Professional Documents

Culture Documents

Sheet 8

Sheet 8

Uploaded by

Bharat GouripurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet 8

Sheet 8

Uploaded by

Bharat GouripurCopyright:

Available Formats

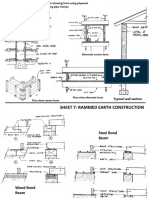

TYPES OF WALL BASE & FOUNDATIONS

The type of material used for the foundations will depend on the availability of

material, its cost and implementation time. The minimum width of the foundations will be

40cm.Nevertheless it is advisable to use a ratio 1.5 times the width of the wall.

Wood column

inside inside

outside

outside

3” nails for

adherance

Foundations: column embedded in

Foundations Cyclopean concrete

the concrete.

SHEET 8: WATTLE & DAUB CONSTRUCTION

TYPES OF WALL BASE & FOUNDATIONS

Wooden

support

inside

outside Hollow

concrete inside

block

outside

Wall base with concrete blocks

Foundations Cyclopean concrete

(39x19x14cm) or similar material

and concrete filling.

SHEET 8: WATTLE & DAUB CONSTRUCTION

STRUCTURE & FILLING - Traditional Wattle & Daub

Traditional wattle and daub consists of a structure made from cylindrical wood or

bamboo filled with earth and straw inside a double structure made from bamboo strips or

thin canes.

column beam

Corner junction

Filling

“ T “ junction

Bamboo Split

Layout bamboo Finishing

grid or cane coat

Earth/ Straw

filling and

underlay

“ + “ junction

Details of the wall structure

SHEET 8: WATTLE & DAUB CONSTRUCTION

STRUCTURE & FILLING - Traditional Wattle & Daub

Details of the support-column

Standard elevation for wall Wall cross-section

SHEET 8: WATTLE & DAUB CONSTRUCTION

STRUCTURE & FILLING - Conventional Wattle & Daub

This type of wattle and daub is a more modern version of traditional wattle and

daub and is the most widely used. It has sections of cane or bamboo poles fixed with wires

and nails to a sawed wooden structure which enables a better finished assembly.

beam

column

Corner junction

column

“ T “ junction

Abutting

Finishing

coat Cane or

Earth/ Straw Bamboo

filling and poles

underlay

“ + “ junction

Details of the wall structure

SHEET 8: WATTLE & DAUB CONSTRUCTION

STRUCTURE & FILLING - Conventional Wattle & Daub

Detail of cane fastening

Detail of anchorage of lower

Standard elevation for wall

plate to foundation

SHEET 8: WATTLE & DAUB CONSTRUCTION

STRUCTURE & FILLING - Prefabricated Panels

The "Quincha" prefabricated panel is a sawed wooden frame, filled with interwoven cane or

bamboo battens, inserted in such a way that they are self-anchoring. After being assembled these panels are

walls which will be plastered with earth and straw mortar with an initial layer and then a thin finishing layer. The

advantage of prefabricated panels is that they enable the panels and the structure that will carry them in the

wall to be made at the same time, thus reducing assembly time

beam

Inside wall Junction

Column

10cm x 10cm

“ T “ junction

Column

10cm x 10cm

Bamboo

battens

"+"junction Wall base

Wattle and

junction between daub

panels Detail of the wall with prefabricated panel

SHEET 8: WATTLE & DAUB CONSTRUCTION

STRUCTURE & FILLING - Prefabricated Panels

Section Elevation

Detail of anchorage of lower

Standard wall panel plate to foundation

SHEET 8: WATTLE & DAUB CONSTRUCTION

You might also like

- Auditing Fundamentals in A South African Context Graded QuestionDocument298 pagesAuditing Fundamentals in A South African Context Graded QuestionMika-eel100% (3)

- Red Hot Workshop ProjectDocument17 pagesRed Hot Workshop ProjectJason N Angelia Jones100% (2)

- Elements of Precast SystemDocument9 pagesElements of Precast SystemRegine Ignacio SobremonteNo ratings yet

