Professional Documents

Culture Documents

Dispatch Checklist

Dispatch Checklist

Uploaded by

Samde LabCopyright:

Available Formats

You might also like

- 32 First Aid Kit Box Inspection ChecklistDocument1 page32 First Aid Kit Box Inspection ChecklistBishop Ojonuguwa Ameh75% (4)

- Protocol For The Conduct of Stability StudiesDocument4 pagesProtocol For The Conduct of Stability StudiesManish shankarpure100% (1)

- Master Formula CardDocument7 pagesMaster Formula CardTrilochan Ayurveda100% (1)

- Alkaline Battery-Panasonic - MSDSDocument6 pagesAlkaline Battery-Panasonic - MSDSISPNo ratings yet

- INSPECTION ENVIRONMENTAL QuestionnaireDocument2 pagesINSPECTION ENVIRONMENTAL QuestionnairekudaiNo ratings yet

- CHEKLISTDocument7 pagesCHEKLISTaltaf.khan139931No ratings yet

- Test Method Acceptance CriteriaDocument3 pagesTest Method Acceptance CriteriaAhmed RazaNo ratings yet

- Container-Truck Check List PDFDocument1 pageContainer-Truck Check List PDFagilvp@yahooNo ratings yet

- Hazardous Materials ManagementDocument1 pageHazardous Materials ManagementkudaiNo ratings yet

- Result Sheets - Newcastle Dis, Q.4, 2016Document2 pagesResult Sheets - Newcastle Dis, Q.4, 2016larep57301No ratings yet

- Line Set Up SopDocument3 pagesLine Set Up SopProf C.S.PurushothamanNo ratings yet

- Testing Kit Availability: ROB ROB ROB ROBDocument3 pagesTesting Kit Availability: ROB ROB ROB ROBOliver CelestialNo ratings yet

- Tile Setter Accomplishment Report: Engr. Amiel Bryan Manreal Project SupervisorDocument1 pageTile Setter Accomplishment Report: Engr. Amiel Bryan Manreal Project SupervisorBryan MänrealNo ratings yet

- YMC Interpretation GuideDocument6 pagesYMC Interpretation Guiderubelyn088No ratings yet

- Bacterial Loads in A Kitchen SpongeDocument4 pagesBacterial Loads in A Kitchen SpongeGUIDO ERNESTO VILLOTA CALVACHINo ratings yet

- MA-K13383-EM Issue 3 Signum Onboard ManualDocument7 pagesMA-K13383-EM Issue 3 Signum Onboard ManualFamilia De Fernando Oscar Bilotti100% (1)

- Bourbon Barrel Aging OptimizationDocument4 pagesBourbon Barrel Aging Optimizationcosmoal.zoomNo ratings yet

- Batch Packing RecordDocument1 pageBatch Packing RecordGBL 22100% (1)

- SOP NEW ModifiedDocument1 pageSOP NEW ModifiedKavita DeviNo ratings yet

- PANERA-04 Artisan BreadsDocument26 pagesPANERA-04 Artisan BreadsGreatRecipeCollectr29No ratings yet

- Labelling Compliance Workshop PM & Region Wise Labelling Routine s9 - Textile S9 v3.2Document100 pagesLabelling Compliance Workshop PM & Region Wise Labelling Routine s9 - Textile S9 v3.2Apurba DeyNo ratings yet

- Surjani Town Shop 1Document4 pagesSurjani Town Shop 1qamarNo ratings yet

- BUNSENDocument14 pagesBUNSENPeter S. SumayangNo ratings yet

- An Approach To M.TBDocument42 pagesAn Approach To M.TBKamala NathanNo ratings yet

- Agama Kunci JawabanDocument6 pagesAgama Kunci JawabanLionus BryanCNo ratings yet

- LabelDocument2 pagesLabelDesi Ris SaputriNo ratings yet

- 127 - Hse Inspection Checklist-Compressed Gas CylinderDocument1 page127 - Hse Inspection Checklist-Compressed Gas CylinderEr Ajenk80% (10)

