Professional Documents

Culture Documents

POF 321 ILI Contractor Compliance Check Tables - P - Nov 2021

POF 321 ILI Contractor Compliance Check Tables - P - Nov 2021

Uploaded by

Satya RaoCopyright:

Available Formats

You might also like

- Cover Sheet For Amendment-Change of AddressDocument1 pageCover Sheet For Amendment-Change of AddressAnonymous nbMe7H6sf33% (3)

- Cover Sheet For Amendment PDFDocument1 pageCover Sheet For Amendment PDFJoseph Eleazar100% (1)

- CCQQ Construction Contractor Qualification QuestionnaireDocument29 pagesCCQQ Construction Contractor Qualification QuestionnaireJeremia Harun100% (1)

- Compendium of Logistics Policies Volume III PDFDocument219 pagesCompendium of Logistics Policies Volume III PDFDon-Juan Casanova92% (12)

- Scope of Work Template 01Document2 pagesScope of Work Template 01voru89100% (1)

- Scope of Work Non Destructive Testing PDFDocument9 pagesScope of Work Non Destructive Testing PDFSatya Rao100% (1)

- Movement Monitoring SpecificationDocument7 pagesMovement Monitoring Specificationjoesissac88No ratings yet

- Engineering Council of India: Registration Form For Student Engineer (SE)Document5 pagesEngineering Council of India: Registration Form For Student Engineer (SE)Surjit DuttaNo ratings yet

- Office Wired Network-Performa V1.0Document1 pageOffice Wired Network-Performa V1.0Muhammad Aqeel ShamasNo ratings yet

- 2018 July Application Product Form-3Document6 pages2018 July Application Product Form-3edwin3168No ratings yet

- Registration FormDocument1 pageRegistration Formpreetatwork7No ratings yet

- Prequalification FormDocument6 pagesPrequalification FormarwajihussainNo ratings yet

- Capability Statement 12Document6 pagesCapability Statement 12Ulek BuluNo ratings yet

- PE, APE, ApE, JrApE-Application Form-27!01!21Document7 pagesPE, APE, ApE, JrApE-Application Form-27!01!21prantikduarahNo ratings yet

- Skilled Employment Reference Example PDFDocument1 pageSkilled Employment Reference Example PDFEl hussein SayedNo ratings yet

- Personal Finance: DSA Application FormDocument4 pagesPersonal Finance: DSA Application FormSuhail KhanNo ratings yet

- Iso Assessment FormDocument1 pageIso Assessment FormRushabh KapadiaNo ratings yet

- BIT TBI Application NewDocument6 pagesBIT TBI Application Newteja4u007No ratings yet

- Cover Sheet For RegistrationDocument4 pagesCover Sheet For RegistrationRobin Vinhur VillarosaNo ratings yet

- Healthcare Provider Relation LetterDocument3 pagesHealthcare Provider Relation LetterKewal TareNo ratings yet

- CGO - Proforma Step 1, 2, 3 & 5, UpdatedDocument4 pagesCGO - Proforma Step 1, 2, 3 & 5, UpdatedFareed KhanNo ratings yet

- Engineer Pre-Qualification FormDocument2 pagesEngineer Pre-Qualification FormRavi Shankar KolluruNo ratings yet

- City of Hamilton-FINAL-DBKHO-multires-oct-29-uploadedDocument6 pagesCity of Hamilton-FINAL-DBKHO-multires-oct-29-uploadedAlvio muzzoNo ratings yet

- Project Charter Template 20Document11 pagesProject Charter Template 20karinesNo ratings yet

- Cover Sheet: Company Registration and Monitoring DepartmentDocument2 pagesCover Sheet: Company Registration and Monitoring DepartmentAdelh VeaNo ratings yet

- Citizen Charter: Registration and Incentives-Local IndustryDocument5 pagesCitizen Charter: Registration and Incentives-Local IndustryAnamul HasanNo ratings yet

- Supplier Contact Directory (SCD) : Key Point(s)Document3 pagesSupplier Contact Directory (SCD) : Key Point(s)nicuNo ratings yet

- BIG Application TemplateDocument9 pagesBIG Application Templaterm6501769No ratings yet

- REOI Form - 20210127 - 144010Document2 pagesREOI Form - 20210127 - 144010md.daud.ul.islamNo ratings yet

- Templatestaff Deluxe Supplier Evaluation Scorecard Rev 02Document17 pagesTemplatestaff Deluxe Supplier Evaluation Scorecard Rev 02Rian LontengNo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01lunwenNo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01aurNo ratings yet

- Building Completion PerformaDocument2 pagesBuilding Completion Performawec11011No ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01Aisha IslamadinaNo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01PAULINE MARIE PARAYNONo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01aurNo ratings yet

- Appendix 2: Tpa Module For XML Services: 2.1. Rosettanet Business SpecificationsDocument9 pagesAppendix 2: Tpa Module For XML Services: 2.1. Rosettanet Business SpecificationsSundar RajaramNo ratings yet

- Dragonpay Merchant Application Form LatestDocument1 pageDragonpay Merchant Application Form LatestDev So NicNo ratings yet

- Entity Relationship Diagram: Applicant Departments FirmDocument1 pageEntity Relationship Diagram: Applicant Departments Firm081134081No ratings yet

- CDF Onward TechnologiesDocument6 pagesCDF Onward TechnologiesBhavana PandeyNo ratings yet

- PMP Application WorksheetDocument2 pagesPMP Application WorksheetMohamed Afsal100% (1)

- POPI For SecretariesDocument2 pagesPOPI For SecretariesLorraine N MangenaNo ratings yet

- Summary Report TemplateDocument2 pagesSummary Report Templatevalli rajuNo ratings yet

- TPA Cirular No. 059-03-2016 Dated 28-03-16Document89 pagesTPA Cirular No. 059-03-2016 Dated 28-03-16NitinNo ratings yet

- Ldap Cheat SheetDocument1 pageLdap Cheat Sheetnitesh77794445No ratings yet

- EVM CommunicDocument2 pagesEVM CommunicGiovanni SarocamNo ratings yet

- ProcessDefinitionDocument TemplateDocument15 pagesProcessDefinitionDocument TemplateSami Shahid Al Islam100% (1)

- Aatatatatahfduudxn 11Document2 pagesAatatatatahfduudxn 11anish03bingNo ratings yet

- Ishrae Membership FormDocument3 pagesIshrae Membership Formnkumaresh8195No ratings yet

