Professional Documents

Culture Documents

8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in Manufacturing

8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in Manufacturing

Uploaded by

Joy SummersCopyright:

Available Formats

You might also like

- Conveyor - EXDocument9 pagesConveyor - EXQuỳnh Nguyễn100% (1)

- Bài Tập Tiểu LuậnDocument5 pagesBài Tập Tiểu LuậnToy and MeNo ratings yet

- Materials Handling and HoistingDocument6 pagesMaterials Handling and HoistingNARGISNo ratings yet

- Agv Ex 1Document1 pageAgv Ex 1Lương Bảo HânNo ratings yet

- Tutorial 2 Storage System PDF FreeDocument2 pagesTutorial 2 Storage System PDF Freepeter oumaNo ratings yet

- Tutorial 2 Storage SystemDocument2 pagesTutorial 2 Storage SystemSu YiNo ratings yet

- Sheet 2 2017-2018Document7 pagesSheet 2 2017-2018Yahya Abdelhameed AamerNo ratings yet

- Mid EXDocument4 pagesMid EXsabeaxNo ratings yet

- Industrial Engineering: Tutorials ForDocument18 pagesIndustrial Engineering: Tutorials ForYahya Abdelhameed AamerNo ratings yet

- REVIEW 1 - MhsDocument3 pagesREVIEW 1 - MhsHoang Anh Huy VoNo ratings yet

- ExercisesDocument4 pagesExercisesTôn Nữ Minh UyênNo ratings yet

- Assignment 2 - Storage SystemsDocument2 pagesAssignment 2 - Storage SystemsTrịnh Thị Khánh TrâmNo ratings yet

- Industrial Engineering Tutorials: 1 Page - 2016-2017Document17 pagesIndustrial Engineering Tutorials: 1 Page - 2016-2017Yahya Abdelhameed AamerNo ratings yet

- Mce - 42052 Fms Tutorial-I 27.8.2019 (Tue)Document2 pagesMce - 42052 Fms Tutorial-I 27.8.2019 (Tue)Ther Htet AungNo ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- Conveyor ExDocument1 pageConveyor Extdkhiem02No ratings yet

- Reviews 1: International UniversityDocument11 pagesReviews 1: International UniversityQuỳnh NguyễnNo ratings yet

- ASRS ExercisesDocument2 pagesASRS ExercisesPhan Gia Nghi100% (1)

- Eazc 4121Document1 pageEazc 4121Priyanka MahajanNo ratings yet

- 5-Conveyor QuestionsDocument4 pages5-Conveyor QuestionsRania ElrifaiNo ratings yet

- Assignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsDocument1 pageAssignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsjcspaiNo ratings yet

- Assignment 5140Document12 pagesAssignment 5140venkatNo ratings yet

- 008987690Document2 pages008987690bbNo ratings yet

- Material Transport Systems TutorialDocument33 pagesMaterial Transport Systems TutorialgidlavinayNo ratings yet

- Question One: Stope Width/m Height/mDocument4 pagesQuestion One: Stope Width/m Height/mTimmy ChawazNo ratings yet

- Reviews 1 - AnswerDocument13 pagesReviews 1 - AnswerQuỳnh NguyễnNo ratings yet

- 15 Integrated Manufacturing Systems Lecture #15 HandoutDocument2 pages15 Integrated Manufacturing Systems Lecture #15 HandoutFelipeNo ratings yet

- M and S QuestionsDocument14 pagesM and S QuestionsswjaffryNo ratings yet

- PDF Gangguan Kelenjar Gonad - CompressDocument9 pagesPDF Gangguan Kelenjar Gonad - CompressAzzNo ratings yet

- Review 1: Focus 1) Chapter 1: Introduction To MHSDocument3 pagesReview 1: Focus 1) Chapter 1: Introduction To MHSKhánh Linh NguyễnNo ratings yet

- Sms Unit-Wise Qs (Sjbit)Document14 pagesSms Unit-Wise Qs (Sjbit)Rudresh CMNo ratings yet

- MM 323 MAN SYS 2012 FALL 6 Automated Production Lines PART 2Document38 pagesMM 323 MAN SYS 2012 FALL 6 Automated Production Lines PART 2ogulcan_aytacNo ratings yet

- Crane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeDocument7 pagesCrane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeGilmar Vieira de SouzaNo ratings yet

