Professional Documents

Culture Documents

SPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS (Singapore Generic - Siphonic) 13092019

SPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS (Singapore Generic - Siphonic) 13092019

Uploaded by

Asoka Kumarasiri JayawardanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS (Singapore Generic - Siphonic) 13092019

SPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS (Singapore Generic - Siphonic) 13092019

Uploaded by

Asoka Kumarasiri JayawardanaCopyright:

Available Formats

SPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS

[Singapore Generic - Siphonic]

1. GENERAL

This section specifies the requirements necessary for the design, supply, installation, testing and

commissioning of a Siphonic Rain Water Drainage System for the conveyance of rainwater from roof areas

and rainwater run-off from adjacent and/or abutting walls.

Siphonic Rain Water Drainage System are specialised in nature. The Contractor shall engage a “Siphonic

Specialist” based on the prerequisites set out below.

The design of the siphonic system must meet the Performance Requirements as stipulated below.

2. PERFORMANCE REQUIREMENTS

The Performance Requirements as set out below are relevant for the drainage of all „open to sky‟ areas such

as roof areas, car park area, canopies all identified in the tender documents.

2.1. The Siphonic Rainwater System shall be capable of draining the effective catchment areas as identified

in the tender drawings. The method of calculation of the effective catchment shall include allowances

and considerations for sloping or curved surfaces and for adjacent vertical surfaces draining to such

areas.

2.2. The rainwater should be conveyed through a suitable pipe conveyance system to the designated

discharge point without leakage.

2.3. The Siphonic Rainwater System should comprise of materials which are suitable for the pressures and

forces resulting from dynamic flow within the siphonic rainwater system. The material should also satisfy

the following criteria for serviceability.

2.3.1. Stability under uv light

2.3.2. Bi-metallic corrosion

2.3.3. Flexural Stiffness

2.3.4. Durability

2.3.5. Expansion and contraction

2.3.6. Loss of strength due to above ambient temperature

2.4. The Siphonic Rainwater System shall be properly supported and braced throughout.

2.5. The Rainfall Intensity to be used in the calculation of the Rate of Run-Off is set out below.

2.5.1. Examples:

2.5.1.1. Rainfall Intensity to Main Roof and Canopies e.g. 330 mm/hr

2.5.1.2. Rainfall Intensity to Car Park Roof e.g. 200 mm/hr

3. PREREQUISITE FOR SIPHONIC SPECIALIST

3.1. The engagement of the Siphonic Specialist by the Contractor is subject to the approval of „X‟ [the Developer,

the Architect, the Consultant, and the Superintending Officer]. Any approval will only be given upon the submission of the

following information being made available to X.

3.2. The Siphonic Specialist shall provide documentary evidence that they have

3.2.1. A minimum of 10 years‟ experience in the design and installation of rainwater systems.

3.2.2. A minimum of 5 years‟ experience in the design and installation of siphonic rainwater drainage

systems.

3.2.3. A minimum of 2 years‟ knowledge of local design practices and local construction

methodologies.

3.2.4. Relevant experience and track record in providing siphonic rainwater solutions for the type of

project being undertaken under this specification.

3.3. The Siphonic Specialist shall provide documentary evidence showing that

1|P age Ver1.0:2019

3.3.1. His design software is suitable for calculating, balancing and generating full design output as

set out in Clause 4 below.

3.3.2. The software has been validated or certified by a recognised and accredited certification body

such as TUV SUD PSB or BBA.

3.3.3. The software is complimentary to and takes into consideration all of the parameters relevant to

the hardware to be used in the siphonic system. These are

3.3.3.1. Pipe roughness coefficient

3.3.3.2. Minor losses due to fittings

3.3.3.3. Outlet resistance (k value)

3.4. The Siphonic Specialist must provide a full Technical Specification of his System(s) which provides

information on

3.4.1. Design and software systems being utilized

3.4.2. Product standards to be offered on all key component parts

3.4.3. System limitations

3.4.4. Installation suitability

3.5. The Siphonic Specialist must submit upon request a list of competent personnel with relevant

experience in the design of siphonic systems and such personnel are sufficient to adequately provide

local support in the design and any design changes throughout the contract period.

