Professional Documents

Culture Documents

WPS No 04 - NTPC TAPOVAN PROJECT - MS TO MS (HIGHER GRADE MATERIAL)

WPS No 04 - NTPC TAPOVAN PROJECT - MS TO MS (HIGHER GRADE MATERIAL)

Uploaded by

alok9870 ratings0% found this document useful (0 votes)

34 views3 pagesWPS MS toMS

Original Title

WPS no 04 -NTPC TAPOVAN PROJECT - MS TO MS (HIGHER GRADE MATERIAL)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS MS toMS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

34 views3 pagesWPS No 04 - NTPC TAPOVAN PROJECT - MS TO MS (HIGHER GRADE MATERIAL)

WPS No 04 - NTPC TAPOVAN PROJECT - MS TO MS (HIGHER GRADE MATERIAL)

Uploaded by

alok987WPS MS toMS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

ea crerel fortes

are cr Lsavad tered

‘ {orn Maton Teta Bown! Coxon Lt

reer

wntie NOIDA

Reference: TVHEPP:902:2254 Date:07-05-10

From: CTF To: Om Metals InfraProjects Ltd.

‘Tapovan Vishnugarh Sh S K Srivastava

Om Metals infraProjects Ltd.

NBCC Plaza, Tower-IIl, 4th

floor

Sector-5, Pushpa Vihar,

‘Saket, New Delhi-110017

ce: kota@ommetals.com

ashok@ommetals.com

nu

in purpose code.

‘SUBJECT : TVHEPP, HYDRO MECHANICAL QA

Please find enclosed following drawings/documents for necessary action at your end as indicated

VENDGR DRG NO:

null

NTPC DRGNO: —_5505-902-QVM-W-04

REVISION NO: 03

DRG TITLE: WPS-04

APP CATEGORY: |

RELEASEDATE: 07-05-10

‘COMMENTS: CAT

Comments in Drawing

fe mn ee, a Bn, ea 3, ee (5 9) F201 S07

ete 320-2805, 21006 -090-260196, 2610397

ste tn: a, mare aes, 7 akan Gey, sie, 10 005,

vee 2 cu-maniow eeros-ais0, FMT MAC cOIO

ENGINEERING OFFICE COMPLEX Plot No: AA Sector Pot Bot Nov 13, Nota (UP Pin 01307

Telephone No:O120 2110855, 210126 Foe 10-200156 2610097

Engineering Division Reputered Ofer NTPC Bhan, Scope Compt 7battinal Ars, Loh Roa New Deil30003

180 9001:2008 Certified: Taephane No OL 2435000 FancIL-2136015, Webs rwwnpesoin

%

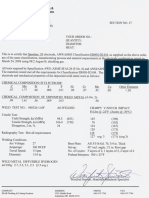

WELDING PROCEDURE SPECIFICATION (WPS)

NAME & ADDRESS OF MANUFACTURER

(OM METALS INFRAPROJECTS LTD.

‘Manufecturer's Logo | B-117/118, 121.4, KOTA-324005 (RAL)

‘WPS, NO. 2 OMN-WPS-E

REY.NO.: 3

(REV, DATE: 34062010

PAGE: 10F2

REF, PACKAGE : HYDRO MECH. PROJECT.

PKG.NO. 5505-002

‘SUPPORTING POR NO: DATE

NIPGISFROIECT TAPOVAN VISHNUGAD EPP MAIN CONTRACTOR: OM METALS INFRAPROWECTSLTD

ITEM DESCRIPTION : Spitlway Radial Cate, Spitway Stoplog

Gate. Intake Service & Emergency Gate Desig Chamber

Ouiftl Gate, Sit Flushing Tunnel - Service & Emergency Gate,

HRT Inake - Service & Emergeacy, Surge Sha Gate, Vall Race

‘Tunnel Gate, Ta Rave Tunnet Qual Gate and Adit Ge,

(cefer io both backing and Feialners

Ld Mew! (J Non fusing Metat

ES Noomeattic 5 otter

Slatches, Production Drawings, Welding Symbols or

‘Weiusn Description should show the general arrangement

‘Of the parts to be welded, Where applicable, the roct

spacing and the details of welling grove may be specified.

(Acthe opdon ofthe Migr, sketches may be tached to

‘huss jot design, weld ayers and bead sequence, e.g.

for mitch toughness procedure for inultipls process

precedures, .)

‘BASE METLATS (Qi-405)

Chern. Analysis & mech Prop.

