Professional Documents

Culture Documents

Materi 2

Materi 2

Uploaded by

Arulloh SonjaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materi 2

Materi 2

Uploaded by

Arulloh SonjaCopyright:

Available Formats

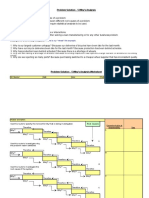

People Parts

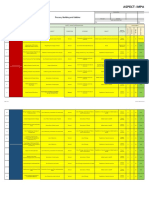

Comprehensive List of Causes

A TOOL FOR ROOT CAUSE ANALYSIS

Solutions

DESCRIPTION OF IMPLEMENTATION & RESEARCH PHASES: ANALYSIS PHASE:

INCIDENT EVIDENCE GATHERING IDENTIFICATION OF CRITICAL FACTORS

• Document the type / severity of • Gather relevant evidence • Organise all evidence

event • Implementation phase = direct evidence (scene and witnesses) • Map evidence Positions Paper

• Cover the who / what / when / • Research phase = indirect evidence (written sources) • Identify critical factors

where / how as known at the time

• Consider People / Parts / Position / Paper • Use CLC to identify all immediate and root causes

POSSIBLE IMMEDIATE CAUSES

ACTIONS CONDITIONS

1. FollowingProcedures 2. Use of Tools or Equipment 3. Use of Protective Methods 4. Inattention / Lack of Awareness 5. Protective Systems 6. Tools, Equipment & Vehicles 7. Work Exposures to 8. Work Place Environment / Layout

1-1 Violation by individual 2-1 Improper use of equipment 3-1 Lack of knowledge of hazards present 4-1 Improper decision making or lack of judgment 5-1 Inadequate guards or protective devices 6-1 Defective equipment 7-1 Fire or explosion 8-1 Congestion or restricted motion

1-2 Violation by group 2-2 Improper use of tools 3-2 Personal protective equipment not used 4-2 Distracted by other concerns 5-2 Defective guards or protective devices 6-2 Inadequate equipment 7-2 Noise 8-2 Inadequate or excessive illumination

1-3 Violation by supervisor 2-3 Use of defective equipment (aware) 3-3 Improper use of proper personal protective 4-3 Inattention to footing and surroundings 5-3 Inadequate personal protective equipment 6-3 Improperly prepared equipment 7-3 Energized electrical systems 8-3 Inadequate ventilation

1-4 Operation of equipment without authority 2-4 Use of defective tools (aware) equipment 4-4 Horseplay 5-4 Defective personal protective equipment 6-4 Defective tools 7-4 Energized systems, other than electrical 8-4 Unprotected height

1-5 Improper position or posture for the task 2-5 Improper placement of tools, equipment or 3-4 Servicing of energized equipment 4-5 Acts of violence 5-5 Inadequate warning systems 6-5 Inadequate tools 7-5 Radiation 8-5 Inadequate work place layout

1-6 Overexertion of physical capability materials 3-5 Equipment or materials not secured 4-6 Failure to warn 5-6 Defective warning systems 6-6 Improperly prepared tools 7-6 Temperature extremes • controls less than adequate

1-7 Work or motion at improper speed 2-6 Operation of equipment at improper speed 3-6 Disabled guards, warning systems or safety 4-7 Use of drugs or alcohol 5-7 Inadequate isolation of process or equipment 6-7 Defective vehicle 7-7 Hazardous chemicals • displays less than adequate

1-8 Improper lifting 2-7 Servicing of equipment in operation devices 4-8 Routine activity without thought 5-8 Inadequate safety devices 6-8 Inadequate vehicle for the purpose 7-8 Mechanical hazards • labels less than adequate

1-9 Improper loading 2-8 Other 3-7 Removal of guards, warning systems or safety 4-9 Other 5-9 Defective safety devices 6-9 Improperly prepared vehicle 7-9 Clutter or debris • locations out of reach or sight

1-10 Shortcuts devices 5-10 Other 6-10 Other 7-10 Storms or acts of nature • conflicting information is presented

1-11 Other 3-8 Personal protective equipment not available 7-11 Slippery floors or walkways 8-6 Other

3-9 Other 7-12 Other

POSSIBLE SYSTEM CAUSES

PERSONAL FACTORS JOB FACTORS

1. Physical Capability 2. Physical 3. Mental State 4. Mental Stress 5. Behavior 6. Skill Level 7. Training / Knowledge 8. Management / 9. Contractor 10. Engineering / 11. Work Planning 12. Purchasing, Material 13. Tools & Equipment 14. Work Rules / Policies / 15. Communication

