Professional Documents

Culture Documents

Vossen Kern Thin Film Processes

Vossen Kern Thin Film Processes

Uploaded by

Deejay MonsmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vossen Kern Thin Film Processes

Vossen Kern Thin Film Processes

Uploaded by

Deejay MonsmaCopyright:

Available Formats

,

THIN FILM PROCESSES

L. ".J

V-1

Chemical Etching

WERNER KERN AND CHERYL A, DECKERT

RCA Laboratories

Princeton, New Jersey

L Introduction 401

[I. Principles and Techniques of Etching 403

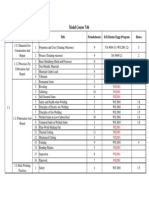

IV, Tables of E!chanh and Etching Con,iltinns 4,13

A, Guide to the 1I se of Tanle, 4B

R, Insulators and Diclcctrics 4

A, Chemistry of Etching 40J

B, Factors AfTecting Etching React,,'ns 404

C Etching Techniques and Procc",,, 405

i), Pattern Delineation Etching for Th", Films 407

E, SUlfate Contamination and Cleanin! I cchniqucs 411

11 L Chemical Etching of Specific Materials 413

A, Insulators and Dielectrics 41l

B, Semiconductof' 424

C Conductors 4n

D, Miscellaneous Matcriah 432

C. Elemental Semiconductors 4JR

0, Compound Semiconductors 451

E, Conductors 463

F, Miscellaneous Material, 479

V, Summary and Cone/usions 481

Acknowledgments 481

References 4RI

I. INTRODUCTION

Chemical etching in thin-film technology plays a prominent role in

both the preparation and the utilization of thin films. Regardless of the

method of film deposition or formation. the substrate must first be suit

401

\) I m Audt'mic I nl.:

"II ntthl'l f't:t'lfuducIUlfl In any form

'

I

'\

1

!)

WERNER KERN AND l\''E-.RYl A. DECKERT

uhly prepured, either by removal of work damaged surface layers or by

creating a relief structure of specific geometry. In the first case, chemical

polish etching is usually the method of choice; in the second case, struc

tural etching is required. Once a thin film has been deposited. chemical

etching is often used again, this lime to create patterns in the appropri

ately masked films.

The aim of this review to provide a broad outline of the subject of

chemical etching and to present tables, with references, of etchants and

etching conditions for inorganic materials.

Numerous excellent books. treatises, and reviews are availuble on

theoretical and practical aspects of chemical etching. covering the chem

istry [1-28] and electrochemistry [29-42] of etching processes. A few

partial bibliogmphies have been published on some aspects of etching

[43. 43a]. However. most information on specific etch ants for different ma

terials. with the possible exception of semiconductors. is widely scattered

throughout the scientific literature and is often difficult to retrieve because

etching is most frequently a means to an end and is usually not the pri

mary subject matter of an investigation. An attempt has been made to

bring together essential information that should prove useful to the scien

tist or engineer who must select an etching process for a specific material.

It is obviously impossible to list all etchants for all materials. Instead, a

selection has been attempted which is based. in the authors' opinion. on

the practical usefulness of an etchant and a solid material in thin-film tech

nology. The most recent and advanced information is generally given

preference. Special emphasis is placed on materials and processes used in

semiconductor microelectronics because a substantial part of thin-film

technology is applied in this area with which we are particularly familiar

from pmctical experience.

One important application of chemical etching is in the structural char

acterization of materials. especially the detection of lattice defects in

semiconductors, the study of distribution of localized impurities. the de

lineation of layer structures and p-n junctions, and the determination of

composition. This specialized field of analytical etching is outside the

scope of the present review. Physical-chemical "dry" etching processes

such as sputter etching, plasma etching, and ion milling, are covered in

Chapter V-2. What will be covered is chemical and electrolytic etching of

insulators, semiconductors. and conductors in solution and in the gas

phase.

Chemical formulas noted for reagents refer to the chemicals in the

usual concentrated form, as defined in Section IV .A; parts are by volume.

The crystallographic notifications used are those quoted by the author(s)

of the reference cited.

lil \ v-I.

II. PRINCIPLES AND TECHNIQUES OF ETCHING

A. Chemistry of Etching

Chemical etching may occur hy any of ,everal llitl..:rl:1l1 pnH.:e"l:'

[ I. 2, 81. The simplest mode of etching involves di,solutwn of the makn;.I

in a liquid solvent without uny change in the chemic<d natlll'<; 01 thl: dis

solved spedes. Relatively few imlw.trially important Illatl:rial, ale etdH:d

in this munner. Although this is the only clching PlllC':" fur which the

word "dissolution" is properly used, the krrn h", Lome Into Cll[l11l1UIl USl'

for describing uny etching procedure car ned 'Hit ill hl.jlllli media.

Most etching processes involve nne 01 more chelllle:.! reactiulls. III

order to be truly an etching reuctinn, the PIll""Ct fllllw.:d 1111"t he ,uluhk

in the etchunt medium. or must at lea,t he carned 110m the ,UIf.llC

by the medium. Various types of reuctiulh Whl':!l m<lY he 111\ ,dv",1 all' l'.'

idation-reduuion, of which e1et:!rochellm:al etching I' a ,pecial case.

Lomplexation. and gas phase etching.

An ,lxidation-reduction, or redllx, ddling proCl'" IIlv{)lve, comci

sion of the Illateriul hr:ing r:lched to it hight'l '''Iddtloll ,I all'

M -+ M'" !

Redox etching may occur either in a completely dlelllll,d 'i'\tefll. {Ill'

use of certain chemicull)xidizing agent;, stich ," Cr:". (II ill an dClilt'

r.:hemicul r.:elll:,!I)J. by making the material to he l'Idl\.:d the 'lIwdl'. ,lIld h

applying a suitable eXlernal electromotive forr.:e. A tYPIC.! pllll "I (UII(1l1

density versus t:ell v,)ltage is given in Fig. I; thr: vanous 'lag..:' "I' .lll,,,\..

ure noted. Ekt:lrochelllical effects cun lead tIl cerLlIll 1'1 "hit-ill, III etc

Cormsion 124, is a special case (If ;;iClt",dlll1l1l,d ctLlllIlg

which occurs whr:n variations produce Illl:,,1 alllldn .1Ilt! (.llh"de\

When films of two dlssimilur mr:tals arc in conlact. thc re,ult,1I1l g,d, ,lIlk

uctton can cause undr:rculling at the interfan.: during L'tdllllg 1441.

,..

....

Ui

z

w D

o

Fig. I. Curren! uen,ily cr,u, vull

....

age. Region A -8 B -(' ,I"hle z

w

plateau with poli,hlng. C -[) ,low ga, ,;\ "I"

'"

'" :0

tion with pilling. D-E pol"hing "'lin I"PIU

U

ga' evolution

o

..

z

A

..

Cell V()llAGt

c

,

t

1

404 WERNER KERN AND CHERYL A, DECKERT

Complex formation is frequently involved in etching processes, often

in conjunction with a redox reaction. The ligand groups surround and

bond chemically to the etched species, forming a complex ion or molecule

that is readily soluble in the etchant medium.

Gas phase etching may involve vaporization of the material being

etched in a vacuum or inert atmosphere or may involve reaction of gas

eous etchants with the surl'ace to produce volatile products, Elevated

temperatures are usually required,

B. Factors Affecting Etching Reactions

Etching reactions typically occur by a process involving several se

quential steps [3. 81. The observed dissolution kinetics depend upon the

nature of the rate-limiting step of the process, If the rate of this step is

determined by the chemical reactivity of the species involved. the process

is said to be activation limited, On the other hand. if the rate is determined

by the speed at which fresh reactant can be supplied to the surface, the

process is said to be dIffusion limited,

If a series of materials are all etched in the same solution by a diffu

sion-controlled prm:ess, then the same etch rate is observed fur all

Some etching processes are diffusion limited at low cuncentrations, but

are activation limited at higher concentrations [31. An increase in etching

temperature may cause a change in the etching kinetics 145J, The presence

of catalytic species in the etchant can also affect the etch rates markecly,

Agitation of the solution may increase etch rate if the reaction is diffusion

limited; it may decn:ase etch rate if, for example, lucalized solution heat

ing occurs; or it may have no effect if activation control is involved, In

pattern etching, the slope of the pattern edges depends on the type of ki

netics involved 1461,

Adsorption and desorption processes can affect the etching

profoundly, Adsorption of reactant from the etchant solution onto the

substrate may produce surface complexes which will facilitate the etching

process: however, in many cases adsorption of nonreactive species or for

mation of passivating surface films can slow down or SlOp further etching

[3]. Oxide films on metals are a good example of this phenomenon, Cer

tain types of impurities in the etchant solution, even though present at low

concentrations, may be adsorbed onto the substrate and hinder etching

[8). Desorption of gaseous reaction products sometimes limits the rates of

etching processes [31,

The kinematic aspecb of etching [8, 47 J should also be mentioned

briefly, This refers mainly to the tendency of various crystallographic

}

v-I, (HIMIC"L titHING

-JI

planes to eh.:h at different rates, Various llrientati"lh oj Slllgle c'l y,(,tI 'lIh,

strates may thus etch very differently in a given cldlHnl, alHI sllh,lrdln ill

varying roughness may also exhibit large differellc", III clLli faIL,

Several additional specific factors affecting etdllllg ieacliolh III \',111

OtiS types of materials will be in the discU"lllih of Hlsldahll, ,til.!

semiconductors (Sections III.A and III.B, respectively).

