Professional Documents

Culture Documents

Catalog Underfloor Wheel Lathe Simple and Tandem en

Catalog Underfloor Wheel Lathe Simple and Tandem en

Uploaded by

bagus diwangkoroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalog Underfloor Wheel Lathe Simple and Tandem en

Catalog Underfloor Wheel Lathe Simple and Tandem en

Uploaded by

bagus diwangkoroCopyright:

Available Formats

Underfloor Wheel Lathe

TF2000 – Underfloor Wheel Lathe

TF2000HD – Underfloor Wheel Lathe – Heavy Duty

SCULFORT Underfloor Wheel Lathe was developed in consultation with metro, tramway and train

operators. The TF2000 Underfloor Wheel Lathe can receive metros, trams and trains with an axle load of

less than 20 tons. The TF2000HD Underfloor Wheel Lathe can receive trains and locomotives with an axle

load of less than 30 tons.

Operation principle:

Single lathe TF2000 and TF2000HD achieve reprofiling two wheels in 30 minutes.

The lathe is CNC controlled and masters the 5 cycles:

• Vehicle positioning

• Profile measuring before machining

• Wheel profiling and break discs machining

• Profile measuring after machining

• Vehicle removal

For each type of wheel, several profiles are available: standard or economy. Once the measurement process achieved, the CNC

can calculate the new wheel dimensions with minimum machining. The operator has the choice between validating and

modifying the CNC proposal.

At the end of the cycle, the CNC delivers a machining report, gathering all the information necessary for the railway operator.

Lathe component

In order to ensure the operator ergonomics, the lathe comprises:

• A control panel facing the working area

• An Autodiagnostic and Telemaintenance system

• An optional positioning shunting device

• A chip disposal device (accessory)

• A smoke extractor (optional)

SAS SCULFORT YEL

ZAC DES FONDS SAINT JACQUES, 59750, FEIGNIES, FRANCE

Tel: +33 3 27 56 71 68 Fax : +33 9 59 38 85 16 N° Siren: 538 374 489

info@sculfort-france.com www.sculfort-france.com

TF2000 – Underfloor Wheel Lathe

TF2000HD – Underfloor Wheel Lathe – Heavy Duty

Underfloor Wheel Lathe

SCULFORT Underfloor Wheel Lathe was developed in consultation with metro, tramway and train

operators. The TF2000 Underfloor Wheel Lathe can receive metros, trams and trains with an axle load of

less than 20 tons. The TF2000HD Underfloor Wheel Lathe can receive trains and locomotives with an axle

load of less than 30 tons.

Technical Characteristics:

Length 5200 mm

Width 2200 mm

Distance between pit floor and rail top 2000 mm

Height (without hold down device) 2200 mm

Weight of the UWL Approximate total weight is 18 000 kg

Track gauge 1000 - 1435 - 1676mm

Maximum axle load 25000 daN

Hold down force (total on wheelset) Max. 5000 daN

Wheel diameter on tread 500 to 1400 mm

Wheel width 80 to 160 mm

Maximum cutting effort 1700 daN

Minimum cutting depth 0.2 mm

Maximum cutting depth 10 mm

Cutting speed 0 to 200 m/min

CNC Model SIEMENS 840D

Measure increment 1 μm

Measure display 1 μm

Quantity of programmed profile data Depending on option

Capacity of stored profile data 100

Program language SIEMENS Step7 (Ladder)

Hydraulic oil 160 L

Recommended hydraulic oil norm ISO HM46

Greasing pump 2L

Recommended lubricating oil norm ISO G68

Total installed power 90 Kw

Power supply required AC 400V - 3ph - 50Hz

Required Compressed air (dry / clean) 1 m3/h – 6 bars

SAS SCULFORT YEL

ZAC DES FONDS SAINT JACQUES, 59750, FEIGNIES, FRANCE

Tel: +33 3 27 56 71 68 Fax : +33 9 59 38 85 16 N° Siren: 538 374 489

info@sculfort-france.com www.sculfort-france.com

Tandem Underfloor Wheel Lathe

TF2000TM – Tandem Underfloor Wheel Lathe

TF2000HDTM – Tandem Underfloor Wheel Lathe – Heavy Duty

SCULFORT Tandem Underfloor Wheel Lathe was developed in consultation with metro, tramway and train

operators. The TF2000TM Tandem Underfloor Wheel Lathe can receive metros, trams and trains with an

axle load of less than 20 tons. The TF2000HDTM Tandem Underfloor Wheel Lathe can receive trains and

locomotives with an axle load of less than 30 tons.