1-1 Vision deficiency Condition 3-1 Poor judgment 4-1 Preoccupation with 5-1 Improper performance 6-1 Inadequate Transfer Supervision / Employee Selection & Design 11--1

11 Inadequate work Handling & Material 13--1 Inadequate

13 Standards / Procedures (PSP) 15--1

15 Inadequate horizontal

1-2 Hearing deficiency 2-1 Previous injury or 3-2 Memory failure problems is rewarded assessment of 7-1 Inadequate knowledge Leadership Oversight 10--1 Inadequate technical

10 planning Control assessment of needs 14--1

14 Lack of PSP for the task communication

1-3 Other sensory illness 3-3 Poor coordination 4-2 Frustration • saves time or effort required skills transfer 8-1 Conflicting roles / 9-1 Lack of contractor design 11--2

11 Inadequate preventive 12--1

12 Incorrect item and risks •lack of defined responsibility between peers

deficiency 2-2 Fatigue or reaction time 4-3 Confusing • avoids discomfort 6-2 Inadequate • inability to responsibilities pre-qualifications • design input maintenance received 13--2 Inadequate human

13 for PSP 15--2

15 Inadequate vertical

1-4 Reduced respiratory • due to 3-4 Emotional directions / • gains attention practice of skill comprehend • unclear reporting 9-2 Inadequate obsolete • assessment of •inadequate factors / ergonomics •lack of job safety analysis communication

capacity workload disturbance demands 5-2 Improper supervisory 6-3 Infrequent • inadequate relationships contractor pre- • design input not needs specifications to considerations •inadequate job safety between supervisor

1-5 Other permanent • due to lack of 3-5 Fears or phobias 4-4 Conflicting example performance of instructor • conflicting reporting qualifications correct • lubrication / vendor 13--3 Inadequate standards

13 analysis and person

physical disabilities rest 3-6 Low mechanical directions / 5-3 Inadequate skill qualifications relationship 9-3 Inadequate • design input not servicing •inadequate or specifications 14--2

14 Inadequate development of PSP 15--3

15 Inadequate

1-6 Temporary • due to aptitude demands identification of critical 6-4 Lack of coaching • inadequate training • unclear assignment of contractor selection available • adjustment / specifications on 13--4 Inadequate availability

13 •inadequate coordination with communication

disabilities sensory 3-7 Low learning 4-5 Meaningless or safe behaviors on skill equipment responsibility 9-4 Use of non -approved • design output assembly requisition 13--5 Inadequate adjustment

13 process / equipment design between different

1-7 Inability to sustain overload aptitude degrading activities 5-4 Inadequate 6-5 Insufficient review • misunderstood • conflicting assignment contractor inadequate • cleaning / •inadequate control / repair / •inadequate employee organizations

body positions 2-3 Diminished 3-8 Influenced by 4-6 Emotional overload reinforcement of of instruction to instructions of responsibility 9-5 Lack of job oversight • design input resurfacing on changes to maintenance involvement in the 15--4

15 Inadequate

1-8 Restricted range of performance medication 4-7 Extreme judgment / critical safe behaviors establish skill 7-2 Inadequate recall of • improper or 9-6 Inadequate oversight infeasible 11--3

11 Inadequate repair orders 13--6 Inadequate salvage

13 development communication

body movement • due to 3-9 Other decision demands • proper 6-6 Other training material insufficient delegation 9-7 Other • design output • communication of •unauthorized and reclamation •inadequate definition of between work groups

1-9 Substance temperature 4-8 Extreme performance is • training not of authority unclear needed repair substitution 13--7 Inadequate removal /

13 corrective actions 15--5

15 Inadequate

sensitivities or extremes o Not Applicable concentration / criticized o Not Applicable reinforced on the job 8-2 Inadequate leadership o Not Applicable • design output not • scheduling of work •inadequate product replacement of •inadequate format for easy communication

allergies • due to oxygen perception • inappropriate peer • inadequate refresher • standards of correct • examination of acceptance unsuitable items use between shifts

1-10 Inadequate size or deficiency demands pressure training frequency performance missing • design output parts requirements 13--8 No equipment record

