Professional Documents

Culture Documents

Daikin FR For PC

Daikin FR For PC

Uploaded by

cwqccq0 ratings0% found this document useful (0 votes)

10 views1 pageFluoropolymers are flame retardant due to the chemical properties of fluorine. Fluorine is difficult to associate with oxygen during combustion, making it less likely to burn. Additionally, the C-C bonds in fluorine materials formed by -CF2- are stronger than the C-C bonds formed by -CH2-, allowing them to withstand attacks that try to break the carbon bonds and make combustion more difficult. Certain Daikin fluoropolymers like PTFE, PFA, FEP, and ETFE have outstanding flame and heat resistance and are rated V-0 according to UL 94 standards, meaning they are unlikely to burn and self-extinguish when the flame source is removed.

Original Description:

Original Title

Daikin Fr for Pc

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFluoropolymers are flame retardant due to the chemical properties of fluorine. Fluorine is difficult to associate with oxygen during combustion, making it less likely to burn. Additionally, the C-C bonds in fluorine materials formed by -CF2- are stronger than the C-C bonds formed by -CH2-, allowing them to withstand attacks that try to break the carbon bonds and make combustion more difficult. Certain Daikin fluoropolymers like PTFE, PFA, FEP, and ETFE have outstanding flame and heat resistance and are rated V-0 according to UL 94 standards, meaning they are unlikely to burn and self-extinguish when the flame source is removed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views1 pageDaikin FR For PC

Daikin FR For PC

Uploaded by

cwqccqFluoropolymers are flame retardant due to the chemical properties of fluorine. Fluorine is difficult to associate with oxygen during combustion, making it less likely to burn. Additionally, the C-C bonds in fluorine materials formed by -CF2- are stronger than the C-C bonds formed by -CH2-, allowing them to withstand attacks that try to break the carbon bonds and make combustion more difficult. Certain Daikin fluoropolymers like PTFE, PFA, FEP, and ETFE have outstanding flame and heat resistance and are rated V-0 according to UL 94 standards, meaning they are unlikely to burn and self-extinguish when the flame source is removed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

ABOUT

Why are fluoropolymers flame retardant?

Unlike hydrocarbon-based

based materials with hydrogen bonded to oxygen, fluoro based materials are less likely to burn thanks to

fluorine which is difficult to associate with oxygen when it comes out.

Furthermore, in fluorine materials, the C C-C bond formed by -CF 2 - is stronger than the C-C bond by --CH

CH 2 -, and thus can

withstand attacks, trying to break the CC bond, making it difficult to burn.

Flame and Smoke retardant polymer and additives

In sensitive

tive applications, flame and smoke prevention during combustion are as crucial as plastic material in standard operating

use. Daikin supports the constraining safety regulation by proposing solutions and expertise in the field of flame retardancy.

The outstanding

tanding flame, smoke, and heat resistance properties of Daikin Fluoropolymers are naturally achieved through its

chemical structures, requiring no additives.

Rated V-0 0 to UL 94, POLYFLON PTFE and NEOFLON FEP or ETFE are less likely to burn and self self-extingu

extinguishes when the

flame source is out. NEOFLON Fluoropolymer is the most adapted solution for building plenum applications, where high

mechanical strength, abrasion resistance also help maintain good cable insulation.

Reduce Flame retardant loading in compoun

compounds

Optimizing flame retardant loading is a challenge for compounders. To serve this constraint, Daikin has developed Polyflon

MPA, an anti-dripping

dripping polymer modifier based on PTFE. With only a limited amount in resins such as PC, ABS, PS, it prevents

dripping

ng during combustion and contributes to achieving V V-0 in UL-94

94 test. Polyflon MPA contributes to reducing flame retardant

loading leading to an optimized formulation cost. MPA also enables demonstrated excellent storage stability and handling

properties. Due

ue to its good dispersibility in the resin, it does not damage the appearance of the molded product.

Properties

Product

Flammability limit oxgen concentration (vol%)

PTFE UL-94 V-0 >95

Fluoropolymer

PFA, FEP, CPT,

Fluoropolymer films

PCTFE UL-94 V-0 >95

Fluoro coatings

Polymer additives

ETFE, EFEP UL-94 V-0 30~5-

Fluoroelastomer UL-94 V-0 >75

Coating resins* UL-94 HB -

*measurement value of coating film blended with curing agent

The above numeric values are representative and not guaranteed.