- Internship Project Registration FormDocument2 pagesInternship Project Registration Formpermggohil12No ratings yet

- Formato de Calificacion LaboralDocument1 pageFormato de Calificacion LaboralJuan Luis Surco AlzamoraNo ratings yet

- ApeprocusercreationDocument2 pagesApeprocusercreationcommissioner social welfareNo ratings yet

- Babilonia AccreditationForm2024Document6 pagesBabilonia AccreditationForm2024Sael BabiloniaNo ratings yet

- Free Job Sheet Template 1Document2 pagesFree Job Sheet Template 1obrienfreddiepetroNo ratings yet

- IAS-01 Audit Application Form V40 (5 May 23)Document7 pagesIAS-01 Audit Application Form V40 (5 May 23)hrdhse. WanxindaNo ratings yet

- 1_Internship Project Registration FormDocument1 page1_Internship Project Registration Formaryapatelll02No ratings yet

- LogiMAT Group Delegate Form EditableDocument1 pageLogiMAT Group Delegate Form EditableRadz123No ratings yet

- CED BCC FormDocument1 pageCED BCC FormShine GopalNo ratings yet

- (Project Title) : Mid Term Project ReportDocument5 pages(Project Title) : Mid Term Project ReportMayank SharmaNo ratings yet

- Project Name Project Leader Leader Signature Description of Services Leader Contact Info Dates Served Number of Honor PointsDocument2 pagesProject Name Project Leader Leader Signature Description of Services Leader Contact Info Dates Served Number of Honor PointsJoeNo ratings yet

- WS-BPEL 2.0 for SOA Composite Applications with Oracle SOA Suite 11gFrom EverandWS-BPEL 2.0 for SOA Composite Applications with Oracle SOA Suite 11gNo ratings yet

- SEO Implementation ChecklistDocument7 pagesSEO Implementation ChecklistSatya RaoNo ratings yet

- Road To Grammar Quiz 45Document2 pagesRoad To Grammar Quiz 45Satya RaoNo ratings yet

- MFL Storage Tank Inspection LimitationsDocument3 pagesMFL Storage Tank Inspection LimitationsSatya RaoNo ratings yet

- Project Problem StatementDocument4 pagesProject Problem StatementSatya Rao100% (1)

- POF 302 ILI Checklists - Nov 2021Document11 pagesPOF 302 ILI Checklists - Nov 2021Satya RaoNo ratings yet

- POF 303 ILI Data Feedback Form - Nov 2021Document4 pagesPOF 303 ILI Data Feedback Form - Nov 2021Satya RaoNo ratings yet

- POF 322 ILI Contractor Compliance Check Extra Table - Nov 2021Document1 pagePOF 322 ILI Contractor Compliance Check Extra Table - Nov 2021Satya RaoNo ratings yet

- ExposureCalculator CM V1.3Document2 pagesExposureCalculator CM V1.3Satya RaoNo ratings yet

- CR Phantom Report: Long-Term Stability Test Procedure For Dürr NDT CR SystemsDocument2 pagesCR Phantom Report: Long-Term Stability Test Procedure For Dürr NDT CR SystemsSatya RaoNo ratings yet

- Tender No.3300004812/05.07.2017: Section IDocument29 pagesTender No.3300004812/05.07.2017: Section ISatya RaoNo ratings yet

- Exertus CircaDocument2 pagesExertus CircaSatya RaoNo ratings yet

- Hindustan Organic Chemicals Limited: Single BidDocument16 pagesHindustan Organic Chemicals Limited: Single BidSatya RaoNo ratings yet

- Screen NingDocument11 pagesScreen NingSatya RaoNo ratings yet

- Integrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFDocument8 pagesIntegrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFSatya RaoNo ratings yet

- Infrared Scanning of Furnaces: Technical Publication 52Document10 pagesInfrared Scanning of Furnaces: Technical Publication 52Satya RaoNo ratings yet

- FLIR GF309 24 Deg. DatasheetDocument8 pagesFLIR GF309 24 Deg. DatasheetSatya RaoNo ratings yet

- Ultrasonic TestingDocument153 pagesUltrasonic Testinglucky kakanNo ratings yet

- Semantic Segmentation Data Labelling: Classes and InstructionsDocument9 pagesSemantic Segmentation Data Labelling: Classes and InstructionsMar FieldsNo ratings yet

- KPI FormulaDocument3 pagesKPI FormulaSrikant GuptaNo ratings yet

- Pre-Test Micro Past Papers 2020Document11 pagesPre-Test Micro Past Papers 2020Thanatchawan Janwaro100% (1)

- Coralia AntenasDocument3 pagesCoralia AntenasALEX_125No ratings yet

- Labour Law - GuidelinesDocument21 pagesLabour Law - GuidelinesJames AdesinaNo ratings yet

- Module 1 - Computer EthicsDocument19 pagesModule 1 - Computer EthicsJay BagayasNo ratings yet

- Mass Intention Request FormDocument1 pageMass Intention Request FormsergioNo ratings yet

- Laurent Giftware TabletopDocument224 pagesLaurent Giftware Tabletopw.z.english1433No ratings yet

- DD RhinosinusitisDocument9 pagesDD RhinosinusitisZuhal Darwis100% (1)

- Terms and Conditions - Deposit BonusDocument4 pagesTerms and Conditions - Deposit BonusNorakmal Andika YusriNo ratings yet

- 2003 Peugeot 807 65093Document184 pages2003 Peugeot 807 65093Jenő Rádi100% (1)

- Lectures On The Comparative Grammar of The Semitic LanguagesDocument308 pagesLectures On The Comparative Grammar of The Semitic LanguagesRob Cordopatri100% (1)

- List of Organisations Covered by Regional Office-Kolar (As On 30.09.2014) (F-Register)Document284 pagesList of Organisations Covered by Regional Office-Kolar (As On 30.09.2014) (F-Register)mutton moonswamiNo ratings yet

- Project Final Report TemplateDocument14 pagesProject Final Report Templatemonparaashvin0% (1)

- Currency Detection For Blind PeopleDocument19 pagesCurrency Detection For Blind Peoplehaffah1245No ratings yet

- Evolution of Media PPT FinalDocument50 pagesEvolution of Media PPT FinalRoxette SantillanNo ratings yet

- Module 7Document5 pagesModule 7marleteNo ratings yet

- Submitted By: Youssef Mohamed BahaaDocument14 pagesSubmitted By: Youssef Mohamed BahaaRouu SamirNo ratings yet