C. Etching Techniques and Processes

Thl' choil:l' of the etching tedwil/lle to be lIsed fOI it givc'lI ,tlilallull

depends upon the material to be etched, the rel/uirClllcllh of /101111:111 gC'1I

eration. the nCl:essary etl:hing rcagellh, the cll:hing pnH:e;"c'S 111\ "Ivn!

and other fal:tllrs slIl:h as eCOnOllllC I:Ollslderatiolls,

I, illl III I'J'sioll

The technil/ue is lil/llid dlelllical immerSion 0' dip ell

where the masked or unmasked objl'l:t i ... III IIll: dl:h ,,,11111"11

Mechallical agitation is usually desirable as it illlplOvn Ihe lilli/'" 11111 \ oIlid

control of the et;,;hing pro;,;ess by enhandng the C\dlallgc <llld 1111\1111' (II

etching at the solid sllrl'm:e with licsil ",ililI

OIl

I h" "h"

local overheating in the case of exutlil'llIlIc IC'''c'llOlh (Ilcleb)

maintaining a uniform and controllahle ctdllllg IaIL'. Huhhle', "I g,"

H,) that nwy form as a reaL'lion prodUL'le:lllcllllg I() IhL' ",h.! 'iii

face and inhibit uniform e\;,;hing, The addition of:, '"llac'c' :Icll vc' dgnll I"

the etch solution can prevent bubhle aCl:ulllUlalloll\ 'Unkll'llll) LIli'C'

ratiu of ekhant tll material being dL'hed should hc' l'lliploycd III 1111 111111 IIc'

reaClant depletion and to maintain the real'liull t..:lllpC(;illlrc' oIlld Ihe' loll,'

of Illtack,

Spray ct.:hll1g IS lI,eflll for gcnerating pal tern, III Id:lIIVd) (lil\ lIilll'

or substrates, especially if steep pallern wal" 'Ill' dL:'IIL:d, '1IlcL: Ihe

pinging imparts a variable degrcl' nl dll CC'IIOIl,lill) III llil'

process, The et.:hing rate is in.:reased llvcr thaI uf inllllL'hlon L:tdllllg, dllll

.:an be regulated by the amount uf pre,slIre applil'd alld thl' \l/c 111 thc'

droplets, Good pro;;es., control Ilnd 1Illifonnily Cdll hl' dlLIIIll'd I>c"'I1'"

fresh etchan! is rilpidly and CUlhtantly ,uppliL'd tu 111l' 11'ac'Iillll Sill' "

the n!actioll producl\ arc continuuusly r..:mOVL:,!.

l'khlllg 1"II,h

self to automation

madllll C"

c .'\dll.d>l.: 1"1

many spel:ilic

r'

',.'.

.

1

,f

.; 406 WERNER KERN AND CHERYL A, DECKERT

J, Electrolytic Etching

Electrically conductive or semiconductive materials are frequently

etched by application of external emf potentials. Electropolishing of

metals and semiconductors is a good example of this technique. The rate

and selectivity of etching can be controlled by the potential and/or the

,:;

current density applied, Electrolytic etching is considerably more compli

:{

cated than other techniques, but can yield results not otherwise attain

able. Specific conditions will be described for various materials in the text

and in the etching tables,

4. Gas-Phase Etching

High-temperature etching in the gas or vapor phase is generally used

for chemically inert materiab that cannot be etched readily in liquid re

agents. A different application is for in situ etching of semiconductor sub

strates immediately prior to epitaxial film growth in the same reactor to

avoid surface contamination that would result by other techniques,

;t

5, Mechanical-Chemical Polishing

:1

This technique is used in semiconductor wafer preparation when a rel

atively defect-free surfa(;e is required, The combination of slow liquid

chemical surface etching with gentle mechanical abrasion to continuously

remove products from the etching reaction can result in a high-quality sur

face polish if carefully optimized conditions are observed, as will be de

"

j

scribed in Section Ill,B,

'p,

$:,

i 6, Isotropic versus Anisotropic Procesus

Isotropic or nonpreferential etching proceeds at an equal rate in all di

f

rections. Amorphous materials of uniform composition etch isotropically,

J'

whereas many crystalline materials etch both isotropically and anisotropi

cally. Anisotropic or preferential etching depends on the crystallographic

i

1

orientation of the material and on the etching reagent used, If polishing

t action is desired. isotropic etching conditions must be selected to achieve

a structureless surface. If structural shaping is the objective. as in the for

mation of deep depressions having side walls of a specific taper angle, ani

sotropic conditions are required, Both liquid and gas-phase etching can be

used for these two types of etching processes,

7, Selective Etching PwcesJes

Selectivity to the differences in etch rate between different ma

teriah, or between compositional or structural variations of the same ma-

T .... )

-'-

v-I, UIEMI(AI. lelnUNG

((' ,

terial. It is one of the most Important faclor, III "pplicd ell hili): '>1.,,(

technological etching processes must he controllahly ,e/eui\ <.: 1>1."'.llI'"

the material to be etched i.s usually part of a ,trllctlile Ihal c"n'l'\l\ ul 'on

eral material components, Seleclivily III etdlillg is :I"hined h) 1'1 (I pc' I

choi..:e of etching techni411e and <:1(:h,1I1I L'uJllj1'I\ilJolI Wllhill tlil' "

straints of the syskms,

Various degrees of etching selecllvit} ai,' dl"II.1hk Inl panl,',II"1 pUI

poses, For example, pattern ell,:hillt! (If Si.,N, or '\11),111111'0 III ",,1 II,I'(),

an et..:h-resistant deposikd SI(), 111m '" III,' ""II Illa,J,. ilillstl,dl' ,j

high degree of dching selectlvil) Oil Ihc olhel Ii,Uld lnllll(llkd P;IIII,,J

etching sele..:tivity of dielectric byel cOlllpo,ill', 1\ IIllI"'ll.lIlI III LIf"'1

ct..:hing, where a desired edge COlliolil c:lIlhl' :lILIIII,'d (Ill Ihl 1",,1, 01 el,'11

rate differem:es of the componelll 1:'Yel' In Ill!' 'd" "I;"IL'I L'klllllg til

eh:L'tri..: "tapt;r'L'olltrol" layer i, !(lIIllL',! nvu Ihe "I,'kdll' 10 he h,'\,'kd

[461, Numerous uther important <lpplic:aliolh 01 'lkcllVc' <.:1c1l'11V ".l\"

been descrihed [26, 27, 415, 49 I.

FII,lioll

(/111 Other }''-IIC(',I.\('.I

('l'rtam highly etl'h-n:sistant m:llcria" ,.Ill h" d,bed h} 11"dllll\'1I1

with moltell salh (uften 'n hUla),) :11 11Igh I,'II'I"'I;""IC' .''''\<'1,11

examples will be noted in Sections I V, B and I V ,I)

Surface oxid,ltlon hy thermal or ;lIhldli': tledllll,'nl" ("I1""ed hI ,1"'111

iGd strippillg of thc nxide films formed, can aho he ,Ihl,kl,'" :111 c'l, llillg

only the ;,econd ,tep, the cl..:illllg "llhe Side--., \\ oil I",

dis":lIssi:d here (Section IILr\),

D, Pattern Delineation Etching for Thin Films

In rnany instan(cs, elching pnlCi:sses arc used I,) J'I\,dIlC,' cllI""1 1'.11

terns in thin Sdected portions of the Ijlm ,II,' 111",J,.cd by .111111"<'1

thin film coating material which is un:dlcded by Ihe ..:1,11"111 (0 hl' 1I'"d I"l

patterning, Etching is then canied (lut so as to re11lm.: <tilth.: 1JIIIIIIIdll'll,'/

in the unprotected regions, The proteC:livc L'oatillg lilill " Ih':l1 IIsll,>lI,

stripped, leaving the desired pallen! in Ihe lIndc") IIll! thlll fillll,

Pattern etching is obviuLJsly a Illllch 1111\1\' dllllples PI')ll'\', 111,11, ""I

pic overall sUIi'aL'c etching, III additloll to ,l'Ieding Ih.' ct,'!liHlI h'''''I!I):'' l

masking material is of prime importance; good aLlhnloll,oIlitlS CO,lill,)! 1<>

the substrate, C'll<lling integrity, aJe4LJate re,ulutillll, ;lIld I L',lSldIlC': hI 111\'

et..:hant arc the main L'onsiderations, Lase in pattelllllll! thc Inasl-,

is important; othCl>I<be thi, plOcedure beCOlllL'S :til ,'I,llIlIg PWlC" 11,,11.

requiring yet ullother mask,

r1

T )

/'1

..OK WERNLR KERN AND CHERYL A, DECKERT

I, Mllsking Materials

The most often used masking materials for high resolution thin film

patterning are photoresists (SOl, organic polymers whose in

certain solvents change drastically as a result of exposure to uv radiation.

Usually, exposure is carried out by placing a glass plate bearing the

sired pattern in an opaque material (such as photographic emulsion or

chromium) over the photoresist-coated substrate and irradiating through

the glass plate, Negative photoresists become less soluble in the de

veloping solution in areas that were irradiated, thus producing a negative

image of the pattern on the glass plate. Positive photoresists become more

soluble in exposed areas and thus produce a positive image of the orig

inal pattern. Excellent photoresists are available commercially from a

number of sources. Negative photoresists are generally tougher than posi

tive resists and can usually withstand more rigorous etching processes,

Positive resists are noted for their superior resolving power, and pallerns

as fine as I lim have been resolved using positive photoresist. Electron

beam and x-ray resists can produce very fine resolution but they have not

yet come into widespread use because of high processing costs,

When the etching process to be used in patterning the in

volves extremes such as elevated temperatures or strong acids,

sist masks may not provide adequate protection, In these cases. metal or

dielectric masks, which can withstand the etching process more effec

tively. are often used, In such cases, the mask is first patterned using a

photoresist process. For example, chemically vapor-deposited (CYD)

is used as a masking material for CYD Si3N4 films. which are typi

cally etched at 180C in H"PO . conditions which would quickly degrade

photoresist films. The Si0

1

itself is readily patterned usinl!. a

perature etching process with a photoresist mask,

Sometimes, a high temperature or extremely degrading chemical etch

ing process can be replaced by an electrochemical procedure which

Iizes a much milder solution, thus allowing a photoresist mask to be

ployed [5

In cases where high resolution is not a requirement, very simple mask

ing procedures are possible. Ordinary cellophane tape is used to mask

against a variety of etchants. Other masking films such as positive

toresist or silver paste can be applied in the areas to be protected using an

artist's paint brush. Certain waxes which melt at temperatures of 100

250C can be painted onto a hot substrate and will resist many etchants,

2. Adhesion and Inler/ace Problems

Good adhesion to the substrate film during etching is the prime re

tll1irf'mf"nl nflhe material. Loss of adhesion usually occurs in one of

CHI:MI(AL EIUIING

-III' j

two 1521: (a) edge allaL'k at the interfill.:e by tlie' t.:lchant (lIlltkn:111

or (b) failure over a large area (lifting, peeling, CidlingJ.