4. DESIGN

4.1. The Siphonic Specialist shall undertake and be responsible for

4.1.1. The calculation of the „Effective Catchment Areas‟ based on the tender drawings. Such

calculation shall be made based on SS 525:2006. Clause 7.1. parts 7.1.1.1 through 7.1.1.4.

4.1.2. The calculation of the Rate of Run-off which will be derived from the Effective Catchment Areas

and the Rainfall Intensity as stated in Clause 2.5 above.

4.2. The Siphonic Specialist shall where practical position the locations of the siphonic rainwater outlets and

follow the general routing of the pipe system to the designated discharge points as shown on the

tender drawings.

4.3. In the event that the Siphonic Specialist identifies that the compliant scheme as shown on the tender

documents is impractical to implement he shall immediately make notification of such issue.

4.4. The Siphonic Specialist may present value engineering solutions for the consideration of X during any

phase of the design process.

4.5. The design of all siphonic systems must be carried out by competent personnel with relevant

experience in such systems.

4.6. The Siphonic Specialist shall develop and coordinate his design within the constraints of the building

fabric and in conjunction with the other building services all to the requirements of X.

4.7. The Siphonic Specialist shall design each siphonic system to

4.7.1. Ensure that all pipe materials and pipe system support structure as specified are capable of

withstanding the forces and reactions so applied to them due to

4.7.1.1. Changes in the dynamic flow of the system

4.7.1.2. Thermal and Seismic effects

4.7.1.3. Static Load

4.7.1.4. Hydrostatic Pressure

4.7.1.5. Deflections in the structural elements of the building directly supporting the

pipework, if identified.

4.8. The Siphonic Rainwater Specialist shall provide the following minimum design outputs prior to, during

and upon completion of the installation. Such outputs shall include

4.8.1. Hydraulic calculation showing frictional losses, local losses, head loss, flow rates, flow velocities

and pressure profile together with resultant pipe sizing.

4.8.2. Static calculations of bracketing and bracing support systems.

4.9. The Siphonic Rainwater Specialist shall provide design input or expert knowledge or advice on the size

of any gutters for which a siphonic system provided by them is being drained by that system.

2|P age Ver1.0:2019

5. PRODUCTS

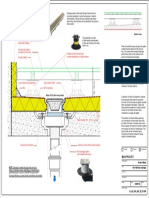

5.1. Siphonic Rainwater Outlets

5.1.1. All key components shall be manufactured from non-corrosive metallic materials such as

Stainless Steel, Aluminium Alloy or equivalent.

5.1.2. The specialist should submit Technical Data Sheets of all outlets to be used in the system

which provide key information including, but not restricted to

5.1.2.1. The vertical height of the air baffle located above the spigot orifice and the horizontal

distance between the air baffle and the spigot wall.

5.1.2.2. The radius of spigot at its interface with the base plate.

5.1.2.3. The flow rate capacity of the outlet and the water depth around the outlet.

5.1.3. All such data should be the result of tests which have been certified or validated by a

recognised accredited certification or validating body. Only outlets which can demonstrate they

meet the requirements of the tests will be allowed. Outlets without fixed Air Baffles are excluded

unless they can demonstrate they work at all dimensional positions.

5.1.4. The siphonic specialist shall provide details showing interface between the outlet and

5.1.4.1. Pipe network

5.1.4.2. Roof membrane/Roof Finishes

5.1.4.3. Gutters

5.1.5. The siphonic outlet should be protected by a leaf guard or be structured to minimise blockage

from leaves, debris and the like.

5.2. Pipe Conveyance Systems

5.2.1. Generally

5.2.1.1. The Siphonic Specialist shall at all times ensure that all pipe materials and pipe

system support structure meets the provisions of Clause 4.7 above.

5.2.1.2. The Specialist shall provide a full specification of all his pipes, fittings, brackets and

bracing required to fulfil the completion of the installation.

5.2.2. Pipe Material & Pipe Support Systems

5.2.2.1. Unless otherwise specified by X, the Siphonic Specialist shall propose the material

for the pipe conveyance which he deems meets all of the technical requirements

stated or specified herein to this Specification for Siphonic Rainwater Drainage of

Roofs.

