Professional Documents

Culture Documents

RD 360 1post File 2019 12 10 161048

RD 360 1post File 2019 12 10 161048

Uploaded by

Adityo Bambang WCopyright:

Available Formats

You might also like

- GMW16066 JN09Document5 pagesGMW16066 JN09Felipe De la cruzNo ratings yet

- Product TechnologyDocument138 pagesProduct TechnologyRaja SekarNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- CIN2Document1 pageCIN2aditya wicaksonoNo ratings yet

- Cin 1 Post File 2019 12 17 100704Document1 pageCin 1 Post File 2019 12 17 100704Adrian SetyadharmaNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- Spek Electoda Nikko CIN-1Document1 pageSpek Electoda Nikko CIN-1anon_962923083No ratings yet

- Data Sheet AL-BRONZEDocument1 pageData Sheet AL-BRONZEAris WicaksonoNo ratings yet

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- NDS-2209R: Section 13Document1 pageNDS-2209R: Section 13hilwan sultonNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12No ratings yet

- Welding Electrodes CatalogueDocument7 pagesWelding Electrodes CatalogueFiroj Al HasanNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- Special Metal Korea Co., LTD.: DescriptionDocument1 pageSpecial Metal Korea Co., LTD.: DescriptionWelli E SNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationRudi SyamNo ratings yet

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Bohler S EMK 6Document1 pageBohler S EMK 6Enaam AtaallahNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- 7075 Aluminium BarDocument1 page7075 Aluminium Barleonardo caicedo mesaNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- SM 385Document1 pageSM 385Arizal Nur ArdhiNo ratings yet

- Special Metal Korea Co., LTDDocument1 pageSpecial Metal Korea Co., LTDWelli E SNo ratings yet

- FCAW Bohler Ti 71 T8 E71T 8 GaslessDocument1 pageFCAW Bohler Ti 71 T8 E71T 8 GaslessKARLNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- 04042016000000A Avesta 2205 Covered ElectrodesDocument1 page04042016000000A Avesta 2205 Covered Electrodesmeckup123No ratings yet

- RO3000 Series BondplyData Sheet Processing GuidelinesDocument4 pagesRO3000 Series BondplyData Sheet Processing GuidelinesEricson NavasNo ratings yet

- DS125NSSUGARR2Document1 pageDS125NSSUGARR2Frandika PrimayogaNo ratings yet

- NSN 308post File 2019 12 11 145456.en - IdDocument1 pageNSN 308post File 2019 12 11 145456.en - Idabu yazidNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- DK 18Document1 pageDK 18nsprasad88No ratings yet

- Product Data Sheet: S 'Submerged Arc Welding'Document1 pageProduct Data Sheet: S 'Submerged Arc Welding'adanmeneses1No ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDocument1 page1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroNo ratings yet

- Cu ZN 05Document2 pagesCu ZN 05wjjt6chgtmNo ratings yet

- Cobalt Based High Temperature AlloysDocument1 pageCobalt Based High Temperature AlloysSalem GarrabNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- Objectives of Heat TreatmentsDocument3 pagesObjectives of Heat TreatmentsNilesh Rana100% (2)

- ESM GR MG GranulesDocument3 pagesESM GR MG GranulesjucyapleNo ratings yet

- Degradation Machanism of Heat Resistant Steel at Elevated TemperaturesDocument180 pagesDegradation Machanism of Heat Resistant Steel at Elevated TemperaturesdantegimenezNo ratings yet

- Chapter 10. Surface Treatments and Coatings.Document3 pagesChapter 10. Surface Treatments and Coatings.BinhNo ratings yet

- Refraction Index of Various Substances For 3D ModelersDocument3 pagesRefraction Index of Various Substances For 3D ModelersescupopaNo ratings yet

- Preventing Stress Corrosion Cracking in The Carbon Dioxide Absorber of Ammonia PlantsDocument8 pagesPreventing Stress Corrosion Cracking in The Carbon Dioxide Absorber of Ammonia PlantsSADIQ KHATTAKNo ratings yet

- Metal Forming Processes - FullDocument5 pagesMetal Forming Processes - FullArjun NbNo ratings yet

- Macroetch Testing Steel Bars, Billets, Blooms, and Forgings: Standard Method ofDocument5 pagesMacroetch Testing Steel Bars, Billets, Blooms, and Forgings: Standard Method of陳勉中No ratings yet

- Besi UNP PDFDocument2 pagesBesi UNP PDFMuhammad IdrusNo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- 2 Corrosion Its ControlDocument36 pages2 Corrosion Its ControlPratik ShekharNo ratings yet