- ChalukyanDocument44 pagesChalukyannimisha jainNo ratings yet

- Nutrition and Metabolism: (Carbohydrates, Lipids, Protein)Document37 pagesNutrition and Metabolism: (Carbohydrates, Lipids, Protein)Trishia BonNo ratings yet

- AIMB-780 Reliability Test ReportDocument60 pagesAIMB-780 Reliability Test ReportNguyen DanhNo ratings yet

- CPL EbrochureDocument4 pagesCPL EbrochureAnuj_WNo ratings yet

- Investors Presentation 1Document26 pagesInvestors Presentation 1Positive ThinkerNo ratings yet

- Chap 1 RevisedDocument5 pagesChap 1 RevisedCess AquinoNo ratings yet

- Ae tt8 Progress Test 3Document7 pagesAe tt8 Progress Test 3Joana Silva100% (1)

- Cisco Cloud DefinitionDocument72 pagesCisco Cloud DefinitionmienmobkNo ratings yet

- QuickRide LogcatDocument179 pagesQuickRide Logcatap131096No ratings yet

- Lead Free DFM Guidelines From SMTCDocument18 pagesLead Free DFM Guidelines From SMTCsmtdrkd100% (4)

POF 321 ILI Contractor Compliance Check Tables - P - Nov 2021

POF 321 ILI Contractor Compliance Check Tables - P - Nov 2021

Uploaded by

Satya RaoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POF 321 ILI Contractor Compliance Check Tables - P - Nov 2021

POF 321 ILI Contractor Compliance Check Tables - P - Nov 2021

Uploaded by

Satya RaoCopyright:

Available Formats

In-line inspection contractor compliance check tables

Recommended Practice

POF 321

2020

Amended November 2021

Pipeline Operators Forum – www.pipelineoperators.org

POF 321 In-line inspection contractor compliance check tables

Foreword

This document has been reviewed and approved by the Pipeline Operators Forum (POF) and is based on knowledge and experience available from POF members and others

at the date of issue. It is stated however, that neither POF nor its member companies (or their representatives) can be held responsible for the fitness for purpose,

completeness, accuracy and/or application of this document.

Comments on this specification and proposals for updates may be submitted to the Administrator at specifications@pipelineoperators.org with the form which is available on

the POF website (www.pipelineoperators.org).

Changes November 2021

The purpose of this revision is to comply with the new POF document numbering system. Changes mainly consist of updated references to other POF documents. In addition,

editorial corrections may have been made.

Introduction

Tables in this document are numbered in accordance with POF 320 In-line inspection contractor compliance check, and reference documents are as listed in POF 320.

Tables 4.1 to 4.8

Date Select date

Table 4.1: Contractor addresses (note: the location to be visited should be marked with a *)

Section Requested information Answers

Headquarters Contractor name [Bedrijf]

Address

Postal address

Phone number

Fax number

E-mail address

Internet site (URL)

Activities and available services at

this location

Research or Development Address

Centre Postal address

Phone number

Fax number

E-mail address

Internet site (URL)

Activities and available services at

this location

Regional offices Postal address

Phone number

Fax number

Pipeline Operators Forum – www.pipelineoperators.org - 2

[Bedrijf]

E-mail address

Internet site (URL)

Activities and available services at

this location

Regional offices Postal address

Phone number

Fax number

E-mail address

Internet site (URL)

Activities and available services at

this location

Regional offices Postal address

Phone number

Fax number

E-mail address

internet site (URL)

Activities and available services at

this location

Pipeline Operators Forum – www.pipelineoperators.org - 3

[Bedrijf]

Table 4.2: Organisational information

Section Requested information Answers

Organizational chart Please provide an organizational

chart for the location with names

of management personnel

Names of key personnel Project management (preparation)

Project management (execution)

NDT specialist (incl. levels)

Head data analysis

QA/QC manager

Sales manager

Names of contact person (1) Contact person (1)

for completion of this Name

questionnaire and for the Phone number

appraisal (2) E-mail address

Contact person (2)

Name

Phone number

E-mail address

Personnel involved during Name Function

visit

Number of personnel in the Total number of staff

following groups Office staff

Research & Development staff

Field Operations staff

Tool Maintenance staff

Data Analysis & Reporting staff

Pipeline Operators Forum – www.pipelineoperators.org - 4

[Bedrijf]

Table 4.3: Available technical facilities

Technical facilities Pipe diameters

Test spool lengths

Speed range

Pull test facilities

Method of advancing tool

Medium

Pressure

Pipe diameters:

Length of pump test

facilities /test loop

Pump test facilities / Type of test facilities / loop

Pump test loop (continuous/single run loop)

Speed range

Medium

Pressure range

Length

Compression chamber Diameter

Maximum pressure

Other facilities

Location of facilities

listed above:

Pipeline Operators Forum – www.pipelineoperators.org - 5

[Bedrijf]

Table 4.4: Overview of available tools, technologies and combinations thereof in one tool to be marked with an X. If applicable, the table is to be completed and expanded

with additional (not listed) technologies. Below the table additional or explanatory remarks can be added.

detection, Circumferential

UT, Compression Wave,

EMAT, crack detection,

EMAT, crack detection,

Single technology tool

EMAT, Wall thickness

UT, Shear wave crack

UT, Shear wave crack

MFL, Circumferential

Available technologies and

detection, Axial

Circumferential

combinations in a tool

Leak detection

Other 1:

Wall thickness

Other 2

Other 3

Eddy Current

MFL, Axial

Mapping

Axial

Main technology as per

performance sheet (extra

lines to be completed if required)

Geometry

MFL, Axial

MFL, Circumferential

UT, Compression wave, Wall thickness

UT, Shear wave crack detection, Axial

UT, Shear wave crack detection, Circumferential

EMAT, wall thickness

EMAT, crack detection, Axial

EMAT, crack detection, Circumferential

Eddy Current

Mapping

Leak detection

Other 1:

Other 2:

Other 3:

Additional remarks:

Pipeline Operators Forum – www.pipelineoperators.org - 6

[Bedrijf]

Table 4.5: Details of inspection tools and technologies

4.5.1 Gauging and cleaning tools

Diameter range

Diameter of smallest single body tool

Design of tools:

Bidirectional or single directional tool

Type of brushes: nylon, metallic, other

Type of sealing devices: discs, cups, material

Minimum bend radius acceptable

Back-to-back forged bends capabilities

Special cleaning tools

Type and design of special cleaning tool

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Restriction capabilities

ATEX

Equipped with a transmitter

Type of batteries

Life time of batteries

Conditions and limitations to detect the tool

Additional remarks

4.5.2 Geometry tools

Diameter range

Diameter of smallest single body tool

Measurement system

Type of sensors

Centre to centre distance of sensors

Axial measurement resolution during inspection

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Pipeline Operators Forum – www.pipelineoperators.org - 7

[Bedrijf]

Minimum bend radius acceptable

Back-to-back forged bends capabilities

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Range of distance

Describe tool sleep mode if available

ATEX certification

Equipped with an SCU

Equipped with an IMU

Type of batteries

Additional remarks

4.5.3 MFL tools, Axial magnetisation:

Diameter range

Diameter of smallest single body tool

Measurement system:

Type and dimensions of primary sensors

Centre to centre distance of primary sensors

Axial measurement resolution during inspection

Type and dimensions of ID/OD sensors

Centre to centre distance of ID/OD sensors

Type of magnets, e.g. brushes, blocs, strips, other

Design of tools

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Range of distance

Describe tool sleep mode if available

Pipeline Operators Forum – www.pipelineoperators.org - 8

[Bedrijf]

ATEX certification

Equipped with a SCU

Equipped with an IMU

Type of batteries

Additional remarks

4.5.4 MFL tools, Circumferential magnetisation

Diameter range

Diameter of smallest single body tool

Measurement system:

Type and dimensions of primary sensors

Centre to centre distance of primary sensors

Axial measurement resolution during inspection

Type and dimensions of ID/OD sensors

Centre to centre distance of ID/OD sensors

Type of magnets, e.g. brushes, blocs, strips, other

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities?

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Range of distance

Describe tool sleep mode if available

ATEX certification

Equipped with a SCU

Equipped with an IMU

Type of batteries

Additional remarks

Pipeline Operators Forum – www.pipelineoperators.org - 9

[Bedrijf]

4.5.5 UT tools, Compression wave for wall thickness measurement

Diameter range

Diameter of smallest single body tool

Measurement system:

Type and frequency of transducers

Diameter of transducers

Centre to centre distance of transducers

Axial measurement resolution during inspection

Design of tools

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Range of distance

Range of velocity

Describe tool sleep mode if available

ATEX certification

Equipped with an SCU

Equipped with an IMU

Type of batteries

Additional remarks

4.5.6 UT tools, Shear wave for crack detection and sizing

Diameter range

Diameter of smallest single body tool

Measurement system

Type of crack detection (axial/circumferential/helical)

Type and frequency of transducers

Diameter of transducers

UT beam angle

Centre to centre distance of transducers

Pipeline Operators Forum – www.pipelineoperators.org - 10

[Bedrijf]

Axial measurement resolution during inspection

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius

Back-to-back forged bends capabilities

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Maximum distance

Describe tool sleep mode if available

ATEX certification

Equipped with an SCU

Equipped with an IMU

Type of batteries

Additional remarks

4.5.7 EMAT tools, Wall thickness measurement

Diameter range

Diameter of smallest single body tool

Measurement system

Type of transducers

Number of transducers

Distance between transducers

Axial measurement resolution during inspection

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Pipeline Operators Forum – www.pipelineoperators.org - 11

[Bedrijf]

Maximum distance

Describe tool sleep mode if available

ATEX certification

Equipped with an SCU

Equipped with an IMU

Type of batteries

Additional remarks

4.5.8 EMAT tools, Crack detection and sizing

Diameter range

Diameter of smallest single body tool

Measurement system

Type of crack detection (axial/circumferential/helical)

Type of transducers

Number of transducers

Distance between transducers

Axial measurement resolution during inspection

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Maximum distance

Describe tool sleep mode if available

ATEX certification

Equipped with an SCU

Equipped with an IMU

Type of batteries

Additional remarks

Pipeline Operators Forum – www.pipelineoperators.org - 12

[Bedrijf]

4.5.9 Eddy current tools

Diameter range

Diameter of smallest single body tool

Measurement system

Type of transducers

Diameter of transducers

Centre to centre distance of transducers

Axial measurement resolution during inspection

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities?

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Maximum distance

Describe tool sleep mode if available

ATEX certification

Equipped with a SCU

Equipped with an IMU

Type of batteries

Additional remarks

4.5.10 Mapping tools

Diameter range

Diameter of smallest single body tool

Measurement system

Design of tools:

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities?

Run conditions:

Pipeline Operators Forum – www.pipelineoperators.org - 13

[Bedrijf]

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Maximum distance

Describe tool sleep mode if available

ATEX certification

Type of batteries

Additional remarks

4.5.11 Leak detection tools

Diameter range

Diameter of smallest single body tool

Measurement system

Design of tools (e.g.):

Bidirectional or single directional tool

Restrictions capabilities

Minimum bend radius acceptable

Back-to-back forged bends capabilities?

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Medium

Maximum distance

Describe tool sleep mode if available

ATEX certification

Type of batteries

Additional remarks

4.5.12 Special and other tools (to be specified)

Information on special tools and tools that are based on technologies that are not listed above can be entered in this table. Extra forms are separately

available in POF 322.

Type of technology e.g. ART, DMR, Helical MFL, etc.

Diameter range

Diameter of smallest single body tool

Pipeline Operators Forum – www.pipelineoperators.org - 14

[Bedrijf]

Measurement system:

Type and dimensions of sensors

Centre to centre distance of sensors

Axial measurement resolution during inspection

Design, type of tool (e.g.):

Multi-diameter tool

Push-Pull tool

Floating Bidirectional tool

Robot (crawler, tether, self-propelling)

Other, specify:

Run conditions:

Minimum/maximum operating pressure

Minimum/maximum tool velocity

Range of distance

Medium

Describe tool sleep mode if available

ATEX certification

Equipped with a SCU

Equipped with an IMU

Type of batteries

Additional remarks

Pipeline Operators Forum – www.pipelineoperators.org - 15

[Bedrijf]

Table 4.6: Complementary services

Information on complementary services in support of ILI that are available from or via the ILI Contractor can be listed in this table. The table can be completed with not

mentioned services.