13 14--3

14 Inadequate implementation of 15--6

15 Inadequate

strength • due to 4-9 Extreme boredom • inadequate 7-3 Inadequate training or not enforced inconsistent • parts substitution •no acceptance history PSP, due to deficiencies communication

1-11 Diminished capacity atmospheric performance effort • inadequate • no independent 11--4

11 Excessive wear and verification 13--9 Inadequate equipment

13 •contradictory requirements methods

4-10 Other

due to medication pressure feedback • inadequate training accountability design review tear performed record history •confusing format 15--7

15 No communication

variation o Not Applicable • inadequate program design • inadequate or 10--2 Inadequate

10 • inadequate 12--2

12 Inadequate research •more than one action per method available

1-12 Other 13-10 Other

2-4 Blood sugar disciplinary process • inadequate training incorrect performance standards, planning for use on materials / step 15-8

15- Incorrect instructions

o Not Applicable insufficiency 5-5 Inappropriate goals / objectives feedback specifications, and / • extension of service equipment •no check- off spaces provided 15--9

15 Inadequate

o Not Applicable

2-5 Impairment due aggression • inadequate new • inadequate work site or design criteria life 12--3

12 Inadequate mode or •inaccurate sequence of steps communication due to

to drug or alcohol 5-6 Improper use of employee walk-through 10--3 Inadequate

10 • improper loading route of shipment •confusing instructions job turnover

use production incentives orientation • inadequate safety assessment of • use by untrained 12--4

12 Improper handling of •technical error / missing 15--10

15 Inadequate

5-7 Supervisor implied • inadequate initial promotion potential failure people materials steps communication of

2-6 Other

haste training 8-3 Inadequate correction of 10--4 Inadequate

10 • use for wrong 12--5

12 Improper storage of •excessive references safety and health

o Not Applicable 5-8 Employee perceived • inadequate means prior hazard / incident ergonomic design purpose materials or spare •potential situations not data, regulations or

haste to determine if 8-4 Inadequate identification 10--5 Inadequate

10 11--5

11 Inadequate reference parts covered guidelines

5-9 Other qualified for job of worksite / job hazards monitoring of materials or publications 12--6

12 Inadequate material 14--4

14 Inadequate enforcement of PSP 15--11

15 Standard terminology

7-4 No training provided 8-5 Inadequate management construction 11--6

11 Inadequate audit / packaging •inadequate monitoring of not used

o Not Applicable • need for training not of change system 10--6 Inadequate

10 inspection / monitoring 12--7

12 Material shelf life work 15--12

15 Verification /

identified 8-6 Inadequate incident assessment of • no documentation exceeded •inadequate supervisory repeat back

• training records reporting / investigation operational • no correction 12--8

12 Improper identification knowledge techniques not used

incorrect or out of system readiness responsibility of hazardous •inadequate reinforcement 15-13

15- Messages too long

date 8-7 Inadequate or lack of 10--7 Inadequate

10 assigned materials •non-compliance not 15--14

15 Speech interference

• new work methods safety meetings monitoring of initial • no accountability 12--9

12 Improper salvage corrected

15-15 Other

introduced without 8-8 Inadequate performance operation for corrective action and / or waste 14--5

14 Inadequate communication of

training measurement & 10--8 Inadequate

10 11--7

11 Inadequate job disposal PSP o Not Applicable\

• decision made not to assessment evaluation and / or placement 12--10

12 Inadequate use of •incomplete distribution to

train 8-9 Other documentation of • appropriate safety and health data work groups

7-5 Other change personnel not 12-11 Other •inadequate translation to

o Not Applicable identified appropriate languages

o Not Applicable 10-9 Other o Not Applicable

• appropriate •incomplete integration with

o Not Applicable personnel not training

available •out of date revisions still in

For each identified critical factor, consider if any of the listed root

• appropriate use

cause categories apply. If 'yes,' circle the specific root cause.

personnel not 14-6 Other

If none of the root causes in the category apply, then check the

provided o Not Applicable

'not applicable' box at the bottom of the column.