You might also like

- Advanced 3 - Workbook - Updated 2017Document116 pagesAdvanced 3 - Workbook - Updated 2017Techbort Technort100% (3)

- SSPC Tu 12 PDFDocument5 pagesSSPC Tu 12 PDFPrashant PandeyNo ratings yet

- © Plastics Design Library Ch. 6: Commercial Grades of CofluoropolymersDocument27 pages© Plastics Design Library Ch. 6: Commercial Grades of CofluoropolymersRajanSharmaNo ratings yet

- REE SPAC Presentation 2021Document41 pagesREE SPAC Presentation 2021Ramon Ramirez TijerinaNo ratings yet

- Gramática AwáDocument422 pagesGramática AwáJaghu San100% (1)

- Hylar 5000 PVDF Intro - EN v2.1 - 0Document3 pagesHylar 5000 PVDF Intro - EN v2.1 - 0Phạm TháiNo ratings yet

- Polyvinylidene Fluoride-Based Coatings Technology PDFDocument8 pagesPolyvinylidene Fluoride-Based Coatings Technology PDFPUENTES2407No ratings yet

- Fluorocarbon Selection GuideDocument6 pagesFluorocarbon Selection Guidedtr17No ratings yet

- What Are The Different Xylan Coatings and How Do I Decide Which Is BestDocument8 pagesWhat Are The Different Xylan Coatings and How Do I Decide Which Is Bestsabari ramasamy100% (1)

- Introduction TRAPYLEN EnglishDocument3 pagesIntroduction TRAPYLEN EnglishHoai thu NguyenNo ratings yet

- Solef PVDF Typical Properties en 229548Document12 pagesSolef PVDF Typical Properties en 229548Addison JuttieNo ratings yet

- Brochure ChemguardDocument7 pagesBrochure ChemguardRangga AsengNo ratings yet

- Chemically Resistant FibersDocument18 pagesChemically Resistant FibersWasi BangashNo ratings yet

- Hyflon PFA GuideDocument8 pagesHyflon PFA GuideRobert MorrisNo ratings yet

- FEVE FluoropolymerDocument10 pagesFEVE FluoropolymerThomas JohnsonNo ratings yet

- DixitDocument4 pagesDixitrajendransuganthNo ratings yet

- Chemline Chemical Resistance Guide 2008 CompleteDocument32 pagesChemline Chemical Resistance Guide 2008 Completesheldon1jayNo ratings yet

- Novel Fluoropolymer-Based Emulsion Technology:: Striving For CoatingsDocument7 pagesNovel Fluoropolymer-Based Emulsion Technology:: Striving For CoatingsFac CeputeNo ratings yet

- Intrinsic Flame Resistance of Polyurethane FlexiblDocument9 pagesIntrinsic Flame Resistance of Polyurethane FlexiblGagan JainNo ratings yet

- Clariant Article Ban of PFOA PCI Magazin 202009 enDocument5 pagesClariant Article Ban of PFOA PCI Magazin 202009 enGonzalo BenavidesNo ratings yet

- Base Resistant FKM Technology in Oilfield SealsDocument15 pagesBase Resistant FKM Technology in Oilfield Sealspeach5No ratings yet

- Polymers: FRX Polymers' Nofia Provides Eco-Friendly Flame Retardance in High-Temperature PUR FoamDocument2 pagesPolymers: FRX Polymers' Nofia Provides Eco-Friendly Flame Retardance in High-Temperature PUR FoamJuan Sebastian Hernandez RochaNo ratings yet

- Brochure Orevac-T Avril-2012Document6 pagesBrochure Orevac-T Avril-2012Le MinhNo ratings yet

- Data Sheet: TechnicalDocument2 pagesData Sheet: TechnicaljasonNo ratings yet

- Fluoropolymers: What Is A Fluoropolymer?Document2 pagesFluoropolymers: What Is A Fluoropolymer?vkmsNo ratings yet

- Flame RetardantsDocument4 pagesFlame Retardants1985krNo ratings yet

- 577 - Chloro and Bromo As FR For FabricsDocument4 pages577 - Chloro and Bromo As FR For FabricsOzgur SelviNo ratings yet

- FluorezDocument27 pagesFluorezRick RgNo ratings yet

- Article FRDocument5 pagesArticle FRThu Trang NguyenNo ratings yet

- Plastics Materials - J. A. Brydson - 7th Edition - Chapter 28Document4 pagesPlastics Materials - J. A. Brydson - 7th Edition - Chapter 28CristianeHenschelNo ratings yet

- Journal 2Document7 pagesJournal 2AISHWARYANo ratings yet

- Laroflex MP 45Document7 pagesLaroflex MP 45wiwat dussadinNo ratings yet

- Ptfe Ptfe Compounds Pfa Technical InformationDocument16 pagesPtfe Ptfe Compounds Pfa Technical InformationMulyanto MulyonoNo ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Exolit AP 740, AP 750 (F (EXOLITAP) GB)Document2 pagesExolit AP 740, AP 750 (F (EXOLITAP) GB)Maximiliano MackeviciusNo ratings yet

- LF 200 F Bulletin 2015 NDocument2 pagesLF 200 F Bulletin 2015 NAlexander Franco CastrillonNo ratings yet

- PST - F5 - AM - F-500 Fire Suppression MechanicsDocument39 pagesPST - F5 - AM - F-500 Fire Suppression MechanicsDSGNo ratings yet

- Oil-Resistant Rubbers: Machine DesignDocument5 pagesOil-Resistant Rubbers: Machine Designrajeevup2004No ratings yet

- CH CH CH - CH CL CL N N: PolymerizationDocument34 pagesCH CH CH - CH CL CL N N: PolymerizationBagoes Rebel CrewNo ratings yet