Section Requested information Answers

Complementary Pipeline cleaning:

services Available from ILI Contractor or contracted out

Type of technologies

Pipeline cleaning procedures

Acceptance criteria

Portable tool traps:

Availability of portable tool traps

Available diameters

Compliance to (local) safety regulations

Above ground markers, types

Permanent magnet markers

Nitrogen (cleaning, purging, run in)

Pumping

Tethered/umbilical operations

Tool cleaning:

Available from Contractor or contracted out?

Types of solvents

Tool cleaning procedures

Acceptance criteria

Acceptance criteria for remnants of NORM

(Naturally Occurring Radioactive Material)

Lifting:

Available from Contractor or contracted out?

FFS analysis, Available algorithms:

NDT services (e.g. for feature verification):

Available from ILI Contractor (in-house):

Technologies and Qualification level(s)

Contracted out:

Technologies and Qualification level(s)

Available procedures

Additional services:

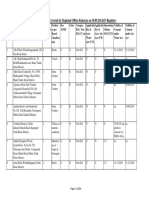

Table 4.7: ILI tool running and performance statistics

Pipeline Operators Forum – www.pipelineoperators.org - 16

[Bedrijf]

Compression wave,

Tool and technology

Crack detection

Circumferential

UT, Shear wave

crack detection

Leak detection

Wall thickness

Wall thickness

Eddy Current

MFL, Axial

Geometry

Mapping

EMAT,

EMAT,

Total

MFL,

UT,

Requested information

Year 20

Year 20

Number of pipelines inspected

Year 20

during the last 5 year

Year 20

Year 20

Year 20

Total number of kilometres of Year 20

pipelines inspected during last 5 Year 20

year Year 20

Year 20

Average of

all runs

Year 20

First run success rate (%) of last Year 20

5-year inspections. To be Year 20

reported per year and as 5-year Year 20

average. Year 20

5 Year average

Year 20

Percentage of runs with Year 20

acceptable or no data loss as part Year 20

of all runs (ref. POF 100 [3], Year 20

Section 7.1). Year 20

5 Year average, all runs

Pipeline Operators Forum – www.pipelineoperators.org - 17

[Bedrijf]

Table 4.8: Client list

Overview of clients of ILI services.

Client Year/period Provided services

Pipeline Operators Forum – www.pipelineoperators.org - 18

[Bedrijf]

Tables 5 to 11

Table 5: Health, safety and environment.

Document, Section Requested information Answers and Observations/Recommendations from Reviewer Verdict

Documented HSE system. If available,

please provide a copy.

Certified to ISO 14001 [6] or equivalent?

If so, please provide copy of certificate.

Certified to ISO 18001 [5] or equivalent?

If so, please provide copy of certificate.

Statistics for number of incidents and Current year 20 , Year 20 Year 20

injuries during current year and last 2 (up to mm, yyyy)

year:

1. Reported incidents (near misses) 1. 1. 1.

2. Medical attention only cases 2. 2. 2.

3. Restricted workday cases 3. 3. 3.

4. Lost workday cases 4. 4. 4.

5. Fatalities 5. 5. 5.

Who has responsibility for HSE

management systems at your facilities

Who has responsibility for HSE

compliance during ILI runs?

Written safety/loss prevention program.

If available, please provide a copy.

Safety Emergency Plan/Procedure for

jobs/locations. If available, please

provide a copy.

POF specifications - Policy of ATEX or equivalent certification

POF 100 [3], Section of tools

3.1, 3.2

Pipeline Operators Forum – www.pipelineoperators.org - 19

[Bedrijf]

Table 6: Quality assurance

Document, Section Requested information Answers and Observations/Recommendations Verdict

Quality system review Are you certified to a quality system? If

so, please indicate the applicable system

and provide copy of the certificate.

(Note: if not ISO 9001 [4], essential

differences should be indicated),

Please provide a copy of the latest

quality audit report and follow-up

actions taken (if required)

If your quality certification is different

from ISO 9001 [4], please provide the

following information:

Internal quality audit scheme.

A copy of latest audit for review.

API 1163 [1], section Compliance to quality system above

10. Quality

management system

Pipeline Operators Forum – www.pipelineoperators.org - 20

[Bedrijf]

Table 7.1: Personnel training and qualification practice/procedure.

Document, Section Requirement Answers and Observations/Recommendations Verdict

ANSI/ASNT-ILI-PQ-2017 Training programs. If available,

[2], Section 7.0 please provide a copy.

ANSI/ASNT-ILI-PQ- Written practice/procedure 4.1:

2017[2], Section 4.0, describing training, experience and 4.2:

9.5 examination for each level of 4.3:

qualification. 4.4:

Note: written practice to be reviewed 4.5:

for items 4.1 - 4.5 of ANSI/ASNT-ILI-

PQ-2017.

Table 7.2: Number and level of certified tool operators.

Document, Section Requirement Answers and Observations/Recommendations Verdict

ANSI/ASNT-ILI-PQ- Number and level of certified tool MFL technology, axial:

2017[2], Section 9.0 operators for each ILI tool technology Level 1:

Note: at random a number of Level 2:

certification documents should be Level 3:

reviewed on compliance to requirements MFL technology, transverse:

of chapter 9 and recommended Level 1:

minimum training and experience levels Level 2:

(tables 1 to 7 of ANSI/ASNT-ILI-PQ-2017 Level 3:

[2] where applicable). Ultrasonic technology, compression wave:

Level 1:

Level 2:

Level 3:

Ultrasonic technology, shear wave:

Level 1:

Level 2:

Level 3:

EMAT technology:

Level 1:

Level 2:

Level 3:

Pipeline Operators Forum – www.pipelineoperators.org - 21

[Bedrijf]

Geometry technology:

Level 1:

Level 2:

Level 3:

Mapping technology:

Level 1:

Level 2:

Level 3:

Additional technology: (describe)

Level 1:

Level 2:

Level 3:

Table 7.3: Number and level of certified data analysts.

Document, Section Requirement Answers and Observations/Recommendations Verdict

ANSI/ASNT-ILI-PQ-2017 Number and level of certified data MFL technology, axial:

[2], Section 9 analysts for each ILI tool technology Level 1:

Level 2:

Level 3:

MFL technology, transverse:

Level 1:

Level 2:

Level 3:

Ultrasonic technology, compression wave:

Level 1:

Level 2:

Level 3:

EMAT technology:

Level 1:

Level 2:

Level 3:

Geometry technology:

Level 1:

Level 2:

Level 3:

Pipeline Operators Forum – www.pipelineoperators.org - 22

[Bedrijf]

Mapping technology:

Level 1:

Level 2:

Level 3:

Additional technology, specify:

Level 1:

Level 2:

Level 3:

Informative What is the physical location (city and

country) where the data analysis is

carried out?