Operation principle:

Tandem lathe TF2000TM and TF2000HDTM achieve reprofiling for wheels of one bogie in less than 40 minutes.

The lathe is CNC controlled and masters the 5 cycles:

• Vehicle positioning

• Profile measuring before machining

• Wheel profiling and break discs machining

• Profile measuring after machining

• Vehicle removal

For each type of wheel, several profiles are available: standard or economy. Once the measurement process achieved, the CNC

can calculate the new wheel dimensions with minimum machining. The operator has the choice between validating and

modifying the CNC proposal.

At the end of the cycle, the CNC delivers a machining report, gathering all the information necessary for the railway operator.

Lathe component

In order to ensure the operator ergonomics, the lathe comprises:

• A control panel facing the working area

• An Autodiagnostic and Telemaintenance system

• An optional positioning shunting device

• A chip disposal device (accessory)

• A smoke extractor (optional)

SAS SCULFORT YEL

ZAC DES FONDS SAINT JACQUES, 59750, FEIGNIES, FRANCE

Tel: +33 3 27 56 71 68 Fax : +33 9 59 38 85 16 N° Siren: 538 374 489

info@sculfort-france.com www.sculfort-france.com

TF2000TM – Tandem Underfloor Wheel Lathe

TF2000HDTM – Tandem Underfloor Wheel Lathe – Heavy Duty

Tandem Underfloor Wheel Lathe

SCULFORT Tandem Underfloor Wheel Lathe was developed in consultation with metro, tramway and train

operators. The TF2000TM Tandem Underfloor Wheel Lathe can receive metros, trams and trains with an

axle load of less than 20 tons. The TF2000HDTM Tandem Underfloor Wheel Lathe can receive trains and

locomotives with an axle load of less than 30 tons.

Technical Characteristics:

Length 5200 mm

Width 5400 mm

Distance between pit floor and rail top 2000 mm

Height (without hold down device) 2200 mm

Weight of the whole machine Approximate total weight is 40 000 kg

Dimensions of the mobile table 2665 mm

Mobile table stroke 1000 mm

Bogie Wheelbase 1600 mm à 2600 mm

Track gauge 1000 - 1435 - 1676mm

Maximum axle load 25000 daN

Hold down force (total on wheelset) Max. 5000 daN

Wheel diameter on tread 500 to 1400 mm

Wheel width 80 to 160 mm

Maximum cutting effort 1700 daN

Minimum cutting depth 0.2 mm

Maximum cutting depth 10 mm

Cutting speed 0 to 200 m/min

CNC Model SIEMENS 840D

Measure increment 1 μm

Measure display 1 μm

Quantity of programmed profile data Depending on option

Capacity of stored profile data 100

Program language SIEMENS Step7 (Ladder)

Hydraulic oil 160 L

Recommended hydraulic oil norm ISO HM46

Greasing pump 2L

Recommended lubricating oil norm ISO G68

Total installed power 90 Kw

Power supply required AC 400V - 3ph - 50Hz

Required Compressed air (dry / clean) 1 m3/h – 6 bars

SAS SCULFORT YEL

ZAC DES FONDS SAINT JACQUES, 59750, FEIGNIES, FRANCE

Tel: +33 3 27 56 71 68 Fax : +33 9 59 38 85 16 N° Siren: 538 374 489

info@sculfort-france.com www.sculfort-france.com

You might also like

- TRUMPF TRUBEND 5230 Technical DataDocument11 pagesTRUMPF TRUBEND 5230 Technical DatacoronaqcNo ratings yet

