

1-Single Zone System

Dr. Ahmed F. Elsafty

2. Reheat System

Dr. Ahmed F. Elsafty

3. Variable Air Volume System

Dr. Ahmed F. Elsafty

Basic Components of Reheat VAV System

Dr. Ahmed F. Elsafty

4. Dual Duct System

4.1 Single Fan Dual Duct System.

4.2 Two Fan Dual Duct System.

Dr. Ahmed F. Elsafty

4.1 Single Fan Dual Duct System

Dr. Ahmed F. Elsafty

4.2 Two Fan Dual Duct System

Dr. Ahmed F. Elsafty

5.Multi-Zone System

Dr. Ahmed F. Elsafty

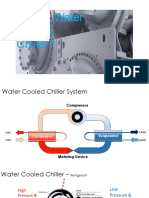

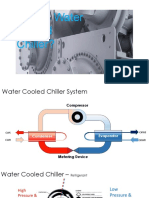

2. All Water System

• Fundamentally, the function of the chilled-

water system is to transport the cooling

fluid from the chillers to the load terminals

and back to the chillers.

• Systems that use water as the heat

transfer medium are called Hydronic

Systems. [Hydronic]

Dr. Ahmed F. Elsafty

2. All Water System

Direction of Water Flow in All Water Systems

Dr. Ahmed F. Elsafty

Water distribution

•Series Loop

•One pipe system

•Two pipes, with or without seasonal changeover

•Three pipes

•Four pipes

Dr. Ahmed F. Elsafty

Methods of Distributing Cooling

and Heating Media:

• Water Piping Arrangements:

– One-pipe arrangement.

– Two-pipe arrangement

– Three-pipe arrangement

– Four-pipe arrangement.

Dr. Ahmed F. Elsafty

1.Series loop

Dr. Ahmed F. Elsafty

2.One pipe system

Dr. Ahmed F. Elsafty

3.Two pipe systems

Dr. Ahmed F. Elsafty

4.Three pipe systems

Dr. Ahmed F. Elsafty

5.Four pipe systems

Dr. Ahmed F. Elsafty

System Advantages

•First cost is often less than for other central systems.

•Less building space is required.

•More suitable for retrofit applications.

•Off-hour conditioning does not require a central air

system operation.

Dr. Ahmed F. Elsafty

System Advantages

•Water is a more energy and space efficient method of

cooling and heating energy distribution.

•Re-circulation of air is unnecessary so mixing of odors

and contaminants, or concerns over fire and smoke

spreading from one zone to another, are minimized.

Dr. Ahmed F. Elsafty

System Disadvantages

•Some maintenance must be performed in occupied areas.

•Ventilation is usually from a wall aperture and is not

easily controlled

•A separate ventilation system is required for quality

installations.

•Relative humidity may be high in summer, particularly if

chilled water flow is modulated for temperature control

Dr. Ahmed F. Elsafty

You might also like

- Pro-Pac Technical Guide v1.3Document24 pagesPro-Pac Technical Guide v1.3Nguyễn Thống NhấtNo ratings yet

- ATA 29 Hidraulic PowerDocument1,487 pagesATA 29 Hidraulic PowerDaniel Santiago Montaño Suarez100% (1)

- Jelecome HAVC Systems-IntroductionDocument70 pagesJelecome HAVC Systems-IntroductionEladl.G AlexNo ratings yet

- 1-Water systems-introduction-RMH (Compatibility Mode)Document51 pages1-Water systems-introduction-RMH (Compatibility Mode)Ali AlmhmudiNo ratings yet

- اليوم الثالثDocument31 pagesاليوم الثالثعاشق الصمتNo ratings yet

- Building Services HVAC08Document11 pagesBuilding Services HVAC08Jayanth S VNo ratings yet

- Comps of Steam Power PLDocument2 pagesComps of Steam Power PLrohit choudharyNo ratings yet

- Prepared by / Eng. Mohamed El-Atfy: S G CompanyDocument4 pagesPrepared by / Eng. Mohamed El-Atfy: S G CompanyRolandNo ratings yet

- 3.air Handling UnitDocument19 pages3.air Handling UnitGauravNo ratings yet

- Notes U8-HVACDocument6 pagesNotes U8-HVACJake BrohawnNo ratings yet

- 24-26 - HVACFundamentals - Primeau - Heat Pump PricipleDocument3 pages24-26 - HVACFundamentals - Primeau - Heat Pump PricipleAJU JOYNo ratings yet

- Automobile Cooling System PDFDocument21 pagesAutomobile Cooling System PDFGomathi SankarNo ratings yet

- Hand Out: Mesin Konversi EnergiDocument28 pagesHand Out: Mesin Konversi EnergiAji AgusNo ratings yet

- Hand Out MKE Bab 1 3Document28 pagesHand Out MKE Bab 1 3Aji AgusNo ratings yet

- 45 5655 EE542 2014 1 1 1 Steam StationsDocument17 pages45 5655 EE542 2014 1 1 1 Steam StationshosamnasifNo ratings yet

