Professional Documents

Culture Documents

16 090 001e V1.0 Tube Installation PVC

16 090 001e V1.0 Tube Installation PVC

Uploaded by

JP BecerraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16 090 001e V1.0 Tube Installation PVC

16 090 001e V1.0 Tube Installation PVC

Uploaded by

JP BecerraCopyright:

Available Formats

Technical Information – Tube Installation PVC

Datasheet

General

During transportation and storage of the straight tube and bends make sure that the ambient

temperature does not exceed + 55°C. PVC becomes soft above + 60°C.

During transportation and storage of the straight tube and bends make sure that it is not pressed or

bended to avoid damage or deformation.

Fixing

For straight tube the rule is: every 2 meters one fixing clamp

For bends the rule is: at every end one fixing clamp

For every offset (chicane): at each end one fixing clamp

Gluing

How to prepare the sleeves Deburr the sleeves both ends on the inside edge thoroughly.

Clean the sleeves inside with cleaner and paper-towels.

Use a new paper-towel for each sleeve!

How to prepare the straight tube and bends Cut the required length exactly in a 90° angle.

Deburr the cut on the inside edge thoroughly.

Clean the tube end surface outside with cleaner and paper-towels on a length of a

half sleeve.

Use a new paper-towel for each joint!

How to apply glue Make sure that the glue-can is closed when not in use to avoid early dry-out.

Use a 1 1/2" flat brush to apply the glue.

Apply the glue quickly, but thoroughly round the tube end over a length of a half

sleeve.

Leave the tube end clean directly at the edge.

Make sure, that there is no glue inside the tube. Shift a cleaned sleeve half way

over the tube end.

Any glue which is pushed out on the tube flatten with the brush.

Prepare the next tube which shall form the joint the same way by deburring,

cleaning and gluing.

Then shift it into the half-fixed sleeve until you hear the "bang" when both tubes

~ÉêçÅçã= touch inside the sleeve.

Any glue which is pushed out on the tube, flatten with the brush.

Aerocom GmbH & Co

Adam-Riese-Str. 16 Note It pays to keep the brush in a half-filled can of cleaner when not in use. Thus the

73529 Schwaebisch Gmuend brush does not dry out.

Germany

Phone +49.71 71.10 45 0

Fax +49.71 71.10 45.2 99

info@aerocom.de

www.aerocom.de 16 090 001eV2.0 Tube Installation PVC

Aerocom GmbH & Co. 2013 - Technical alterations reserved Page 1 of 2

Technical Information – Tube Installation PVC

Datasheet

Characteristics/Fire risk

PVC-FORWARDING TUBE DIN 6660/8061/8062

Our program for pneumatic tube systems comprises a special HARD-PVC-tube, coloured

silvergrey/RAL7001 or designed in transparent.

The exact measurements for our forwarding tube for pneumatic tube systems remain under the fixed

tolerance of the respective DIN.

Characteristics

Physical tensile strength 55 N/mm²

E-Module 3000 N/mm²

Resistance to impact High resistance, at 20° C without breaking

Thermal coefficient of linear expansion 80 x 10-6K-1

Heat conductivity 0,16 W/mk

Inherent stability up to 60° C

Electric surface resistibility 10-12 Ohm

Density 1,38 kg/dm³

Water absorption during 24 hours 0,03 %

Combustibility Self-extinguishing

Building material class

wall thickness < 3,20 mm B1 difficult to inflame

wall thickness > 3,20 mm B2 difficult to inflame

Diameter mm Outside diameter mm Wall thickness mm Combustion heat in KWH/m

55 60 2,50 3,80

63 63 1,90 2,55

65 70 2,50 3,70

75 80 2,50 4,35

90 90 2,00 3,85

90 90 2,50 4,80

100 108 4,00 9,30

110 110 2,30 5,45

110 110 3,20 7,50

124 132 4,00 11,60

125 125 2,60 7,00

160 160 3,20 11,05

200 200 4,00 17,25

315 315 6,20 35,35

PVC tubing until OD 160 is classified in building material class B1 (difficult to inflame) according to

additional regulations for DIN 4102 part 4.