(/, f.;duC' AIIUCh. If pt.:rkLl thlullgl".1I1

etching, and if the etlhing process is isotropic, a ddilll'<llI:d Pdlllill Ilhe

that in Fig. 2a will If the ct.:hant atlad,s Ih..: lulL'lfde..: be'(\'l'l'11

mask and suhslfatc film, however, the top edge of th..: pattelilld Ilhll ,.oil

become quite gradually (/iig, 2h). This phcnol11e'lltHl is cidkd

dercutting. Ullderlutting is a common OlCLIlrelllC bleall'l' 11I,)sl

mask/substrate film comhina!ions involvc no chellliL'al bonding. Iel

y

lug

solely on van dcr Waah fon:es for intcrfalial adhesion. Thc'c rorn's al c

strong enough to good bond ullder oHlina!y contilt">!1S

<i.e .. no eh:hing). hut in the et.:hing ,11'0 tl'nd ( 1"1111

van dcr Waah honds to the mask and suhslrate film Slllr,,<.:..:,. ,tlld III '''Iif,'

thescitlleraL'lions can hI.' strongcr than the m;"k/'<llils!I<tll'

bond, thus lalJsing adhesion failure at the edges of thc paltcln.l\dllc"It>1I

promoters such hc",lmcthyldisihllalle, which Icntin SiO, '"lla,'l'S c',

sentially nonpolar. kad to bettcr etch reslstan<.:c I ql \\ IIh plll'!O"'SI,>1

mu,b simply belallse thc polar ctchan!s arl less attladl'd I" tlil' Iillu

face. even though the a\.:lual van del' Wa,,!'s forces hl'l\H'l'1I till' mudrlll'"

SiO" and the photlllcSlS1 may he smaller than Wililoll! "dlll'Sltl" 1'1<1111<11('1

QUllC often it is that a small amollnt or l\lllll"lkd IlIhkl

(a)

( bl

=---FAST- ETCHIN\J

COATlN6

rlLM

/ //// PATTERNED FILM

SUBSTRATE

(el

Fig. 2. Diffn:nl euge pr.lliiL-.., from htllUU" dl.:grl.'l"'1 (il lllldL'jlUlllllg, jiLt tlll\},l

prlluul'c"I (Hk' of t"JgL', tn) umll.'ll.,,'lIlllllg 11,1'> \I\.:\,:WI.:J .tI flId"f.,.

film ie! of.\ h ... , >'L,h;n" L,,, II.! ,

'T

410 wtRNER KERN AND CHERYL A, DECKERT

ting take place, since a sloped substrate edge is easier to coal uniformly

than a sharp edge, if additional layers are to be deposited subsequently,

In such cases, a very thin layer of nraterial. which dissolves in the etchant

more rapidly than the substrate film, may be deposited prior to masking in

order to achieve controlled undercutting, This is depkted in Fig, 2c, A

recent example of this method is the beveling of permalloy films using a Ti

overcoat [54],

h, Large-Area Failure, Sometimes mask/substrate film adhesion fail

ure occurs over a large area of the interface, This failure can show up in

several ways. A portion of mask coating may be lifted completely from

the surface, it may peel up either from the edges only or else craze and

peel over the whole surface, or it may blister or bubble across the surface.

These failures are usually due to differential stress buildup in the sub

strate film and mask layers, Thermal or chemical treatments can cause the

masking film to go into tensile stress relative to the substrate layers. in

which case peeling. crazing. or lifting can occur, On the other hand. if

stresses in the mask become highly compressive compared with the thin

film/substrate composite, blisters and bubbles will appear in the mask

layer. These problems can be minimized by using a mask material either

with a similar coefficient of thermal expansion to that of the substrate or

witt! sufficient elasticity to conform more easily to the substrate,

3. Factors Affecting Image Resolution

The most obvious factor inHuencing image resolution is, of course. the

resolving capability of the masking material. As already mentioned, nega

tive photoresists have considerably poorer resolving power (- 3 I-Lm line

widths or spacings) than positive resists (- I I-Lm), Metal and dielectric

mask coatings are capable of generally finer resolution, down to the order

of the grain size, Electron beam and x-ray resists cat. also be imaged to

very fine dimensions (-80 Aresolution has been reported

The thicknesses of both the masking material and substrate film limit

their resolution capability when chemical developing and etching proce

dures are used. Since isotropic chemical dissolution produces sloped

edges, a good rule of thumb is that the thickness of the layer to be pat

terned should be no more than one-third of the resolution to be achieved.

Dry etching processes, such as plasma and sputter etching [56], can pro

duce very steep pattern edges, and thus finer resolution can be attained

with a given film thickness,

Etching processes which involve gas evolution can lead to poor image

resolution because of gas bubbles clinging to the substrate, particularly

along the edges. This problem can usually be alleviated by the use of a

)

v-I. CHI MICA] 1,I<llIl'-i(i

.j I

suitable surfaclant in the etching 1lI, by hcat

ing or good agitation throughout the clI.:hing pmcedun:,

In etching where the IJlm becul11cs uxidilCd Ie,g

metals. silicon). masks of a nobler met;11 can lead tll acccicrated

thus producing pronounced underciliting alld Ilh' (II' 1441 By

the use of certain carefully chemical thc

can be markedly reduced [57,58],

E. Surface Contamination and Cleaning Techniques

The important subject or conlalllin,llitlil and Ck"lIillJ,: of surf,lI:n hc

fore and after etching is dosely aSSlll'lalcd "'Ilh pra,'!I,',i1 deh pru,'C"III)!

A detailed discussion of this separate topic is (1lIhllk Ihc ,,'opc "I' Ihi,

chapter; some general alld a hlld Illcr a[lIIe \ce')

arc presented,

Sudace cont<lmin<ltion as r.:lated to elL'hil1g call hc c''''hldel c'd 1111111

two aspet:ts: (I) initially present contaminanb and thc'III,'llhIV,,1 IHllil III

etching, and (2) resiuual contaminanb ariSing frum l.'ldllllg t rl.,III11CII" dlld

their removal as a postelch step if traces ur illlpuri[io e,1I1I1<11 hI.' l<lkl "kd

on the etched surface,

Contamination on prior 10 etching Illay I.lIll'I'1 til palllc'lIlale'

materials, organic re:,idues, or inorganic surface lililh dJ!ferl.'lll f'OIll 111l'

material to be etcheJ, These impurities shuIIIJ he rClllu\cd Sille, Ihq' !II"}

interfere Wilh lhe etching by masking or unul.'sirablc 1,<11.'111 HI '" ilh I Ii,

etchant. Particulate removal t:an be accomplished hy 1I1I1,1'>01l1C Ill'.11

ments in cleaning solutions, use of compressl.:u gas jl.'l" .IPphc'dllon "t IJ"

uid sprays or jet:>, or simple mechamc,\1 mcan, sudl as sU'uhblllg III

Organic n':,sidues are removahle dllwn It) IllUll,llaYI.'1 !evc'l, h)

dissolution in suitable organic solvenb, or hy vapm IdhlXlllg in oigallic

solvents or azeotropic mixtures, Cumpicle IClllo\;d I'

possible only by plasma ashing. glow ui,charge 'P" Ill.: Illig , "I dltllllLl1

reaction leauing to dissolution, Inorganic surface film, he aIL,d,,'d

by specific chemical reagents designeJ to pmullce sulllhlc n:acllt)f}

that can be Hushed away,

Whereas the treatments noteu ahllve ,lie geIK'I;dl} .1I11l

lively noncritical. the effective n.:movaillf rcsiduallr'I\.' c"lIlldllllll,lllh I,'

suiting from etching b far nHlrc diflic'ult III acc Ulllph,h, SUI!." I.'

contaminants are very critical in tel'hnoillgies, sudl ." "ulid'ldlL' dn "l

processing. where the nucleation, growth, "dhesi'III, ,tlllllllll.', and Ik'i

fection of a depositeu hIm can be critically affcc'lL'u 111I1)[llill"" oil till'

substrate surface, High-temperature pwc'c',,_,ing llIil\ Ie'ldlial 'ill

1

(

412 WERNER KERN AND CHERYL A, DECKERT

face impurities to penetrate into the substrate and give rise to undesirable

effects, such as electrical instability of semiconductor devices,

The deposition of especially heavy metals, from liquid

etchants onto semiconductor surfaces is well known since the early ex

perimental work by Holmes el ai, 15,591. and the reviews by Gatos and

Lavine [8] and later by Faust 160], Kane and Larrabee [17] reviewed the

literature up to 1969 on the deposition of chemical impurities from solu

tion onto semiconductors, More recently, Kern reported results of com

prehensive radioactive tracer adsorption studies of anionic and cationic

etch components [61] and trace contaminants [62, 63) on Si, Ge, GaAs,

and surfaces [64], In addition, a decontamination method based on

sequential oxidative desorption and complexing with Ht 0 2 -NH.OH

H

2

0 followed by H20cHCI-H20 was devised [64, 65J, Its remarkable ef

fectiveness was verified specifically [66-69al and indirectly (70-721 by

several authors,

Various additional aspects of cleaning Si surfaces have been reported

[66, 71-77], Surface contamination of GaAs has been reviewed by Stir

land and Straughan 123), Meek PH] used Rutherford ion bachcatlering of

high-energy ions as a sensitive surface analysis tool to determine the im

purities left on clean Si surfaces from various etch components and or

ganic solvents, Neutron activation analysis of Si slices that had been ex

posed to buffered HF etchant was employed to identify problematic trace

contaminants in the NH4F component as As and Cu [79]; purification of

the etchant by treatment with Si chips (80) effectively removed the im

purities,

A series of 18 symposium papers on the preparation and characteriza

tion of clean surfaces indudes theoretical and practical aspects related to

surface contamination on a variety of materials [811. Ryan ('I ai, 1821 and

De Forest [83] have described the preparation of clean surfaces prior to

photoresist coating, Holland [84] discussed cleaning treatments for glass

surfaces, Brown [85], and more recently Mattox ('I (ii, [86, H7] have re

viewed those for thin film substrates of many types, Short-wave uv radia

lion has been found effective for removing hydrocarbons from glass sur

faces 187. 88] and for removing photoresist residues tH9], Ozonization is

an alternate method that offers several advantages [YO], Selection, specifi

cations. and other aspects of surface preparation processes for numerous

materials have been compiled by Snogren [911,

Surface cleaning by glow discharge sputtering techniques can also be

very effective [851, Most organic suM'ace contaminants are removable by'

