Professional Documents

Culture Documents

Technical Terms Chapter 47

Technical Terms Chapter 47

Uploaded by

thena Martin0 ratings0% found this document useful (0 votes)

64 views5 pages1. The document describes various vehicle cooling systems including engine cooling systems, supercharger cooling systems, turbocharger cooling systems, high voltage battery cooling systems, high voltage motor-generator cooling systems, and hybrid vehicle cooling systems.

2. It discusses the components that make up these systems such as radiators, fans, pumps, hoses, thermostats, sensors and more.

3. The purpose of the cooling systems is to regulate operating temperatures of engines, motors, batteries and other components to prevent overheating.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document describes various vehicle cooling systems including engine cooling systems, supercharger cooling systems, turbocharger cooling systems, high voltage battery cooling systems, high voltage motor-generator cooling systems, and hybrid vehicle cooling systems.

2. It discusses the components that make up these systems such as radiators, fans, pumps, hoses, thermostats, sensors and more.

3. The purpose of the cooling systems is to regulate operating temperatures of engines, motors, batteries and other components to prevent overheating.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

64 views5 pagesTechnical Terms Chapter 47

Technical Terms Chapter 47

Uploaded by

thena Martin1. The document describes various vehicle cooling systems including engine cooling systems, supercharger cooling systems, turbocharger cooling systems, high voltage battery cooling systems, high voltage motor-generator cooling systems, and hybrid vehicle cooling systems.

2. It discusses the components that make up these systems such as radiators, fans, pumps, hoses, thermostats, sensors and more.

3. The purpose of the cooling systems is to regulate operating temperatures of engines, motors, batteries and other components to prevent overheating.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 5