11-8 Other

o Not Applicable

CORRECTIVE PHASE: PROPOSALS FOR CORRECTIVE ACTION

• Align with ‘Getting HSE Right’ elements

ELEMENTS OF GETTING HSE RIGHT

Leadership and Risk Assessment and People, Training and Working with Facilities Design and Operations and Management of Information and Customers and Community and Crisis and Emergency Incidents Analysis and Assessment, Assurance

Accountability Management Behaviours Contractors and Others Construction Maintenance Change Documentation Products Stakeholder Awareness Management Prevention and Improvement

You might also like

- Full Download PDF of Test Bank For Clinical Nursing Skills: A Concept-Based Approach, Volume Iii 3rd Edition by Barbara Callahan All ChapterDocument36 pagesFull Download PDF of Test Bank For Clinical Nursing Skills: A Concept-Based Approach, Volume Iii 3rd Edition by Barbara Callahan All Chaptershwyatnahna100% (3)

- TapRoot DictionaryDocument78 pagesTapRoot Dictionaryransmultikreasi100% (2)

- Predictions OnlyDocument89 pagesPredictions OnlyJan Crizza Dale R. Franco73% (11)

- Comprehensive List of Causes: A Tool For Root Cause AnalysisDocument1 pageComprehensive List of Causes: A Tool For Root Cause AnalysisChandru75% (4)

- CLC Poster AWDocument1 pageCLC Poster AWmharja100% (2)

- Comprehensive List of CausesDocument1 pageComprehensive List of Causessocrates1958240550% (2)

- TapRooT BriefDocument16 pagesTapRooT Briefmuhammadsuhaib100% (3)

- Document 312 - Assessment 10.2 - Older Adult Programv2 FINAL v3Document17 pagesDocument 312 - Assessment 10.2 - Older Adult Programv2 FINAL v3Ronald Zapata TNo ratings yet

- TW Nabors Chevron HES Bridging Document Annual Revision 2014Document35 pagesTW Nabors Chevron HES Bridging Document Annual Revision 2014bilouNo ratings yet

- Incident Classification and ReportingDocument56 pagesIncident Classification and ReportingMahmoud Ahmed Ali Abdelrazik100% (2)

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument6 pagesSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartSalman Alfarisi100% (1)

- FIELD GUIDE Preventing Serious Injury & FatalitiesGO1965Document16 pagesFIELD GUIDE Preventing Serious Injury & FatalitiesGO1965ekoimampNo ratings yet

- HSE Manual: Tripod-DELTADocument52 pagesHSE Manual: Tripod-DELTAClive Nicli100% (4)

- Comprehensive List of CausesDocument1 pageComprehensive List of CausesTuan VuNo ratings yet

- Checklist For Lifting Plan: S/N Items YES NO RemarksDocument1 pageChecklist For Lifting Plan: S/N Items YES NO RemarksAndrianoNo ratings yet

- OHS-PR-02-22 Procurement Contractor ManagementDocument25 pagesOHS-PR-02-22 Procurement Contractor ManagementSn Ahsan100% (3)

- CLC - Poster Causas ACR PDFDocument1 pageCLC - Poster Causas ACR PDFMiguel Romero75% (4)

- 14 RCAT - Root Cause Analysis TechniquesDocument3 pages14 RCAT - Root Cause Analysis TechniquesDanny Durham50% (2)

- Comprehensive List of Causes: A Tool For Root Cause AnalysisDocument2 pagesComprehensive List of Causes: A Tool For Root Cause Analysissheerazali100% (2)

- Hazard HuntDocument1 pageHazard HuntGrace PassiniNo ratings yet

- JHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion FormDocument3 pagesJHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion Formtjeng syuwenNo ratings yet

- System Cause Analyzed Technique Accident Investigation Root Analysis Cause ChecklistDocument5 pagesSystem Cause Analyzed Technique Accident Investigation Root Analysis Cause ChecklistponggoooNo ratings yet

- CLS Root Cause Analysis Tool2Document2 pagesCLS Root Cause Analysis Tool2mouataz elsherbiny100% (1)

- Causation Analysis ModelDocument1 pageCausation Analysis ModelElla Agbettor100% (1)

- S C A T: Ystematic Ause Nalysis EchniqueDocument15 pagesS C A T: Ystematic Ause Nalysis Echniqueauyin100% (1)

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument4 pagesSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartponggoooNo ratings yet

- Procedure For Job Safety Analysis (Final CO-HSE)Document17 pagesProcedure For Job Safety Analysis (Final CO-HSE)sanrexiNo ratings yet

- Incident Investigation ORG RSK PRO 001Document16 pagesIncident Investigation ORG RSK PRO 001ChrisNo ratings yet

- Root Cause Analysis Template 44Document3 pagesRoot Cause Analysis Template 44Devi Chintya100% (1)

- New Incident Reporting MatrixDocument2 pagesNew Incident Reporting MatrixRohan Shelar100% (2)