Table 7.4: Number and qualification of FFS analysts

Document, Section Requirement Answers and Observations/Recommendations Verdict

POF specifications - If FFS analysis is available (ref. Table

POF 100 [3], chapter 4.6), what are the number and

2.6 qualifications of analysts for each

analysis method.

Table 7.5: Qualifications of assigned personnel for field operations, data analysis and reporting.

Document, Section Requirement Answers and Observations/Recommendations Verdict

Team leader during ILI field activities:

Level II tool operator for the applicable

technology

POF specifications - POF Data analysis and reporting Lead: Level

100 [3], II Data Analyst for the applicable

Section 7 technology

Review of final Client report: Level III

Data Analyst for the applicable

technology

Pipeline Operators Forum – www.pipelineoperators.org - 23

[Bedrijf]

Table 8: Compliance of technical requirements of ILI tools (note: it should be indicated in this table if the performance specifications, qualification requirements and other

requested information is available and the Reviewer is requested to review examples and give his/her observations, recommendations and a verdict.

Document, Section Requirement Answers and Observations/Recommendations Verdict

API 1163 [1], section 6.2 Performance specifications; available

Performance for full range of tools:

specifications 6.2.1: General

6.2.2: Applicable anomalies

POF specifications - POF components, features and

100 [3], section 4.4.1 characteristics

(appendix 5) 6.2.3: Detection thresholds and

probability of detection

6.2.4: Probability of identification

6.2.5: Sizing accuracy

6.2.6: Sizing capability

6.2.7: Limitations

6.2.8: Geometric passage capabilities

6.2.9: Other capabilities

API 1163 [1] section 6.3 Qualification requirements; available

Qualification for full range of tools:

requirements 6.3.1: General

6.3.2: Essential variables

6.3.3: Data and analysis requirements

6.3.4: Validation based on historic data

6.3.5: Validation based on full scale

tests

6.3.6: Validation based on small-scale

tests, modelling and analyses

API 1163 [1] section 6.4 6.4.1: General

Documentation and 6.4.2: Detection thresholds, PODs and

other requirements POIs

6.4.3: Sizing accuracies

6.4.4: Review and revision

requirements

POF specifications - POF Basis of performance specifications for

100 [3], Section 4.4.2. each (series of) tools

Basis of performance

Pipeline Operators Forum – www.pipelineoperators.org - 24

[Bedrijf]

POF specifications - POF Exclusions and limitations for each

100 [3], Section 4.4.3. (series) of tools

Exclusions and

limitations

POF specifications - POF Access to information in support of

100 [3], Section 4.4.4. stated tool performance specification

Access to supporting

performance

information

POF specifications - POF Verification of basis of tool

100 [3], Section 4.5. performances through formal testing

Tool performance or field verification

verification

POF specifications - POF Changes to tool and performance

100 [3], section 4.6. specifications in Contractor quality

Changes to tool system

specification or

performance

specification sheets

Pipeline Operators Forum – www.pipelineoperators.org - 25

[Bedrijf]

Table 9: Compliance of operations and project management. (note: it should be indicated in this table if the documentation is available and the Reviewer is requested to

review it and give his/her observations, recommendations and a verdict.

Document, Section Requirement Answers and Observations/Recommendations Verdict

API 1163 [3], section 7 Procedures describing:

System Operational 7.2: Project requirements 7.2:

Verification 7.3: Pre-inspection requirements 7.3:

Note: Moments of documented quality

checks:

- prior to shipping the tool

- arrival on site

- prior to launching the tool

Covering items like, but not limited to:

battery life, initiation technique,

maintenance records for components,

corrective actions from past failures,

mobilisation of spares & tools, any

client specific modifications for pipeline

geometry, pipeline operating

parameters, loading/retrieving

equipment

7.4: Inspection requirements 7.4:

7.5: Post inspection requirements 7.5:

Note: Moments of documented quality

checks:

- After receiving the tool

- Prior to shipping the tool back

Informative Procedure describing actions to take

when a tool got stuck in a pipeline

Pipeline Operators Forum – www.pipelineoperators.org - 26

[Bedrijf]

Table 10: Compliance to reference documents of ILI reporting. (note: it should be indicated in this table if reporting is compliant and formats are available. The Reviewer is

requested to review examples and give his/her observations, recommendations and a verdict

Document, Section Requirement Answers and Observations/Recommendations Verdict

Reporting requirements Compliance of reports to requirements

API 1163 [3], section 9 9.2: Report contents 9.2:

9.3: Reporting formats 9.3:

9.4: Data deliverable 9.4:

POF specifications - POF Reporting formats:

100 [3], 7.1: Operations report 7.1:

section 7 7.2: Preliminary report 7.2:

7.3: Final report 7.3:

7.4: Raw data report 7.4:

7.5: Multiple run comparisons report 7.5:

7.6: Experience report 7.6:

7.7: Additional reporting 7.7:

Table 11: Observations of specific aspects (optional stage)

Specific aspects Observations Verdict

Pipeline Operators Forum – www.pipelineoperators.org - 27

[Bedrijf]

You might also like

- Cover Sheet For Amendment-Change of AddressDocument1 pageCover Sheet For Amendment-Change of AddressAnonymous nbMe7H6sf33% (3)

- Cover Sheet For Amendment PDFDocument1 pageCover Sheet For Amendment PDFJoseph Eleazar100% (1)

- CCQQ Construction Contractor Qualification QuestionnaireDocument29 pagesCCQQ Construction Contractor Qualification QuestionnaireJeremia Harun100% (1)

- Compendium of Logistics Policies Volume III PDFDocument219 pagesCompendium of Logistics Policies Volume III PDFDon-Juan Casanova92% (12)

- Scope of Work Template 01Document2 pagesScope of Work Template 01voru89100% (1)

- Scope of Work Non Destructive Testing PDFDocument9 pagesScope of Work Non Destructive Testing PDFSatya Rao100% (1)

- Movement Monitoring SpecificationDocument7 pagesMovement Monitoring Specificationjoesissac88No ratings yet

- Engineering Council of India: Registration Form For Student Engineer (SE)Document5 pagesEngineering Council of India: Registration Form For Student Engineer (SE)Surjit DuttaNo ratings yet

