Professional Documents

Culture Documents

Safari - 21

Safari - 21

Uploaded by

bernardOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safari - 21

Safari - 21

Uploaded by

bernardCopyright:

Available Formats

Volvo FH

‹ The template Infobox automobile is

being considered for merging. ›

The Volvo FH is a heavy truck range

produced by Swedish truck

manufacturer Volvo Trucks. Introduced

in late 1993 as FH12 and FH16,

production still continues with the now

the second generation of FH range

model lineup. FH stands for Forward

control High entry, where numbers

denominate engine capacity in litres.

The FH range is one of the most

successful truck series ever having sold

more than 400,000 units worldwide.[1]

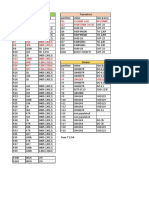

Volvo FH series

Overview

Manufacturer Volvo Trucks

Volvo FH Bitren

Also called

(Argentina)

Production 1993–present

Gothenburg, Sweden

Ghent, Belgium

Wacol, Queensland,

Australia

Durban, South Africa

Assembly Kaluga, Russia

Bangalore, India

Curitiba, Brazil

Tehran, Iran

Cairo, Egypt (Ghabbour

Group)

Body and chassis

Class Heavy truck

COE

Day cab

Body style Sleeper cab

Globetrotter High

cab

Ford F-MAX/JMC

Related

Weilong HV5

Powertrain

Inline 6 turbodiesel

intercooled

Volvo

D12A(12.1 L)

420 309kW

1993–1998

D12C(12.1 L)

420 309kW,

460 340kW

1998–2001

D12D(12.1 L)

420 309kW,

460 340kW

2001–2005

D12F(12,1 L)

420 309kW,

460 340kW

2004–2006

Engine EGR

D13A,B,C(12.7

L) 2005–

present

D13K(12.9 L)

2012-present

(Euro VI)

D16A,B(16.1 L)

1993–2001

D16C,E,G(16.1

L) 2006–

present

D16K(16.1 L)

2015–present

(Euro VI)

Cummins

ISX600(14.91

L) 1998–2006

(Australia)

14 speed synchro

manual

SR1900

(1993–1998)

SR(O)2400

(1993–1998)

VT2514(OD)

(1998–

present)

VT2814(OD)

(2006–

present)

VT(O)2214B

(2012-

present)

VT(O)2514B

(2012-

present)

VT(O)2814B

(2012-

present)

16 speed synchro

manual (ZF)

ZT1816

12 speed semi-

automatic (I-Shift)

V2512AT

Transmission

(2007–

present)

V(O)2812AT

(2007–

present)

VO3112AT

(2008–

present)

AT2412D

(2012-

present)

AT(O)2612D

(2012-

present)

AT2812D

(2012-

present)

ATO3112D

(2012-

present)

ATO3512D

(2012-

present)

6 speed automatic

(Powertronic)

VT1706PT

VT1906PT

Chronology

Predecessor Volvo F series

In September, 2012, Volvo Trucks re-

launched the Volvo FH with significant

technology upgrades.[2]

History

In late 1993 Volvo had unveiled its

replacement for the legendary F

cabover series in production for almost

15 years.[3] The development of FH in

what it appeared to be a clean sheet of

paper design took seven long years.

The development of the all-new design

12 litre engine with its overhead

camshaft and electronic unit injectors

technology placed Volvo among the

world's leading engine designers.

First Generation (1993–

1998)

A first generation FH16 prime mover

There were two models, FH12 and FH16

which shared common cabs and

chassis and the FH12 immediately won

"Truck of the year" award in 1994. The

16 litre engine, gearboxes and the

driveline were carried over from

previous generation albeit with many

improvements and the host of

additional features including all new

Volvo engine management and its

diagnostics for the D12A engine.