- PPT MFG Chapter05 FinalDocument36 pagesPPT MFG Chapter05 Final劉德信No ratings yet

- Impact AR500 PlateDocument2 pagesImpact AR500 PlateMario Diez100% (1)

- 2019 - Corani - Ni43-101 - r1 - Final - Compressed (2) - 56-104Document49 pages2019 - Corani - Ni43-101 - r1 - Final - Compressed (2) - 56-104Jheison YunguriNo ratings yet

- Blockflow Diagram Smelter Nikel LateritDocument2 pagesBlockflow Diagram Smelter Nikel LateritNur PertiwiNo ratings yet

- Material Science (MS) and Heat Treatment (HT) Mechanical Engineering Interview Questions Answers - The FREE STUDYDocument14 pagesMaterial Science (MS) and Heat Treatment (HT) Mechanical Engineering Interview Questions Answers - The FREE STUDYAvanishPrajapatiNo ratings yet

- Dokumen - Tips Amtd Dc2010 Revl Nadca North American Die Casting Die Insert MaterialDocument35 pagesDokumen - Tips Amtd Dc2010 Revl Nadca North American Die Casting Die Insert MaterialAke BergmanNo ratings yet

- Group Assignment (Corrosive Environment)Document6 pagesGroup Assignment (Corrosive Environment)Ahmad DanialNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument19 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or Bothlei huNo ratings yet

- Defect in CastingDocument13 pagesDefect in CastingAmniAzmiNo ratings yet

- Magnesia, Magnesia-Chrome, Magnesia-Spinel, Dolomite, Forsterite: Magnesia RefractoryDocument10 pagesMagnesia, Magnesia-Chrome, Magnesia-Spinel, Dolomite, Forsterite: Magnesia RefractoryRishu DeyNo ratings yet

- SAF-FRO - Welding Consumables CatalogueDocument194 pagesSAF-FRO - Welding Consumables CatalogueLLNo ratings yet

- 02 Raw MaterialDocument14 pages02 Raw MaterialGustavo Alberto De Almeida PezaoNo ratings yet

- Steam TurbineDocument8 pagesSteam TurbinepearlcityrjtNo ratings yet

- Mechanisms of Wear in HSS Cutting ToolsDocument31 pagesMechanisms of Wear in HSS Cutting Toolsjyoti ranjan nayak100% (2)

- ALS Aqua Regia To 4 Acid Technical NoteDocument2 pagesALS Aqua Regia To 4 Acid Technical NotecalebNo ratings yet

RD 360 1post File 2019 12 10 161048

RD 360 1post File 2019 12 10 161048

Uploaded by

Adityo Bambang WOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RD 360 1post File 2019 12 10 161048

RD 360 1post File 2019 12 10 161048

Uploaded by

Adityo Bambang WCopyright:

Available Formats

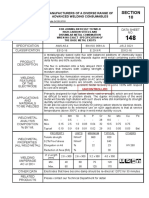

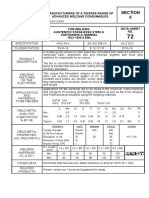

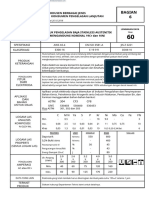

MANUFACTURERS OF A DIVERSE RANGE OF SECTION

ADVANCED WELDING CONSUMABLES 4

WI-0304 DS22 RD-360-1 Rev. 5, Date 02.09.2019

DATA SHEET

BASIC LOW HYDROGEN ELECTRODE NO.

RD-360-1 FOR WELDING STRUCTURAL STEELS

WITH HIGHER SUB-ZERO TOUGHNESS PROPERTIES

22

SPECIFICATION AWS A5.1 EN ISO 2560-A JIS Z 3212

CLASSIFICATION E7016-1 E 46 4 B D5016

The design emphasis of the chemically basic flux is engineered to ensure the

optimum weld metal properties demanded by the specification are fully met.

PRODUCT The basic flux containing the appropriate alloying elements but minimal iron

DESCRIPTION powder, is extruded onto a high purity ferritic core wire and bound with a blend of

silicates that ensure both coating strength and a coating resistant to subsequent

moisture absorption.

The chemical nature of the flux together with its controlled coating factor allows

WELDING the electrode to be used at relatively low amps. This factor together with the fairly

fluid but quick freezing slag facilitate vertical up welding including controlled

FEATURES

penetration root runs. UNCONTROLLED

OF THE

ELECTRODE Overall the arc is very stable, slag detachability is good, fillet welds are slightly

convex and metal recovery is some 98% with respect to weight of the core wire.