Athena Mz Period 6th

1. Cooling system- designed to control the operating temperature of a

mechanical and electrical assembly

2. Engine cooling system- controls the operating temperature of the

cylinder heads and cylinder block

3. Supercharger cooling system- must keep the blower intercooler

temperature cooler than the engines operating temperature

4. Blower intercooling temperature- must be kept cooler than the

engine's operating temperature by the supercharger cooling system

5. Turbocharger cooling system- forces coolant through the turbo

bearing housing to keep the turbo from overheating under prolonged

high boost

6. HV battery cooling system- uses air or liquid to remove battery cell

hear when under prolonged high amperage draw

7. HV motor-generator cooling system- uses liquid coolant to prevent

motor-generator overheating in full-electric and high gas-electric

vehicles

8. HV engine control module cooling system- forces air or liquid through

or over an aluminum heat sink surrounding the high-power transistors

for each leg of the three-phase

9. Engine operating temperature- is the temperature the engine coolant

reaches under normal running conditions

10. Heater core- a small liquid-to-air exchanger mounted under the dash in

the passenger compartment

11. Air cooling system- uses large cylinder cooling fins and outside aisr to

remove excess heat from the engine

12. Cooling fins- a series of thin metal strips placed between cooling

passages to help dissipate heat

13. Shrouds- a plastic or metal enclosure around a fan to guide and

facilitate airflow

14. Liquid cooling system- circulates coolant through the water jackets in

the engine’s cylinder block and cylinder head

15. Conventional-flow cooling- hot coolant flows from the cylinder head

to the radiator and after being cooled the coolant flows back into the

engine block

16. Reverse-flow cooling- flows the opposite direction, cool coolant enters

the head and hot coolant exits the block to return to the radiator

17. Closed cooling system- type of cooling system that uses an overflow

bottle and a radiator cap with pressure and vacuum valves

18. Open cooling system- does not use coolant reservoir, the overflow

tube is not connected to a coolant reservoir, and excess coolant leaks

onto the ground

19. Water pump- forces coolant through the engine and other system part

20. Radiator hoses- connect the engine to the radiator

21. Radiator- transfers engine coolant heat to the outside air

22. Fan- draws air through the radiator

23. Thermostat- controls the coolant flow and engine operating

temperature

24. Water pump impeller- is a disk with fan-like blades with an impeller

that spins and produces pressure and flow

25. Water pump shaft- is a steel shaft that transfers turning force from

the hub to the impeller

26. Water pump seal- prevents coolant from leaking between the pump

shaft and pump housing

27. Water pump bearings- are plain ball bearings that allow the pump

shaft to spin freely in housing

28. Water pump hub- provides a mounting place for the belt pulley and

fan

29. Water pump housing- is an iron or aluminum casting that form the

main body or pump

30. Water pump gasket- fits between the engine and pump housing to

prevent coolant leakage

31. Electric water pump- uses a large dc motor and impeller that forces

coolant through the engine's water jackets or through an HV cooling

system, used in place of a belt-driven water pump

32. Molded hose- made in a special shape, with bends to clear the cooling

fan and other parts

33. Flexible hose- has an accordion shape and can be bent to different

angles

34. Hose spring- frequently used in the lower radiator hose to prevent the

hose from collapsing

35. Heater hoses- are small-diameter hoses that carry coolant to the

heater core

36. Hose clamps- hold the radiator hoses and heater hoses on their fittings

37. Worm-drive hose clamp- uses a warm gear that engages slots in the

clamp strap to allow tightening around the hose

38. Radiator core- is the fragile center section of a radiator and is made up of

tubes and cooling fins

39. Radiator tanks- are the metal or plastic ends that fit over the core

tube ends to provide storage for coolant and fittings for hoses

40. Radiator filler neck- is an opening for adding coolant that also holds a

removable radiator pressure cap to prevent coolant from boiling when

above 212°F

41. Transmission oil cooler- is an inner tank or cooling automatic

transmission or transaxle fluid

42. Radiator petcock- is a fitting on the bottom of the tank for draining

coolant

43. Radiator cap- pressurizes the water and antifreeze solution so that is

does not boil when operating above 212°F

44. Downflow radiator- the tanks are on the top and bottom of the core,

and the core tubes run vertically between the tanks

45. Crossflow radiator- more modern design that has the tanks on the

sides of the core

46. Radiator cap pressure valve- consists of a spring loaded disk that

contacts the filler neck, the spring pushes the valve into the neck to

form a seal

47. Radiator cap vacuum valve- opens to allow flow back into the radiator

when the coolant temperature drops after engine operation

48. Cooling system fan- pulls air through the core of the radiator and over

the engine to help remove heat

49. Engine-powered fan- bolts to the water pump hub and pulley,

sometime a fan spacer fits between the fan and pulley to move fan

closer to the radiator

50. Fan spacer- part that fits between an engine powered fan and pulley to

move the fan closer to the radiator

51. Flex fan- has thin, flexible blades that alter airflow with engine speed,

at low speeds, the fan blades remain curved and pull air through the

radiator, at higher engine speeds, the blades flex until they are almost

straight

52. Fluid coupling fan clutch- designed to slip at higher engine speeds. It

performs the same function as a flexible fan

53. Thermostatic fan clutch- has a temperature- sensitive, bimetal spring

that controls fan action. The spring controls oil flow in the fan clutch

54. Electric cooling fan- uses an electric motor, the coolant temperature

sensor, and the engine EMC to provide airflow and heat transfers out of

the radiator

55. Fan motor- is a small dc motor with brushes that mounts on a bracket

secured to the radiator, a metal or plastic fan blade mounts on the end

of the motor shaft to create airflow when the vehicle is not moving

56. Fan switch (thermo switch)- is a temperature sensitive switch that

controls fan motor operation

57. Coolant temperature sensor- used by the engine control ECM to

determine how much fuel is needed and when to enter closed loop

operation

58. Radiator shroud- helps ensure that the fan pulls air through the

radiator

59. Thermostat rating- information stamped on a thermostat to indicate

the operating (opening) temperature of the thermostat

60. Bypass valve- used to permit coolant flow when the thermostat is

closed.