- Sampling Oil Schedule: Technical DeptDocument6 pagesSampling Oil Schedule: Technical Deptkanthi_weningNo ratings yet

- NECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Document14 pagesNECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Thai Hai LyNo ratings yet

- In Line Inspection - BBLK-PO-9477-27-01-2020Document2 pagesIn Line Inspection - BBLK-PO-9477-27-01-2020prageethnirudakaNo ratings yet

- Mock Drill TemplateDocument7 pagesMock Drill TemplateAnkurNo ratings yet

- PIHECDocument9 pagesPIHECMuhammad Izat Abu TalibNo ratings yet

- Delivery Information Sheet ScienceDocument15 pagesDelivery Information Sheet ScienceRODNIE GUBATONNo ratings yet

- Bahan Prevetting OBDocument3 pagesBahan Prevetting OBpmt xlv1115No ratings yet

- List DBL Papua Crew 2019Document4 pagesList DBL Papua Crew 2019Muhammad RidwanNo ratings yet

- Abinbev November Newsletter PDFDocument10 pagesAbinbev November Newsletter PDFBenson MangomaNo ratings yet

- Biology Plan and Design Lab - Darren RamnarineDocument7 pagesBiology Plan and Design Lab - Darren Ramnarinedarrenramnarine2007No ratings yet

- What Is Aql 1.5 Aql 2.5 Inspection System in Clothing Manufacturers Garments Industry What Is Aql in Clothing Manufacturers Quality Control SynergDocument7 pagesWhat Is Aql 1.5 Aql 2.5 Inspection System in Clothing Manufacturers Garments Industry What Is Aql in Clothing Manufacturers Quality Control Synerggolam.rumyNo ratings yet

- Amx125 &250Document2 pagesAmx125 &250Ashish SharmaNo ratings yet

- Soal Label MakananDocument1 pageSoal Label MakananDodi SaputraNo ratings yet

- Gtc-Spe-Bbs-004 A v3 12x6 OzDocument1 pageGtc-Spe-Bbs-004 A v3 12x6 OzEDUARDONo ratings yet

- Astm e 1346 - 90 R00Document3 pagesAstm e 1346 - 90 R00o_l_0No ratings yet

- CDS 1 General Knowledge 2017Document48 pagesCDS 1 General Knowledge 2017Anonymous HHVNkaNo ratings yet

- Marigold 11kDocument58 pagesMarigold 11kDiogenes Laban B. PosadasNo ratings yet

- Agar Preparation: Course: MCB 103 Lab Section: 1 Name: Noor-E-Khadiza Shama ID: 1921168 Date: 03/03/20Document4 pagesAgar Preparation: Course: MCB 103 Lab Section: 1 Name: Noor-E-Khadiza Shama ID: 1921168 Date: 03/03/20ShamaNo ratings yet

- Toys Direct 2009 Catalog v.001 - 8MBDocument177 pagesToys Direct 2009 Catalog v.001 - 8MBToys Direct Inc100% (2)

- Inspection Report Certificate No. 069/INS-FISH/VI/2012Document5 pagesInspection Report Certificate No. 069/INS-FISH/VI/2012chemistry-rocketNo ratings yet

- STP tm05Document7 pagesSTP tm05prajapati28No ratings yet

- NO Facts Available? StatementsDocument5 pagesNO Facts Available? StatementsYahya Bayu PurnomoNo ratings yet

- Microbiologist Work FlowDocument10 pagesMicrobiologist Work FlowAri DanteNo ratings yet

- Qty Itemsdescription: 3000 Aurora Blvd. Pasay City Metro Manila Tel.#852-0308,853-1812 - Fax # 852-9431Document1 pageQty Itemsdescription: 3000 Aurora Blvd. Pasay City Metro Manila Tel.#852-0308,853-1812 - Fax # 852-9431Jessie GargantosNo ratings yet