chemical sputtering in 0" [92 -941, Sputter etching in Ar removes residual

oxide layers on metals, as noted in Chapter I, Section V,c. However,

"uM'ace recontamination due to backscattering [95-97J or ion migration

)

v-I. CflEMICAL I:.ICHING

11 \

can occur dunng rf sputtering treatillellh,

processing arc employed [91'11. Ultrahigh vacuum h<.:ating <lftn

sputter deaning is effective for dl'sorhing gase,> that Illay b<.:co[lll: inlur

porated into the substrate suM'ace during this operatlO[) I',N -I 0 II,

Finally, glow discharge plasma cleaning should be Iloted ,I" llill.' 01 Illl'

most effective methods for suM'ace decontamination, Klfk /I0211"t:vl,'w",1

its application to semil'ollductor device processing, alld Klllllilliak alld

Mattox described reactive plasma cleaning of metab 11011 Many aspl.'l"l'

associated with plasma reactions at solid surfal'e have h<.:ell discu".sed "

recent symposium 11041,

Two additional very important aspech of ,urface

treatment and storage of the cleaned material. The final rilhillg ill Wi: I

cleaning and etching processes is usually done with water. '111<.: PUI ity "I

the water i" then.::fore extremely critical. Deionized and di'lIllcd watl'l

should be to ;,void recontaminatIOn of tht: High'purity l'ln

ic-grad.: isopropyl akohol a good altt:rnative fin;d rill,t: al ..... , \\;tll'l

The removal of water or "kohol i!\ be"t cfft:Llt:d by gc'n

tic centrifugation rather than by baking, Finally, storage or LkalH:d

teriah bc minimized or preferably avoided altogether hy cilrry IlIg

out the cleaning treatment immediately before the l1e.\t pn'Ll',slIlg Opc't.t

tion. If storage is necessary, chemically cleaned clusl'd gLl" C'OIl!;lll,,'I'

(such <I" Petri dishe,,) should be used and kept in a lOlltdllllllaliull lice

dean-mom almosphne, The frequently plastIC CUlildllll'l , ,Ill' IlIdd"

lluate for this purpose, as they usually CdliSC reCl)(l!;lIllllldtWIl "I Lle;tll Sill

faces due to the emissioll of organic vapor" 17')1,

III, CHEMICAL ETCHING OF SPECIFIC MATERIALS

A, Insulators and Dielectrics

I, (jel/eral COllsideri/l ioll.\

Important msulating and dielectric materials Il1clude dlld dl'p,ts

ited vitreous and Lrystalline llxides, chemically vapordcPlhllcli ICV I) I

binary !\ilicates, fused multicomponent silicate glasse" ('VI) 0" spullLT

deposited nitrides and llxynitrides, and several other Lllmpolllllh III

film or bulk form, The chemical dching properties III each ,.f thl'''l' gnlufh

of compounds will be discussed in this sectioll.

In general, insulating and dielectric material" arc relatlvel),' Iller( dlelll

ically and hence require highly reactive media for etching I,:tchallh of

technical importan..:c arc ammonium Iluoride-buflered hylirllllllllli.: dCld

T

414 WERNI:R KERN AND CHERYL A, DECKERT

t

t. used for patterning by photolithographic techniques, strong aqueous hy

drofluoric acid at room temperature, hot 85% phosphoric acid for pattern

etching with oxide or metal masks, and miscellaneous other etchants,

usually strong mineral acids or bases. Vapor or gas phase etching is used

only in the preparation of insulator substrates,

The majority of insulator and dielectric compounds, being amorphous

or extremely microcrystalline, are classified as glasses, Therefore, etch

ing in these cases proceeds isotropically, and variations in the etch rate of

a specific material in a given etchant are functions of chemkal composi

tion, film density, residual stress, defect density, and microstructure. The

etch rate generally decreases as the density or crystallinity of a material

increases.

As in all etching processes, selectivity is one of the most important

etchant parameters in practical applications, A survey of the uses of se

lective etching of dielectrics in semiconductor device processing and in

analytical applications for compositional and structural characterization

has been published recently 1271.

A qualitative summary of etchants for important insulators and dielec

trics is presented in Table II of Section IV, A more concise compilation

would be of questionable value because the etch rates depend very

strongly on the exact conditions of film formation, Furthermore, materials

consisting of more than one single component, such as silicate glasses,

vary continuously in their etch ralC according to composition, so that a

graphical etch rate presentation is more instructive, Emphasis in this sec

tion is therefore placed on the discussion of general trends and a survey of

specific results and references from the literature,

:1, Single

u, SiO

I

. Etchants for Si0

2

are based almost exclusively on aqueous flu

oride solutions, usually HF with or without the addition of NH, F. The

exact chemical mechanism of dissolution is quite complex; it depends

strongly on the ionic strength, the solution pH, and the etchant composi

tion which determine the available quantities of solu tion species including

Hfo"'2, HF, F-, H+, and various fluoride polymers. Raman spectroscopy

has indicated the presence of numerous reaction product species (such as

hexafluorosilicate ions) in etch solution [281. Detailed studies of the reac

tion mechanism underlying etching of Si0

2

have been reported by several

investigators [28, 105-1111,

Addition of NH.F to HF to control the pH yield" so-called buffered

HF (BHF); it is imponant in pattern etching of Si0

2

films using photore

sist masks ll4J where attack of the photoresist masking layer and the

v-I. CHI;MICAI. ElUIlNG

I I )

polymer /dielectric inteliace must bL' minimil.ed, Ammolliul1l l1uuride illl

dition also prevents depletion of the Ilullnde ions. thu, lIlailllaining stahlL'

etching characteristics, The actual rule of Nil, F mali h..: one "I ;'11

SiF

" (NH')2 precipitating or complexing agcllt mlher than Ihat (11'.111'1,.

buffer 11061,

Selcl:tivity in pattern etching of SiO, laya., 'HI AI devil.:" llIet,t1Ii".tllllll

can be improved over BHF by additIon of it dihydroxy;\k"ll/wIII12Iur .,1

glycerollll3ltll the BHF to inhibit allal.:k of the.: lll,'lal

Pattern etching of SiO" tilms in vapnrs !'rurn aqlll'olis III:, althulI!-!h

used, is an interesting alternative tn liquid c:tehing .iIl.! Ciln Yield

comparable results at rcasonabk rates 111011. It P"H':":"<I, h

y

to! l1I<1tiuli .. I

tluosilicil: al:id, which dissociates in the.: v,lpor phase.: III Sil', and III ..

As with insulator Iii illS in general. the liquid eteh raiL' dC:PL'lllb IIllt

on etchant composition, agitation, and It:mpaature, hilI ai,,, Ull th..: It.-n

porosity, residual stre.:ss, micmstru..:tlllc. ddeLt den'lt y. oad ,ltll

and purity of SiO,. A sub,tantial IIlClca'L' In Ihc Jilk ,)1

SiO, hlms has been observed as ,I n:.,uh uf dcl'eLl gL'lIl'lation by cll:LlJ1l1l

beam irradiation [1151. Ar ion implantation 11161, alld IIlIl homhdrdlllelli

[1171 Heat treatments of SiO" lilms dcpllsikd OJ gl 0\\ II ,II j, ,v,. IL'IllPL'I,1

ture decrease the etch rate due to den.,ilkalHlIl ,)f the ... 1111..:1111": IIIX I

the same holds for other dielectric lilm ....

Silicon dioxide films formed hy diffcrenl prOl:":S.,L'S \,11) wlJcly III Iltl'll

etch rate, mainly because of dirferent:..:, in IIlIClI "IIIJLtlill'.

and/or film density. For exampk. the etch rale of SI( I, al ::OS ( in I'L'k"

(2 vol fiNO" 70'7<, 3 vol HF 49%, 6() vul 1I,OII12111(l1 tilL'lmally ).:1(1\\11

(lOO{)Cl or densitied IihllS is 2.0 A/sct:, for rf sputtered IllIns 01 I A ,,'l

for organopyrolytil: (undensified) hlms A/,el:, 1111 l'i":dl<lIl glill

evaporated films 20-7ll A/sec, and for anodized lilms IX-22l'1 A/,el:! llX

Additional etl.:h rate values for variously prcpan:d Si( J, lillll' 111 III

and in BHF etchants have been n:poned for SiO, gruv,1I by thellll;" 0.\1<1.1

tlon[65.105.106, IOX,1I0,1I1,

evaporation [16], halide reaction [1281, pyrolysi, or v.lr')! o"iLiall()11

of organics [16,129-131]. ()xidation of SiB. at low (- SOO'C, 1119, 12()

132-138] and high temperature [l39-142\. anodizatiOll 116, 101] I. hy ,pill

on reagent solutions [1441. and by plasma reaction" 11015-10171. Norlllal

ized etch rates for various types of Si0

2

lilms have he..:n pUhl"hed 1I-l7a

The effects of HF concentration and temperature [lOS, 107-111, I-lX I.so

and the effects of agitation 1109.123. 14XI on etching ,If SiOllilrn, h'\\..:

been examined.