- Parts Manual Yanmar VIO55 5Document159 pagesParts Manual Yanmar VIO55 5MontyNo ratings yet

- Simba L6CDocument4 pagesSimba L6CsasidharreddyNo ratings yet

- Astm E1975 - 1 (En)Document17 pagesAstm E1975 - 1 (En)Dinesh Sai100% (1)

- I-110 - 2010 - Spec Sheet 1 PDFDocument4 pagesI-110 - 2010 - Spec Sheet 1 PDFeaglego00No ratings yet

- wc1000 Product SpecificationDocument2 pageswc1000 Product SpecificationElijah TanNo ratings yet

- Datasheet Kleemann Mco9 EVO enDocument4 pagesDatasheet Kleemann Mco9 EVO enGemma KemalNo ratings yet

- Sculfort Technical CatalogueDocument10 pagesSculfort Technical Catalogueapi-251352527No ratings yet

- 2018 - DVM 2017 - 5 AxesDocument16 pages2018 - DVM 2017 - 5 AxesAbhishek VelagaNo ratings yet

- Terex Finlay I-110 Impact Crusher PDFDocument4 pagesTerex Finlay I-110 Impact Crusher PDFeaglego00No ratings yet

- Prospekt-844 EN LowResDocument6 pagesProspekt-844 EN LowResIslam ElhabsheNo ratings yet

- TwinTrak 4pp Jan17 WebDocument4 pagesTwinTrak 4pp Jan17 WebEldar AtakishyyevNo ratings yet

- UTMII - Rotating Torque Metter PDFDocument40 pagesUTMII - Rotating Torque Metter PDFHuỳnh LêNo ratings yet

- SMH14 03 2000008Document8 pagesSMH14 03 2000008Bullet DassNo ratings yet

- Flyer-U2000-400 2018 en RGBDocument2 pagesFlyer-U2000-400 2018 en RGBLukáš ČochnerNo ratings yet

- Thyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetDocument15 pagesThyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetTek tek hapNo ratings yet

- Competior InformationDocument27 pagesCompetior Informationmmoran298No ratings yet

- Simba M7 - 9851 2194 01Document4 pagesSimba M7 - 9851 2194 01Rodrigo ContrerasNo ratings yet

- AccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21Document5 pagesAccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21EnriqueMiguelPriceNo ratings yet

- Concrete PumpDocument2 pagesConcrete PumpwulanNo ratings yet

- Charmec LC 605 D (V) : Technical Data Sheet 100064402 23.06.2014 AustraliaDocument8 pagesCharmec LC 605 D (V) : Technical Data Sheet 100064402 23.06.2014 Australiajuan eduardo rodriguezNo ratings yet

- SM 14Document8 pagesSM 14fjhernandez_76No ratings yet

- Terex Finlay I-110RS Impact Crusher PDFDocument4 pagesTerex Finlay I-110RS Impact Crusher PDFeaglego00No ratings yet

- Arx Malbikunarvaltarar Fra AmmannDocument24 pagesArx Malbikunarvaltarar Fra AmmannhathamphanNo ratings yet

- Pm0uk Dmu Evo Series PDF DataDocument32 pagesPm0uk Dmu Evo Series PDF Datamail2jyothishdsNo ratings yet

- RS1500 BROCHURE 2020.01 - EmailDocument12 pagesRS1500 BROCHURE 2020.01 - EmailKshitiz MittalNo ratings yet

- SM401Document8 pagesSM401sistemavictorsinaisNo ratings yet

- AgXeed AgBot 5.115T2 Specifications-1Document1 pageAgXeed AgBot 5.115T2 Specifications-1Manoj JanduNo ratings yet

- Chaapter 3 Part 2Document11 pagesChaapter 3 Part 2robelNo ratings yet

- Scamec FB223 MM V1Document11 pagesScamec FB223 MM V1Ernesto BahamondeNo ratings yet

- DL420 15c SpecificationsDocument4 pagesDL420 15c Specificationsesteban muñozNo ratings yet