- Bamboo ConstructionDocument33 pagesBamboo ConstructionEg EdNo ratings yet

- Wall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesDocument16 pagesWall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction Commencesarchitectfemil6663No ratings yet

- Foundation Rebar ArrangementDocument3 pagesFoundation Rebar ArrangementGaurav MallaNo ratings yet

- Docslide - Us Vernacular Terms in PhilippiDocument10 pagesDocslide - Us Vernacular Terms in PhilippiClarisse GeronimoNo ratings yet

- Docslide Us Vernacular Terms in PhilippiDocument10 pagesDocslide Us Vernacular Terms in PhilippiJessica Irene Dela CruzNo ratings yet

- L14 Composite Concrete SlabsDocument50 pagesL14 Composite Concrete SlabsErnst VenterNo ratings yet

- Bamboo Construction: January 2019Document30 pagesBamboo Construction: January 2019Mark Eli RebustilloNo ratings yet

- 3 Estimate For Ag High SchoolDocument6 pages3 Estimate For Ag High Schoolteblayson wion jr.No ratings yet

- Final Final-MinDocument2 pagesFinal Final-Minapi-289046783No ratings yet

- Floor SystemDocument6 pagesFloor SystemBezawit TeshomeNo ratings yet

- Bamboo As Building Material Case StudyDocument6 pagesBamboo As Building Material Case StudyNavya desaiNo ratings yet

- Design2ch10 PDFDocument6 pagesDesign2ch10 PDFZXCvincentNo ratings yet

- Concrete Construction Article PDF - Construction Details For Earth-ShelteringDocument3 pagesConcrete Construction Article PDF - Construction Details For Earth-ShelteringCharlie GrazebrookNo ratings yet

- Concrete ProportionDocument2 pagesConcrete ProportionJuviya LockserNo ratings yet

- Construction Technology Diploma 3rd SemDocument19 pagesConstruction Technology Diploma 3rd SemToby My GantzNo ratings yet

- White Line Dezign: Terrace Landscape PlanDocument1 pageWhite Line Dezign: Terrace Landscape PlanShah PrachiNo ratings yet

- 1BQ19AT058 MOULYA R Bamboo MMBC PDFDocument1 page1BQ19AT058 MOULYA R Bamboo MMBC PDFMoulya RajuNo ratings yet

- BambooDocument23 pagesBamboopurged_160151093_920100% (1)

- Wall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesDocument16 pagesWall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesMadalina SilaiNo ratings yet

- Wall Details PDFDocument3 pagesWall Details PDFBharathVenkatachalam0% (1)

- S-01 Building SectionDocument1 pageS-01 Building SectionSAMUEL MUMO KIOKONo ratings yet

- CH 5Document9 pagesCH 5crazybuttfulNo ratings yet

- Bsd210timberbuilding (2020 - 10 - 08 14 - 20 - 04 Utc)Document73 pagesBsd210timberbuilding (2020 - 10 - 08 14 - 20 - 04 Utc)moonsy starNo ratings yet

- Screenshot 2023-09-26 at 18.49.01Document1 pageScreenshot 2023-09-26 at 18.49.01kylejim11No ratings yet

- FlooringDocument5 pagesFlooringChristian James TuazonNo ratings yet

- Product: Bubbledeck Structure SolutionsDocument11 pagesProduct: Bubbledeck Structure SolutionsmichelzzNo ratings yet

- BambooDocument60 pagesBamboorahul sulakheNo ratings yet

- Presentation 1Document11 pagesPresentation 1A.B.M ARIYANNo ratings yet

- Engineered Wood Products and An Introduction To Timber Structural SystemsDocument7 pagesEngineered Wood Products and An Introduction To Timber Structural SystemsSang Keun YooNo ratings yet

- 03-Clay Bricklaying Made EasyDocument4 pages03-Clay Bricklaying Made Easysantoshkumar gurmeNo ratings yet