- Accident - Incident InvestigationDocument62 pagesAccident - Incident InvestigationSubhendu HatiNo ratings yet

- CHESM GuidanceDocument27 pagesCHESM GuidanceFitri MunicaNo ratings yet

- HSE CaseDocument95 pagesHSE CaseHafiz Akhtar100% (3)

- Operational Excellence OemsDocument12 pagesOperational Excellence OemsSatria 'igin' Girindra NugrahaNo ratings yet

- How To Carry Out Problem Solving: Value Chain Competitiveness (VCC)Document26 pagesHow To Carry Out Problem Solving: Value Chain Competitiveness (VCC)suhasNo ratings yet

- University of Nevada, Reno: Crane & Hoist Safety ProgramDocument31 pagesUniversity of Nevada, Reno: Crane & Hoist Safety ProgramSs SelvanNo ratings yet

- QEHS Manual PDFDocument113 pagesQEHS Manual PDFSubhi El Haj SalehNo ratings yet

- Questions For Root Cause Analysis Participants (Job Titles)Document4 pagesQuestions For Root Cause Analysis Participants (Job Titles)paul_aldNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: Corporate HSE AuditsDocument21 pagesPetroleum Development Oman L.L.C.: Document Title: Corporate HSE AuditsMashur Al JunaibiNo ratings yet

- 5 Whys Analysis SheetDocument3 pages5 Whys Analysis SheetbhushansalunkeNo ratings yet

- GembaWalk TemplateDocument1 pageGembaWalk TemplateDaniel100% (2)

- Permit To Work ProcedureDocument18 pagesPermit To Work ProcedureRaghavendra Kiran100% (1)

- Stop Work Authority TBTDocument9 pagesStop Work Authority TBTEeverPaul Casaclang DeLeonNo ratings yet

- Emergency PreparednessDocument15 pagesEmergency PreparednessDaniel67% (3)

- EGPC PSM GL 007 Safety Critical Element SCE Management GuidelineDocument49 pagesEGPC PSM GL 007 Safety Critical Element SCE Management Guidelinekhaled farag100% (6)

- HSE HandbookDocument53 pagesHSE Handbookmuthuswamy77No ratings yet

- Truck Load-Out ChecklistDocument3 pagesTruck Load-Out ChecklistIsaac Anthony100% (2)

- HSE-000-GUD-0001 Guideline To Elaborate HSE PlanDocument16 pagesHSE-000-GUD-0001 Guideline To Elaborate HSE PlanernestoNo ratings yet

- TAP ROOT Course OutlineDocument1 pageTAP ROOT Course OutlineRonald Aranha100% (1)

- SSE ChevronDocument12 pagesSSE ChevronFajriansyah MahfudNo ratings yet

- Drop Object Prevention PlanDocument8 pagesDrop Object Prevention PlanAui Piando100% (1)

- Paparan QhseDocument25 pagesPaparan Qhseherisb100% (1)

- SCAT Systematic Cause Analysis TechniqueDocument36 pagesSCAT Systematic Cause Analysis TechniqueWang Fermi100% (1)

- Critical Equipment Identification and MaintenanceDocument10 pagesCritical Equipment Identification and MaintenanceSyed Mustafa HussainNo ratings yet

- HSE - Operation Controls ABE-HSE-OP-01Document6 pagesHSE - Operation Controls ABE-HSE-OP-01Faisal RazaNo ratings yet

- Audit ProceduresDocument5 pagesAudit Procedureskenoly123No ratings yet

- Hse Directive 8 Electrical PlantsDocument28 pagesHse Directive 8 Electrical PlantsHendri PoerbaNo ratings yet

- Aspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesDocument4 pagesAspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesSir ZenNo ratings yet

- Proposal 1st Aid DrillDocument2 pagesProposal 1st Aid DrillMohamad Hidayat Zainul MasriNo ratings yet

- Standart Anzi Eyewash PDFDocument12 pagesStandart Anzi Eyewash PDFDwiki Yanuar Ramadhan100% (1)

- ROOT CAUSE Analysis Model PDFDocument1 pageROOT CAUSE Analysis Model PDFRoy Situmorang100% (1)

- N11 Chan Chloe Micropara 103 Compilation of Microbial Diseases Final RequirementDocument46 pagesN11 Chan Chloe Micropara 103 Compilation of Microbial Diseases Final RequirementCHLOE CATHERINE CHANNo ratings yet