- Week 13 OR 27122022 023700pm 09052023 095850am 2 11102023 122223pmDocument31 pagesWeek 13 OR 27122022 023700pm 09052023 095850am 2 11102023 122223pmRITHMETICNo ratings yet

- ProblemsDocument3 pagesProblemsAaqid BhatNo ratings yet

- 15P701Document4 pages15P701rajakrishnanNo ratings yet

- Model Paper 18ME7G3Document4 pagesModel Paper 18ME7G3Xaf FarNo ratings yet

- 07a80307 AutomationinmanufacutringDocument8 pages07a80307 AutomationinmanufacutringSharanya ThirichinapalliNo ratings yet

- Equipment Assignment-3Document4 pagesEquipment Assignment-3Mam's DaughterNo ratings yet

- Assignment FMSDocument2 pagesAssignment FMSAnuragShrivastavNo ratings yet

- 07a81402 Flexible Manufacturing SystemsDocument4 pages07a81402 Flexible Manufacturing SystemsSharanya ThirichinapalliNo ratings yet

- Ee6801 QBDocument15 pagesEe6801 QBtiaNo ratings yet

- Design ExamplesDocument2 pagesDesign ExamplesShivam ShuklaNo ratings yet

- R05220104-Hydraulics and Hydraulic MachineryDocument8 pagesR05220104-Hydraulics and Hydraulic MachinerySRINIVASA RAO GANTANo ratings yet

- Weaving - PickingDocument2 pagesWeaving - PickingSUMONA CHAKRABARTINo ratings yet

- Tutorial - 9 : U18Ci606 Process Control B.Tech. VI Sem (EIE) 03.04.2022Document2 pagesTutorial - 9 : U18Ci606 Process Control B.Tech. VI Sem (EIE) 03.04.2022Raviteja DhammishettyNo ratings yet

- CH3080 Problem Set1to3 2014Document7 pagesCH3080 Problem Set1to3 2014iifNo ratings yet

- Trabajo en Clase No 6Document2 pagesTrabajo en Clase No 6Maria Valentina Mendez PardoNo ratings yet

- Time-Efficient Input Shaping Control of Container Crane SystemsDocument6 pagesTime-Efficient Input Shaping Control of Container Crane SystemsAhmed AricheNo ratings yet

- Ejercicios de ConfiabilidadDocument3 pagesEjercicios de ConfiabilidadIvan Jose HerreraNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.CjananiNo ratings yet

- Tutorial QuestionsDocument4 pagesTutorial Questionsn01910077kNo ratings yet

- MTM CYCLE Test 1 Question BankDocument3 pagesMTM CYCLE Test 1 Question BankRanilprabhu MNo ratings yet

- Ropeway Conveyor and Unloading System Using PLCDocument3 pagesRopeway Conveyor and Unloading System Using PLCeditor_ijcatNo ratings yet

- IMP Questions UEEDocument3 pagesIMP Questions UEEHEMANT ROYNo ratings yet

- Case Study: Design of A Conveyorized Production LineDocument10 pagesCase Study: Design of A Conveyorized Production LineEkta GhongeNo ratings yet

- Ad Iit PDFDocument10 pagesAd Iit PDFsatydevsinghnegiNo ratings yet

- Paper 2 - PYQDocument26 pagesPaper 2 - PYQnitin khariNo ratings yet

- 8478 ESE DEC21 SOE 7 B.tech (ASE) ASEG4014 Gas Dynamics & Jet PropulsionDocument11 pages8478 ESE DEC21 SOE 7 B.tech (ASE) ASEG4014 Gas Dynamics & Jet PropulsionJoy SummersNo ratings yet

- 4-M-UAVSystemDesign 20181101163954.901 XDocument8 pages4-M-UAVSystemDesign 20181101163954.901 XJoy SummersNo ratings yet

- 8448 ESE DEC21 SOE 7 B.tech (ME) EPEG3002 Power Electronics & DrivesDocument2 pages8448 ESE DEC21 SOE 7 B.tech (ME) EPEG3002 Power Electronics & DrivesJoy SummersNo ratings yet

- BBA AVO-III - Airport Functions of AirlinesDocument5 pagesBBA AVO-III - Airport Functions of AirlinesJoy SummersNo ratings yet

- StakeholdersDocument3 pagesStakeholdersโอม' อาฟNo ratings yet

- Mani ResumeDocument3 pagesMani ResumemanikandanNo ratings yet

- A Project Management Meeting: Preparation Task VocabularyDocument2 pagesA Project Management Meeting: Preparation Task VocabularyGissell A Gutierrez GuerreroNo ratings yet