- Roof Covering - 01Document115 pagesRoof Covering - 01Sameer ShaikhNo ratings yet

- Bamboo Joinery DetailsDocument9 pagesBamboo Joinery DetailsHariniNo ratings yet

- Unit Iv Cost Effective Construction Techniques Roofing TypesDocument9 pagesUnit Iv Cost Effective Construction Techniques Roofing TypesDevakumarNo ratings yet

- 1.1 Besco BrochureDocument29 pages1.1 Besco BrochureSilvana DwijayantiNo ratings yet

- Building Technology 5 - Activity 1Document10 pagesBuilding Technology 5 - Activity 1judy ann vidalNo ratings yet

- Rumah Gadang: AR5995A - Tropical Timber Construction Tan Wenkai, Rafael A0166776LDocument10 pagesRumah Gadang: AR5995A - Tropical Timber Construction Tan Wenkai, Rafael A0166776LRafael Tan100% (1)

- Construction Material:: Bamboo - The Eco-Friendly MaterialDocument10 pagesConstruction Material:: Bamboo - The Eco-Friendly MaterialNimse ManavNo ratings yet

- 1 Building Const 2Document89 pages1 Building Const 2Iyan Kenet HerodicoNo ratings yet

- FLOORSDocument27 pagesFLOORSjai singhNo ratings yet

- Eaves DetailDocument14 pagesEaves Detailapi-606257698No ratings yet

- Basement ConstructionDocument5 pagesBasement ConstructionWayne BurgessNo ratings yet

- Dylan Gibbs University of Virginia School of ArchitectureDocument36 pagesDylan Gibbs University of Virginia School of ArchitectureDylan GibbsNo ratings yet

- Site/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Toilet ConstructionDocument2 pagesSite/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Toilet Constructionbiniyymail.com100% (1)

- Supreme Beam and Block FloorDocument7 pagesSupreme Beam and Block FloorhemendraengNo ratings yet

- Cavity WallDocument4 pagesCavity Wallarmaan.dinajpurNo ratings yet

- What Is Waffle SlabDocument2 pagesWhat Is Waffle SlabNekhebet Medina ZafrancoNo ratings yet

- Guide To Assessment and Repair of Flood Damaged Timber and Timber Framed Houses Ver 5 Feb 2022Document9 pagesGuide To Assessment and Repair of Flood Damaged Timber and Timber Framed Houses Ver 5 Feb 2022DmacNo ratings yet

- Civil Question and AnswerDocument20 pagesCivil Question and AnswerAnirudh AgarwallaNo ratings yet

- Lecture No.3 - Bridge-SuperstructureDocument29 pagesLecture No.3 - Bridge-SuperstructureHarold Jackson MtyanaNo ratings yet

- Plates: Level, Bearing SupportsDocument2 pagesPlates: Level, Bearing SupportsRaval Shivam100% (1)

- Bamboo As A Construction Material: With Emphasis On Building ElementsDocument29 pagesBamboo As A Construction Material: With Emphasis On Building ElementsAnkita MehtaNo ratings yet

- Foundations Lighting Columns PDFDocument2 pagesFoundations Lighting Columns PDFtexas_peteNo ratings yet

- BAMBOODocument8 pagesBAMBOOdphilip96No ratings yet

- Building ConstDocument38 pagesBuilding ConstRoyal BlueNo ratings yet

- Buildright BCGBC4010A Wall Systems - NoggingsDocument1 pageBuildright BCGBC4010A Wall Systems - NoggingsOwen PerrinNo ratings yet

- Ce 423 TIMBER DESIGN IMDocument15 pagesCe 423 TIMBER DESIGN IMJohn Ronald Rio Fortuito100% (1)

- Eoi Extension NoticeDocument1 pageEoi Extension NoticeBharat GouripurNo ratings yet

- Practice F.stone-Walls FinalDocument5 pagesPractice F.stone-Walls FinalBharat GouripurNo ratings yet