Suitable for all grades of C-Mn structural steels. However, it is used to best

APPLICATIONS advantage on fully deoxidised C-Mn steels when high toughness values are

AND specified down to -45 °C.

MATERIALS These toughness properties are maintained even after extended PWHT making it

TO BE WELDED ideal for pressure vessel work. The low weld Si and high Mn to Si ratio ensure

maximum resistance to solidification cracking on thick restrained sections.

WELD METAL C Mn Si S P Cr Ni Mo V Fe

ANALYSIS Min. - - - - - - - - -

COMPOSITION Max. 0.15 1.6 0.75 0.035 0.035 0.20 0.30 0.30 0.08

% BY Wt. Typical 0.06 1.4 0.4 0.01 0.02 0.05 0.05 0.05 0.01 Bal.

PROPERTY UNITS MINIMUM TYPICAL OTHERS

Tensile strength N/mm 2

490 660

WELD METAL 0.2% Proof stress N/mm 2

400 600

PROPERTIES Elongation on 4d % 22 26

(ALL WELD METAL)

Reduction of Area (RA) % - 70

Impact energy -45oC J 27 80

Ø x Length

WELDING 2.6 x 350 3.2 x 350 4.0 x 400 5.0 x 400

(mm)

AMPERAGE Min. 50 75 130 180

AC or DC+

Max. 85 125 170 220

OTHER DATA Electrodes that have become damp should be re-dried at 150oC for 1 hour

RELATED

Please contact our Technical Department for detail

PRODUCTS

APPROVED BY LR – Grade 4Y H5

You might also like

- GMW16066 JN09Document5 pagesGMW16066 JN09Felipe De la cruzNo ratings yet

- Product TechnologyDocument138 pagesProduct TechnologyRaja SekarNo ratings yet

- RD 360R3Document1 pageRD 360R3Rachmad Budi WNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- NSN 309post File 2019 12 11 151332Document1 pageNSN 309post File 2019 12 11 151332Gristio PratamaNo ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptionFery FebryantoNo ratings yet

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarNo ratings yet

- Section 6: Specification ClassificationDocument1 pageSection 6: Specification ClassificationDimas Wisnu WardanaNo ratings yet

- CIN2Document1 pageCIN2aditya wicaksonoNo ratings yet

- Cin 1 Post File 2019 12 17 100704Document1 pageCin 1 Post File 2019 12 17 100704Adrian SetyadharmaNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- Spek Electoda Nikko CIN-1Document1 pageSpek Electoda Nikko CIN-1anon_962923083No ratings yet

- Data Sheet AL-BRONZEDocument1 pageData Sheet AL-BRONZEAris WicaksonoNo ratings yet

- Ds134ns Eco 6r0Document1 pageDs134ns Eco 6r0yadi_baeNo ratings yet

- NDS-2209R: Section 13Document1 pageNDS-2209R: Section 13hilwan sultonNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12No ratings yet

- Welding Electrodes CatalogueDocument7 pagesWelding Electrodes CatalogueFiroj Al HasanNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- Pr01, Pr02, Pr03: Vishay BccomponentsDocument19 pagesPr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- Special Metal Korea Co., LTD.: DescriptionDocument1 pageSpecial Metal Korea Co., LTD.: DescriptionWelli E SNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationRudi SyamNo ratings yet

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Bohler S EMK 6Document1 pageBohler S EMK 6Enaam AtaallahNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- 7075 Aluminium BarDocument1 page7075 Aluminium Barleonardo caicedo mesaNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- SM 385Document1 pageSM 385Arizal Nur ArdhiNo ratings yet

- Special Metal Korea Co., LTDDocument1 pageSpecial Metal Korea Co., LTDWelli E SNo ratings yet

- FCAW Bohler Ti 71 T8 E71T 8 GaslessDocument1 pageFCAW Bohler Ti 71 T8 E71T 8 GaslessKARLNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- 04042016000000A Avesta 2205 Covered ElectrodesDocument1 page04042016000000A Avesta 2205 Covered Electrodesmeckup123No ratings yet

- RO3000 Series BondplyData Sheet Processing GuidelinesDocument4 pagesRO3000 Series BondplyData Sheet Processing GuidelinesEricson NavasNo ratings yet

- DS125NSSUGARR2Document1 pageDS125NSSUGARR2Frandika PrimayogaNo ratings yet

- NSN 308post File 2019 12 11 145456.en - IdDocument1 pageNSN 308post File 2019 12 11 145456.en - Idabu yazidNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- DK 18Document1 pageDK 18nsprasad88No ratings yet