Design and Technology

Cab

The cab produced at Umeå from hot dip

galvanized, high tensile steel allowed

for greater strength at thinner panels

and box sections while reducing overall

weight. The new FH cab was a logical

progression from, for its days spacious

but boxy F series cab to more

aerodynamically efficient, with much

improved ergonomics and much better

seating unit while reducing overall

weight of the cab by almost 30%.[4] The

cabin was extensively tested in a wind

tunnel to confirm shape aerodynamics

properties to reduce air-drag thus

improving fuel efficiency. The cab

featured more sharply raked

windscreen while wedge shaped sides

rounded into front panel at much wider

radius corners and the rear vision

mirrors were also streamlined. The

cabin was subject to the toughest cab

impact test where procedure involved

placing a 15 tonne static weight on the

roof and one tonne pendulum striking at

the cab rear wall and at the windscreen

pillars, at the end of which the cab

doors must be able to be opened.[5] In

1995 Volvo FH series became first

heavy duty truck to be fitted with a SRS

airbag to further improve passive

safety.[6]

D12 engine

From the design angle the new D12A

engine was one of the largest engine

projects from Volvo Trucks since the

1950s at the time. The basic design was

still based on direct injection in-line six

diesel engine around 12 litres

displacement but with entirely different

fuel and valve systems when compared

with previous Volvo engines. Built at the

purpose-built facility at Skövde on a

fully automated line where the bulk of

the engine assembly is done by robots

and the final engine dressing is carried

out manually. The D12A was designed

as a "world engine" to be able to meet

the latest demands in high power

output, low fuel consumption and lower

emissions with its single OHC (overhead

camshaft) design, four valves per

cylinder and one centrally located

electronic unit injector, integrated

engine compression brake and two-

piece, steel and aluminium pistons. The

engine design left the door open for

future upgrades in both power output

and emission technologies.

VEB

VEB The Volvo Engine Brake is a

compression type engine brake first

introduced on D12A and since used on

later designed OHC engines from 9 to

16 litre displacement. The brake

operates on a principle where exhaust

valve cam followers acts on secondary

cam profile when engine brake is

activated. Engine oil pressure is used to

eliminate extra valve clearance thus this

action forces the follower against

secondary lobes and unseating exhaust

valves temporarily to achieve so-called

compression bleeding as employed by

similar systems from Jacobs, Cummins

and Mack however Volvo system has an

extra cam lobe thus giving two openings

of the exhaust valves and is designed to

work in conjunction with an exhaust

brake so two of the engine's four

strokes are used to raise engine braking

effect - Exhaust and Compression

strokes.

A view of VEB rocker arms

Operation Description

The exhaust stroke is used

when exhaust brake shutter

closes exhaust manifold after

turbocharger opening as a

result exhaust back pressure

is raised creating braking

effect.

The compression stroke is

used next to utilise the back

pressure in exhaust where at

the piston's Bottom Dead

Centre the exhaust valve are

opened briefly and high

pressure in exhaust manifold

is than let in acting against the

piston moving upwards on its

compression stroke thus

slowing it even more [further

explanation needed, exhaust

braking functions in relation to

cylinder pressure, not piston

speed] and increasing the

engine braking effect.

At the end of the compression

stroke just before piston's Top

Dead Centre exhaust valves

are open briefly again to

release "bleed" compression

thus again slowing the piston

on its subsequent downwards

movement and consequently

achieving engine braking

effect while also storing the

pressure in the exhaust

manifold again using the

exhaust brake shutter ready

for the next repeat of the

cycle.

Version 98 (1998–2002)

FH12

In conjunction with introduction of FM

series in 1998,[7] Volvo had facelifted

existing FH series with minor

modifications to the cab but major

upgrade to the electrical system, engine

and gearbox. The so-called TEA (Truck

Electronic Architecture) introduced a

technical solution to possibility of

various electronic control units to work

and communicate with one another. The

systems have been linked using two

data buses or data links which allowed

control units to exchange relevant

information over the data network.

Electronics

TEA is a computerized control and

monitoring system which is used to

control and coordinate the various

functions of the vehicle main

components. The control units

communicate over what is known as

CAN at two speeds SAEJ1587/1708

@9600 bit/s and SAEJ1939 @ 250 000

bit/s where up to eight Electronic

Control Units were used to control

various functions. J1939 data link is

used for mission critical rapid

communication among ECUs and

J1587/1808 is used for diagnostic and

programming link as well as "slow"

communication e.g. for back up

purpose. The new instrument cluster

included a LCD panel to show

information or diagnostic messages

from the systems broadcast via J1708

data link.