- Office Wired Network-Performa V1.0Document1 pageOffice Wired Network-Performa V1.0Muhammad Aqeel ShamasNo ratings yet

- 2018 July Application Product Form-3Document6 pages2018 July Application Product Form-3edwin3168No ratings yet

- Registration FormDocument1 pageRegistration Formpreetatwork7No ratings yet

- Prequalification FormDocument6 pagesPrequalification FormarwajihussainNo ratings yet

- Capability Statement 12Document6 pagesCapability Statement 12Ulek BuluNo ratings yet

- PE, APE, ApE, JrApE-Application Form-27!01!21Document7 pagesPE, APE, ApE, JrApE-Application Form-27!01!21prantikduarahNo ratings yet

- Skilled Employment Reference Example PDFDocument1 pageSkilled Employment Reference Example PDFEl hussein SayedNo ratings yet

- Personal Finance: DSA Application FormDocument4 pagesPersonal Finance: DSA Application FormSuhail KhanNo ratings yet

- Iso Assessment FormDocument1 pageIso Assessment FormRushabh KapadiaNo ratings yet

- BIT TBI Application NewDocument6 pagesBIT TBI Application Newteja4u007No ratings yet

- Cover Sheet For RegistrationDocument4 pagesCover Sheet For RegistrationRobin Vinhur VillarosaNo ratings yet

- Healthcare Provider Relation LetterDocument3 pagesHealthcare Provider Relation LetterKewal TareNo ratings yet

- CGO - Proforma Step 1, 2, 3 & 5, UpdatedDocument4 pagesCGO - Proforma Step 1, 2, 3 & 5, UpdatedFareed KhanNo ratings yet

- Engineer Pre-Qualification FormDocument2 pagesEngineer Pre-Qualification FormRavi Shankar KolluruNo ratings yet

- City of Hamilton-FINAL-DBKHO-multires-oct-29-uploadedDocument6 pagesCity of Hamilton-FINAL-DBKHO-multires-oct-29-uploadedAlvio muzzoNo ratings yet

- Project Charter Template 20Document11 pagesProject Charter Template 20karinesNo ratings yet

- Cover Sheet: Company Registration and Monitoring DepartmentDocument2 pagesCover Sheet: Company Registration and Monitoring DepartmentAdelh VeaNo ratings yet

- Citizen Charter: Registration and Incentives-Local IndustryDocument5 pagesCitizen Charter: Registration and Incentives-Local IndustryAnamul HasanNo ratings yet

- Supplier Contact Directory (SCD) : Key Point(s)Document3 pagesSupplier Contact Directory (SCD) : Key Point(s)nicuNo ratings yet

- BIG Application TemplateDocument9 pagesBIG Application Templaterm6501769No ratings yet

- REOI Form - 20210127 - 144010Document2 pagesREOI Form - 20210127 - 144010md.daud.ul.islamNo ratings yet

- Templatestaff Deluxe Supplier Evaluation Scorecard Rev 02Document17 pagesTemplatestaff Deluxe Supplier Evaluation Scorecard Rev 02Rian LontengNo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01lunwenNo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01aurNo ratings yet

- Building Completion PerformaDocument2 pagesBuilding Completion Performawec11011No ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01Aisha IslamadinaNo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01PAULINE MARIE PARAYNONo ratings yet

- Scope of Work Template 01Document2 pagesScope of Work Template 01aurNo ratings yet

- Appendix 2: Tpa Module For XML Services: 2.1. Rosettanet Business SpecificationsDocument9 pagesAppendix 2: Tpa Module For XML Services: 2.1. Rosettanet Business SpecificationsSundar RajaramNo ratings yet

- Dragonpay Merchant Application Form LatestDocument1 pageDragonpay Merchant Application Form LatestDev So NicNo ratings yet

- Entity Relationship Diagram: Applicant Departments FirmDocument1 pageEntity Relationship Diagram: Applicant Departments Firm081134081No ratings yet

- CDF Onward TechnologiesDocument6 pagesCDF Onward TechnologiesBhavana PandeyNo ratings yet

- PMP Application WorksheetDocument2 pagesPMP Application WorksheetMohamed Afsal100% (1)

- POPI For SecretariesDocument2 pagesPOPI For SecretariesLorraine N MangenaNo ratings yet

- Summary Report TemplateDocument2 pagesSummary Report Templatevalli rajuNo ratings yet

- TPA Cirular No. 059-03-2016 Dated 28-03-16Document89 pagesTPA Cirular No. 059-03-2016 Dated 28-03-16NitinNo ratings yet

- Ldap Cheat SheetDocument1 pageLdap Cheat Sheetnitesh77794445No ratings yet

- EVM CommunicDocument2 pagesEVM CommunicGiovanni SarocamNo ratings yet

- ProcessDefinitionDocument TemplateDocument15 pagesProcessDefinitionDocument TemplateSami Shahid Al Islam100% (1)

- Aatatatatahfduudxn 11Document2 pagesAatatatatahfduudxn 11anish03bingNo ratings yet

- Ishrae Membership FormDocument3 pagesIshrae Membership Formnkumaresh8195No ratings yet

- Internship Project Registration FormDocument2 pagesInternship Project Registration Formpermggohil12No ratings yet

- Formato de Calificacion LaboralDocument1 pageFormato de Calificacion LaboralJuan Luis Surco AlzamoraNo ratings yet

- ApeprocusercreationDocument2 pagesApeprocusercreationcommissioner social welfareNo ratings yet

- Babilonia AccreditationForm2024Document6 pagesBabilonia AccreditationForm2024Sael BabiloniaNo ratings yet

- Free Job Sheet Template 1Document2 pagesFree Job Sheet Template 1obrienfreddiepetroNo ratings yet

- IAS-01 Audit Application Form V40 (5 May 23)Document7 pagesIAS-01 Audit Application Form V40 (5 May 23)hrdhse. WanxindaNo ratings yet

- 1_Internship Project Registration FormDocument1 page1_Internship Project Registration Formaryapatelll02No ratings yet

- LogiMAT Group Delegate Form EditableDocument1 pageLogiMAT Group Delegate Form EditableRadz123No ratings yet

- CED BCC FormDocument1 pageCED BCC FormShine GopalNo ratings yet

- (Project Title) : Mid Term Project ReportDocument5 pages(Project Title) : Mid Term Project ReportMayank SharmaNo ratings yet