In addition to HF-.;ontaining et..:hanh. SiO" ,lrghlly !II hili

and hot For examph:, thelllwlly glllwn SI(), I,

etched bv SM KOH at 8'ioC at 50 A/min 11511. and 0.1.\1 N"OH at J(lIlfll

,

f

,

416

WERNER KERN AND CHERYL A, DECKERT

!

temperature at :50,2 A/min [152J. The etch rate in lO wt % NaOH at 23C

f

is 0,1 A/min, at 55C 5 A/min, and at 9OC 500 A/min 1153]. The etch rate

! of oxygen-deficient Si0

2

in HF solutions decreases, and SiO requires the

addition of HNO

a

to attain etchability. Alternatively, hot solutions of con

centrated NfLF mixed with NH.OH or alkali hydroxides can be used for

etching SiO films [14].

b, Ti0

2

, Ta205. and Zr0

2

As a general rule. dielectric films deposited at

low temperature exhibit high etch rates (often due to their low density and

amorphous structure), whereas films of the same compound that are an

nealed or deposited at high temperature exhibit consistently lower etch

rates. For example. low-temperature (l50-3OOC) CVO Ti0

2

[154-156] is

readily etchable in 0.5% HF or in warm 98% H

2

SO whereas films an

nealed at IOOOC etch only slowly in 48% HF or in hot H

2

S0

4

or H

3

PO.

{154, 154a, 1551.

Pyrolytic Ta

z

0

5

films deposited at 500C are soluble in dilute HF [157].

Films of amorphous (but not high-temperature crystalline

films 1158)) formed by anodization of deposited Ta films can be etched in

HF-NH.F solutions [159, 160], Electron irradiation of Ta205 (and AlzOa)

films decreases their etch rates [161], in contrast to SiO

z

films. Tantalum

penlOxide films can be patterned with 9 vol NaOH or KOH (30%) plus I

vol H,D: (3()%') at 90C using a Au mask; the etch rate ranges from 1000 to

2000 A/min 1I62. 1631.

Monoclinic zr0

2

films prepared by CV 0 from ZrCl. at 800-1000C are

slowly etchable only in hot H

3

PD

4

[164].

c. AI

2

0

a

. Films of AI

2

prepared by CVO below 500C [165-169], 0

a

grown by plasma oxidation [147. 1701 formed anodically [161, 171, 172],

or deposited at low temperature by evaporation [ 161, 1731, obtained on Al

by boiling in H

2

0 [174], or deposited by sputtering [175-1771. are etchable

in HF. BHF. warm HaPO., and etchants based on HaPO. Thermal densi

fication at 7oo-8ooC tends to form crystalline modifications that exhibit

much lower etch rates [165, 168].

Aluminum oxide films deposited by the AICI

3

hydrolysis process at

9OO-IOOOC are nearly unetchable even in concentrated HF solution and

require boiling 85% HaPD. [135. 178-180). The etch rate in 85% HaP04 at

180C is typically 100 A/min; etch masks of CVO Si02 are useful for pat

terning these films [181].

Selective etching of anodic AI

2

0

a

on Al in multilevel integrated cir

cuits can be accomplished, without attacking the AI. by use of a solution

containing HaPO. and CrDa [182J.

d. Bulk Oxides. Sapphire (a-AI

2

0

J

), spinel and beryllia (BeD)

ulled as substrates for heteroepitaxiaJ CVO of silicon layers are slowly

,}

v-I. CHEMICAL t.T(tllNG

..J17

etchable in /)ollmg concentrated H;;PO,-H

2

SO, mixtlln:, IMI.

phase dchlng at high temperatures has abo been u'>l'd slIccl'.ssfully for

polishing sapphire [ISS) and spinel 1 OissollHion l)f surfacl' irn:gul;1/

itles from crystalline AI"O" has been accomplished by trl'alll]cnh \\ IIIi

molten V" 0" above HOWe 1 mclls of K,S,O,. PhO PhF" <tlld v,n

have been used for dissLllving sapphile 1 lkO call be clL"hcd III hOI

(120"(,) HCI , .... ,

e. OIlier o.ridl:'s. Films of Nb"(), ) and CVI> 111'0, ) IX');Jj ;I/C

etehable in HF. The etchability or (ieO, depends Oil ils IT)stallllgldphlc

moditkation, as noted in Table I of Sc.;ction IV, S,\t:lal 0111,1 llxidcs "I'

importance are classilied under Compound Sl'flllCllllllllclors and arc diS

cussed in Section III.B.4,

3. Einarv (llId tertiary Silical' G/II.I.I/'I IItld Or/dl'.1

a, PIIO,lphwiliclIl'S, The inCLlrporation of I',(), III thL' Si(), lid V>, 1I J...

yields technically very import,mt phosphosih,at.: gtl"l" (PS( i). Ihl' .:tl Ii

rate in bLlth HF and BHF increases wilh increa;..ing p, ;I, shown in Fig 1

for a variety of tilm and etchant compositions. Th.: Illw-lelllj1e'ratlll" ('V t)

lilms were prepared by chemical vapor reactIon frulll Sill" PH,. ;lIld (),

in N, at 450(' 1190-lnl. Densitkation trl'atmenh were dune in N; :d

1000"(' for 60 min. as indit:atcd The thelmall'S(j layer, We'll'

taim:d by rem:tmg vapors of PO(,I" II '>3lllr 1',0, II 9-l1 Will! SiO, al 1000 (

The graphs illustrate al a glance the prollllUIlC.:d .:1'1',,:1., of COlllpusilllll1

and densily for a given phosphorus cllllcelltration, ;lIld thl' ",nt.'ll'IlL" III

Selectivity of a typical BHF compositIOn and" VdflCly or IIl1hult't:rcd III

mixture..,. Note that tht: ekh rate of PSG ill Bill: i, Illlllh k\\ allCC:kd h"

the film compositiolll137. 1l)511han in the 1Il1hurfcre'd Illl.\lurc, Ilu\\l'\'l'l.

the logarithm of the cll:h rate varies in all case, linearly \\lIh Iht.' P e<HIC,1I

tration. More complete graphs relating etch rate with Ijlm l'omp!hllltill

and CYO conditioos have been published clsewhen: /117. 1951

The eteh rates Llr PSG films deposited from Sill, ' PH" and (), III '\1 .II

350C, and containing 0-9 mole P,o", exhibit a maximulll in 'i0';

diluted buffer etch (48% HF:40% NH,F: H,O, I: 10: II hy Volume) llie'

increase in etch rate with increasing P CLHltent in the glass suggests lltal

the SiOi component of the PSG is dissolved by the hufkred HI' alld Ille

1'2

0

5 component principally by waleI' /196/,

Additional etch rale studies have been n:ported IlII PSG Iilms Ple'

pared by low-temperature (300-500C) oxidation ofthc hydride, 1136,1')7

20 I], by high temperature (1000-1100"(.') reaction of SIO, wilh 1'0(1, oJ

[150, 193, 194. 197,202,2031, and by pyroly,is "I' 'ligall')lIIet;tlli

l

',

(700-800C) 1204J,

()

41M WERNER KERN AND CHERYL A. DECKERT

60001 I r

I HF/Z HzO,U'C /

10

I

I

HzO

, I HFI ,

,

,

2t 8 io 4 6 12 14

GLASS COMPOSITION, molt ... P

2

0

5

Fig. J. Etch rates of phospho silicate glass films versus mol % P,O, in the glass. 450C:

CVD films from SiH.-PH,-O,-N,; IOOOC: CVD film densified at IOOOC in N, for I hr.

Thermal, HF/H,O, P/H,O: SiO, + POCI.<O,J at IOOOC [193]. Thermal, P-etch: SiO, +

P,O.(Nal at I02O"C [1941 (from Kem [271. This figure was originally presemed at the 149th

Sprin& Mulin& of The Electrochemical Society, Inc. in Washington, D.C.).

b. Borosilicates. Binary borosilicate glasses (BSG) are important as dop

ant sources and in silicon passivation [77,205]. In early literature, it was

reported that the HF etch rate of CVD, BSG, typically deposited at 450C

from Sill., and O

2

in N

z

, increases strongly with increasing B con

tent, whereas in BHF it decreases sharply with increasing B content to a

minimum and then increases with further B increase [190,199]. These re

sults have since been confirmed [126, 196, 206-209]. A series of graphs

exemplifying the etching behavior of BSG films is shown in Fig. 4 [1%].

Boron oxide at moderate concentrations in BSG, existing as a borosilicate

rather than as B

2

0

3

, appears to protect the SiO

z

from attack by buffered

HF; at high concentrations B

2

0

3

bonding may be impaired and solubility

in water becomes a more important factor, resulting in an increased etch

rate [196). Several other explanations have been proposed [28, 199,206,

'071.

1000

:

,

....

x

u

..