- Proflok Cav AbDocument6 pagesProflok Cav Abikram chohanNo ratings yet

- Airfix Magazine - Volume 5 6Document48 pagesAirfix Magazine - Volume 5 6Cem Avci100% (1)

- Estimating Package Stability of Coatings For Ultraviolet CuringDocument2 pagesEstimating Package Stability of Coatings For Ultraviolet Curingsaifullah629No ratings yet

- CO2 4.5 KG Fire ExtinguisherDocument2 pagesCO2 4.5 KG Fire ExtinguishervivekvpsfeNo ratings yet

- SPECIFICATION SHEET (Tilapia Fillet)Document1 pageSPECIFICATION SHEET (Tilapia Fillet)compras.colsenNo ratings yet

- ProductsdataDocument1 pageProductsdataganeesh.g94No ratings yet

- States of Matter NotesDocument8 pagesStates of Matter NotesRaya Ibarra LumogdangNo ratings yet

- Chapter 6 Chm431 ColloidDocument48 pagesChapter 6 Chm431 ColloidSiti Wajihah Mohd NazriNo ratings yet

- Guidance For Accreditation of Laboratories Under RNTCP For Mycobacterial Culture &DSTDocument13 pagesGuidance For Accreditation of Laboratories Under RNTCP For Mycobacterial Culture &DSTSravan SravanNo ratings yet

- Collection and Preservation of Water SamplesDocument24 pagesCollection and Preservation of Water SamplesSyed Talha AhmedNo ratings yet

- Effect of Homogenizing Pressure and Sterilizing Condition On Quality of Canned High Fat Coconut MilkDocument7 pagesEffect of Homogenizing Pressure and Sterilizing Condition On Quality of Canned High Fat Coconut MilkAn TrầnNo ratings yet

- Dse4120 Manual PDFDocument30 pagesDse4120 Manual PDFnhocti007No ratings yet

- BROCHURE Low Range DIGI Water KitDocument2 pagesBROCHURE Low Range DIGI Water KitZts MksNo ratings yet

- Qualcast 430W Grass Trimmer: Instruction ManualDocument17 pagesQualcast 430W Grass Trimmer: Instruction ManualbhupstaNo ratings yet

- Assembling Extension CordDocument14 pagesAssembling Extension CordPaul Bulanadi Badiang67% (3)

- AAAC ButteDocument2 pagesAAAC ButtePhillippe FoixNo ratings yet

- Basic Concepts in Engineering MetallurgyDocument2 pagesBasic Concepts in Engineering Metallurgykaru320No ratings yet

- Wellsteg eDocument14 pagesWellsteg eron_danyNo ratings yet

- Nibco CatalogueDocument104 pagesNibco CatalogueIvan KolicNo ratings yet

- 3.1 Clothing Performance Requirements - March 22Document60 pages3.1 Clothing Performance Requirements - March 22Rohan KabirNo ratings yet

- Vessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure VesselDocument19 pagesVessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure Vesselbhalchandrak1867No ratings yet

- WAEC Metal Work Past QuestionsDocument7 pagesWAEC Metal Work Past QuestionsCharles Obaleagbon0% (1)

- Ceiling Recessed LightDocument1 pageCeiling Recessed LightMohamedNo ratings yet

- Exposure Lamps, UV & IR LampsDocument3 pagesExposure Lamps, UV & IR LampsBruce KampermanNo ratings yet

- Astm C497 20Document11 pagesAstm C497 20Tayef TalukderNo ratings yet

- ElectrogravimetryDocument11 pagesElectrogravimetryElijah AlvesNo ratings yet

- EX - CX - 044 - Master Inspection Characteristics MICDocument61 pagesEX - CX - 044 - Master Inspection Characteristics MICyramasapNo ratings yet

- Report Scince 2 (SEM 2)Document10 pagesReport Scince 2 (SEM 2)Hanani KharudinNo ratings yet