- AVSI - D1.1 - Inception Report - Lixeira - 12 - 02Document29 pagesAVSI - D1.1 - Inception Report - Lixeira - 12 - 02Jorge Da Argentina ChicavanneNo ratings yet

- CV Reneda MehmetajDocument3 pagesCV Reneda Mehmetajluiza muhametajNo ratings yet

- Code of Governance For Private Organizations in KenyaDocument26 pagesCode of Governance For Private Organizations in KenyaLeila Kay-heen100% (1)

- Cost Accounting Midterm Exam - Attempt ReviewDocument18 pagesCost Accounting Midterm Exam - Attempt ReviewkielmorganzapietoNo ratings yet

- MSBP Assignment 2 Brief - Sem 1 - 2023-2024Document6 pagesMSBP Assignment 2 Brief - Sem 1 - 2023-2024Ngọc Phương Trịnh100% (1)

- Principles of Marketing Canadian 9th Edition Kotler Test BankDocument25 pagesPrinciples of Marketing Canadian 9th Edition Kotler Test BankKaylaSmithdbwf100% (38)

- Systems Verification Evidence Report - 3022846 - NVQ2Work - 25012019 PDFDocument8 pagesSystems Verification Evidence Report - 3022846 - NVQ2Work - 25012019 PDFanthony jamesNo ratings yet

- Essay Supply Chain ManagementDocument9 pagesEssay Supply Chain ManagementPelogejywkaNo ratings yet

- Report For Gujarat Conclave Ahmedabad On 5th December 2023Document12 pagesReport For Gujarat Conclave Ahmedabad On 5th December 2023jin leoNo ratings yet

- Strategic Analysis of Marico Industry Ltd.Document15 pagesStrategic Analysis of Marico Industry Ltd.Hitesh Goyal86% (7)

- Blue Light Financial Analyst Simple Profile Resume CV - 20230918 - 120431 - 0000Document1 pageBlue Light Financial Analyst Simple Profile Resume CV - 20230918 - 120431 - 0000Shahzad KhanNo ratings yet

- Small Hotel Housekeeping Organizational Chart: HousekeeperDocument3 pagesSmall Hotel Housekeeping Organizational Chart: HousekeeperMarjaunette Anne C. PosadasNo ratings yet

- Developing Performance Based Work Statements (Compatibility Mode)Document17 pagesDeveloping Performance Based Work Statements (Compatibility Mode)RMANO123No ratings yet

- (VAT) in To: Clarifying (RR) No. The The Tax of (TaxDocument13 pages(VAT) in To: Clarifying (RR) No. The The Tax of (TaxShiela Marie Maraon100% (1)

- Commitment &leadershipDocument8 pagesCommitment &leadership2C ChannelNo ratings yet

- IC Project Schedule Template 10689Document3 pagesIC Project Schedule Template 10689Hichem GuendouzNo ratings yet

- EA List As at 01.02.2022Document5 pagesEA List As at 01.02.2022Radhika YalavarthiNo ratings yet

- IBTDocument3 pagesIBTjoy mesanaNo ratings yet

- Lecture 08: Addressing Competition and Driving Growth: You Are WithDocument26 pagesLecture 08: Addressing Competition and Driving Growth: You Are Witheshu agNo ratings yet

- BRC Vs FSSC 22000: HACCP SystemDocument2 pagesBRC Vs FSSC 22000: HACCP SystemShuvo036No ratings yet

- 310-A STO FY 2024 TIER 1Document12 pages310-A STO FY 2024 TIER 1MOTC INTERNAL AUDIT SECTIONNo ratings yet

- Dupont Analysis of Asian PaintsDocument4 pagesDupont Analysis of Asian Paintsdeepaksg787No ratings yet

- Orient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Document2 pagesOrient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Ravi Shankar ChakravortyNo ratings yet

- Mitchell Financial LeannessDocument25 pagesMitchell Financial LeannessLauren PorterNo ratings yet

- BUS7B50 - BUSI704 Assignment 1 GuideDocument2 pagesBUS7B50 - BUSI704 Assignment 1 Guide1403810245No ratings yet

- Chapter 04 - Organizing The Sales EffortDocument42 pagesChapter 04 - Organizing The Sales EffortAhmad SheiKhNo ratings yet