'"

X

y

450' /

I HFl2 XOL,22'

/

//

//1/

I

//

/11/

/ / THERMAL

I /'-P-ETCH,

/

//

-

-----

I I _

/ .-<'" ERIlAL

I . H

Z

O,24

1f

)

v-I. CHEMICAL lTCHINt;

-J I '}

8001 r-----r T - - r

I

700

.,

I

-I

1

z -I

.i

I

200

J

I

I

1

,00

-i

I

1

_L j

0 10 20 JO

I/OLE'I. 8,0, IN GLASS

Fig. 4. Etch rale' al 26" , IT uf heal'[rea[ed horu."licalc gl.,,, III"" III Bill, 01 ',II ''''',

mole percent H20:.! 10 the gl<l\.'I. i:lt.:hlllg '10111111111'1 \.\.L'It: II)

adding di,[IIlcd H,O in [he proportion, indicalcd [0 B H I, ( I () vol N 11.1' I '01 III ; ,

Afler lIl;n a[ 1000"(' III Ar .), IlXl'X buffered HI': .',. \()'; huflcled 111, . 10'; I"dklcd

HF: A, 17< buffered HF (frolll Tenney and Ghe//o 11%1. lel'lIll1ed h) l'elllll"IOIl 01 1"1'

publi,her, The Eleclruchemlcdl Society, Inc I

Etchant for I3SG hav.: b.:.:n r,:pllrtcd lilal arc p.lIlll[1

larly selective with to the B t.:onl.:nIIIIX. 1%, Il}I). 2111

these are useful III analytical and applll'dIIUII' Ikn,i/Il'''"''11

by thermal treatmenb lowers the etch ral.: of BS(, III "II eldldlll, II'JI,

19M, 199,212].

c. Arsenosilicutes. Chemically ar'':lIo,illl'dll: gl""c'

(AsSG), used as diffusion in deVIl'': l.:dlllUlogy. c;ln he

pattern etched readily in BHF [200, 213). Th.: ell'il I'd!\:' 1l1('VI) :\,\(,

films densified at llOOQC in Ar increase logarithmil'ally ano IilllilOlllnll'all)

with increasing AS20 3 content from 0 to H mole I;; :\'i ),1, a, ,h()wlI III

Fig. 5, with a nearly twofold increase III the ett.:h r;ll.: mcr lhi, UlIll'':1I

tration range [196, 214 J. The incorporation of in lhl: fhS(, ,I [[[l'1111 e

during CVD, used to improve the l'il'lladelbllc,. en

hances the etch rate of the film [215 J.

d. A/ufl/illo.lilic(ltl's. Chemically ,ilLIIIlIl\I),dll'dll' b

l

.. "

(AISG) films are abo ett.:hable in H F and III B/I F II h 7. I II')" 2 I I..

420

l

WERNER KERN AND CHERYL A. DECKERT

1500r,----,r--,---,-----y

;1000

i

:!

...

:..

Ill:

J

l

0

__-L----L_ L_ _

I 2

WOlt % As! 0, IN GLASS

Fig. 5. Etch rates al 26"": loe of heat-Ireated arsenosilicatc gla" films in BHf versus

mole percent As...Q, in the glass. Etching Mllutions were prepared as noted in Fig. 4_ After 5

hr at Ilooe in Ar: 0,1000/0 buffered Hf; to. 50% buffered HF; . 100/0 huffered Hf; . 1%

buffered HF (from Tenney and Ghezzo 11%1. reprinted by permiion of the publisher. The

Electrochemical SocielY. Inc).

217]. The incorporation of AltO;J into the glass structure tends to decrease

the P-etch rate of the AISG, whereas the addition of PbO increases it in

comparison with Si0

2

[16]. High-temperature CVD films containing more

than AI

2

0

a

are resistant to HF but are etchable in hot HaPO, similar

to AI

2

0

a

.

e. Other Silicates alld Oxides. Additional binary and ternary silicate

glass films synthesized by CVD bdow 500C are all etchable in aqueous

HF solutions, and include zinc silicates, zinc borosilicates, alumino

borosilicates, aluminophosphosilicates, lead silicates. and lead borosili

cates [190, 191, 199J. Chemically vapor-deposited AltO:! containing sev

eral percent Ta.JOs becomes amorphous and etchable with HF or BHF

(218). Germanosilicates are etchable in BHF.

Anodically grown native oxide films on GaAs are readily etched in di

lute HCI solutions. Films heat treated at 600C become unetchable in

Hel, HN0

3

NH.OH, or NaOH solutions, but they can be etched in hot

concentrated HaPO. [2191 or concentrated HF.

Plasma-grown oxide films on GaAs are practically insoluble in acids

and alkalis except boiling HCI (50-80 A/min) [220). Plasma-grown

oxides of complex composition on GaAsu.tiP

o

, and GaP, on the other

hand. arc easily soluble in acids amI alkalis! 220J.

- ._------------

f

)

v-I. CIH-MKAL ETUllNG -I I

4. Mliltic()llIpollt'1I1 Silinlft' Gla.\.\c,1

Lileralllre rden:nt:es on etching of llllllticompoll<:llt "ili":<lt<: gld"<:'

are very st:ant and are mostly cont:erned wllh ..:hemical durahility and "Ill

wsion effects 1221, 222J. The essential component in all gla" .:1 ... 11

ants is HF. In general, addition of 13

2

0

3

ZnO, and PhO to the SiO

t

lIel

work im:reases the etch rate, whereas incorporatlllg AI,O, hd' ..

de!.:reasing effect and leads to improved ..:hcmical n;"htallL:': of the glil\\

[2221.

Certain glass compositions reqllire th<: additIOn of eompicxlIlg ag,'lIh

to minimize precipitation of insoluble metal iluoride n:actants Ihat Ill.!,,,

and hinder smooth etching. Agitation, important III all <:tching proc<:"c,_

may therefore prove particularly important in attainillg good lIllifolllll!)

Ultrasonic treatment during ett:hing can aho be useful. A...ld,tabk '111

factants funuion.ing at low pH can be added to tilL' <:Ichanl tn <:Ilh<lll":

wetting characteristics and, in the ..:ase ofpatkrn <:tdllllg, fUrlh<:r impml<:

pattern resolution. Additlllll of HCI and H,S04 to aqU ...'Ulh 11/: .... khanl L';tll

convert insoluble fluorides into solllhk salts I 1

Some silicate glasses wilh very high Pb content ar.... 'lllllhk ill "'Ill<:"11'o

H NO., /2241. A reagent containing !.:<ltedwl and cthylell<:lliailline t .... lliI;\l1'

tic acid etches soda-Iim<: glass at a uniforlll rate of 10- 15 IlllL:rfel,'lll"

fringes per hour I.

Etch rates in P-et .... h of fused BSU and Pb-llSG lilllls have heell I,'

ported [118, 2261. Some lead have et .... h ralc, In I'-el<..' h lip ("

SOU A/se..:. as .... ompared to Corning 7740 Pyrex gla'o\ wilh II A/we. alld

thermal SiO, with A/sc..: [2261. Etch have alSll heelll<:pllltcd III I II

sputtered Corning code 172U AISG [2271 and (Jenelal lle.... l.ic (lSC' 1 BS( i

[22HI.

Most sili..:att: glasses arc slowly <Lltac"ed by hot ( ",po,.

for example. ct..:hes al a rate 01'0.05 /-Allli mill at I 'iW( 'I :>:"11 Pyn:x glil\\

also et..:hed slowly by hot 9H% H"SO, 11,0, ( 1 . II. alld I,} h"l Cllii

centrated solutions of NaOH or KOH 1791.

Etch rates of several types of glasses in the forlll "r pld"" .... 11' nil

tained in our laboratory 1791; it summary of thl' Ic,ull'> " pI <:,<:lltcd III

Table II (Section lV.AI.

5. Nitrides ami

Silicon nitride in thc form of thin lilms is uf grcal pla,-llc,1I

in semicondUl:tor electronics because of lis ctlcctlVetle\S ii' ilil al"ali dil

fusion barrier. Chemi!.:ally vapor-deposited Si,N, hlllh .lIe deil;d,,," al

room temperature in concentrated IIF or Bill-', III IU'(), at 140--:'00 (.

in 49'/? H F -70% H NO, (3: 10) at 70"C, and in molt<:1l N a011 at 4)0 ( I 14.

T

422 WERNER KERN AND CHERYL A. DECKERT

230). The etch nile is strongly affected by the presence of any oxygen

linkages in the films; in HF and BHF it increases with increasing oxygen

content, while in it decreases.

The dissolution process for CVD films in acidic fluoride media

follows the same rate law as does thermal Si0

2

l23

R =A[HF] + B(HFil + C,

whereR is in angstroms per minute and the concentrations are molar. The

rate constants for the dissolution processes are summarized in the accom

panying tabulation.

Film Temp,oC A B C

Si.N. 25 0.16 0,31 <0,0001

60 1.9 3.7 - 0,02

Sio. 25 2,50 9.66 0,14

60 10.4 48.6 102

Pattern etching of films is usually carried out by reflux boiling of

85% HaPO. at 180C, with CVD SiOi as an etch mask. The etch rate under

these conditions is typically 100 A/min for CVD SiaN., but only 0-25

A/min for the CVD Si0

2

etch mask and 3 A/min for any exposed single

crystal Si [232]. It should be noted, in this connection, that boiling

must be treated with special care because of its complex chemistry [232.

233J. Etch rate plots as a function of temperature and H

3

P04 concentra

tion are presented in Fig. 61232].

Equal or similar etch rates for SiOi and are required in applica

tions where the etched composite structure must have patterned walls with

uniform taper angle. Hydrogen fluoride-water mixtures of optimal ratio

at elevated temperature can etch composite layers of SiaN. and Si0

2

at an

equal rate lllO, III J, A 0.25 wt % HF solution at 90

D

C etches thermally

grown Si0

2

and typical CVD SiaN. films at an equal rate of 70 A/min

[234]. A 0.20 wt% HF solution at 90C etches SiO, at 45 A/min and SiaN.

at 60 A/min; a near-unity etch rate ratio is generally preferable for film pat

terning of this type [234J. Comparison of activation energies for Si3N4 and

Si0

2

dissolution processes suggests [231] that achievement of equal etch

rates is also facilitated by use of low pH etchants, which maximize [HF]

and minimize [HFi].

Films of "silicon nitride" deposited by plasma-enhanced CVD at low

temperature [235] have very much higher etch rates than high-tempera

ture CVD SiaN. [137, 146. 147, 236-240]. These rates depend strongly

upon the film composition, which may be expressed as SirNwH. [235]. It

has been suggested that these plasma silicon nitride films should be re

-l \ \

v-I. CHEMICAL I:TCHIN(;

2

\:

loor

\

\

8 \

6 \

\

41- \ \ "0.. S',N.

\

\

\0

\

\

\

"

...

E

\

.",

10 . \

\ S"N. AT CONST CONe Of w

I- 8

.. \ 94::. ... H,f>O.

'"' 6

:x:

<.)

I-

w 4

\" \

S,O. (660'C S, CI. +0t + H.I

2

__I

26 f('K")l< 10'

94.5 93 91.5 895 81 83,5 19.5 CONCE"'TRATION ("'H,PO.)