- AASHTO T 328-05 Reducing Samples of Hot Mix Asphalt To Testing SizeDocument8 pagesAASHTO T 328-05 Reducing Samples of Hot Mix Asphalt To Testing Sizeclint silNo ratings yet

- Hobersal Muffle Furnaces PR SeriesDocument2 pagesHobersal Muffle Furnaces PR Seriesinna husnaNo ratings yet

- Shop Floor Management TutorialDocument45 pagesShop Floor Management TutorialDilan FernandoNo ratings yet

- 815 Plus Single HingeDocument2 pages815 Plus Single HingeSaepul RochmanNo ratings yet

- Catalogue FSA 50Hz Rev.02Document6 pagesCatalogue FSA 50Hz Rev.02Heri SulasionoNo ratings yet

- Ohm's LawDocument13 pagesOhm's LawVenu GopalNo ratings yet

- MS51844EDocument5 pagesMS51844Eugur kandemirNo ratings yet

Dispatch Checklist

Dispatch Checklist

Uploaded by

Samde LabOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dispatch Checklist

Dispatch Checklist

Uploaded by

Samde LabCopyright:

Available Formats

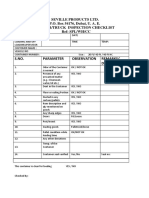

RM INSPECTION CHECKLIST Format No.

: QA/CHK/01

Page No.: 1 of 1

NAME OF THE PRODUCT :

SUPPLIER NAME :

BATCH NO /LOT NO :

DATE OF RECEIVED :

REPRESENTING QTY :

To Draw Sample/Sealing of Drum-if required :

1 Proper Melting(if required in winters) &Shaking of Drums YES

2 METAL PIPETTE USED TO DRAW OIL FROM INDIVIDUAL DRUM (Pipette should go up to the base of

drum. So that it may cover the all layers of oil and may draw true representative sample for whole

drum.)

YES

3 COLLECTED ALL THESE SAMPLES IN CLEAN RINSED GLASS BEAKER/POT TO MAKE A COMPOSITE

SAMPLE

YES

4 CHECK THE LABELS: Check that Labels are Proper with(Supplier Name, Product name, Batch

Number, Drum No., Mfg. date & Expiry date, Weight(Gross, Tare & Net Wt.),

YES

5

COVERING THE LIDS Cover both the top holes by respective lids .Seal both the properly tighten

lids on top of drums.

YES

6

FILL COMPOSITE SAMPLE IN STANDARD ALUMINIUM SAMPLE BOTTLES ( 100 grams) Yes

LABELLING ON DRUMS

1 LABEL ON DRUMS/BOTTLES YES

2 PRODUCT NAME ON LABEL YES

3 BATCH/ LOT NO ON LABEL YES

4 BUYER ON LABEL YES

5 QUANTITY ON LABEL YES

6 MFG/EXP DATE ON LABEL Yes

7 PACKING LIST PREPARED Yes

FINAL INSPECTION ALL DRUMS ARE TIGHTLY SEALED OR NOT AND

8 DRUMS SHOULD BE IN GOOD CONDITION O.K.

9 COA AND MSDS GIVEN YES

10 PRODUCT LABEL ARE PROPERLY COATED ON BOTTLES YES

11 CO-SHIPMENT SAMPLE COLLECTED Not Required

CHECKED BY : APPROVED BY :

You might also like

- 32 First Aid Kit Box Inspection ChecklistDocument1 page32 First Aid Kit Box Inspection ChecklistBishop Ojonuguwa Ameh75% (4)

- Protocol For The Conduct of Stability StudiesDocument4 pagesProtocol For The Conduct of Stability StudiesManish shankarpure100% (1)

- Master Formula CardDocument7 pagesMaster Formula CardTrilochan Ayurveda100% (1)

- Alkaline Battery-Panasonic - MSDSDocument6 pagesAlkaline Battery-Panasonic - MSDSISPNo ratings yet

- INSPECTION ENVIRONMENTAL QuestionnaireDocument2 pagesINSPECTION ENVIRONMENTAL QuestionnairekudaiNo ratings yet