5.2.2.2. The Siphonic Specialist shall

5.2.2.2.1. Identify the maximum positive and negative pressure within the

Specialist‟s pipe conveyance system based on the hydraulic

calculations and shall provide adequate test data in support of the

adequacy of pipe system intended to be installed. Such test data must

include the pressure ratings (both positive and negative) of the pipe

material, the pipe fittings and any other pipe jointing system being

utilised within the pipe conveyance system.

5.2.2.2.2. Upon request, provide calculations, data and product information

supporting the design and installation of the support system to the pipe

conveyance system.

5.2.3. Pipe Material for Hydrostatic Pressure

5.2.3.1. Where a potential blockage can occur in a rainwater drainage system, the pipe

system must be capable of resisting the hydrostatic forces from such blockage.

Where this pressure exceeds the pressure rating of the pipe system designed for

dynamic pressure under siphonic full-bore flow the specification of the pipe system

under hydrostatic should be made from a suitable metallic pipe material.

6. BCA GREEN MARK AND THE ENVIRONMENT

6.1. NRB 3-2 Sustainable Products – Siphonic Specialists who promote the use of environmentally friendly

products that are certified by an approved local certification body and supply such „Sustainable

Products‟ as part of their system forming part of this specification and which will lead to the

3|P age Ver1.0:2019

achievement of Green Mark Points for the Project will be given preferential consideration over other

Siphonic Specialists who do not provide such „Sustainable Products‟.

6.2. NRB 5-1 Green Features and Innovations – Where the Siphonic Specialist is providing a Siphonic

System in whole or as part of his overall rainwater drainage scheme, such Siphonic System shall be

validated to meet the requirements of Green Mark under Other Green Features.

7. INSTALLATION

7.1. System Installation

7.1.1. All Siphonic Rainwater Drainage systems must be installed strictly in accordance to the design

and installation requirements of the Siphonic Specialist which include

7.1.1.1. Schematics in 3D

7.1.1.2. Layout drawings and details

7.1.1.3. System Installation Manual and Installation Instructions

7.1.1.4. Technical Data Sheets

7.2. System Changes and/or Modifications

7.2.1. The Specialist shall allow for minor changes due to site coordination subject to agreement with

the Contractor. Notwithstanding such changes, X shall be kept informed of such adhoc change

on a regular basis and such changes must be incorporated into the final/as-built schematics and

drawings prior to testing and handover.

7.2.2. Both the Contractor and the Siphonic Specialist shall ensure that significant changes in the

position of the siphonic rainwater outlets or discharge points or of the routing of the pipework

must at all times be approved by the Siphonic Specialist prior to being submitted to X for

acceptance into the final design, installation, testing and commissioning, and handover.

7.3. System Protection

7.3.1. The Siphonic Rainwater Drainage System shall not be used as the temporary rainwater

drainage system without the express approval of X.

7.3.2. The Siphonic Specialist shall take measures to prevent the entry of debris or foreign material

likely to affect the system performance prior to handover of the system at project completion.

During construction such measures may include protective covers to the rainwater outlets or

temporary caps to open ended pipe systems.

7.3.3. The Siphonic Specialist shall if requested and upon approval of X make available either part of

or the whole of the siphonic installation for the use as a temporary rainwater drainage system.

The responsibility for any liabilities which arise from such use of the system will lie with the party

requesting such use.

8. TESTING AND COMMISIONING

8.1. Inspection

8.1.1. The system should be inspected for any visible defects, and where deemed necessary tested,

before any insulation, boxing up, etc is installed.

8.1.2. The system should be visibly inspected to determine whether the system as installed conforms

to the design. Any discrepancies should be referred back to the designer to assess whether any

remedial works are required.

8.2. Concealed Works

8.2.1. The testing regime of all works that are to be concealed within a concrete structure should be

identified and agreed prior to installation.

8.2.2. All works that are to be concealed other than described in 7.2.1 above should, where practical,

be tested in accordance to 8.3 below, before they are finally enclosed.

8.3. Positive Pressure Testing

8.3.1. The system should be tested (see 8.3.2 and 8.3.3) either in parts or as a whole, to check its

integrity against positive pressure. Where the integrity of the pipe system (see 5.2.2.2.1) has

been tested and validated by a recognised and accredited certification body such as TUV SUD

PSB or BBA, such systems shall be exempt from 8.3.2 below.