Fig, 6. Solid linc" elch ralc of SI,N" SIO" and Si III [diu,"" h.,dlll); pil'"l'iI''' k .h hi ,il

pre\:-.un..: a fUIKIlOn ofhoiling lCmpl,..'ratl.lfl' and .iI.!t! ((lIh.TOII,ltWIl I)" ... hl..'d

line. etch raie l)f at a com.:entratiun 1)1',)4 )(''t .I'" d jlllldlOIl tllll.'IIIPU,l

lure only (from Van and liall,,,r 1232). repnnled by permi"I"" "I Ill" puh",h", I h,'

ElCLlroo.:hemICal Soo,:,ely, Inci

gan.led as a polysilaLane with unique i'<lthel Ihdl1 ;1' ;, val Il'l \ "I

silicon nitride 12401.

Sili.:on nitride deposited by te..:hniqu..:, "hi) hill,' 11,'

quently lower et.:h rates than Si,N I if they are kss d..: II ,e , I,ll gc'

quantities of gases. and luI' nonsllli.:hiollll.!tl'li':,

A very extensive review uf the IIkrature on d.:i1ing d"ta or Si, N j ;lIld

silicon oxynitrides was prepared by Mikk 12301. Mor..: le..:ent resulh ul

etching have been report;:d llll Si" NI prepared hy ev J) 1110, I [ I ,

241-243], by sputtering te.:hniques [244 -2461. ,Ind 1'01 anodi..: ":UII"":"'1<1I1

of Si,N. to [247

,

,

KERN AND CHERYL A. DI:CKERT

Thl! elch rall! 01 !>11l..:un <JA) 1IIlIh.lI: 01 lilt: generi:1ll1JnTIUI...

is strongly influenced by the conditions and by film den!>ity and

stoichiometry 12301. Typical ett.:h rates for CVD Si.,-NUO" films (prepared

from SiH NH

3

, and NO) in 48% HF are 300-500 A/min, as compan:d

with 30.000-50,000 A/min for and 130-150 A/min for in tWc

HJPO. at l80

a

C the etch rates are 10-100 A/min (or Si".NuO" 8-10 A/min

for SiO

z

, and 60-100 A/min for 1248). More recently, some addl'

tional data have been published f 249], including data for glow-dist.:hargc

deposited films 1147].

Other nitrides for which etching data are available include CVD amur

phous films that rapidly dissolve in concentrated HF, HNO", and

hot HJPO. [250, 250al. Aluminum nitride, BN, and GaN and have been

included in Section III.B.4 on compound semiconductors.

B. Semiconductors

J. Elemental Semiconductors

Silicon is by far the most important elemental semicondut.:tor

of its widespread use in modern microelectronic and photovoltaic

Another elemental semiconductor, germanium, has be.:ome of lesser im

portance. Because of their similarities many of the etching processcs can

be applied to both. The discussion of Si and Ge etching shall be kept 'ier)

brief because of space limitations. A more detailed presentation has been

published elsewhere [27a). Specific details on etchant t.:omposition. et..:h

ing conditions, etch rates, and applications are listed in thc tables of &,;

tion IV.C.

Selenium is a group VI elcmental semiconductor for whit.:h very lillie

information on etching ex.ists. However, all three forms of Sc. are sulubk

in HzSO . In addition, the amorphous modifications are soluble ahu In

CSt. the monoclinic form in HN0

3

, and the hex.agonal crystal form In

CHCI

3

The discussion of elemental semiconductor etching that follows is t.:un

cerned ex.c1usively with Si and Ge.

a. bmtropic Liquid Etching. Isotropic chemical etching of semicondu..:

tors in liquid reagents is the most widely used etching prol:ess for remu .aJ

of work-damaged surfaces, for creating structures or planar surfaces In

single-crystal slices. and for pallerning deposited semiconductor

For Si, etchants containing HF, HNO

a

, and H

2

0 are most frequentl)

used; Ge etchants based on HF. H

2

0

Z

' and H

2

0 are typical. Extcn,i.c:

!>tudies have been reported on the mechanism ofSi etching in HF-HNO,

)

.j ) ,

v-I. CHEMICAl. [ICIllN(i

HF (49

50

40

30

H

2

0 90 80 70 60 50 40 30 20 10 HN0, (b'l %)

fig. 7. Curvc\ of ton!',ltwt fate of I.:hangt:' of die loi(klll..'''''' (I1ul" I'd 1IIIIliltlc' >wUllllllllt.:d

I""U Si ""arcr d\ a fun..:tion of i,.'olllpo\uillll, III till' ,..Pi'; ffJ 70'; Jfl\.t

,),Iem (from SchwurlJ. und I{oholn, [256). repnnkJ by perm",,,,,, "I II.c puhl"hc. I Ill'

S''''lcI y, Inc L

1,2521, in ternary mixtures of HF-HNO:,-HtO, ami in .HjU":OIl\

HF-HNO,,-CHaCOOH compositions 1253 -2561. In high III dd}anh III..:

HNO

a

(ofll.:cntration ddcrmincs the ett.:h rate bCC<lll\": (l.\llbIIOn I, III..:

rate-limiting step. In high-HNO

a

the etch 1<11..:, alc a tUllc

lIuI1 of only the H F becallsl; in this case dissolution is til..: (all'lillli [(Ilg pi"

1253]. In Figs. 7 and i\ iSllctch rate o!!l' ,hUWIl lor III,

HF

b(),

20 iO HNO\i'l(J4b"t..)

fig. 8. Curve!:lo of rate of I.:hunge of dH.': thil..'kIH.. PI,,'I HHUlil",' dHnhlllL'd

1"'0 SI wafer ,urfa,e,) a, a fl'nd;on of eldlanl ,ompo,Jiwn.o Ihc' (.0'; III' 9(1'; IIN() '>'

lem. the dYed of added ,,,taly'l (NaNO,) is ,ho.... n '" Ihe d",heu IlIIe\ (110m Selman, ,Hld

RobbinS 1256], reprinted hy permi,sion of Ihe pub!"her. The Ekelr(J,"clI",',,! S"c'lel)

426 WlRNlR KERN AND CHERYL A. DECKlRI

t1f(4925%)

O

PEAKED CORNERS

a EDGES

rn!!I SQUARE CORNERS

Ii:i;I a EDGES

rn

ROUNDED CORNER

a EDGES

t1

Z

0

Fig. 9. Resultant geometry of the etched Si die as a function of the etthant comp<hHlUO

in the 48% HF-70% HNO:. system (from Schwartz and Robbins [256], reprinted by perm ..

sion of the publisher. The Electrochemical Sodety. Inc.).

HN0

3

-H

1

0 in normal and high concentration acids. The resulting ge:om

etry effects on initially rectangular (I I I)-plane parallelepipeds (II-type:.

2n-cm dice) are indicated in Figs. 9 and 10 for the same elcnants. The: ac

tivation energies for both Si and Ge in HF-HNOa-CHaCOOH eh.:hant

confirmed that the processes are diffusion controlled [257]. Silicon is aho

soluble. to a very small extent, in HF solutions and BHF [258-260J. 11.0'

Hf(59n%1

o PEAKED EDGES a

CORNERS

. SQUARE EDGES a

O CORNERS

m

ROUNDED EDGES

a CORNERS

O

CONI/EX LENS

. SHAPED

H2 0

Fig. 19. itesuJtant geometry of the etched Si die as a function of the etc:hant wmp.., ..I"",

IR the 6O'JI) HF-9O% HNo" system (from Schwanz and Robbins [2561. reprinted b) pel"u>

sion of the publisher. The Electrochemical Society, Inc.j.

,.,-,

v-I. CHEf'ileAl EICHIN(, ,",.1

tropic liquid etching has been used for thinning tlf tie ami Si 1261

266]. for prepassivation surface cleanup 12671. and fnr poli,hlflg 126X-2791.

Germanium etchants based nn HNO,,-HF-Il,O 01 HNO,,-lIF

CH

3

COOH are difficult to control, mainly hccau,e III varlahk

periods [280-2841. The -H/) etch system alTolo, mudl hell<:1

control !280, 284,2851. Removal of thin layers Cie can aC(llrnplished

with 3% H,O, at pH 3.8[286]. Additional iSHlropic ckhanb I ::!X7 -2<).'\ I Ill(

Gc: have been included in Table IV of Section IV.

b. Allisotropic LicluiJ /:'tchitlf{. In anislltmpi.: or orientaliolHJepcmkll1

etching, the etch rate varies within the crY,lallllglilphic .lile<.:

tions of the semiconductor single nyslal. Orientation dln:h have been

allributed III crystallographic pmpertie" parti,ulady Ihi.: denSity of ,til

face free bonds, the relative etch rate IIlcrea,ing wilh Ihe numher of avail

able free bonds 18,.296-2981.

Anisotropic liqlliu e!chants for Si arc 1I,1Ially ,11"alill .... ,uiulillll., l"ed <II

elevated temperature 121. 124, 121 The e"enlial kdlilfe lor ,ilicun

technology of all these solutions is their lip to 100 time' IlIgh<:l el .... h ratt: til

the ( 100) uirection than in the <II t) direction 1J<n, 10..) I hll i.:),.;lIl1pk ill

the case of the water-ethylenediamine-pyn.H:atechol etch'lIlt. the i.:l<.;h

rales of (100). (110), and (III) oriented Si are appr"xlIllilIL'lj- . .lli. \

p.m/hr. respectively !J Ill. Anisotropic etchin or (100) SI through " p;t1

temed SiO, mask creates precise V grooves with Ih.... i.:ug.... " heing I II II

planes, at an angle of 54.r rmlll the (IOU) ,lIrt'ace I'll'krcllIi.d etcilllig

allows fabrication of high-ucnsity monolithic imegratt:d c'lrc'Ulh 10 ..1\1.