D12 facelift

The original D12A engine was

considered as a rather conservatively

power rated and expectations of higher

power output from such an engine

design was always at the mind of not

only designer but customers alike. The

D12C differs from earlier version

substantially with completely

redesigned engine head, timing gears

and addition of bottom end of

reinforcement with a stiffening

subframe to cope with increased power

output to 460 hp (340 kW).

Gearbox

The gearboxes were based on previous

SR1900 series and shared the same

number of gears and gear change

pattern. The SR2400 series gearbox

was discontinued and replaced with the

now same model shared across entire

FH and FM range. Torque increases

from 1900 Nm to 2500 Nm were due to

changes to machining of the gears as

well as use of the new type of narrower

synchromesh mechanism allowing

increased gear width. The single control

housing and the synchro mechanism

reduced gearchange effort by about

50%.[8] The control housing was also

identical for left and right hand drive

versions reducing overall production

cost and assembly.

Version 2 (2002–2012)

FH version 2

In 2001 Volvo introduced the third

generation of the FH and FM series with

the cab and driveline given major

makeover.[9] with an investment cost of

600 million euros [10] Major changes

included redesign of the cab to improve

aerodynamics, the new automatic

gearchange transmission, I shift, new

electronics system and engine

improvements.

New Cab

The changes to the cab included a new

day cab, which is 150 mm longer with

redesigned air intake and flat floor. New

rear view mirrors were introduced to

reduce blind spots and improve air flow,

new headlights and front side marker

lights, new split sunvisor and new wider

front steps complemented the external

modifications. The interior was

redesigned with more rounded edges

around the dashboard and new seats

with integrated seatbelts. Integrated

telephone speaker and microphone with

steering wheel controls for radio and

inbuilt GSM phone were an option.

As a standard equipment FH models

also included FUPS (Front Underrun

Protection System) to further enhance

safety by preventing smaller vehicles

from being "underrun" or wedged under

front of the truck in an event of frontal

collision.

TC and I-Shift

D12D's further development of

venerable D12C resulted in

increased power output to 500 hp

(370 kW) equipped with turbo

compound (TC) technology which

utilise more energy from exhaust

gases after the turbocharger using

an extra turbine to drive the engine

crankshaft via hydraulic clutch and

reduction gearing. The cooling

system changes coincided with

more advanced electronics for

engine management system (EMS)

with electronically controlled

cooling fan which was now fully

controlled by the Engine ECU

(EECU) and as a result fuel

consumption is also reduced.

I-Shift control housing

You might also like

- A4cf0 - HyundaiDocument29 pagesA4cf0 - Hyundaijair75% (4)

- JPNZ International LTD 0800 MANUALS WWW - Jpnz.Co - NZ Look Inside To Find The Owners Manual For Your Japanese Spec VehicleDocument18 pagesJPNZ International LTD 0800 MANUALS WWW - Jpnz.Co - NZ Look Inside To Find The Owners Manual For Your Japanese Spec Vehiclemikeadrian50% (6)

- Unimog U 1550 L / U 1550 L/37: Technical DataDocument2 pagesUnimog U 1550 L / U 1550 L/37: Technical Dataquzwzwvfxuyoiovwnc100% (1)

- Automotive Milestones: The Technological Development of the Automobile: Who, What, When, Where, and How It All WorksFrom EverandAutomotive Milestones: The Technological Development of the Automobile: Who, What, When, Where, and How It All WorksNo ratings yet

- How To Make An Orgone Field PulserDocument59 pagesHow To Make An Orgone Field PulserDon Templeton100% (2)

- Instructions PDFDocument2 pagesInstructions PDFjorge maganinhoNo ratings yet

- Transmission Oil Cooler Recommendations - ESA - 04 - 877724 PDFDocument6 pagesTransmission Oil Cooler Recommendations - ESA - 04 - 877724 PDFApdel Rahman Razzouk100% (1)

- Osk Catalog 2019Document50 pagesOsk Catalog 2019Francisco JimenezNo ratings yet

- Hino Dutro Ranger Profia EnginesDocument2 pagesHino Dutro Ranger Profia Enginesmei jonie83% (12)

- Alarmes - Fiberhome (Ok) PDFDocument282 pagesAlarmes - Fiberhome (Ok) PDFiury garcia100% (2)