- Clinical Manifestations and Diagnostic Evaluation of Benign Prostatic Hyperplasia - UpToDateDocument11 pagesClinical Manifestations and Diagnostic Evaluation of Benign Prostatic Hyperplasia - UpToDateFeer VillarrealNo ratings yet

- Laboratory AnalysisDocument6 pagesLaboratory AnalysisJm CoguincoNo ratings yet

- Short-Term Results of Percutaneous Treatment ofDocument6 pagesShort-Term Results of Percutaneous Treatment ofgevowo3277No ratings yet

- Manual, Bacteria and Yeast Work UpDocument12 pagesManual, Bacteria and Yeast Work UpFilipus HendiantoNo ratings yet

- NCP Hep2Document3 pagesNCP Hep2Jordz PlaciNo ratings yet

- Cashless Request FormDocument3 pagesCashless Request FormAbhineet GargNo ratings yet

- 5 Bone TumorsDocument8 pages5 Bone TumorsKatNo ratings yet

- COPDSwissguidelinesDocument16 pagesCOPDSwissguidelinesNurul Kamilah SadliNo ratings yet

- Detailed Lesson Plan in Health Vi: (H6PH-lab-18)Document8 pagesDetailed Lesson Plan in Health Vi: (H6PH-lab-18)payno gelacio100% (1)

- Proforma For Registration of Subject For Dissertation Dissertation ProposalDocument11 pagesProforma For Registration of Subject For Dissertation Dissertation Proposalkuruvagadda sagarNo ratings yet

- Ethical Considerations From Prisoners inDocument17 pagesEthical Considerations From Prisoners inNino MdinaradzeNo ratings yet

- Heroine Source: by Waqas, Email 21waqas@stu - Edu.cnDocument14 pagesHeroine Source: by Waqas, Email 21waqas@stu - Edu.cnwaqasNo ratings yet

- Navod Tejpovani BB Tape PDFDocument32 pagesNavod Tejpovani BB Tape PDFgvozdenNo ratings yet

- Recruitment of Probationary OfficersDocument4 pagesRecruitment of Probationary OfficersMouna GuruNo ratings yet

- English A Summary PracticeDocument2 pagesEnglish A Summary PracticeDanah SkinnerNo ratings yet

- 90 AMP Flux Wire Welder: Owner's Manual & Safety InstructionsDocument28 pages90 AMP Flux Wire Welder: Owner's Manual & Safety InstructionsCarlos Zep'edaNo ratings yet

- 1 - Uncomplicated Malaria and TreatmentDocument35 pages1 - Uncomplicated Malaria and Treatmentstivana26No ratings yet

- Case StudyDocument13 pagesCase StudySanthiya MogenNo ratings yet

- DR Nune Research ProposalDocument27 pagesDR Nune Research ProposalibrahimNo ratings yet

- DIC - Case Study (Blood 2)Document2 pagesDIC - Case Study (Blood 2)Aen BridgetteNo ratings yet

- Amref Health Africa, Ethiopia office intends to invite all interested and eligible bidders by this bid invitation for the procurement of Reusable Sanitary Pad (Washable Ladies Modes) _ Reporter TendersDocument5 pagesAmref Health Africa, Ethiopia office intends to invite all interested and eligible bidders by this bid invitation for the procurement of Reusable Sanitary Pad (Washable Ladies Modes) _ Reporter TendersProNo ratings yet

- Scientific Study of Oscillococcinum PDFDocument5 pagesScientific Study of Oscillococcinum PDFDeepak KumarNo ratings yet

- Hypoxic Ischemic EncephalopathyDocument10 pagesHypoxic Ischemic EncephalopathyPadmaNo ratings yet

- Physical Activity Promotion in Physiotherapy Practice: A Systematic Scoping Review of A Decade of LiteratureDocument7 pagesPhysical Activity Promotion in Physiotherapy Practice: A Systematic Scoping Review of A Decade of Literaturearaaela 25No ratings yet

- 38 Tzanck Smear, Auspitz Sign, Nikolsky Sign, Le Cell $ Koebners PhenonmenonDocument29 pages38 Tzanck Smear, Auspitz Sign, Nikolsky Sign, Le Cell $ Koebners Phenonmenonimi4No ratings yet

- Faktor Resiko Infeksi SCDocument11 pagesFaktor Resiko Infeksi SCAlberto BrahmNo ratings yet