3141. Si-on-"apphire integrateu I26X. j051. altd ,)lllel SI dnicn

that require structuring and patterning 1311 , 315 -3::!OI. i\lmlllloplC ek h

of Ge I'm crystallographic studies has been reporled 13211

(". Electrochemical (llld Selective Chellllcul Ercililll:l. Fkliillg ot" 'ellllLllll

ductms in liquid reagents by application o/" an extallal emf i, 1I.,ed Illi

preparing mirrorlike surfaces and creating very thin 'Ingk Ct y,l.d tilin,

Fundamental, theoretical, and practical aspects of semlcondllctor ekcllll

chemistry have been thoroughly treated in ,everal b"o"" and reVll'V'

130-37,39-41].

Specific shapes can be imparted to Ge and Si ,ulltl"lllled

localized electrochemical etching 1322-3:!41, uf (J I.: allli

Si has been achieved by several techniques 1325-32XI

Selective electrochemical etching of single-crystal Si ,ub,lIak." hdV

ing suitable epitaxial structures has been empillyed fllr preparing very thin

Si crystals [269,329-336], P-type and heavily dllpeu Illypl' SI call hi.:

dissolved anodically in dilute (1-5 tv) HF al sufticiently In .... voltage,

.,.,hereas II-type Si does not dissolve. Selective "I

f

WERNER KERN AND CHERYL A. DECKERI

n' -type Si substrates is also possible with alkali solutions in which Ihe:

etch rates are strongly dependent on the electrode potentials [303, 337.

338].

Anodic oxidation of Si in electrolyte solutions based on organic mel"a

{339], followed by oxide dissolution, has been described for sectioning 10

the determination of Si diffusion profiles {340J. Objects in contact with the

Si surface can either slow down or enhance the local etch rate consider

ably [34l}. Substrate and etching conditions in the anodic dissolution of Si

in aqueous HF can lead to brown layers, etch pits, and porous channel)

1269,322,328,329,331-333,337.342-344] caused by preferential etching

and partial dissolution at localized sites (251, 331-333].

films of porous Sit formed purposely from n- and p-type Si by anodic reac

tion in concentrated HF 1329, 344-346], are very similar or identical to

these brown channeled layers.

Selective etching to dissolve Si of different dopant types and re!>i!>ti\i

ties can also be achieved by chemical technique without use of external

electrodes [263.268.304.347-3581. exemplified by Fig. II and the dat.a

presented in Table VI of Section IV.

d. Gas- and Vapor-Phase Etching. Gas- and vapor-phase etching ale

widely used for polishing of Si substrate wafers in situ prior to epitaxl.d

crystal growth. The most successful reagent is sulfur hexafluoride. Sf,.

It produces a smooth, mirrorlike surface when reacted in a dilution v.ith

HI at 950C [359) or (more usually) above I050C. according to the overall

reaction [360]:

4 Si (.) + 2 SF, (gl -+ SiS-, (!> or l) + 3 SiFt (8)

1 I==PRfFfHp::J

l:

..

....

...

o

l:

u

....

w

I I

--r '.

1 )( 10

11

, )( 10'8 , )( 10'9 , )( 10

20

BORON CONCENTRATION

!'i,. II. Selective etching of .ilicon: Si (100) etch rate per minute ver>u. boron cuo,cn

tralion. Etch"nl i. KOH-H,O-i>opropyl alcohol at sire (from Kuhn an.J Itll

(34!1). reprinted by of the publisher, The Electrochemical Society. Inc.).

.j

v I. CHEMICAl. ETCHING

Since the free energy of the reaction is 706.l:l1 10.<.:,11/111<)1.: at 140W('

[361], the etching proceeds and irrevcl'lhly. pludu<.:ing

volatile sulfides and fluorides of 5i as the readioll PWdll<.:h 13hOI. The

etch rate as a function of temperature for O. I SF" i, ,tWWII in

and as a function of SF" partial pressure in Fig. 1.1 1.1021. The

of SF

6

over other reagents lie in the non<.:orro,ivellc", 1l0lllOXlcity, and

low temperature needed, in :.Jdditiun to the cxcellent pl;ulanly attainahle

which makes the process applicable for waleI' thtnllillg.

Other vapor etchants used fur polishing Si arc IICI I \IlJ .nO \, HBI

[365[, HI [371.3721. CI2 [373], H

2

S [1741. HI-HI' In.'' .l7hl, and 11,0

[377,3781.

In general. gas- and vapor-phase eteillng is not depelllkill 011 the le,l,

tivity level or type of the Si. Condition, call be ,elected Jlt the tI('J -tl,

etching system that -result in anisotropic etching of vam>!I' cl st;1I plalles

al difTerent rates; this has been exploitcd lechnolnglcally III ,ei.:clivl'

taxy 1367,309,370], as noted in Section IV, Table VII.

Similar to Si, (IIIJ-Ge can be puli,h et<.:hed With IICI, III

H,. H,5-H, !3t\01. Superior results arc (lbt,linahle with II: -II,() vapul "t

'JOO"C which produces clean, structurc!es, surfaces 11XOI.

TCMPEI,Ai Ufll

121>":/ 'lIN

.!:

:;

..

1,.'l1tv'

,;

u

' ..

:

>- ""

(ii

1

J

""

Fig. 12 ""1: IJ

FIg, 12, Vdpnf uf SI J.th: \l'j '1\1\ \Ulhll,II,: h.:t1Ij\t.'!,llWl' I'll

.. of 10 .1 dun (fl Stln"ofl t'l al" 1,1621, ICpl Inkd h) p.:rllll",,>jull 01 lilt.' pubh"hLI

rh( Ek';\Il)chcmicJI SOCl"t y. Inc!

fig. J3. Vapor phase eh:hing DI \dl(on: Sf ch.:h rak Vel 'Ill") SFji p'lillJtI pi t'",\111 C ,d IUt)O (

,trum Sun"," ,'I ul. /1621, perm""'''1 01 the puhlhhc, I he l.icd,uclicllllc

StJt.:1(ly. Inc.).

430 WERNER KERN AND CHERYL A. DECKERl

e. Chemical-Mechanical Polishing. Polishing by combined chemical

and mechanical processes is usually the last step in preparing flat and spec

ular wafers in silicon device manufacture. The generally preferred tech

nique is the silica-sol (Syton [381]) method [382, 383]. The medium con

sists of a colloidal suspension of silica gel in aqueous NaOH solution of

controlled pH and is dispensed on the polishing pad of a rotating poli!>hing

machine. Silicon removal proceeds by oxidation of the surface by water in

the presence of the alkali ions and continuous dissolution of the surface

oxide, aided by the silica gel which serves as a mild abrasive [383-31561.

The process can also be used for polishing Ge wafers, but H

2

0

2

be

added to the dispersion to achieve a smooth surface finish [3153].

Another process for 5i employs an aqueous solution containing copper

and fluoride ions [387, 388]. The Cu+

2

ions are reduced by Si to metallic

Cu, and Si is oxidized to Si". The Cu deposit on the wafer surface re

moved by a polishing cloth, while the oxidized Si dissolves as fluosilicate.

Mechanical polishing without use of abrasive particles can be com

bined with liquid chemical etching by moving the semiconductor wafer

with uniform pressure on a polishing cloth soaked with the etchantliquid.

This technique has been used for Ge [389] and GaAs [390, 391].

Several reviews are available on semiconductor slicing, lapping, an"

polishing, and the damage introduced by these operations [5, 3!52-3H5.

387, 392-394).

2. Compound Semiconductors

Several reviews are available on etching of compound semiconductor,.

[2,5,7.10,13,19-23, 43a); a very recent survey [27a] was prepared in con

junction with this chapter to complement the tables in Section lV.D. We

shall therefore only outline this section, and present the details later 10

Tables VlIl-XIII.

a. Group IV Compound Semiconductors. The only group IV compoulki

semiconductor of technical importance is silicon carbide (SiC). Etchanl\

consist of molten alkalis or borax [395-397 j, Cla-Oa at 900C and aJ:x.l\e

[396, 398J, and H2 above I 600C (399J (Table VIII). Electrolytic etching III

HF solution is specific for p-type SiC [397, 400].

b. Group III-V Compound Semiconductors. The single most impor'

tant compound semiconductor is single-crystal gallium arsenide

Etching reactions of this, as well as other compound semiconductor" 4f(,

complicated because of crystallographic surface orientation elTe.:t

Chemical etching of GaAs (and other III-V and II - V I compound l>Cml

conductors) proceeds by oxidation-reduction-complexing a.Jl4I.

ogous, in principle. to the general mechanism for Si and Ge etching.

)

vI. Clll.MICt\I II CIlI N(, ..HI

The mo,t commonly employed etchanh for (jaA, an: Ih, ('H"UII

-404], NaOH-H,Ot 1405, 4061, H,SO,-H,O,-H,O 1 4()6-40H I, <lnd

NU,OH -H"Ot-HtO 1404, 4091. High-viscosity ct<.:hanh 'lich a,

HCI-HNo., are prderred for chemical polishing 14101. Jet etching aml/ol

rotation on a polishing pad have been used with several et.:hallh f'lI

polishing and thinning 123, 266, 390, 391, 404, 411, 412

Orientation-dependent etching charaderisti.:, of HH,O" - IH,O

IH,SO. were utilized for etching .::hanneb of V<I(iou, geometric, fur

Gunn.. effect logic circuits 14131 and for superlatlice stllictUI es deposited

by molecular beam epitaxy 14141. Gallium an.enidc douhle helt.:rostfuc

ture lasers have been fabricated using a SllHHJthly acting sekctive elcllant

(onsisting of CH"OH-H"PO,-H,O, 14151. Several addiliunal etehal1h

have been used for crystallographi<.:ally preferential eh:hing 14tU. 40K.

4O'J, 416-41!-:1. Older but useful chemical solution clehanh 419 4241

arc: also listed in Section IV. Table IX. It should abo he noted that very

thin ( 100 A) carbon films are imperviolls to C0l11111011 ..:h:ilallts for 111 V

..:ompounds and can therefore be us;:d as eXl.:dlenl P<Ltl<:ru ddillilllll1

masks 14251.

Etching of GaAs can abo be accomplished by e lect 1111; IiI.: leLillllljllCS

10 alkali solutions [426-4301. in HCI-Ht<) 1411 J. Ill' in IINO, !I,014121