~ÉêçÅçã=

Aerocom GmbH & Co

Adam-Riese-Str. 16

73529 Schwaebisch Gmuend

Germany

Phone +49.71 71.10 45 0

Fax +49.71 71.10 45.2 99

info@aerocom.de

16 090 001eV2.0 Tube Installation PVC www.aerocom.de

Page 2 of 2 Aerocom GmbH & Co. 2013 - Technical alterations reserved

You might also like

- WT-H750, WT-H755 Service ManualDocument60 pagesWT-H750, WT-H755 Service ManualRoberto Augusto Aristizabal MorenoNo ratings yet

- Colorfastness To Perspiration: AATCC Test Method 15-2009Document3 pagesColorfastness To Perspiration: AATCC Test Method 15-2009Milagros Wieczorek100% (1)

- Advanced Welding Electrofusion Best Practice 2018Document16 pagesAdvanced Welding Electrofusion Best Practice 2018Igor IvanovskiNo ratings yet

- Cronox 240 MSDSDocument11 pagesCronox 240 MSDSJunMamauagDelaCruz100% (2)

- Simple ORC Model SQ110918Document9 pagesSimple ORC Model SQ110918radanpetricaNo ratings yet

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDocument10 pagesDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqNo ratings yet

- Wrapping Coating Application SequenceDocument2 pagesWrapping Coating Application SequencesenthilkumarNo ratings yet

- CCB Sleeve Weld ProcedureDocument2 pagesCCB Sleeve Weld ProcedureIME SOLUTIONSNo ratings yet

- WCD Densopol Tapes - IfU 2020Document5 pagesWCD Densopol Tapes - IfU 2020Makamu Max Las MokgaoganyiNo ratings yet

- Effast Solvent Jointing Guide 0 0Document6 pagesEffast Solvent Jointing Guide 0 0MeNo ratings yet

- Katalog HDPE Sea Jacket Dan CatodicDocument53 pagesKatalog HDPE Sea Jacket Dan CatodicAbdul JabbarNo ratings yet

- Handleiding S-Lon TraditionDocument3 pagesHandleiding S-Lon Traditionw6rNo ratings yet

- PVC - 57-87Document46 pagesPVC - 57-87fitiranNo ratings yet

- 200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsDocument4 pages200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsCesar PreciadoNo ratings yet

- Cac Buoc Lam Dau Cap Trung TheDocument12 pagesCac Buoc Lam Dau Cap Trung ThevuhalongNo ratings yet

- ISTRCSSJ25ENGDocument6 pagesISTRCSSJ25ENGHector Vidal Rodriguez ValdezNo ratings yet

- Brochure BC PetrotapeDocument13 pagesBrochure BC PetrotapeDianWidodoNo ratings yet

- Hose AssemblyDocument1 pageHose AssemblyScott SepperNo ratings yet

- Maintenance Coupling: Assembly Instructions For Butt-End Joints and RepairDocument2 pagesMaintenance Coupling: Assembly Instructions For Butt-End Joints and RepairmusNo ratings yet

- Hss Installation CanusaDocument2 pagesHss Installation Canusaresp-ectNo ratings yet

- EL-BR-023-CA-EN-0120.1_PVC-Duct-DB2-ES2-Pipe-FittingsDocument8 pagesEL-BR-023-CA-EN-0120.1_PVC-Duct-DB2-ES2-Pipe-Fittingsjoeshmo339No ratings yet

- Premcote Wrapping Manual IFUDocument4 pagesPremcote Wrapping Manual IFUNamta GeorgeNo ratings yet

- u-PVC InchDocument46 pagesu-PVC Inchegemen7404612No ratings yet

- Pinhole PorosityDocument20 pagesPinhole Porositykptl6185No ratings yet

- Pinhole & Porosity DetectionDocument20 pagesPinhole & Porosity Detectionyasser awadallhNo ratings yet

- Hy Lok Tube Fitting Installation Instruction v2 PDFDocument15 pagesHy Lok Tube Fitting Installation Instruction v2 PDFCemal NergizNo ratings yet

- Bending PVC PipesDocument15 pagesBending PVC Pipesmelecio.franzontNo ratings yet

- Premier Butyl Tape System IFU DENSODocument4 pagesPremier Butyl Tape System IFU DENSOChuck AnsphilNo ratings yet

- EV West HTG 2-0 Cable Crimp PublishDocument2 pagesEV West HTG 2-0 Cable Crimp PublishHeritier HabumugishaNo ratings yet

- OsmaDrain Jointing Quick GuideDocument2 pagesOsmaDrain Jointing Quick GuideHatem AbdelnabiNo ratings yet

- 3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Document22 pages3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Gaurav BedseNo ratings yet

- Scotchrap™ 52 Tape: Installation TechniquesDocument7 pagesScotchrap™ 52 Tape: Installation TechniquesHJNo ratings yet