- Product Data Sheet: S 'Submerged Arc Welding'Document1 pageProduct Data Sheet: S 'Submerged Arc Welding'adanmeneses1No ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDocument1 page1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroNo ratings yet

- Cu ZN 05Document2 pagesCu ZN 05wjjt6chgtmNo ratings yet

- Cobalt Based High Temperature AlloysDocument1 pageCobalt Based High Temperature AlloysSalem GarrabNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- Objectives of Heat TreatmentsDocument3 pagesObjectives of Heat TreatmentsNilesh Rana100% (2)

- ESM GR MG GranulesDocument3 pagesESM GR MG GranulesjucyapleNo ratings yet

- Degradation Machanism of Heat Resistant Steel at Elevated TemperaturesDocument180 pagesDegradation Machanism of Heat Resistant Steel at Elevated TemperaturesdantegimenezNo ratings yet

- Chapter 10. Surface Treatments and Coatings.Document3 pagesChapter 10. Surface Treatments and Coatings.BinhNo ratings yet

- Refraction Index of Various Substances For 3D ModelersDocument3 pagesRefraction Index of Various Substances For 3D ModelersescupopaNo ratings yet

- Preventing Stress Corrosion Cracking in The Carbon Dioxide Absorber of Ammonia PlantsDocument8 pagesPreventing Stress Corrosion Cracking in The Carbon Dioxide Absorber of Ammonia PlantsSADIQ KHATTAKNo ratings yet

- Metal Forming Processes - FullDocument5 pagesMetal Forming Processes - FullArjun NbNo ratings yet

- Macroetch Testing Steel Bars, Billets, Blooms, and Forgings: Standard Method ofDocument5 pagesMacroetch Testing Steel Bars, Billets, Blooms, and Forgings: Standard Method of陳勉中No ratings yet

- Besi UNP PDFDocument2 pagesBesi UNP PDFMuhammad IdrusNo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- 2 Corrosion Its ControlDocument36 pages2 Corrosion Its ControlPratik ShekharNo ratings yet

- PPT MFG Chapter05 FinalDocument36 pagesPPT MFG Chapter05 Final劉德信No ratings yet

- Impact AR500 PlateDocument2 pagesImpact AR500 PlateMario Diez100% (1)

- 2019 - Corani - Ni43-101 - r1 - Final - Compressed (2) - 56-104Document49 pages2019 - Corani - Ni43-101 - r1 - Final - Compressed (2) - 56-104Jheison YunguriNo ratings yet

- Blockflow Diagram Smelter Nikel LateritDocument2 pagesBlockflow Diagram Smelter Nikel LateritNur PertiwiNo ratings yet

- Material Science (MS) and Heat Treatment (HT) Mechanical Engineering Interview Questions Answers - The FREE STUDYDocument14 pagesMaterial Science (MS) and Heat Treatment (HT) Mechanical Engineering Interview Questions Answers - The FREE STUDYAvanishPrajapatiNo ratings yet

- Dokumen - Tips Amtd Dc2010 Revl Nadca North American Die Casting Die Insert MaterialDocument35 pagesDokumen - Tips Amtd Dc2010 Revl Nadca North American Die Casting Die Insert MaterialAke BergmanNo ratings yet

- Group Assignment (Corrosive Environment)Document6 pagesGroup Assignment (Corrosive Environment)Ahmad DanialNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument19 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or Bothlei huNo ratings yet

- Defect in CastingDocument13 pagesDefect in CastingAmniAzmiNo ratings yet

- Magnesia, Magnesia-Chrome, Magnesia-Spinel, Dolomite, Forsterite: Magnesia RefractoryDocument10 pagesMagnesia, Magnesia-Chrome, Magnesia-Spinel, Dolomite, Forsterite: Magnesia RefractoryRishu DeyNo ratings yet

- SAF-FRO - Welding Consumables CatalogueDocument194 pagesSAF-FRO - Welding Consumables CatalogueLLNo ratings yet

- 02 Raw MaterialDocument14 pages02 Raw MaterialGustavo Alberto De Almeida PezaoNo ratings yet

- Steam TurbineDocument8 pagesSteam TurbinepearlcityrjtNo ratings yet

- Mechanisms of Wear in HSS Cutting ToolsDocument31 pagesMechanisms of Wear in HSS Cutting Toolsjyoti ranjan nayak100% (2)

- ALS Aqua Regia To 4 Acid Technical NoteDocument2 pagesALS Aqua Regia To 4 Acid Technical NotecalebNo ratings yet