- Six SigmaDocument23 pagesSix Sigmashubham shindeNo ratings yet

8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in Manufacturing

8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in Manufacturing

Uploaded by

Joy SummersOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in Manufacturing

8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in Manufacturing

Uploaded by

Joy SummersCopyright:

Available Formats

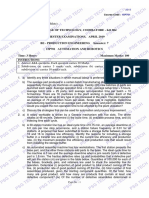

Name:

Enrolment No:

UNIVERSITY OF PETROLEUM & ENERGY STUDIES

Online End Semester Examination , Dec 2021

Course: Automation In Manufacturing Semester:VII

Program:B.Tech Mechatronics & Mechanical Time:03 Hrs

Course Code: MEPD4014 Max Marks: 100

Common for B.Tech ADE, Mechatronics & Mechanical

Section A

1. Each Question will carry 4 Marks

Sl.N Question CO’s

Q1 List for the reasons for Automation. CO1

Q2 Identify the various types of variables and parameters in CO1

process industries and discrete manufacturing industries

Q3 Define the term sensor, transducer and actuator. CO2

Q4 Classify different types of material handling equipment. CO2

Q5 List the different types of AGV (automated guided CO2

vehicles) i.e. being used in industrial automation.

Section B

1. Each Question will carry 10 Marks

Q1 Comment the significance of manual labor in CO2

manufacturing support system.

Q2 A planned fleet of forklift truck has an average travel CO3

distance per delivery =500 ft loaded and an average empty

travel distance =350 ft. The fleet must make a total of 60

del/hour. Loads and unload times are each 0.5 minute and

the speed of the vehicles 300ft/minutes. The traffic for the

system is 0.85. Availability is expected to be 0.95 and

worker efficiency is assumed to be 0.90. Determine: (a)

Ideal cycle time per delivery (b) the resulting average

number of deliveries per hour that a forklift truck can make

and (d) how many trucks are required to accomplish the

60del/hour.

Q3 A roller conveyor moves tote pans in one direction at CO4

150ft/min between a load station

and an unload station, a distance of 200 ft. The time to load

parts into a tote pan at the load

station is 3sec per part. Each tote pan holds 8 parts, In

addition, it takes 9sec to load a tote

pans onto the conveyor. Determine: (a) spacing between tote

pan centers flowing in the conveyor system and (b) flow rate

of parts on the conveyor system. (c) Consider the effect of

the unit load principle. Suppose the tote pans were smaller

and could hold only one part

rather than eight. Determine the flow rate in this case if it

takes 7 sec to load a tote pan onto

the conveyor (instead of 9 sec for the larger tote pan .and it

takes the same 3 sec to load the

part into the tote pan.

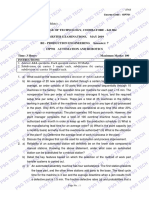

Q4 An automated storage/retrieval system installed in a CO4

warehouse has five aisles. The storage racks in each aisle are

30 ft high and 150fl long. The S/R machine for each aisle

travels at a horizontal speed of 350 It/min and a vertical

speed of 60 ft/min. The pick-and-deposit lime = 0.35 mm.

Assume that the number of single command cycles per hour

is equal to the number of dual command cycles per hour and

that the system operates at 75% utilization.

Determine the throughput rate (loads moved per hour) of the

AS/RS.

Section C

1. Each Question carries 20 Marks.

Q1 (a) Describe the different types of Automated guided CO3

vehicles systems.

(b) Describe the parameters of storage system performance

OR

A 10-aisle automated storage/retrieval system is located in

an integrated factory-warehouse facility. The storage racks

in each aisle are IS m high and 95 m long. The S/R machine

for each aisle travels at a horizontal speed of 1.5 m/sec and

a vertical speed of 0.5 m/sec. Pick-and-deposit time = 20

sec. Assume that the number of single command cycles per

hour is one-hall the number of dual command cycles per

hour and that the system operates at 80% utilization.

Determine the throughput rate (loads moved per hour] of the

AS/RS

Q2 Describe the function and design of carousel storage system. CO4

A single carousel storage system has an oval rail loop that is

30ft long and 3ft wide .Sixty Cameras are equally spaced

around the oval. Suspended from each carrier and five bins.

Each bin has a volumetric capacity = 0.75ft3 .Carousel

speed = 100ft/min. Average pick-and—deposit time for a

retrieval = 20 sec. Determine: (a) volumetric capacity of the

storage system and (b) hourly retrieval rate of the storage

system.