- Dokumen - Tips Kota Super Thermal Power Plant KstpsDocument23 pagesDokumen - Tips Kota Super Thermal Power Plant KstpsKishan SinghNo ratings yet

- Chiller TrainingDocument16 pagesChiller TrainingMuhammad Khairol OmarNo ratings yet

- ChillerDocument16 pagesChillerMuhammad Khairol OmarNo ratings yet

- Chiller TrainingDocument16 pagesChiller TrainingMuhammad Khairol OmarNo ratings yet

- Instrumentation of HVACDocument20 pagesInstrumentation of HVACthaiNo ratings yet

- Chiller 2023Document25 pagesChiller 2023Andri Polban100% (1)

- Fundamentals of Heating, Ventilation & Air-ConditioningDocument12 pagesFundamentals of Heating, Ventilation & Air-ConditioningHemant Singh RajpootNo ratings yet

- Lecture 21 Intro To Primary SystemsDocument48 pagesLecture 21 Intro To Primary SystemsRhizhailNo ratings yet

- Cooling Water Treatment Liberty 01Document174 pagesCooling Water Treatment Liberty 01Masood Ahmed67% (3)

- Chilled Water System Fundemental Optimization Concepts 1699840047Document30 pagesChilled Water System Fundemental Optimization Concepts 1699840047NL ChanNo ratings yet

- Andrea Ramirez - Lab 3Document3 pagesAndrea Ramirez - Lab 3andreaxb2448No ratings yet

- Day 1 - 0 AC GeneralDocument19 pagesDay 1 - 0 AC GeneraltehtehtehNo ratings yet

- CH 02 - Intro To HVAC Systems - Oct 2020Document39 pagesCH 02 - Intro To HVAC Systems - Oct 2020Nur Atiqah NabilaNo ratings yet

- CH 02 - Overview of AC SystemsDocument45 pagesCH 02 - Overview of AC SystemsNoridhamNo ratings yet

- Geothermal Power Plant EquipmentDocument38 pagesGeothermal Power Plant EquipmentMuqtiNo ratings yet

- MENG615L-Experiment 1-1-JFDocument16 pagesMENG615L-Experiment 1-1-JFMohammad AL-MasriNo ratings yet

- Boiler General Over View: PT. ALSTOM Power Energy Systems IndonesiaDocument42 pagesBoiler General Over View: PT. ALSTOM Power Energy Systems IndonesiaRebby2412100% (2)

- Blowdown Valve Adjusting Screw Spring Spindle Disc NozzleDocument4 pagesBlowdown Valve Adjusting Screw Spring Spindle Disc NozzleAsong, Daniel LorenzNo ratings yet

- BoP GTCDocument81 pagesBoP GTCKshirod007No ratings yet

- Air Conditioning and Mechanical Ventilation System (ACMV)Document10 pagesAir Conditioning and Mechanical Ventilation System (ACMV)AsmawiayobNo ratings yet

- Machi9ne 2Document3 pagesMachi9ne 2Cantera, Cris Bryan E.No ratings yet

- Air Conditioning RepairedDocument30 pagesAir Conditioning RepairedendyNo ratings yet

- PDFDocument29 pagesPDFmustafa100% (1)

- How Heat Pumps WorkDocument4 pagesHow Heat Pumps Worksh5bootNo ratings yet

- Alvarez Plate 2 IceDocument8 pagesAlvarez Plate 2 IceYhuloopz AlvarezNo ratings yet

- Ammonia Plant Equipment ListDocument3 pagesAmmonia Plant Equipment ListMusa Kaleem100% (1)

- BU589 Heat Pump Water HeatingDocument8 pagesBU589 Heat Pump Water HeatingSuttisak SuriyachanhomNo ratings yet

- 2 Air-ConditioningDocument147 pages2 Air-ConditioningChengxi FUNo ratings yet

- Steam Power PlantsDocument73 pagesSteam Power PlantsILEENVIRUS100% (1)

- Machine 4Document2 pagesMachine 4Cantera, Cris Bryan E.No ratings yet

- SE 01 IntroDocument36 pagesSE 01 IntroRisky YulianNo ratings yet

- ReportDocument2 pagesReportHaposanNo ratings yet

- E11 PDFDocument16 pagesE11 PDFDANIELANo ratings yet

- Steam Power PlantsDocument73 pagesSteam Power PlantsManvendra Pratap Singh Bisht95% (20)

- Attachment - En-1398248294 GEA Vacuum CoolingDocument16 pagesAttachment - En-1398248294 GEA Vacuum CoolingDima ArfNo ratings yet

- RefrigerationDocument50 pagesRefrigerationGurunath EpiliNo ratings yet

- Principles of Steam GenerationDocument30 pagesPrinciples of Steam GenerationAnil KumarNo ratings yet

- Lecture 21: Introduction To Primary Systems (Central Plants)Document48 pagesLecture 21: Introduction To Primary Systems (Central Plants)Velupucharla Saiprasad ReddyNo ratings yet