4|P age Ver1.0:2019

8.3.2. Internal rainwater pipes should be tested with water to whatever pressure is likely to be exerted

within the pipe in the event of a blockage occurring.

8.3.3. Internal rainwater pipes should be capable of withstanding a constant air pressure of 38 mm

water gauge for a period of 3 minutes, after equilibrium has been established. Any drop in

pressure should be investigated, remedial works undertaken and the system retested until no

pressure drop is observed.

8.4. Negative Pressure Testing

8.4.1. Negative pressure testing is considered impractical. In the absence of any practical test regime,

special attention should be made during all visual inspections to the method of jointing of the

pipe system to ensure that it meets the design criteria for negative pressure.

8.5. Flow Testing

8.5.1. It is impractical to flow test an installed siphonic roof drainage system under its design

conditions. Where testing is to be carried out to ensure the integrity of

8.5.1.1. Roof membranes and their interface with rainwater outlets and/or

8.5.1.2. Gutters and their interface with rainwater outlets through ponding on the membrane

roof or filling of gutters (not covered under this specification) then upon completion of

such testing a simple flow test can be observed which will demonstrate that the

system is free flowing.

9. HANDOVER

9.1. Where systems have been sealed to prevent the ingress of debris, all seals should be removed

immediately prior to handover.

9.2. Where systems have been left unprotected the system and the catchment areas feeding such systems

shall be checked to ensure they are free from any debris.

5|P age Ver1.0:2019

You might also like

- Normas Siemens VaiDocument668 pagesNormas Siemens VaiLeonardo CarvalhoNo ratings yet

- Qcs 2010 Part 28.02 Irrigation System SpecificationsDocument38 pagesQcs 2010 Part 28.02 Irrigation System SpecificationsRotsapNayrb100% (1)

- Siphonic System Spec (05.02.2014)Document9 pagesSiphonic System Spec (05.02.2014)zeroicesnowNo ratings yet

- Concrete Cube Testing Template Blank)Document2 pagesConcrete Cube Testing Template Blank)Tamilchelvam MurogayahNo ratings yet

- HRM - Thomas CookDocument52 pagesHRM - Thomas CookSabrish Nair50% (2)

- Basics of EN 206:2013Document41 pagesBasics of EN 206:2013اسماعيل جودة100% (1)

- SRDA-The Siphonic Guide-V1-1305 PDFDocument18 pagesSRDA-The Siphonic Guide-V1-1305 PDFYaseen MallickNo ratings yet

- R Building EnvelopeDocument40 pagesR Building EnvelopeZuhair MasedNo ratings yet

- Synthetic FibersDocument4 pagesSynthetic FibersKhaled Aldossari100% (1)

- Main Project: Roof Terrace Drainage Project NameDocument1 pageMain Project: Roof Terrace Drainage Project Nameing arduzNo ratings yet

- C-SAS-2012 - Concrete Anchor Bolts Catalogue - SimpsonDocument252 pagesC-SAS-2012 - Concrete Anchor Bolts Catalogue - SimpsonRay CoelloNo ratings yet

- Construction Technology 2Document27 pagesConstruction Technology 2SamZa ChiewNo ratings yet

- NEC 3 - When Is The Project Manager Obliged To Notify A Compensation Event, and What Are The Effects of His Failure To Do SoDocument3 pagesNEC 3 - When Is The Project Manager Obliged To Notify A Compensation Event, and What Are The Effects of His Failure To Do SoPaul MaposaNo ratings yet

- The Definition of Green BuildingDocument7 pagesThe Definition of Green BuildingDinidu PradeepNo ratings yet

- Lysaght Roofing Walling Installation Manual Jul 2015Document68 pagesLysaght Roofing Walling Installation Manual Jul 2015hedyNo ratings yet

- Week 2 Ensociety Gineer and Societyrev2Document54 pagesWeek 2 Ensociety Gineer and Societyrev2jhjjhNo ratings yet

- Completion, Taking Over and The Taking Over Certificate in Construction - Why Itâ S ImportantDocument3 pagesCompletion, Taking Over and The Taking Over Certificate in Construction - Why Itâ S ImportantMohamed El Abany100% (1)