- XxaaDocument15 pagesXxaaGobi NavaNo ratings yet

- Catalogue - New QPF PDFDocument32 pagesCatalogue - New QPF PDFShaiju EbrahimNo ratings yet

- Open Source Vacbed v1Document18 pagesOpen Source Vacbed v1John HaggonNo ratings yet

- Hl500pin ManualDocument1 pageHl500pin ManualMarious NavNo ratings yet

- Spears - Solvent Cementing & Threaded Joints SOLV-3P-1006 - 0218 - WebDocument32 pagesSpears - Solvent Cementing & Threaded Joints SOLV-3P-1006 - 0218 - WebSatees KrishnanNo ratings yet

- C2020 Standard: Assembly & Installation InstructionsDocument5 pagesC2020 Standard: Assembly & Installation InstructionsHidetoshi NakataNo ratings yet

- Properties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensDocument3 pagesProperties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensMuhsin KhanNo ratings yet

- Cross Cut Adhesion Test Kit cc2000 m44 1 14Document4 pagesCross Cut Adhesion Test Kit cc2000 m44 1 14OMATNo ratings yet

- Wencon Pipe TapeDocument2 pagesWencon Pipe TapePartagon PowNo ratings yet

- Autoclave - Tools, Installation, Operation and MaintenanceDocument20 pagesAutoclave - Tools, Installation, Operation and Maintenancejbjb2000100% (1)

- Application Instructions Denso Butyl Tape System1Document4 pagesApplication Instructions Denso Butyl Tape System1Khoh Kai ShengNo ratings yet

- ACU Cassette ManualDocument43 pagesACU Cassette ManualJolina PanaoNo ratings yet

- Montagekit Polystyrene: Strong, Solvent-Free Assembly Adhesive Based On Acrylic DispersionDocument2 pagesMontagekit Polystyrene: Strong, Solvent-Free Assembly Adhesive Based On Acrylic DispersionAmina ČivaNo ratings yet

- Interpretation of Effective Stress Friction Angle From In-Situ Tests - MayneDocument5 pagesInterpretation of Effective Stress Friction Angle From In-Situ Tests - MayneTargetRockNo ratings yet

- DWD-M12CK (Desu)Document20 pagesDWD-M12CK (Desu)cavmfrNo ratings yet

- KORAFIT Adhesive Is The Really Reliable ConnectionDocument2 pagesKORAFIT Adhesive Is The Really Reliable ConnectionhudileksonoNo ratings yet

- Nashua 327 Nashua 367-17: Mastic Tape Foilmastic™ Ul181B-FxDocument1 pageNashua 327 Nashua 367-17: Mastic Tape Foilmastic™ Ul181B-FxArca MakmurNo ratings yet

- 39 Pinhole Porosity 5 SLDocument11 pages39 Pinhole Porosity 5 SLJosé SermeñoNo ratings yet

- Tools Install PDFDocument20 pagesTools Install PDFmfj79607555No ratings yet

- Fire Chief HoseDocument4 pagesFire Chief HoseAnandNo ratings yet

- Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)Document2 pagesConnectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)ruizinho 1No ratings yet

- Dunlop Express Wet Area Tape DatasheetDocument2 pagesDunlop Express Wet Area Tape DatasheetPaul DouglasNo ratings yet

- WT 16 WSBDocument55 pagesWT 16 WSBJuan ChávezNo ratings yet

- Om9010 39Document2 pagesOm9010 39Paul CraciuneanuNo ratings yet

- INS3000ENG Bondstrand 3000 Series Installation InstructionsDocument8 pagesINS3000ENG Bondstrand 3000 Series Installation InstructionsFirasNo ratings yet

- KHVT 3c Install Rev1Document5 pagesKHVT 3c Install Rev1Mark Anthony MatampacNo ratings yet

- HUGO SR23 InstallationManualDocument12 pagesHUGO SR23 InstallationManualAnastasia KharchenkovaNo ratings yet

- Technical Information: Pipe Jointing ProceduresDocument17 pagesTechnical Information: Pipe Jointing ProceduresJerusalemsNo ratings yet

- INSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVDocument6 pagesINSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanNo ratings yet

- Biquad Antenna ConstructionDocument8 pagesBiquad Antenna ConstructionwaarlokNo ratings yet

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- 16 214 401-21e V2.0 AC 3000 PTS-Controller For Advanced AC 3000 ApplicationsDocument1 page16 214 401-21e V2.0 AC 3000 PTS-Controller For Advanced AC 3000 ApplicationsJP BecerraNo ratings yet

- 06 090 001e V2.1 Power PackDocument1 page06 090 001e V2.1 Power PackJP BecerraNo ratings yet