- Project Name Project Leader Leader Signature Description of Services Leader Contact Info Dates Served Number of Honor PointsDocument2 pagesProject Name Project Leader Leader Signature Description of Services Leader Contact Info Dates Served Number of Honor PointsJoeNo ratings yet

- WS-BPEL 2.0 for SOA Composite Applications with Oracle SOA Suite 11gFrom EverandWS-BPEL 2.0 for SOA Composite Applications with Oracle SOA Suite 11gNo ratings yet

- SEO Implementation ChecklistDocument7 pagesSEO Implementation ChecklistSatya RaoNo ratings yet

- Road To Grammar Quiz 45Document2 pagesRoad To Grammar Quiz 45Satya RaoNo ratings yet

- MFL Storage Tank Inspection LimitationsDocument3 pagesMFL Storage Tank Inspection LimitationsSatya RaoNo ratings yet

- Project Problem StatementDocument4 pagesProject Problem StatementSatya Rao100% (1)

- POF 302 ILI Checklists - Nov 2021Document11 pagesPOF 302 ILI Checklists - Nov 2021Satya RaoNo ratings yet

- POF 303 ILI Data Feedback Form - Nov 2021Document4 pagesPOF 303 ILI Data Feedback Form - Nov 2021Satya RaoNo ratings yet

- POF 322 ILI Contractor Compliance Check Extra Table - Nov 2021Document1 pagePOF 322 ILI Contractor Compliance Check Extra Table - Nov 2021Satya RaoNo ratings yet

- ExposureCalculator CM V1.3Document2 pagesExposureCalculator CM V1.3Satya RaoNo ratings yet

- CR Phantom Report: Long-Term Stability Test Procedure For Dürr NDT CR SystemsDocument2 pagesCR Phantom Report: Long-Term Stability Test Procedure For Dürr NDT CR SystemsSatya RaoNo ratings yet

- Tender No.3300004812/05.07.2017: Section IDocument29 pagesTender No.3300004812/05.07.2017: Section ISatya RaoNo ratings yet

- Exertus CircaDocument2 pagesExertus CircaSatya RaoNo ratings yet

- Hindustan Organic Chemicals Limited: Single BidDocument16 pagesHindustan Organic Chemicals Limited: Single BidSatya RaoNo ratings yet

- Screen NingDocument11 pagesScreen NingSatya RaoNo ratings yet

- Integrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFDocument8 pagesIntegrated Approach RLA of Reformer Tubes NDT (ARTiS) PDFSatya RaoNo ratings yet

- Infrared Scanning of Furnaces: Technical Publication 52Document10 pagesInfrared Scanning of Furnaces: Technical Publication 52Satya RaoNo ratings yet

- FLIR GF309 24 Deg. DatasheetDocument8 pagesFLIR GF309 24 Deg. DatasheetSatya RaoNo ratings yet

- Ultrasonic TestingDocument153 pagesUltrasonic Testinglucky kakanNo ratings yet

- Semantic Segmentation Data Labelling: Classes and InstructionsDocument9 pagesSemantic Segmentation Data Labelling: Classes and InstructionsMar FieldsNo ratings yet

- KPI FormulaDocument3 pagesKPI FormulaSrikant GuptaNo ratings yet

- Pre-Test Micro Past Papers 2020Document11 pagesPre-Test Micro Past Papers 2020Thanatchawan Janwaro100% (1)

- Coralia AntenasDocument3 pagesCoralia AntenasALEX_125No ratings yet

- Labour Law - GuidelinesDocument21 pagesLabour Law - GuidelinesJames AdesinaNo ratings yet

- Module 1 - Computer EthicsDocument19 pagesModule 1 - Computer EthicsJay BagayasNo ratings yet

- Mass Intention Request FormDocument1 pageMass Intention Request FormsergioNo ratings yet

- Laurent Giftware TabletopDocument224 pagesLaurent Giftware Tabletopw.z.english1433No ratings yet

- DD RhinosinusitisDocument9 pagesDD RhinosinusitisZuhal Darwis100% (1)

- Terms and Conditions - Deposit BonusDocument4 pagesTerms and Conditions - Deposit BonusNorakmal Andika YusriNo ratings yet

- 2003 Peugeot 807 65093Document184 pages2003 Peugeot 807 65093Jenő Rádi100% (1)

- Lectures On The Comparative Grammar of The Semitic LanguagesDocument308 pagesLectures On The Comparative Grammar of The Semitic LanguagesRob Cordopatri100% (1)

- List of Organisations Covered by Regional Office-Kolar (As On 30.09.2014) (F-Register)Document284 pagesList of Organisations Covered by Regional Office-Kolar (As On 30.09.2014) (F-Register)mutton moonswamiNo ratings yet

- Project Final Report TemplateDocument14 pagesProject Final Report Templatemonparaashvin0% (1)

- Currency Detection For Blind PeopleDocument19 pagesCurrency Detection For Blind Peoplehaffah1245No ratings yet

- Evolution of Media PPT FinalDocument50 pagesEvolution of Media PPT FinalRoxette SantillanNo ratings yet

- Module 7Document5 pagesModule 7marleteNo ratings yet

- Submitted By: Youssef Mohamed BahaaDocument14 pagesSubmitted By: Youssef Mohamed BahaaRouu SamirNo ratings yet

- ChalukyanDocument44 pagesChalukyannimisha jainNo ratings yet

- Nutrition and Metabolism: (Carbohydrates, Lipids, Protein)Document37 pagesNutrition and Metabolism: (Carbohydrates, Lipids, Protein)Trishia BonNo ratings yet

- AIMB-780 Reliability Test ReportDocument60 pagesAIMB-780 Reliability Test ReportNguyen DanhNo ratings yet

- CPL EbrochureDocument4 pagesCPL EbrochureAnuj_WNo ratings yet

- Investors Presentation 1Document26 pagesInvestors Presentation 1Positive ThinkerNo ratings yet

- Chap 1 RevisedDocument5 pagesChap 1 RevisedCess AquinoNo ratings yet

- Ae tt8 Progress Test 3Document7 pagesAe tt8 Progress Test 3Joana Silva100% (1)

- Cisco Cloud DefinitionDocument72 pagesCisco Cloud DefinitionmienmobkNo ratings yet

- QuickRide LogcatDocument179 pagesQuickRide Logcatap131096No ratings yet

- Lead Free DFM Guidelines From SMTCDocument18 pagesLead Free DFM Guidelines From SMTCsmtdrkd100% (4)