- Plastic Pipe Pressures in Siphonic Roof Drainage Systems: Building Research and Information February 2011Document2 pagesPlastic Pipe Pressures in Siphonic Roof Drainage Systems: Building Research and Information February 2011imam muhsinNo ratings yet

- Pipe Wall Buckling in Siphonic Systems - IAHR Conference 2011 by Terry Lucke and Simon BeechamDocument7 pagesPipe Wall Buckling in Siphonic Systems - IAHR Conference 2011 by Terry Lucke and Simon BeechampradiptyaNo ratings yet

- Hydromax™ Siphonic Drainage 17-2-12Document83 pagesHydromax™ Siphonic Drainage 17-2-12Dan O Villarreal100% (1)

- Route To Be A PEngDocument27 pagesRoute To Be A PEngzakwanramliNo ratings yet

- Assignment 2 (Drainage)Document8 pagesAssignment 2 (Drainage)kian hongNo ratings yet

- Wavin QuickStream Specification Oct 14Document6 pagesWavin QuickStream Specification Oct 14Syahrisal SaputraNo ratings yet

- Chapter 22 - Formwork SystemDocument62 pagesChapter 22 - Formwork SystemshingkeongNo ratings yet

- Moment® Post Tensioning System Brochure - Ver2Document12 pagesMoment® Post Tensioning System Brochure - Ver2mdkmlNo ratings yet

- A Guide To Siphonic Roof DrainageDocument16 pagesA Guide To Siphonic Roof DrainageLightninWolf32No ratings yet

- BCAAwards 2011Document156 pagesBCAAwards 2011Chao Yin LingNo ratings yet

- SDS ConceptDocument4 pagesSDS ConceptssarangNo ratings yet

- Culvert DddesignDocument98 pagesCulvert DddesignShashank YadavNo ratings yet

- Cold Water SupplyDocument18 pagesCold Water Supplyrenatosalazar21No ratings yet

- Precast Concrete Piles (JKR) Concrete Products MalaysiaDocument1 pagePrecast Concrete Piles (JKR) Concrete Products Malaysiafaraeiin57100% (1)

- SPRA Design Guide 2012Document42 pagesSPRA Design Guide 2012TomChalmersNo ratings yet

- Frequently Asked Questions: Geberit SupertubeDocument9 pagesFrequently Asked Questions: Geberit Supertubemohaideen kasimNo ratings yet

- JKR SIRIM PrePDFDocument4 pagesJKR SIRIM PrePDFkhairul AnwarNo ratings yet

- 04 - Planning SI and Interpretation of Results PDFDocument16 pages04 - Planning SI and Interpretation of Results PDFDaniel YongNo ratings yet

- Calculation of Safe Bearing Capacity of Soil Onsite - Liquefaction - SBC ValuesDocument9 pagesCalculation of Safe Bearing Capacity of Soil Onsite - Liquefaction - SBC Valuesvenkateswara rao pothinaNo ratings yet

- Productivity Rate AnalysisDocument6 pagesProductivity Rate AnalysismhdfhmNo ratings yet

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Document8 pagesHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedNo ratings yet

- LCP Multideck® 90Document6 pagesLCP Multideck® 90GarfieldNo ratings yet

- Water PipingDocument15 pagesWater Pipingroinbanerji100% (1)

- Flexible Sprinkler HoseDocument7 pagesFlexible Sprinkler HoseSopi LabuNo ratings yet

- ASCE 7-16 Live Load CDocument6 pagesASCE 7-16 Live Load CNgoc TonNo ratings yet

- Mebs6000 1011 01 Cold & Flush WaterDocument70 pagesMebs6000 1011 01 Cold & Flush Waterstaryklt100% (1)

- Refresher Exam Takehome 1Document16 pagesRefresher Exam Takehome 1Christopher Joshua MartinezNo ratings yet

- Sewer CCTV Guidebook PDFDocument105 pagesSewer CCTV Guidebook PDFMark Anthony GaguiNo ratings yet

- What Is The Green Building IndexDocument2 pagesWhat Is The Green Building IndexTayaabaranNo ratings yet