- CHEKLISTDocument7 pagesCHEKLISTaltaf.khan139931No ratings yet

- Test Method Acceptance CriteriaDocument3 pagesTest Method Acceptance CriteriaAhmed RazaNo ratings yet

- Container-Truck Check List PDFDocument1 pageContainer-Truck Check List PDFagilvp@yahooNo ratings yet

- Hazardous Materials ManagementDocument1 pageHazardous Materials ManagementkudaiNo ratings yet

- Result Sheets - Newcastle Dis, Q.4, 2016Document2 pagesResult Sheets - Newcastle Dis, Q.4, 2016larep57301No ratings yet

- Line Set Up SopDocument3 pagesLine Set Up SopProf C.S.PurushothamanNo ratings yet

- Testing Kit Availability: ROB ROB ROB ROBDocument3 pagesTesting Kit Availability: ROB ROB ROB ROBOliver CelestialNo ratings yet

- Tile Setter Accomplishment Report: Engr. Amiel Bryan Manreal Project SupervisorDocument1 pageTile Setter Accomplishment Report: Engr. Amiel Bryan Manreal Project SupervisorBryan MänrealNo ratings yet

- YMC Interpretation GuideDocument6 pagesYMC Interpretation Guiderubelyn088No ratings yet

- Bacterial Loads in A Kitchen SpongeDocument4 pagesBacterial Loads in A Kitchen SpongeGUIDO ERNESTO VILLOTA CALVACHINo ratings yet

- MA-K13383-EM Issue 3 Signum Onboard ManualDocument7 pagesMA-K13383-EM Issue 3 Signum Onboard ManualFamilia De Fernando Oscar Bilotti100% (1)

- Bourbon Barrel Aging OptimizationDocument4 pagesBourbon Barrel Aging Optimizationcosmoal.zoomNo ratings yet

- Batch Packing RecordDocument1 pageBatch Packing RecordGBL 22100% (1)

- SOP NEW ModifiedDocument1 pageSOP NEW ModifiedKavita DeviNo ratings yet

- PANERA-04 Artisan BreadsDocument26 pagesPANERA-04 Artisan BreadsGreatRecipeCollectr29No ratings yet

- Labelling Compliance Workshop PM & Region Wise Labelling Routine s9 - Textile S9 v3.2Document100 pagesLabelling Compliance Workshop PM & Region Wise Labelling Routine s9 - Textile S9 v3.2Apurba DeyNo ratings yet

- Surjani Town Shop 1Document4 pagesSurjani Town Shop 1qamarNo ratings yet

- BUNSENDocument14 pagesBUNSENPeter S. SumayangNo ratings yet

- An Approach To M.TBDocument42 pagesAn Approach To M.TBKamala NathanNo ratings yet

- Agama Kunci JawabanDocument6 pagesAgama Kunci JawabanLionus BryanCNo ratings yet

- LabelDocument2 pagesLabelDesi Ris SaputriNo ratings yet

- 127 - Hse Inspection Checklist-Compressed Gas CylinderDocument1 page127 - Hse Inspection Checklist-Compressed Gas CylinderEr Ajenk80% (10)

- Sampling Oil Schedule: Technical DeptDocument6 pagesSampling Oil Schedule: Technical Deptkanthi_weningNo ratings yet

- NECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Document14 pagesNECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Thai Hai LyNo ratings yet

- In Line Inspection - BBLK-PO-9477-27-01-2020Document2 pagesIn Line Inspection - BBLK-PO-9477-27-01-2020prageethnirudakaNo ratings yet

- Mock Drill TemplateDocument7 pagesMock Drill TemplateAnkurNo ratings yet

- PIHECDocument9 pagesPIHECMuhammad Izat Abu TalibNo ratings yet

- Delivery Information Sheet ScienceDocument15 pagesDelivery Information Sheet ScienceRODNIE GUBATONNo ratings yet