You might also like

- Conveyor - EXDocument9 pagesConveyor - EXQuỳnh Nguyễn100% (1)

- Bài Tập Tiểu LuậnDocument5 pagesBài Tập Tiểu LuậnToy and MeNo ratings yet

- Materials Handling and HoistingDocument6 pagesMaterials Handling and HoistingNARGISNo ratings yet

- Agv Ex 1Document1 pageAgv Ex 1Lương Bảo HânNo ratings yet

- Tutorial 2 Storage System PDF FreeDocument2 pagesTutorial 2 Storage System PDF Freepeter oumaNo ratings yet

- Tutorial 2 Storage SystemDocument2 pagesTutorial 2 Storage SystemSu YiNo ratings yet

- Sheet 2 2017-2018Document7 pagesSheet 2 2017-2018Yahya Abdelhameed AamerNo ratings yet

- Mid EXDocument4 pagesMid EXsabeaxNo ratings yet

- Industrial Engineering: Tutorials ForDocument18 pagesIndustrial Engineering: Tutorials ForYahya Abdelhameed AamerNo ratings yet

- REVIEW 1 - MhsDocument3 pagesREVIEW 1 - MhsHoang Anh Huy VoNo ratings yet

- ExercisesDocument4 pagesExercisesTôn Nữ Minh UyênNo ratings yet

- Assignment 2 - Storage SystemsDocument2 pagesAssignment 2 - Storage SystemsTrịnh Thị Khánh TrâmNo ratings yet

- Industrial Engineering Tutorials: 1 Page - 2016-2017Document17 pagesIndustrial Engineering Tutorials: 1 Page - 2016-2017Yahya Abdelhameed AamerNo ratings yet

- Mce - 42052 Fms Tutorial-I 27.8.2019 (Tue)Document2 pagesMce - 42052 Fms Tutorial-I 27.8.2019 (Tue)Ther Htet AungNo ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- 15P701Document3 pages15P701rajakrishnanNo ratings yet

- Conveyor ExDocument1 pageConveyor Extdkhiem02No ratings yet

- Reviews 1: International UniversityDocument11 pagesReviews 1: International UniversityQuỳnh NguyễnNo ratings yet

- ASRS ExercisesDocument2 pagesASRS ExercisesPhan Gia Nghi100% (1)

- Eazc 4121Document1 pageEazc 4121Priyanka MahajanNo ratings yet

- 5-Conveyor QuestionsDocument4 pages5-Conveyor QuestionsRania ElrifaiNo ratings yet

- Assignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsDocument1 pageAssignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsjcspaiNo ratings yet

- Assignment 5140Document12 pagesAssignment 5140venkatNo ratings yet

- 008987690Document2 pages008987690bbNo ratings yet

- Material Transport Systems TutorialDocument33 pagesMaterial Transport Systems TutorialgidlavinayNo ratings yet

- Question One: Stope Width/m Height/mDocument4 pagesQuestion One: Stope Width/m Height/mTimmy ChawazNo ratings yet

- Reviews 1 - AnswerDocument13 pagesReviews 1 - AnswerQuỳnh NguyễnNo ratings yet

- 15 Integrated Manufacturing Systems Lecture #15 HandoutDocument2 pages15 Integrated Manufacturing Systems Lecture #15 HandoutFelipeNo ratings yet

- M and S QuestionsDocument14 pagesM and S QuestionsswjaffryNo ratings yet

- PDF Gangguan Kelenjar Gonad - CompressDocument9 pagesPDF Gangguan Kelenjar Gonad - CompressAzzNo ratings yet

- Review 1: Focus 1) Chapter 1: Introduction To MHSDocument3 pagesReview 1: Focus 1) Chapter 1: Introduction To MHSKhánh Linh NguyễnNo ratings yet

- Sms Unit-Wise Qs (Sjbit)Document14 pagesSms Unit-Wise Qs (Sjbit)Rudresh CMNo ratings yet

- MM 323 MAN SYS 2012 FALL 6 Automated Production Lines PART 2Document38 pagesMM 323 MAN SYS 2012 FALL 6 Automated Production Lines PART 2ogulcan_aytacNo ratings yet

- Crane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeDocument7 pagesCrane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeGilmar Vieira de SouzaNo ratings yet

- Week 13 OR 27122022 023700pm 09052023 095850am 2 11102023 122223pmDocument31 pagesWeek 13 OR 27122022 023700pm 09052023 095850am 2 11102023 122223pmRITHMETICNo ratings yet