- Boiler & Steam System EfficiencyDocument30 pagesBoiler & Steam System EfficiencyMuhammad SalmanNo ratings yet

- The Basics of Heating, Ventilation and Air ConditioningDocument33 pagesThe Basics of Heating, Ventilation and Air ConditioningDaryan HoshangNo ratings yet

- Basic Plant CycleDocument87 pagesBasic Plant CycleRobin RobinNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- RS5000 Training ManualDocument159 pagesRS5000 Training ManualLPR thecnologyNo ratings yet

- M-061 Control Air DryerDocument11 pagesM-061 Control Air DryerВасиль ГудзьNo ratings yet

- BOQDocument9 pagesBOQGarimaSinghNo ratings yet

- Amendment No. 1 January 2020 TO Is 11329: 2018 Finned Type Heat Exchanger For Room Air ConditionerDocument7 pagesAmendment No. 1 January 2020 TO Is 11329: 2018 Finned Type Heat Exchanger For Room Air ConditionerAMIT VERMA100% (1)

- Repair Parts List by ModelDocument12 pagesRepair Parts List by Modelrikachu2015No ratings yet

- All BomDocument46 pagesAll Bomrajsingh199819No ratings yet

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocument4 pages2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNo ratings yet

- Proposed Camps and Wellsites Maintenance and Fumigation Schedule For Tullow 2020-2Document25 pagesProposed Camps and Wellsites Maintenance and Fumigation Schedule For Tullow 2020-2Oscar IsingomaNo ratings yet

- General Notes Symbol List Abbreviations: Reference Sheet - SprinklerDocument64 pagesGeneral Notes Symbol List Abbreviations: Reference Sheet - SprinklerAnonymous qOBFvINo ratings yet

- Technical Manual: Air-Water Chillers and Heat Pumps For Outdoor InstallationDocument56 pagesTechnical Manual: Air-Water Chillers and Heat Pumps For Outdoor InstallationDumitru MariusNo ratings yet

- Water Hammer and Design of Surge Protection SystemsDocument73 pagesWater Hammer and Design of Surge Protection SystemsAhceneNo ratings yet

- Normally Closed Solenoid Valves PDFDocument55 pagesNormally Closed Solenoid Valves PDFrahulNo ratings yet

- Investigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusDocument14 pagesInvestigation On The Heating Performance of The Heat Pump Withwaste Heat Recovery For The Electric BusEmre EmlekNo ratings yet

- Air Conditioner Control (Heating and Air Conditioning) - ALLDATA RepairDocument2 pagesAir Conditioner Control (Heating and Air Conditioning) - ALLDATA Repairmemo velascoNo ratings yet

- Refrigeration ExperimentDocument60 pagesRefrigeration ExperimentQQR8 /trollNo ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- Water Jacket Curves - C7.1 Marine Propulsion EngineDocument3 pagesWater Jacket Curves - C7.1 Marine Propulsion EnginejudarangocaNo ratings yet

- Catalogo Unidades DAIKINDocument42 pagesCatalogo Unidades DAIKINBraulio Ramón PeñaNo ratings yet

- Manual Pump Down On An Air ConditioningDocument7 pagesManual Pump Down On An Air ConditioningRay Ravel100% (1)

- Snomaster Catalogue 2015Document60 pagesSnomaster Catalogue 2015daanNo ratings yet

- Indirect Heated Vaporizer: Hot Water / SteamDocument4 pagesIndirect Heated Vaporizer: Hot Water / SteamAquim Francisco BonillaNo ratings yet

- NPS D N M M OD Inches (Millimete RS) Wall Thickness Inches (Millimeters) SCH 5 SCH 10 SCH 30 SCH 40 SCH 80 SCH 120 XXS 6Document4 pagesNPS D N M M OD Inches (Millimete RS) Wall Thickness Inches (Millimeters) SCH 5 SCH 10 SCH 30 SCH 40 SCH 80 SCH 120 XXS 6markom123No ratings yet

- Mycom Data SheetDocument1 pageMycom Data SheetAshraf N HaniaNo ratings yet

- ESD ValveDocument4 pagesESD ValveKyrie Abaya100% (1)

- Air Conditioning Systems in BuildingsDocument38 pagesAir Conditioning Systems in BuildingsFarhan Danish100% (1)

- Filters Part No. CPCB1 and CPCB2Document34 pagesFilters Part No. CPCB1 and CPCB2Gorav rajput393100% (1)

- 1612 13-4-105 - Rev. 0 - BMS Description Boiler 1Document9 pages1612 13-4-105 - Rev. 0 - BMS Description Boiler 1pepenapao1217No ratings yet

- Combi Oven Cleveland PartsDocument15 pagesCombi Oven Cleveland PartsGregorio EstevezNo ratings yet

- Pressure Relief Valves Standard Range: Safety DevicesDocument2 pagesPressure Relief Valves Standard Range: Safety DevicesPaweł HejmowskiNo ratings yet