- Civil Engineer Resume - Sample 1Document4 pagesCivil Engineer Resume - Sample 1anandkumarrs6No ratings yet

- F-Number Cost FactorsDocument4 pagesF-Number Cost FactorsGeorge CharitouNo ratings yet

- Aco Rainwater Outlets BrochureDocument32 pagesAco Rainwater Outlets Brochurerajkumar_chinniah100% (1)

- Rainwater Systems: Design and Installation GuideDocument22 pagesRainwater Systems: Design and Installation GuideGELIGNITENo ratings yet

- 3.6 Active Fire ControlDocument33 pages3.6 Active Fire Controlmuchelia0% (1)

- Installation of HDPE Lining On R.C TankDocument3 pagesInstallation of HDPE Lining On R.C TankTamil Da Rasckalz100% (1)

- Water Supply Booster PumpDocument5 pagesWater Supply Booster PumpMahmoud MahmoudNo ratings yet

- General Conditions of Contract: Defects Liability Period: School of Engineering & TechnologyDocument37 pagesGeneral Conditions of Contract: Defects Liability Period: School of Engineering & TechnologyPriyam AndhariaNo ratings yet

- Une P 25082015Document257 pagesUne P 25082015Zubaida MaqsoodNo ratings yet

- Concrete Thumb RulesDocument9 pagesConcrete Thumb RulesNoshad Ul HaqNo ratings yet

- Shear Wall MOSDocument8 pagesShear Wall MOSAsdia Aseffah FathiyaNo ratings yet

- Mechanical FastenersDocument6 pagesMechanical FastenersGray Fox GarcíaNo ratings yet

- GBI RNC Residential Tool V1.0 FinalDocument14 pagesGBI RNC Residential Tool V1.0 FinalNorFarah ShahiraNo ratings yet

- Construction Supervisor II: Passbooks Study GuideFrom EverandConstruction Supervisor II: Passbooks Study GuideNo ratings yet

- Bid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRDocument7 pagesBid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRFrancis Nano FerrerNo ratings yet

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- Ifrc Drink Driving 2022 FinalDocument84 pagesIfrc Drink Driving 2022 FinalAsoka Kumarasiri JayawardanaNo ratings yet

- Eurocode 7, Geotechnical Design, Part 3 Design Assisted by FieldtestingDocument150 pagesEurocode 7, Geotechnical Design, Part 3 Design Assisted by FieldtestingAsoka Kumarasiri JayawardanaNo ratings yet

- Fire Doors 101 Testing Certification BeyondDocument55 pagesFire Doors 101 Testing Certification BeyondAsoka Kumarasiri JayawardanaNo ratings yet

- Fire Door Label RequirementsDocument1 pageFire Door Label RequirementsAsoka Kumarasiri JayawardanaNo ratings yet

- IB Certification Field Labeling BPIBNA03 3Document2 pagesIB Certification Field Labeling BPIBNA03 3Asoka Kumarasiri JayawardanaNo ratings yet

- Knauf Type X Fire Rated GW TX 1Document2 pagesKnauf Type X Fire Rated GW TX 1Asoka Kumarasiri JayawardanaNo ratings yet

- srds3 Siphonic Roof Drainage Jan19Document12 pagessrds3 Siphonic Roof Drainage Jan19Asoka Kumarasiri JayawardanaNo ratings yet

- Data Sheet Cement Bonded Particle Board BetonwoodDocument4 pagesData Sheet Cement Bonded Particle Board BetonwoodAsoka Kumarasiri JayawardanaNo ratings yet

- Pluvia BrochureDocument11 pagesPluvia BrochureAsoka Kumarasiri JayawardanaNo ratings yet

- 2017 Brochure Pluvia Final Singles - 2Document20 pages2017 Brochure Pluvia Final Singles - 2Asoka Kumarasiri JayawardanaNo ratings yet

- The Cell As An Open SystemDocument2 pagesThe Cell As An Open SystemmunawarNo ratings yet

- Obadia Pricing Final JIM ReseasearchGateDocument40 pagesObadia Pricing Final JIM ReseasearchGateJai VermaNo ratings yet

- Graphical Representation of DataDocument7 pagesGraphical Representation of Datatazim18No ratings yet