- ProblemsDocument3 pagesProblemsAaqid BhatNo ratings yet

- 15P701Document4 pages15P701rajakrishnanNo ratings yet

- Model Paper 18ME7G3Document4 pagesModel Paper 18ME7G3Xaf FarNo ratings yet

- 07a80307 AutomationinmanufacutringDocument8 pages07a80307 AutomationinmanufacutringSharanya ThirichinapalliNo ratings yet

- Equipment Assignment-3Document4 pagesEquipment Assignment-3Mam's DaughterNo ratings yet

- Assignment FMSDocument2 pagesAssignment FMSAnuragShrivastavNo ratings yet

- 07a81402 Flexible Manufacturing SystemsDocument4 pages07a81402 Flexible Manufacturing SystemsSharanya ThirichinapalliNo ratings yet

- Ee6801 QBDocument15 pagesEe6801 QBtiaNo ratings yet

- Design ExamplesDocument2 pagesDesign ExamplesShivam ShuklaNo ratings yet

- R05220104-Hydraulics and Hydraulic MachineryDocument8 pagesR05220104-Hydraulics and Hydraulic MachinerySRINIVASA RAO GANTANo ratings yet

- Weaving - PickingDocument2 pagesWeaving - PickingSUMONA CHAKRABARTINo ratings yet

- Tutorial - 9 : U18Ci606 Process Control B.Tech. VI Sem (EIE) 03.04.2022Document2 pagesTutorial - 9 : U18Ci606 Process Control B.Tech. VI Sem (EIE) 03.04.2022Raviteja DhammishettyNo ratings yet

- CH3080 Problem Set1to3 2014Document7 pagesCH3080 Problem Set1to3 2014iifNo ratings yet

- Trabajo en Clase No 6Document2 pagesTrabajo en Clase No 6Maria Valentina Mendez PardoNo ratings yet

- Time-Efficient Input Shaping Control of Container Crane SystemsDocument6 pagesTime-Efficient Input Shaping Control of Container Crane SystemsAhmed AricheNo ratings yet

- Ejercicios de ConfiabilidadDocument3 pagesEjercicios de ConfiabilidadIvan Jose HerreraNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.CjananiNo ratings yet

- Tutorial QuestionsDocument4 pagesTutorial Questionsn01910077kNo ratings yet

- MTM CYCLE Test 1 Question BankDocument3 pagesMTM CYCLE Test 1 Question BankRanilprabhu MNo ratings yet

- Ropeway Conveyor and Unloading System Using PLCDocument3 pagesRopeway Conveyor and Unloading System Using PLCeditor_ijcatNo ratings yet

- IMP Questions UEEDocument3 pagesIMP Questions UEEHEMANT ROYNo ratings yet

- Case Study: Design of A Conveyorized Production LineDocument10 pagesCase Study: Design of A Conveyorized Production LineEkta GhongeNo ratings yet

- Ad Iit PDFDocument10 pagesAd Iit PDFsatydevsinghnegiNo ratings yet

- Paper 2 - PYQDocument26 pagesPaper 2 - PYQnitin khariNo ratings yet

- 8478 ESE DEC21 SOE 7 B.tech (ASE) ASEG4014 Gas Dynamics & Jet PropulsionDocument11 pages8478 ESE DEC21 SOE 7 B.tech (ASE) ASEG4014 Gas Dynamics & Jet PropulsionJoy SummersNo ratings yet

- 4-M-UAVSystemDesign 20181101163954.901 XDocument8 pages4-M-UAVSystemDesign 20181101163954.901 XJoy SummersNo ratings yet

- 8448 ESE DEC21 SOE 7 B.tech (ME) EPEG3002 Power Electronics & DrivesDocument2 pages8448 ESE DEC21 SOE 7 B.tech (ME) EPEG3002 Power Electronics & DrivesJoy SummersNo ratings yet

- BBA AVO-III - Airport Functions of AirlinesDocument5 pagesBBA AVO-III - Airport Functions of AirlinesJoy SummersNo ratings yet

- StakeholdersDocument3 pagesStakeholdersโอม' อาฟNo ratings yet

- Mani ResumeDocument3 pagesMani ResumemanikandanNo ratings yet

- A Project Management Meeting: Preparation Task VocabularyDocument2 pagesA Project Management Meeting: Preparation Task VocabularyGissell A Gutierrez GuerreroNo ratings yet