61. Bypass thermostat- thermostat with an additional valve that blocks off

the bypass for routing all the hot coolant through the radiator, not just

most of the hot coolant

62. Temperature light warning- informs the driver when the engine is

overheating. When the coolant becomes too hot, a temperature

sending unit in the engine block closes

63. Engine temperature gauge- shows the exact operating temperature of

the engine coolant. A vari- able resistance sending unit and a gauge are

used in the circuit

64. Antifreeze- is mixed with water to produce engine coolant

65. Block heater- may be used on an engine to help with engine starting in

cold weather by heating the coolant. A block heater is most commonly

used on diesel engines because they are harder to start in cold weather

66. Hybrid cooling system- can use either circu- lated air or circulated

liquid coolant to remove excess heat from components in the electric

powertrain

67. Hybrid air cooling system- uses an electric blower fan and a system of

ducts to route cool passenger compartment air around the high voltage

battery pack

68. Hybrid liquid cooling- system uses an electric water pump, small

diameter hoses, and a separate radiator or heat exchanger to pull heat

out of the HV battery, HV PCM, and motor-generator

69. HV battery radiator- small air-to-liquid heat exchanger is mounted in

the battery housing

70. HV battery fan- can be energized by the HV ECM to force fresh air

through the air-to-liquid heat exchanger and over the battery pack

outer surfaces for cooling

71. Motor-generator water jackets- carry liquid coolant are formed or

machined inside the stator housing during manufacture

72. Motor-generator coolant hoses- carry cooled coolant to, and heated

coolant from, the motor-generator jackets

73. Motor-generator coolant fittings- allow rubber hoses to be clamped

around the hose for leak-proof antifreeze connections

74. Motor-generator water pump- an electric coolant pump mounted

between the system radiator and the stator housing

75. HV PCM cooling system- often uses the same electric water pump and

circulated liquid coolant as the motor-generator and HV battery

76. HV PCM water jacket- is formed between the inner and outer housings

that surround the high- power, control circuit boards mounted on a

heat sink

77. Coolant heat storage system- needed to help keep the hybrid’s piston

engine warm when it is not running and the vehicle is in full electric

propulsion

You might also like

- Hitachi Wheel Type Excavator Troubleshooting Manual PDFDocument618 pagesHitachi Wheel Type Excavator Troubleshooting Manual PDFPrudz75% (4)

- TM 08780B-24PDocument1,605 pagesTM 08780B-24Pssgtcampbell77No ratings yet

- Automobile Cooling System Lesson PlanDocument8 pagesAutomobile Cooling System Lesson PlanAyobami olaNo ratings yet

- GETrans - GEVO Tier 4 Locomotive Support SystemsDocument142 pagesGETrans - GEVO Tier 4 Locomotive Support SystemsTim MarvinNo ratings yet

- PID On A Ship's Main EngineDocument2 pagesPID On A Ship's Main EngineRae angelo Agonoy100% (1)

- Record Drawings GENERAC PDFDocument85 pagesRecord Drawings GENERAC PDFasdrubalaraujoNo ratings yet

- Liquid Cooled SystemsDocument9 pagesLiquid Cooled Systemsananth k rNo ratings yet

- Cooling SystemsDocument2 pagesCooling SystemsLazarus GutaNo ratings yet

- Autonext Study Material 2 (Cooling System)Document9 pagesAutonext Study Material 2 (Cooling System)SouravNo ratings yet

- Engine Cooling SystemDocument3 pagesEngine Cooling SystemSurjit Kumar GandhiNo ratings yet

- Presentation On Cooling SystemDocument26 pagesPresentation On Cooling SystemPawan Kumar100% (1)

- 1 4 4 RadiatorDocument8 pages1 4 4 RadiatorShambhuNath VermaNo ratings yet

- Engine Cooling SystemDocument5 pagesEngine Cooling SystemAnoj pahathkumburaNo ratings yet

- Cooling System PresentationDocument19 pagesCooling System PresentationHari Purwadi100% (1)

- Effects of OverheatingDocument46 pagesEffects of OverheatingSajjad Hossain ShuvoNo ratings yet

- Engine Cooling SystemsDocument5 pagesEngine Cooling SystemsAdnan ParkerNo ratings yet

- AUTOTECH Cooling SystemDocument47 pagesAUTOTECH Cooling SystemSesatthiri SesatNo ratings yet

- Engine Cooling System and Servicin1Document37 pagesEngine Cooling System and Servicin1Emmanuel KutaniNo ratings yet

- Cooling and Preheating SystemDocument3 pagesCooling and Preheating SystemHema RajNo ratings yet

- Cooling System in Transformer and CarDocument9 pagesCooling System in Transformer and CarAizaz KhanNo ratings yet

- Automotive Cooling SystemDocument58 pagesAutomotive Cooling SystemMoniruzzaman ShuvoNo ratings yet

- Lecture 2Document2 pagesLecture 2Dharmishtha PatelNo ratings yet

- Shivani Project ReportDocument20 pagesShivani Project ReportShivaniNo ratings yet

- Automobile Engg (Unit-03)Document15 pagesAutomobile Engg (Unit-03)SUDHARSHAN REDDYNo ratings yet

- Lect02 - Engine Cooling SystemDocument19 pagesLect02 - Engine Cooling SystemMaunish Shah100% (1)

- Als - Cooling System of EngineDocument3 pagesAls - Cooling System of EngineMarcial MilitanteNo ratings yet