- Bahan Prevetting OBDocument3 pagesBahan Prevetting OBpmt xlv1115No ratings yet

- List DBL Papua Crew 2019Document4 pagesList DBL Papua Crew 2019Muhammad RidwanNo ratings yet

- Abinbev November Newsletter PDFDocument10 pagesAbinbev November Newsletter PDFBenson MangomaNo ratings yet

- Biology Plan and Design Lab - Darren RamnarineDocument7 pagesBiology Plan and Design Lab - Darren Ramnarinedarrenramnarine2007No ratings yet

- What Is Aql 1.5 Aql 2.5 Inspection System in Clothing Manufacturers Garments Industry What Is Aql in Clothing Manufacturers Quality Control SynergDocument7 pagesWhat Is Aql 1.5 Aql 2.5 Inspection System in Clothing Manufacturers Garments Industry What Is Aql in Clothing Manufacturers Quality Control Synerggolam.rumyNo ratings yet

- Amx125 &250Document2 pagesAmx125 &250Ashish SharmaNo ratings yet

- Soal Label MakananDocument1 pageSoal Label MakananDodi SaputraNo ratings yet

- Gtc-Spe-Bbs-004 A v3 12x6 OzDocument1 pageGtc-Spe-Bbs-004 A v3 12x6 OzEDUARDONo ratings yet

- Astm e 1346 - 90 R00Document3 pagesAstm e 1346 - 90 R00o_l_0No ratings yet

- CDS 1 General Knowledge 2017Document48 pagesCDS 1 General Knowledge 2017Anonymous HHVNkaNo ratings yet

- Marigold 11kDocument58 pagesMarigold 11kDiogenes Laban B. PosadasNo ratings yet

- Agar Preparation: Course: MCB 103 Lab Section: 1 Name: Noor-E-Khadiza Shama ID: 1921168 Date: 03/03/20Document4 pagesAgar Preparation: Course: MCB 103 Lab Section: 1 Name: Noor-E-Khadiza Shama ID: 1921168 Date: 03/03/20ShamaNo ratings yet

- Toys Direct 2009 Catalog v.001 - 8MBDocument177 pagesToys Direct 2009 Catalog v.001 - 8MBToys Direct Inc100% (2)

- Inspection Report Certificate No. 069/INS-FISH/VI/2012Document5 pagesInspection Report Certificate No. 069/INS-FISH/VI/2012chemistry-rocketNo ratings yet

- STP tm05Document7 pagesSTP tm05prajapati28No ratings yet

- NO Facts Available? StatementsDocument5 pagesNO Facts Available? StatementsYahya Bayu PurnomoNo ratings yet

- Microbiologist Work FlowDocument10 pagesMicrobiologist Work FlowAri DanteNo ratings yet

- Qty Itemsdescription: 3000 Aurora Blvd. Pasay City Metro Manila Tel.#852-0308,853-1812 - Fax # 852-9431Document1 pageQty Itemsdescription: 3000 Aurora Blvd. Pasay City Metro Manila Tel.#852-0308,853-1812 - Fax # 852-9431Jessie GargantosNo ratings yet

- Proflok Cav AbDocument6 pagesProflok Cav Abikram chohanNo ratings yet

- Airfix Magazine - Volume 5 6Document48 pagesAirfix Magazine - Volume 5 6Cem Avci100% (1)

- Estimating Package Stability of Coatings For Ultraviolet CuringDocument2 pagesEstimating Package Stability of Coatings For Ultraviolet Curingsaifullah629No ratings yet

- CO2 4.5 KG Fire ExtinguisherDocument2 pagesCO2 4.5 KG Fire ExtinguishervivekvpsfeNo ratings yet

- SPECIFICATION SHEET (Tilapia Fillet)Document1 pageSPECIFICATION SHEET (Tilapia Fillet)compras.colsenNo ratings yet

- ProductsdataDocument1 pageProductsdataganeesh.g94No ratings yet

- States of Matter NotesDocument8 pagesStates of Matter NotesRaya Ibarra LumogdangNo ratings yet