- AVSI - D1.1 - Inception Report - Lixeira - 12 - 02Document29 pagesAVSI - D1.1 - Inception Report - Lixeira - 12 - 02Jorge Da Argentina ChicavanneNo ratings yet

- CV Reneda MehmetajDocument3 pagesCV Reneda Mehmetajluiza muhametajNo ratings yet

- Code of Governance For Private Organizations in KenyaDocument26 pagesCode of Governance For Private Organizations in KenyaLeila Kay-heen100% (1)

- Cost Accounting Midterm Exam - Attempt ReviewDocument18 pagesCost Accounting Midterm Exam - Attempt ReviewkielmorganzapietoNo ratings yet

- MSBP Assignment 2 Brief - Sem 1 - 2023-2024Document6 pagesMSBP Assignment 2 Brief - Sem 1 - 2023-2024Ngọc Phương Trịnh100% (1)

- Principles of Marketing Canadian 9th Edition Kotler Test BankDocument25 pagesPrinciples of Marketing Canadian 9th Edition Kotler Test BankKaylaSmithdbwf100% (38)

- Systems Verification Evidence Report - 3022846 - NVQ2Work - 25012019 PDFDocument8 pagesSystems Verification Evidence Report - 3022846 - NVQ2Work - 25012019 PDFanthony jamesNo ratings yet

- Essay Supply Chain ManagementDocument9 pagesEssay Supply Chain ManagementPelogejywkaNo ratings yet

- Report For Gujarat Conclave Ahmedabad On 5th December 2023Document12 pagesReport For Gujarat Conclave Ahmedabad On 5th December 2023jin leoNo ratings yet

- Strategic Analysis of Marico Industry Ltd.Document15 pagesStrategic Analysis of Marico Industry Ltd.Hitesh Goyal86% (7)

- Blue Light Financial Analyst Simple Profile Resume CV - 20230918 - 120431 - 0000Document1 pageBlue Light Financial Analyst Simple Profile Resume CV - 20230918 - 120431 - 0000Shahzad KhanNo ratings yet

- Small Hotel Housekeeping Organizational Chart: HousekeeperDocument3 pagesSmall Hotel Housekeeping Organizational Chart: HousekeeperMarjaunette Anne C. PosadasNo ratings yet

- Developing Performance Based Work Statements (Compatibility Mode)Document17 pagesDeveloping Performance Based Work Statements (Compatibility Mode)RMANO123No ratings yet

- (VAT) in To: Clarifying (RR) No. The The Tax of (TaxDocument13 pages(VAT) in To: Clarifying (RR) No. The The Tax of (TaxShiela Marie Maraon100% (1)

- Commitment &leadershipDocument8 pagesCommitment &leadership2C ChannelNo ratings yet

- IC Project Schedule Template 10689Document3 pagesIC Project Schedule Template 10689Hichem GuendouzNo ratings yet

- EA List As at 01.02.2022Document5 pagesEA List As at 01.02.2022Radhika YalavarthiNo ratings yet

- IBTDocument3 pagesIBTjoy mesanaNo ratings yet

- Lecture 08: Addressing Competition and Driving Growth: You Are WithDocument26 pagesLecture 08: Addressing Competition and Driving Growth: You Are Witheshu agNo ratings yet

- BRC Vs FSSC 22000: HACCP SystemDocument2 pagesBRC Vs FSSC 22000: HACCP SystemShuvo036No ratings yet

- 310-A STO FY 2024 TIER 1Document12 pages310-A STO FY 2024 TIER 1MOTC INTERNAL AUDIT SECTIONNo ratings yet

- Dupont Analysis of Asian PaintsDocument4 pagesDupont Analysis of Asian Paintsdeepaksg787No ratings yet

- Orient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Document2 pagesOrient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Ravi Shankar ChakravortyNo ratings yet

- Mitchell Financial LeannessDocument25 pagesMitchell Financial LeannessLauren PorterNo ratings yet

- BUS7B50 - BUSI704 Assignment 1 GuideDocument2 pagesBUS7B50 - BUSI704 Assignment 1 Guide1403810245No ratings yet

- Chapter 04 - Organizing The Sales EffortDocument42 pagesChapter 04 - Organizing The Sales EffortAhmad SheiKhNo ratings yet

- Six SigmaDocument23 pagesSix Sigmashubham shindeNo ratings yet