- UC-481 2040, European MarketDocument4 pagesUC-481 2040, European MarketAchmatAfipudinNo ratings yet

- Jumbo Dl420 7cDocument4 pagesJumbo Dl420 7cRodrigo ContrerasNo ratings yet

- KMT CatalogueDocument13 pagesKMT Cataloguepriyanka.vijayNo ratings yet

- AV1-2 Tandem Vibrating Rollers 1.4 - 1.7 T: MachinesDocument8 pagesAV1-2 Tandem Vibrating Rollers 1.4 - 1.7 T: MachinesfernandoNo ratings yet

- 620b77cbcf61268fdadca3de - 60 - Seaeye Survey Plus DatasheetDocument2 pages620b77cbcf61268fdadca3de - 60 - Seaeye Survey Plus Datasheetmuhammed kamalNo ratings yet

- HDD HK80CK enDocument2 pagesHDD HK80CK enuri0% (1)

- Walk-Behind Roller: A 2-In-1 MachineDocument2 pagesWalk-Behind Roller: A 2-In-1 MachineAndré LinharesNo ratings yet

- BC Doosan DB130 Lot 1Document3 pagesBC Doosan DB130 Lot 1Welly CholilNo ratings yet

- Terex Finlay J-1160Document4 pagesTerex Finlay J-1160eaglego00No ratings yet

- 2021 Launch Tire&maintenance EquipmentDocument6 pages2021 Launch Tire&maintenance EquipmentEzequiel Dos SantosNo ratings yet

- Bou CatddDocument2 pagesBou CatddDJNo ratings yet

- UD210 SpecDocument2 pagesUD210 Specfelipe hinojosaNo ratings yet

- Vertical Turret Lathe Imo Kd4S 40: AnlagenbauDocument6 pagesVertical Turret Lathe Imo Kd4S 40: AnlagenbauSamik MukherjeeNo ratings yet

- Hydrostatic Vibratory Plate: A Trusted CompactorDocument2 pagesHydrostatic Vibratory Plate: A Trusted Compactorhamdi galipNo ratings yet

- Aph6585vibratoryplatesellsheetmss 1062 07 En200305Document2 pagesAph6585vibratoryplatesellsheetmss 1062 07 En200305Apo ghasan Al shargapiNo ratings yet

- 6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Document6 pages6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Farkas Pal100% (1)

- TX Catalogue EnglishDocument12 pagesTX Catalogue EnglishDjuraTheHarpYNo ratings yet

- Alpha 30 - Robot ShotcreteroDocument14 pagesAlpha 30 - Robot ShotcreteroErnesto BahamondeNo ratings yet

- Wittur Range of Systems: Machine Roomless EfficiencyDocument16 pagesWittur Range of Systems: Machine Roomless EfficiencyLe Huynh LongNo ratings yet

- Final HMTDocument45 pagesFinal HMTAnubhav SharmaNo ratings yet

- Sandvik DT1130-C Data: Application Main SpecificationsDocument4 pagesSandvik DT1130-C Data: Application Main SpecificationsLuis JaimesNo ratings yet

- 50t Crawler Crane Hire RB Ch50 Technical DataDocument8 pages50t Crawler Crane Hire RB Ch50 Technical Datakbadran.timsahNo ratings yet

- CNC Routers Jan 2023Document2 pagesCNC Routers Jan 2023don bothaNo ratings yet

- TUP650 2018 EN Electron.Document4 pagesTUP650 2018 EN Electron.Khhg AgddsNo ratings yet

- Sandvik Ds210l VDocument4 pagesSandvik Ds210l Vlorenzo henerNo ratings yet

- DL411Document4 pagesDL411megamNo ratings yet

- Drive System Product Overview enDocument9 pagesDrive System Product Overview enPatricio Alarcon CastroNo ratings yet

- Schindler 7000Document30 pagesSchindler 7000Nguyen PhatNo ratings yet

- TDS Alpha 30 (EN) Rev6 PDFDocument10 pagesTDS Alpha 30 (EN) Rev6 PDFFelipe Andrés Camarada SilvaNo ratings yet