- Aluminium Glass Shutter Profile 2Document2 pagesAluminium Glass Shutter Profile 2Bharat GouripurNo ratings yet

- GROHE Specification Sheet 39328000Document2 pagesGROHE Specification Sheet 39328000Bharat GouripurNo ratings yet

- MT Handbook GrainDocument250 pagesMT Handbook GrainBharat GouripurNo ratings yet

- Enrolment Numbers 2018-19 BatchDocument2 pagesEnrolment Numbers 2018-19 BatchBharat GouripurNo ratings yet

- Eoi Notice Dated 27.07.2023Document6 pagesEoi Notice Dated 27.07.2023Bharat GouripurNo ratings yet

- 1Document40 pages1Bharat GouripurNo ratings yet

- RESUME and Work Experience 080723Document9 pagesRESUME and Work Experience 080723Bharat GouripurNo ratings yet

- Parent LetterDocument38 pagesParent LetterBharat GouripurNo ratings yet

- New Doc 2020-04-12 14.01.13Document1 pageNew Doc 2020-04-12 14.01.13Bharat GouripurNo ratings yet

- Avalanche 2020Document1 pageAvalanche 2020Bharat GouripurNo ratings yet

- Course PendingDocument1 pageCourse PendingBharat GouripurNo ratings yet

- Class - Section - Wise - ATSEC ADocument1 pageClass - Section - Wise - ATSEC ABharat GouripurNo ratings yet

- Class Section WiseDocument1 pageClass Section WiseBharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester2 SECBDocument1 pageCIE - MIS Architecture Architecture Semester2 SECBBharat GouripurNo ratings yet

- 11 - Chapter 2Document37 pages11 - Chapter 2Bharat GouripurNo ratings yet

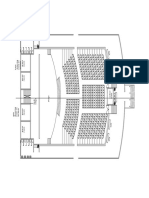

- Auditorium PlanDocument1 pageAuditorium PlanBharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester6 SECADocument2 pagesCIE - MIS Architecture Architecture Semester6 SECABharat GouripurNo ratings yet

- LibraryDocument5 pagesLibraryBharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester6 SECBDocument2 pagesCIE - MIS Architecture Architecture Semester6 SECBBharat GouripurNo ratings yet

- CIE - MIS Architecture Architecture Semester6 SECBDocument2 pagesCIE - MIS Architecture Architecture Semester6 SECBBharat GouripurNo ratings yet

- BrochureDocument44 pagesBrochureBharat GouripurNo ratings yet

- Lec 2Document17 pagesLec 2Bharat GouripurNo ratings yet

- Lec 1Document14 pagesLec 1Bharat GouripurNo ratings yet

- School RequirementsDocument3 pagesSchool RequirementsBharat GouripurNo ratings yet

- Master PlanDocument1 pageMaster PlanBharat GouripurNo ratings yet

- Quiz GuideDocument18 pagesQuiz GuideBharat GouripurNo ratings yet

- Sheet 7Document3 pagesSheet 7Bharat GouripurNo ratings yet

- Sheet 6Document4 pagesSheet 6Bharat GouripurNo ratings yet

- Motor CatalogDocument85 pagesMotor CatalogHarshad AthawaleNo ratings yet

- Lecture 1 Notes: Introduction 1 Compiled Languages and C++Document266 pagesLecture 1 Notes: Introduction 1 Compiled Languages and C++Abdullah NazirNo ratings yet

- NST32031-Practical For Wireless Network: Department of ICT Faculty of Technology South Eastern University of Sri LankaDocument9 pagesNST32031-Practical For Wireless Network: Department of ICT Faculty of Technology South Eastern University of Sri Lankaaiz15563No ratings yet

- Rocker Arm & Valve Train Geometry - Circle Track Magazine All PagesDocument5 pagesRocker Arm & Valve Train Geometry - Circle Track Magazine All PagesDinesh Kumar SNo ratings yet