- FMP-617 Farm Mechanization Practical 3Document2 pagesFMP-617 Farm Mechanization Practical 3رانا ریحان انور خاںNo ratings yet

- Automobile 6th SemesterMechanicalDocument25 pagesAutomobile 6th SemesterMechanicalSumit ManwarNo ratings yet

- Description: Cooling SystemDocument2 pagesDescription: Cooling SystemvixentdNo ratings yet

- 2 Gill APST201 AC ComponentsDocument35 pages2 Gill APST201 AC Componentscibaya4619No ratings yet

- 07-Fuel Supply & Cooling Systems of TractorDocument30 pages07-Fuel Supply & Cooling Systems of TractoroscarjamesonwattsonNo ratings yet

- Cooling SystemDocument47 pagesCooling Systemandualem nigussieNo ratings yet

- Lecture 6 Engine CoolingDocument18 pagesLecture 6 Engine CoolingMemo KhalidNo ratings yet

- Chapter 2 - Cooling System: Prepared by Muhammad Hilmi Bin ZaidDocument49 pagesChapter 2 - Cooling System: Prepared by Muhammad Hilmi Bin ZaidTyler GoodwinNo ratings yet

- Basic Heat Pump ComponentsDocument6 pagesBasic Heat Pump Componentsdrabc123No ratings yet

- UNIT IV - Engine Cooling SystemsDocument55 pagesUNIT IV - Engine Cooling SystemsANSH ROHATGI (RA2111011010002)No ratings yet

- Cooling System Report (Automotive Tech.)Document5 pagesCooling System Report (Automotive Tech.)Mohamed AhmedNo ratings yet

- Cooling SystemDocument3 pagesCooling SystemDavid Marzel jiing19No ratings yet

- Test Cooling - Arman ShaikhDocument4 pagesTest Cooling - Arman ShaikhArmanNo ratings yet

- Cooling Systems AssignmentDocument14 pagesCooling Systems AssignmentBecky DavisNo ratings yet

- NTPC Project ReportDocument31 pagesNTPC Project ReportDeepak Ranjan ParidaNo ratings yet

- Cooling Sys Fall 17 PDFDocument41 pagesCooling Sys Fall 17 PDFEmirBerkCanpolatNo ratings yet

- Cooling Systems For I.C. EnginesDocument33 pagesCooling Systems For I.C. EnginesRachitNo ratings yet

- Me Lab ReportDocument20 pagesMe Lab ReportJassondemapan100% (1)

- Task 3: Liquid CoolingDocument4 pagesTask 3: Liquid CoolinghabibullaNo ratings yet

- SSP 222 Electronically Mapped Cooling SystemDocument28 pagesSSP 222 Electronically Mapped Cooling Systemภูเก็ต เป็นเกาะNo ratings yet

- OsosDocument15 pagesOsoshakeemmouneer123No ratings yet

- Cooling SystemDocument7 pagesCooling SystemNilamadhabananda ParidaNo ratings yet

- CFD Radiator by Nano AjayDocument35 pagesCFD Radiator by Nano AjayPooja BanNo ratings yet

- Engine Cooling SystemDocument16 pagesEngine Cooling SystemGODNo ratings yet

- INFORMATION SHEET 1 Trainers MethodologyDocument9 pagesINFORMATION SHEET 1 Trainers MethodologyPolaris PenidoNo ratings yet

- Land Robert EnfriamientoDocument8 pagesLand Robert EnfriamientoJose Luis LopezNo ratings yet

- Chilled Water SystemsDocument10 pagesChilled Water SystemsLavanya...100% (5)

- Lab Report 3 Agr318.Document6 pagesLab Report 3 Agr318.Azrul AmryNo ratings yet

- Cooling JeppesonDocument4 pagesCooling JeppesonSutanu MishraNo ratings yet

- 1995 Toyota Camry Cooling System Technical ManualDocument30 pages1995 Toyota Camry Cooling System Technical ManualKevin Reilly100% (1)

- Automobile Engineering - Engine Cooling SystemsDocument16 pagesAutomobile Engineering - Engine Cooling SystemsAhmed Zawad Shovon50% (2)

- MEng3102 Chapter 10Document31 pagesMEng3102 Chapter 10dagimawgchew777No ratings yet

- Understanding Central Cooling System: Sea Water CircuitDocument6 pagesUnderstanding Central Cooling System: Sea Water Circuitმარიამ აბაშიძეNo ratings yet