- 3484 Magazine Spring 2023Document36 pages3484 Magazine Spring 20233484 MagazineNo ratings yet

- Aminul Kibria - Reporter ListDocument7 pagesAminul Kibria - Reporter ListADVANCE POWER ENGINEERINGNo ratings yet

- TR - Driving (Bus) NC IIIDocument80 pagesTR - Driving (Bus) NC IIICOR JESU COLLEGE VoctechNo ratings yet

- Air Law PPL Notes PDFDocument10 pagesAir Law PPL Notes PDFosama saifNo ratings yet

- TSB Gen 022 Rev 2Document6 pagesTSB Gen 022 Rev 2Trọng Nghĩa VõNo ratings yet

- Ch. 12-The Endomembrane System and Protein SortingDocument35 pagesCh. 12-The Endomembrane System and Protein Sortingnkorkmaz1357No ratings yet

- DHS 15apDocument14 pagesDHS 15apadelNo ratings yet

- Baba TicketDocument2 pagesBaba TicketkushalchatterjeeNo ratings yet

- TicketDocument2 pagesTicketjohnwick6151No ratings yet

- MGT Capstone 3-4Document2 pagesMGT Capstone 3-4Shakeel SajjadNo ratings yet

- Gas Power CyclesDocument19 pagesGas Power CyclesMa. Monica ConsulNo ratings yet

- 8.control Arm - WDocument50 pages8.control Arm - WEleazar PavonNo ratings yet

- Resume of Jensens33Document1 pageResume of Jensens33api-30970004No ratings yet

- P.S.E Engineering & Construction Pte LTD Vehicle Pre-Start ChecklistDocument5 pagesP.S.E Engineering & Construction Pte LTD Vehicle Pre-Start ChecklistWunna LwinNo ratings yet

- Climate Action in Indian Cities An Emerging New Research AreaDocument13 pagesClimate Action in Indian Cities An Emerging New Research AreaNithya Sree ANo ratings yet

- Technological Institute of The Philippines Quezon City 938 Aurora BLVD., Cubao, Quezon CityDocument12 pagesTechnological Institute of The Philippines Quezon City 938 Aurora BLVD., Cubao, Quezon CityKaty PerryNo ratings yet

- Codename AnastasiaDocument455 pagesCodename AnastasiaalfiamohiuddinNo ratings yet

- One2One Panama 2015Document6 pagesOne2One Panama 2015Dhaval ShahNo ratings yet

- TWG Mobile Crane Fact SheetDocument4 pagesTWG Mobile Crane Fact Sheetj24maybe5963No ratings yet

- List of Mayday Episodes PDFDocument22 pagesList of Mayday Episodes PDFpoddaszeNo ratings yet

- HomeworkDocument6 pagesHomeworkVictor AquinoNo ratings yet

- Auction Pricelist 021822Document16 pagesAuction Pricelist 021822Raj AmilbaharNo ratings yet

- Re 79093Document4 pagesRe 79093Anonymous lIJl27QBXLNo ratings yet

- WP05 AI.4 ICAO - Review New ANP PDFDocument265 pagesWP05 AI.4 ICAO - Review New ANP PDFMaverickNo ratings yet

- Initial Cost Comparison of Rigid and Flexible Pavements Case Study Khartoum State PDFDocument8 pagesInitial Cost Comparison of Rigid and Flexible Pavements Case Study Khartoum State PDFHùng NguyễnNo ratings yet

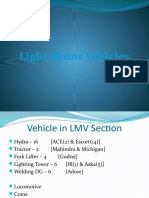

- Light Motor VehiclesDocument27 pagesLight Motor VehiclesPRANAY JOSHINo ratings yet

- RegsssDocument44 pagesRegsssPrerak Kumar SharmaNo ratings yet

- Monitoring and Enhanced Fatigue Evaluation of A Steel Railway BridgeDocument10 pagesMonitoring and Enhanced Fatigue Evaluation of A Steel Railway BridgeSaba AliyariNo ratings yet