‘Thickness range ; Buse Metal Groove

Other

‘HILLER METALS (QW 0H

Spec. No. (SFA) AWS:5. 7

ANS No. (Class) I

ENO

WELDING PROCESS ( TYPES ANAL

TOUTS (QW 402)

Joint Design __Double “Wiiuu Joint

Backing (YesTNioj_X

‘Bucking Material (Fype)__—_

PLNe 1 Group No, wP.NO, Group No.

ae

‘Spesfication ype & gre 1S; 2062:2006 1535041 /E4S0) OR Seilma 3504/41 0}1VSSU4i1__to specification spe & grade

1S. 2000:2005 cA SOMEA OES) OR Suma SSOHUIOKASOHL ORT sichestorade isto be used for POR

__ To Chem, Analysis & Mes. Prop.

wwe

'T FOR WELDING PROCEL ASF Eat es Re

ia elie

genset rer e507 ——

ee a

TEE See GMT e08 20

Coeation,

WES Approved subjew to Sutstavtory POR

ENGGDIVIOA 81

WELDING PROCEDURE SPECIFICATION (WIS) | WS. NO. OMIL-WESoE

NAME & ADDRESS OF MANUFACTURER [REV.NO.: 3

(OM METALS INFRAPROJECTS LTD. REV. DATE: 70543010

[Pate Ura. Kotaan08 eA) PAGE :2 OF?

mea ai

POSTWELD WEAT TREATMENT (W207)

Fever 3G “enpeltec Rong MA |

Webting Progression. Up — pall Diana Time as

Posoon hori exsron ay *

ies ferent Cmporton

ses) Mose ow ate

swictting “ia

Traten :

Prat Manca = Eset

‘Contino pci wha epee Ra Be “

estat E —

ELECTRICAL CHARACTERISTICS (GVW

Gansat Aor be De Paar

‘Amps Range) 362805 ——_ Vote (anges Ea

(Aas and voli ange ui be voter Sed foreach slerode ie, pose, diss, ee This information may be sed natn ors

‘Eanlrwtha hows below )

Tugs Bectodesceand Type MA Pure Tangata, 96 That. te)

Mods of sea Truster fr GMAW NA (Spy at suing a,c)

Blea me fed sped NA es

TECHNIQUE (QW)

‘Seng o Weave Bead ‘Sine Hess wih a a

‘Gesitor Gas Cup Sua = = =

{oa and inerpass Cleaning Gnshing. Grinding eis) Choong. hing @ Gading = |

Mie otBuck Coming nding = pe

Qraaton :

eau Toco Work Bae C

Mule Single Pus per 85) Mb om

Yipee Sige Hlecrodes __Sinte int Ru, 18m in Oban At a

Troe Speot Range) "Te inte

Becoeg a

{Stee LN

Peal byes ras car

| Gis te

HAWES [TG | DAE aaa as

tinue

or

Aoviute

sia

erie oe a Se aie Ne :

ROE OWANY SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WIS) AS PER S007 ASHES OWA Bal

Bal Pear Vessel Coe (Reter QW 2001)

WHS Approved subjeet ws Suatacany POW

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A5 6-84RPVDocument4 pagesA5 6-84RPValok987No ratings yet

- 00 WPS STR 10-12-2018Document35 pages00 WPS STR 10-12-2018alok987No ratings yet

- Specification For Copper and Copper-Alloy Electrodes For Shielded Metal Arc WeldingDocument6 pagesSpecification For Copper and Copper-Alloy Electrodes For Shielded Metal Arc Weldingalok987No ratings yet

- Welding EstimationDocument2 pagesWelding Estimationalok987No ratings yet

- WPS No. 05 - TAPOVAN PROJECT MS TO MS (IS 2062 E250B)Document3 pagesWPS No. 05 - TAPOVAN PROJECT MS TO MS (IS 2062 E250B)alok987No ratings yet

- EN ISO 15609-1 135 PG A Step-By-Step ExplanationDocument8 pagesEN ISO 15609-1 135 PG A Step-By-Step Explanationalok987No ratings yet

- WPS No. 01 - NTPC TAPOVAN PROJECT SS TO MSDocument3 pagesWPS No. 01 - NTPC TAPOVAN PROJECT SS TO MSalok987No ratings yet

- Cerjak Enzinger Pudar 39735Document18 pagesCerjak Enzinger Pudar 39735alok987No ratings yet

- DBL-HCC (JV) : /EPC/Bharuch/2020-21/69 ToDocument1 pageDBL-HCC (JV) : /EPC/Bharuch/2020-21/69 Toalok987No ratings yet

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapDocument1 pageESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987No ratings yet

- Listing Department BSE Limited Listing Department National Stock Exchange of India LimitedDocument9 pagesListing Department BSE Limited Listing Department National Stock Exchange of India Limitedalok987No ratings yet