- 5630 InstructionsDocument8 pages5630 InstructionsGrzegorz ŚliwaNo ratings yet

- Alfa Disc ManualDocument427 pagesAlfa Disc ManualmarketingalbieNo ratings yet

- Data Sheet 9500 Euro 6 EN 2017Document4 pagesData Sheet 9500 Euro 6 EN 2017lopezNo ratings yet

- Voltage Regulator NikkoDocument1 pageVoltage Regulator Nikkomuhammad aliNo ratings yet

- SB 10072051 7690Document2 pagesSB 10072051 7690johndere2090No ratings yet

- GAL1880CV Part ListDocument1 pageGAL1880CV Part ListLjubitelji Lepih RukotvorinaNo ratings yet

- GAL1880CV Part ListDocument1 pageGAL1880CV Part ListПавлин Пейков0% (1)

- Service BulletinDocument19 pagesService BulletinChaly AaSaNo ratings yet

- Data Sheet B13R 6x2 LE Euro 6 en 2022Document3 pagesData Sheet B13R 6x2 LE Euro 6 en 2022Giuseppe AndrewNo ratings yet

- List of Lubricants ZF AstronicDocument14 pagesList of Lubricants ZF AstronicBroCactusNo ratings yet

- Data Sheet B8R Low Entry 4x2 Euro 6 EN 2020Document4 pagesData Sheet B8R Low Entry 4x2 Euro 6 EN 2020Gustavo Andres PinedaNo ratings yet

- Ningbo Zhongwang Auto Fittings Co.,Ltd: Regulator ListDocument15 pagesNingbo Zhongwang Auto Fittings Co.,Ltd: Regulator ListRichard BlancoNo ratings yet

- Water Pump Quotation From Cinaautoparts 2020.11.09 Email Cinaautoparts@Document6 pagesWater Pump Quotation From Cinaautoparts 2020.11.09 Email Cinaautoparts@Wang KathyNo ratings yet

- Service Bulletin 21-008-06Document8 pagesService Bulletin 21-008-06Red Hat2KNo ratings yet

- WAI Štartér Alternátor A Diely 2013 Made in Korea PDFDocument8 pagesWAI Štartér Alternátor A Diely 2013 Made in Korea PDFEmad SmsaahNo ratings yet

- Part 3D: Full - Time 1WD With Engageable 2WD (Non - Diff)Document27 pagesPart 3D: Full - Time 1WD With Engageable 2WD (Non - Diff)Maties MotoNo ratings yet

- Diesel Information: DT5230 (EN)Document2 pagesDiesel Information: DT5230 (EN)AminadavNo ratings yet

- SPS PB AutomotiveStandardsMatrix 1207 e 0004Document1 pageSPS PB AutomotiveStandardsMatrix 1207 e 0004Krzyszto FPNo ratings yet

- Honda: Group Engine Year No. Displace No. Model Cyl. Ment G A18A G A20ADocument7 pagesHonda: Group Engine Year No. Displace No. Model Cyl. Ment G A18A G A20AЕвгений Дынник100% (1)

- 8018 MiniEx Spec Revised EnglishDocument4 pages8018 MiniEx Spec Revised EnglishGuptaNo ratings yet

- Ipdstyle 1-2-3™ Gasket Sets: The Standard For Quality, Innovation, Service and Support Since 1955Document28 pagesIpdstyle 1-2-3™ Gasket Sets: The Standard For Quality, Innovation, Service and Support Since 1955Marlon GeronimoNo ratings yet

- Lexus Toyota ManualDocument37 pagesLexus Toyota Manualjorge morillo100% (1)

- Data Sheet B8R 6x2 Euro 6 en 2020Document4 pagesData Sheet B8R 6x2 Euro 6 en 2020Giuseppe AndrewNo ratings yet

- SB 10059670 2273Document10 pagesSB 10059670 2273benjaminNo ratings yet

- MTU Marine Spec 10V12V16V2000M96LX 1DSDocument2 pagesMTU Marine Spec 10V12V16V2000M96LX 1DSfernando machadoNo ratings yet

- 13.GPD155-F All New Nmax 155 Connected Version TransmissionDocument1 page13.GPD155-F All New Nmax 155 Connected Version Transmissionandi yusufNo ratings yet

- L958FDocument2 pagesL958FUbaldo Enrique Caraballo EstradaNo ratings yet

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDocument16 pagesAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezNo ratings yet