- Chih-Hwa Chen, MD, MBADocument10 pagesChih-Hwa Chen, MD, MBABabar Manzoor GhauriNo ratings yet

- Artikel 13 Hak Dan Kewajiban Anak Terhadap Orang TuaDocument12 pagesArtikel 13 Hak Dan Kewajiban Anak Terhadap Orang TuaMuhammad Irfan SaputraNo ratings yet

- CH U3 A1 Atomic History WorksheetDocument2 pagesCH U3 A1 Atomic History WorksheetАбдурахман Псикс0% (1)

- The Case Study of OliviaDocument2 pagesThe Case Study of Oliviabilly bongNo ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument4 pagesShell Turbo Oil T46: Performance, Features & Benefits Main Applicationshaider100% (1)

- Java Lab (Mca) SyllabusDocument2 pagesJava Lab (Mca) SyllabusAMAN PANDEY 22SCSE2030634No ratings yet

- Westing Sonata Hotel-Mock-Up King Guestroom SLP - Lbx-NodimDocument1 pageWesting Sonata Hotel-Mock-Up King Guestroom SLP - Lbx-NodimrbelduaNo ratings yet

- Vega 450 Installation ManualDocument35 pagesVega 450 Installation ManualZeljko TomicNo ratings yet

- SPE-177971-MS - Processing Formation Test Data To Reduce The Risk Inherent in Capturing Representative Samples in Zones With Highly Varying PermeabilitiesDocument13 pagesSPE-177971-MS - Processing Formation Test Data To Reduce The Risk Inherent in Capturing Representative Samples in Zones With Highly Varying PermeabilitiesSamanta MirandaNo ratings yet

- IR2116J Parts CatalogDocument78 pagesIR2116J Parts CatalogFaisal MasucalNo ratings yet

- Power in sCHOOLDocument7 pagesPower in sCHOOLRIEL JEAN GAVIOLANo ratings yet

- Up-Date TI 2017 Site AdaroDocument51 pagesUp-Date TI 2017 Site AdaroCavandraNo ratings yet

- COLREG2014Document3 pagesCOLREG2014jean.bitereNo ratings yet

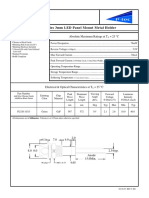

- PL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CDocument1 pagePL320 Series 3mm LED Panel Mount Metal Holder: Features Absolute Maximum Ratings at T 25 °CJajang JajaNo ratings yet

- Resume - Alexis GibsonDocument1 pageResume - Alexis Gibsonapi-521009603No ratings yet

- Technical Data Book PDFDocument79 pagesTechnical Data Book PDFRuth Santos NaranjoNo ratings yet

- Maxillofacial Anatomy: Rachmanda Haryo Wibisono Hendra Benyamin Joana de FatimaDocument47 pagesMaxillofacial Anatomy: Rachmanda Haryo Wibisono Hendra Benyamin Joana de FatimaDipo Mas SuyudiNo ratings yet

- Panasonic Air Condicioner CU-2E15LBE Service ManualDocument103 pagesPanasonic Air Condicioner CU-2E15LBE Service Manualjoxebike100% (1)

- Donau CarbonDocument2 pagesDonau CarbonLim Chee SiangNo ratings yet

- Quality of Work Life in Selected Public Universities in Dar Es Salaam, TanzaniaDocument6 pagesQuality of Work Life in Selected Public Universities in Dar Es Salaam, TanzaniaInternational Journal of Arts, Humanities and Social Studies (IJAHSS)No ratings yet

- Mil STD 461eDocument288 pagesMil STD 461ech.navnNo ratings yet

- Holocaust Essay Thesis StatementDocument6 pagesHolocaust Essay Thesis Statementmmwsmltgg100% (2)

- Rashtriya Uchchatar Shiksha Abhiyan (National Higher Education Mission)Document228 pagesRashtriya Uchchatar Shiksha Abhiyan (National Higher Education Mission)Delhi University Teachers AssociationNo ratings yet

- Aircraft Maintenance ManualDocument118 pagesAircraft Maintenance ManualcleberNo ratings yet

- Mathematics Actual SBaDocument8 pagesMathematics Actual SBaRohan lall100% (1)