- Chapter 6 Chm431 ColloidDocument48 pagesChapter 6 Chm431 ColloidSiti Wajihah Mohd NazriNo ratings yet

- Guidance For Accreditation of Laboratories Under RNTCP For Mycobacterial Culture &DSTDocument13 pagesGuidance For Accreditation of Laboratories Under RNTCP For Mycobacterial Culture &DSTSravan SravanNo ratings yet

- Collection and Preservation of Water SamplesDocument24 pagesCollection and Preservation of Water SamplesSyed Talha AhmedNo ratings yet

- Effect of Homogenizing Pressure and Sterilizing Condition On Quality of Canned High Fat Coconut MilkDocument7 pagesEffect of Homogenizing Pressure and Sterilizing Condition On Quality of Canned High Fat Coconut MilkAn TrầnNo ratings yet

- Dse4120 Manual PDFDocument30 pagesDse4120 Manual PDFnhocti007No ratings yet

- BROCHURE Low Range DIGI Water KitDocument2 pagesBROCHURE Low Range DIGI Water KitZts MksNo ratings yet

- Qualcast 430W Grass Trimmer: Instruction ManualDocument17 pagesQualcast 430W Grass Trimmer: Instruction ManualbhupstaNo ratings yet

- Assembling Extension CordDocument14 pagesAssembling Extension CordPaul Bulanadi Badiang67% (3)

- AAAC ButteDocument2 pagesAAAC ButtePhillippe FoixNo ratings yet

- Basic Concepts in Engineering MetallurgyDocument2 pagesBasic Concepts in Engineering Metallurgykaru320No ratings yet

- Wellsteg eDocument14 pagesWellsteg eron_danyNo ratings yet

- Nibco CatalogueDocument104 pagesNibco CatalogueIvan KolicNo ratings yet

- 3.1 Clothing Performance Requirements - March 22Document60 pages3.1 Clothing Performance Requirements - March 22Rohan KabirNo ratings yet

- Vessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure VesselDocument19 pagesVessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure Vesselbhalchandrak1867No ratings yet

- WAEC Metal Work Past QuestionsDocument7 pagesWAEC Metal Work Past QuestionsCharles Obaleagbon0% (1)

- Ceiling Recessed LightDocument1 pageCeiling Recessed LightMohamedNo ratings yet

- Exposure Lamps, UV & IR LampsDocument3 pagesExposure Lamps, UV & IR LampsBruce KampermanNo ratings yet

- Astm C497 20Document11 pagesAstm C497 20Tayef TalukderNo ratings yet

- ElectrogravimetryDocument11 pagesElectrogravimetryElijah AlvesNo ratings yet

- EX - CX - 044 - Master Inspection Characteristics MICDocument61 pagesEX - CX - 044 - Master Inspection Characteristics MICyramasapNo ratings yet

- Report Scince 2 (SEM 2)Document10 pagesReport Scince 2 (SEM 2)Hanani KharudinNo ratings yet

- AASHTO T 328-05 Reducing Samples of Hot Mix Asphalt To Testing SizeDocument8 pagesAASHTO T 328-05 Reducing Samples of Hot Mix Asphalt To Testing Sizeclint silNo ratings yet

- Hobersal Muffle Furnaces PR SeriesDocument2 pagesHobersal Muffle Furnaces PR Seriesinna husnaNo ratings yet

- Shop Floor Management TutorialDocument45 pagesShop Floor Management TutorialDilan FernandoNo ratings yet

- 815 Plus Single HingeDocument2 pages815 Plus Single HingeSaepul RochmanNo ratings yet

- Catalogue FSA 50Hz Rev.02Document6 pagesCatalogue FSA 50Hz Rev.02Heri SulasionoNo ratings yet

- Ohm's LawDocument13 pagesOhm's LawVenu GopalNo ratings yet

- MS51844EDocument5 pagesMS51844Eugur kandemirNo ratings yet