- ADS1115 ComparatorDifferentialDocument5 pagesADS1115 ComparatorDifferentialLeandro De VegaNo ratings yet

- Sixteen - What Now? AnswersDocument4 pagesSixteen - What Now? AnswersAdrián RedalNo ratings yet

- Organic Chemistry 8Th Edition Brown Test Bank Full Chapter PDFDocument36 pagesOrganic Chemistry 8Th Edition Brown Test Bank Full Chapter PDFtonya.paongo686100% (11)

- CSE460: VLSI Design: Lecture 5: Finite State Machines (Part 1)Document13 pagesCSE460: VLSI Design: Lecture 5: Finite State Machines (Part 1)Shovon BhowmickNo ratings yet

- 2 SavedDocument17 pages2 SavedJabonJohnKennethNo ratings yet

- Costbenefit Analysis 2015Document459 pagesCostbenefit Analysis 2015TRÂM NGUYỄN THỊ BÍCHNo ratings yet

- Entrep 10 Activity 1Document4 pagesEntrep 10 Activity 1Ma'am JeeNo ratings yet

- Human Trafficking by The Numbers, 2016Document110 pagesHuman Trafficking by The Numbers, 2016Houston Chronicle100% (2)

- Math10 Q1 Mod2-3 Week3Document54 pagesMath10 Q1 Mod2-3 Week3Grace Joy CansecoNo ratings yet

- Persuasion in IMC PDFDocument7 pagesPersuasion in IMC PDFYatendra VarmaNo ratings yet

- White Paper A I Ops Use Cases 1563909601853Document4 pagesWhite Paper A I Ops Use Cases 1563909601853Janer GraciaNo ratings yet

- Oil Specs Silver State BrandDocument1 pageOil Specs Silver State BrandAllen WilburNo ratings yet

- Diagrama General Refrigerador Frijidare Ffss2312lsaDocument2 pagesDiagrama General Refrigerador Frijidare Ffss2312lsaRegulo GomezNo ratings yet

- Unit 3Document18 pagesUnit 3Christel Joy TagubaNo ratings yet

- Unit Test1Document3 pagesUnit Test1Gonzalo VillanustreNo ratings yet

- Specific and Non Specific DimersDocument6 pagesSpecific and Non Specific DimersDattu AbhiNo ratings yet

- Measures of Dispersion: Lecture by Dr. Reena NupurDocument70 pagesMeasures of Dispersion: Lecture by Dr. Reena NupurPRIYAL GUPTANo ratings yet

- Optimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFDocument19 pagesOptimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFEnrique Javier González HenríquezNo ratings yet

- Gadamer, H-G - Truth and Method, 2d Edn. (Continuum, 2004) 01Document635 pagesGadamer, H-G - Truth and Method, 2d Edn. (Continuum, 2004) 01lam lamNo ratings yet

- Automatic Search of Attacks On Round-Reduced AES and ApplicationsDocument40 pagesAutomatic Search of Attacks On Round-Reduced AES and Applicationssomeone :-ONo ratings yet

- English 7 Directions: Read The Questions Carefully and Select The Correct AnswerDocument8 pagesEnglish 7 Directions: Read The Questions Carefully and Select The Correct AnswerDafchen Nio MahasolNo ratings yet

- Arduino Based Pressure Sensor Integration in The Measurement of Flow FieldDocument12 pagesArduino Based Pressure Sensor Integration in The Measurement of Flow FieldIJRASETPublicationsNo ratings yet

- Selection SheetDocument6 pagesSelection Sheethussam_98No ratings yet

- 35.HF Deluxe I3s (Jan, 2020)Document139 pages35.HF Deluxe I3s (Jan, 2020)Raj Auto Agency Mandvi100% (1)

- Nissan Unicarriers Forklift Truck Part Catalog Service Manual PDF ComboDocument22 pagesNissan Unicarriers Forklift Truck Part Catalog Service Manual PDF Combojayrodriguez021099esp100% (127)