- 16 090 001e V1.0 Arrival SignalsDocument1 page16 090 001e V1.0 Arrival SignalsJP BecerraNo ratings yet

- Pelton and Crane Magnaclave Control Relay Kit Installation InstructionsDocument4 pagesPelton and Crane Magnaclave Control Relay Kit Installation InstructionsJP BecerraNo ratings yet

- Modern Thermodynamics For Chemists and Biochemists 2Nd Edition Dennis Sherwood Full ChapterDocument67 pagesModern Thermodynamics For Chemists and Biochemists 2Nd Edition Dennis Sherwood Full Chapterraymond.cobb946100% (18)

- SPE36919 A Novel Graphical Method For Determining Dewpoint Pressures of Gas CondensatesDocument3 pagesSPE36919 A Novel Graphical Method For Determining Dewpoint Pressures of Gas CondensatesWaleed Barakat MariaNo ratings yet

- Cotton Fabric and Uv-ProtectionDocument2 pagesCotton Fabric and Uv-Protectionstylish eagleNo ratings yet

- Experimental Study On Self-Healing Concrete Using GGBS and MetakaolinDocument9 pagesExperimental Study On Self-Healing Concrete Using GGBS and MetakaolinIJRASETPublicationsNo ratings yet

- Details of Meet 3, Meet 4, Meet 5Document25 pagesDetails of Meet 3, Meet 4, Meet 5Gaurav VermaNo ratings yet

- Gelatin YesDocument80 pagesGelatin YesOliver AbordoNo ratings yet

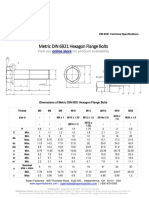

- Metric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityJaganNo ratings yet

- Accumulator Selection: Fawcett ChristieDocument2 pagesAccumulator Selection: Fawcett ChristieAalap DerasaryNo ratings yet

- Oxygen Concentrator PDFDocument25 pagesOxygen Concentrator PDFPavithran SKNo ratings yet

- T424TS040XPK AshcroftDocument6 pagesT424TS040XPK AshcroftTaQuangDucNo ratings yet

- Week 1a Course DetailsDocument19 pagesWeek 1a Course DetailsAraasu EgambaramNo ratings yet

- Aliphatic Hydrocarbons: LAB #1 Reactions of HydrocarbonsDocument7 pagesAliphatic Hydrocarbons: LAB #1 Reactions of HydrocarbonsJoshuaArryNo ratings yet

- Ultra Fine Grinder: Date: 24-10-2019Document5 pagesUltra Fine Grinder: Date: 24-10-2019UsamaNo ratings yet

- Brochure WixS-AutoDocument2 pagesBrochure WixS-AutoAuto DiagNo ratings yet

- Project Specification PaintingDocument13 pagesProject Specification PaintingBudi Indra100% (1)

- Sepbox Technique in Natural ProductsDocument6 pagesSepbox Technique in Natural Productshuynh dungNo ratings yet

- Condenser SizingDocument22 pagesCondenser Sizinglibid_rajNo ratings yet

- 015 Emat Slofec TechniqueDocument9 pages015 Emat Slofec TechniquejasminneeNo ratings yet

- Paper 3Document10 pagesPaper 3zulhariszan abd mananNo ratings yet

- Measurement (Multiple Choice) QPDocument8 pagesMeasurement (Multiple Choice) QPHridyansh KothariNo ratings yet

- Sustainability 12 08968 v2Document22 pagesSustainability 12 08968 v2Seri DewiNo ratings yet

- COA Garcinia Cambogia Extract HCA 60Document1 pageCOA Garcinia Cambogia Extract HCA 60Ali Zainal Abidin100% (1)

- ISI7Document42 pagesISI7최승원No ratings yet

- Stress Concentrations - Lab ReportDocument6 pagesStress Concentrations - Lab ReportArunodha HettiarachchiNo ratings yet

- Aqa Bly2h W Ms Jan12Document13 pagesAqa Bly2h W Ms Jan12ApplemeisterNo ratings yet

- Cold Pad Batch CPB - A Sustainable Dyeing Process For Woven and Knit IndustryDocument5 pagesCold Pad Batch CPB - A Sustainable Dyeing Process For Woven and Knit IndustryJohurul HoqueNo ratings yet

- Ammonia Probe: Model ISENH318101 or ISENH318103: Safety InformationDocument14 pagesAmmonia Probe: Model ISENH318101 or ISENH318103: Safety InformationwaskitaNo ratings yet