- Chapter 9Document47 pagesChapter 9Siraj MohammedNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Entrenamineto OperacionDocument53 pagesEntrenamineto OperacionMax Rojas100% (1)

- Caterpillar Operation Maintenance Manual C9 C13 C15 C18 Generator SetsDocument156 pagesCaterpillar Operation Maintenance Manual C9 C13 C15 C18 Generator SetsVinicius Alves Oliveira de Lima100% (1)

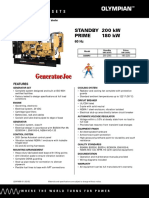

- Standby 200 KW Prime 180 KW: Diesel Generator SetsDocument4 pagesStandby 200 KW Prime 180 KW: Diesel Generator SetsJaimecolina2004No ratings yet

- Chapter 12-Heating, Air Conditioning, and Ventilating: 1 Healthy Housing Reference ManualDocument21 pagesChapter 12-Heating, Air Conditioning, and Ventilating: 1 Healthy Housing Reference ManuallmelendeziNo ratings yet

- LG Therma V MonoblocDocument47 pagesLG Therma V MonoblocMuhidin KozicaNo ratings yet

- Cat 3508 750KW - 938kvaDocument6 pagesCat 3508 750KW - 938kvaIvan DumontNo ratings yet

- V410KDocument4 pagesV410KMourad AziriNo ratings yet

- Eberspacher Heater Hydronic 10 Installation ManualDocument20 pagesEberspacher Heater Hydronic 10 Installation ManualMrJuniorolssonNo ratings yet

- CMP450D 9588 PDFDocument188 pagesCMP450D 9588 PDFagatha drumondNo ratings yet

- CFD Analysis of Automobile Radiator - A Review: March 2014Document4 pagesCFD Analysis of Automobile Radiator - A Review: March 2014arNo ratings yet

- Ielts Academic Writing-Task-1 Anna-ConwayDocument38 pagesIelts Academic Writing-Task-1 Anna-ConwayΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣNo ratings yet

- Manual Generador CAT C15 IbaguéDocument6 pagesManual Generador CAT C15 IbaguéAndres VargasNo ratings yet

- F 008am - Plta Pscs Pc1250 8Document6 pagesF 008am - Plta Pscs Pc1250 8TaufikNo ratings yet

- W211 Fan Shroud RemovalDocument2 pagesW211 Fan Shroud Removalniladam2002No ratings yet

- 2006 Eclipse Parts ListDocument121 pages2006 Eclipse Parts ListWilbert TyNo ratings yet

- Forward: Y96-1026S02 Y96-1026S02Document1 pageForward: Y96-1026S02 Y96-1026S02Gonzalo GalvezNo ratings yet

- Master Part Okt 2014Document1,402 pagesMaster Part Okt 2014Aprie Dana PratamaNo ratings yet

- Cooling System WA600!6!22272Document15 pagesCooling System WA600!6!22272Ventsislav VenevNo ratings yet

- Automotive Radiator Performance - Review PDFDocument3 pagesAutomotive Radiator Performance - Review PDFAnoop CadlordNo ratings yet

- Advanced Thermal Management For Internal Combustion Engines PDFDocument114 pagesAdvanced Thermal Management For Internal Combustion Engines PDFtroublezaurNo ratings yet

- G3516B Cooling SystemDocument6 pagesG3516B Cooling SystemNimNo ratings yet

- General Characteristics: 3029TFS29 G3Document6 pagesGeneral Characteristics: 3029TFS29 G3Padmount SumnistrosNo ratings yet

- Heat TransferDocument9 pagesHeat TransferHectorCabzNo ratings yet

- Chapter 11 Thermal Energy TransferDocument53 pagesChapter 11 Thermal Energy TransferMatthew John RashadMehanyNo ratings yet

- Chevrolet S/T Truck Incomplete Vehicle DocumentDocument75 pagesChevrolet S/T Truck Incomplete Vehicle DocumentAdam CollinsNo ratings yet

- Fitting LocationsDocument154 pagesFitting LocationsAlexander the great100% (1)

- Technical Data: 60Hz/1800R.P.M 3-Phase Power Factor Factor Cos Φ = 0.8 Emissions N/ADocument7 pagesTechnical Data: 60Hz/1800R.P.M 3-Phase Power Factor Factor Cos Φ = 0.8 Emissions N/AJonathan CastilloNo ratings yet