- Heavy Duty Products 2019-2020Document55 pagesHeavy Duty Products 2019-2020jakapurnama97No ratings yet

- Transmission Oil Cooler - Eng - 03 - 1983226Document12 pagesTransmission Oil Cooler - Eng - 03 - 1983226Giovani Pardinho100% (1)

- 8227-60mw Wartsila PP Scope of SupplyDocument4 pages8227-60mw Wartsila PP Scope of SupplyCursed RonyNo ratings yet

- GR 00 GENERALDocument8 pagesGR 00 GENERALAffan fNo ratings yet

- Basic of LawDocument108 pagesBasic of Lawชม พู่No ratings yet

- Capacidades y Dimensiones de MontacargasDocument16 pagesCapacidades y Dimensiones de MontacargasFredy ReyesNo ratings yet

- Parts Catalog - Power Train - 2Document273 pagesParts Catalog - Power Train - 2Val SoquilaNo ratings yet

- Static Pneumatic Tired RollerDocument2 pagesStatic Pneumatic Tired RollerKaharuddin PutraNo ratings yet

- S1-Yfce18k 1 PDFDocument723 pagesS1-Yfce18k 1 PDFVictor Montesdeoca100% (1)

- Productivity For A World That'S Always N.: X12 For Truck ApplicationsDocument6 pagesProductivity For A World That'S Always N.: X12 For Truck ApplicationsOscar CampoNo ratings yet

- Citroen OBD-2 Diagnostic Pinout Diagram @Document1 pageCitroen OBD-2 Diagnostic Pinout Diagram @Antonio Cerracín GonzálezNo ratings yet

- Cat - Throttle BodyDocument27 pagesCat - Throttle BodyAndres PachecoNo ratings yet

- Lol Te ML 13 enDocument3 pagesLol Te ML 13 enmuhammad saputraNo ratings yet

- 120GCDocument20 pages120GCPram BudiNo ratings yet

- ts200-t2 201811Document2 pagests200-t2 201811Tasman SevenNo ratings yet

- LEDriving LED NB Fahrzeugliste en 25102023Document11 pagesLEDriving LED NB Fahrzeugliste en 25102023pabloNo ratings yet

- JCB Vibromax - Compaction Equipment Self-Propelled Vibratory Roller Vm46D/Vm46PdDocument2 pagesJCB Vibromax - Compaction Equipment Self-Propelled Vibratory Roller Vm46D/Vm46PdArbey GonzalezNo ratings yet

- Eol Us 2005Document1 pageEol Us 2005Anonymous mqsR6k1q6No ratings yet

- Jepretan Layar 2023-01-09 Pada 12.34.36 PDFDocument2 pagesJepretan Layar 2023-01-09 Pada 12.34.36 PDFYana SurianaNo ratings yet

- Parts Air Suspensions Leaflet PTDocument4 pagesParts Air Suspensions Leaflet PTFlávio MirandaNo ratings yet

- Carros 2Document43 pagesCarros 2Nathan CrestaniNo ratings yet

- Vehicle Service Quick Reference Guide: Covering 1998-2012 Honda VehiclesDocument64 pagesVehicle Service Quick Reference Guide: Covering 1998-2012 Honda VehiclesCharles IsaacsNo ratings yet

- Diesel Engines 10V/12V/16V 2000 M86: For Fast Vessels With Intermittent Load Factors (1D)Document2 pagesDiesel Engines 10V/12V/16V 2000 M86: For Fast Vessels With Intermittent Load Factors (1D)Micael FigueiraNo ratings yet

- Super Great 1Document2 pagesSuper Great 1PTG SerenNo ratings yet

- FMDS0796Document26 pagesFMDS0796Felipe Mees FaracoNo ratings yet

- Piston Diagnosis Piston Diagnosis - A Rough Guide: Generally Well Set UpDocument7 pagesPiston Diagnosis Piston Diagnosis - A Rough Guide: Generally Well Set UpÁlvaro Jiménez OrtizNo ratings yet

- Dishwasher Is A Machine For Cleaning Dishware and Cutlery Automatically. Unlike ManualDocument4 pagesDishwasher Is A Machine For Cleaning Dishware and Cutlery Automatically. Unlike ManualXMEN ツ MoRtAlNo ratings yet

- Damped Oscillations - Forced Oscillations and ResonanceDocument27 pagesDamped Oscillations - Forced Oscillations and ResonanceVirgilioNo ratings yet

- Week 9 Data Warehouse ConceptsDocument35 pagesWeek 9 Data Warehouse Conceptssavvy_as_98-1No ratings yet

- BDC MatDocument6 pagesBDC Matsathish11407144No ratings yet

- IBM Think Pad ManualDocument630 pagesIBM Think Pad ManualRasdumi100% (3)

- Hilti Firestop Application Handbook 2017 A4 14Document36 pagesHilti Firestop Application Handbook 2017 A4 14dexterbox1No ratings yet

- A 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsDocument4 pagesA 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsRamanathanNo ratings yet

- A Comparative Study of Different Materials of Connecting Rod: A ReviewDocument4 pagesA Comparative Study of Different Materials of Connecting Rod: A ReviewSairaj AcharyNo ratings yet

- Ecsch Vtu SyllabusDocument7 pagesEcsch Vtu SyllabusPradeepKumarSKNo ratings yet

- Refer DXF or DWG File For Laser Cutting. 2. Part Inspection Is On Finished DimensionDocument1 pageRefer DXF or DWG File For Laser Cutting. 2. Part Inspection Is On Finished DimensionBala MuruganNo ratings yet

- Project Brief SummaryDocument19 pagesProject Brief SummaryResearcherNo ratings yet

- CFA PilesDocument293 pagesCFA Pilesfludor100% (1)

- TS 147 Surge Mitigating Infrastructure 20160407Document30 pagesTS 147 Surge Mitigating Infrastructure 20160407Vinish HARIDAS NAIRNo ratings yet

- What Is The Difference Between Bios and CmosDocument27 pagesWhat Is The Difference Between Bios and CmosArchie KinsNo ratings yet

- Ventilator Drager Carina PDFDocument4 pagesVentilator Drager Carina PDFlukas adi nugrohoNo ratings yet

- Sling 4 TSi Pilot Operating Handbook - Rev 2.2Document174 pagesSling 4 TSi Pilot Operating Handbook - Rev 2.2Gourav DasNo ratings yet

- 29 GIS SeismicDocument6 pages29 GIS SeismicKhader Abu-daggaNo ratings yet

- 6N137 HCNW137 HCNW2601 HCNW2611 HCPL 0600 HCPL 0601 HCPL 0611 HCPL 0630 HCPL 0631 HCPL 0661 HCPL 2601 HCPL 2611 HCPL 2630 HCPL 2631 HCPL 4661 - High CMR High Speed TTL Compatible OptocouplersDocument21 pages6N137 HCNW137 HCNW2601 HCNW2611 HCPL 0600 HCPL 0601 HCPL 0611 HCPL 0630 HCPL 0631 HCPL 0661 HCPL 2601 HCPL 2611 HCPL 2630 HCPL 2631 HCPL 4661 - High CMR High Speed TTL Compatible OptocouplersGiapy Phuc TranNo ratings yet

- Iphone 8 Plus D21 PCB LayoutDocument2 pagesIphone 8 Plus D21 PCB LayoutPablo ArancibiaNo ratings yet

- Gmail - FWD - Mechanical National Conference - Udpdate in Website-RegardsDocument4 pagesGmail - FWD - Mechanical National Conference - Udpdate in Website-RegardsYUVA RAJA BNo ratings yet

- The Data Warehouse Environment - Building The Data WareHouseDocument52 pagesThe Data Warehouse Environment - Building The Data WareHousebondaigiaNo ratings yet

- Pulk / Sled / Ahkio: Huck Finland OutsidecampingDocument10 pagesPulk / Sled / Ahkio: Huck Finland OutsidecampingquaeNo ratings yet

- How To Write SAS Code in SAS Enterprise GuideDocument20 pagesHow To Write SAS Code in SAS Enterprise GuidemrtooncesNo ratings yet

- History of ReliabilityDocument7 pagesHistory of ReliabilitypirotteNo ratings yet

- Lab ExerciseDocument3 pagesLab ExerciseUmie Nur AisyaNo ratings yet

- FLAT CurriculumDocument1 pageFLAT CurriculumPunithRossiNo ratings yet