- DịchDocument30 pagesDịchKhánh Nguyễn NgHNo ratings yet

- Perfluoroelastomer and Fluoroelastomer Seals For Photovoltaic Cell Manufacturing ProcessesDocument12 pagesPerfluoroelastomer and Fluoroelastomer Seals For Photovoltaic Cell Manufacturing ProcessesJagdish PatelNo ratings yet

- Basf-Flamestab Nor 116Document2 pagesBasf-Flamestab Nor 116ssczusNo ratings yet

- Resilient Seat/Seal Materials: VITON® (Fluorocarbon, FKM, or FPM)Document1 pageResilient Seat/Seal Materials: VITON® (Fluorocarbon, FKM, or FPM)automettNo ratings yet

- Journal Pre-Proof: Polymer TestingDocument42 pagesJournal Pre-Proof: Polymer TestingEkansh ChoudharyNo ratings yet

- Seal Material MemoDocument1 pageSeal Material MemoUmairNo ratings yet

- MOV Grease BrochureDocument6 pagesMOV Grease BrochureKenneth John BrownNo ratings yet

- LA Cable Materials Applications RelativeCostsDocument1 pageLA Cable Materials Applications RelativeCostsAnonymous 12Chu26JlzNo ratings yet

- Urethane Foams Move From HCFCs To Cleaning AgentsDocument6 pagesUrethane Foams Move From HCFCs To Cleaning AgentspramitanyrmaNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinNo ratings yet

- Kynar Kynar Flex PVDF PerformanceDocument20 pagesKynar Kynar Flex PVDF PerformancenarmathaNo ratings yet

- CP-7540 (Alternate AP-13)Document1 pageCP-7540 (Alternate AP-13)Muhammad AHSAN ISHAQNo ratings yet

- CH CH CH - CH CL CL N N: PolymerizationDocument40 pagesCH CH CH - CH CL CL N N: PolymerizationAkash YadavNo ratings yet

- Super Durable Finish Coating System: AdvantagesDocument2 pagesSuper Durable Finish Coating System: AdvantagessampathkumarNo ratings yet

- ElastomersDocument42 pagesElastomersAkash YadavNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typescoolguy12345No ratings yet

- Ami Cable 2015 ArkemaDocument34 pagesAmi Cable 2015 Arkemaabilio_j_vieiraNo ratings yet

- 1 s20 S0141391023003117 Main-2Document10 pages1 s20 S0141391023003117 Main-2Angela PajaresNo ratings yet

- Phenolic Epoxy SystemDocument2 pagesPhenolic Epoxy SystemAnand MNo ratings yet

- Piping Engineer BookDocument107 pagesPiping Engineer BookMiguel Angel GrimaldoNo ratings yet

- Advanced Level of Dental Resins - Material Science & Technology: 2nd Edtion / 2nd VersionFrom EverandAdvanced Level of Dental Resins - Material Science & Technology: 2nd Edtion / 2nd VersionNo ratings yet

- TR 28Document4 pagesTR 28cwqccqNo ratings yet

- 2018 Montan Waxes in Plastics - When Performance Counts 5 enDocument7 pages2018 Montan Waxes in Plastics - When Performance Counts 5 encwqccqNo ratings yet

- Tds-Fa-500h-E Ver01 Mar 2018Document1 pageTds-Fa-500h-E Ver01 Mar 2018cwqccqNo ratings yet

- Tioxide TR28 3Document2 pagesTioxide TR28 3cwqccqNo ratings yet

- 3M - New-Approaches-To-The-Processing-Of-Rutile-Filled-PolyolefinsDocument32 pages3M - New-Approaches-To-The-Processing-Of-Rutile-Filled-PolyolefinscwqccqNo ratings yet

- Conversion Denier To MicronDocument6 pagesConversion Denier To Microncwqccq100% (1)

- Alcudia PE-003Document1 pageAlcudia PE-003cwqccqNo ratings yet

- 11ropoten KB-02-208Document1 page11ropoten KB-02-208cwqccqNo ratings yet

- Dow HFDG4201Document3 pagesDow HFDG4201cwqccqNo ratings yet

- Amanpulo FactsheetDocument6 pagesAmanpulo FactsheetAlexNo ratings yet

- AHF Thesis - CorrectedDocument146 pagesAHF Thesis - CorrectedAlasdair FikourasNo ratings yet

- IB Physics Formula Booklet 2025Document8 pagesIB Physics Formula Booklet 2025Ahmad OmarNo ratings yet

- DHS Coast Guard LetterDocument13 pagesDHS Coast Guard LetterThe Hill NewspaperNo ratings yet

- Tows Matrix: Developing StrategiesDocument29 pagesTows Matrix: Developing StrategiesalkalkiaNo ratings yet

- Bihar Agri Investment Promotion PolicyDocument3 pagesBihar Agri Investment Promotion Policyp4625347No ratings yet

- 8 SWOT Analysis Tools For Small Businesses: 1. SmartsheetDocument3 pages8 SWOT Analysis Tools For Small Businesses: 1. SmartsheetSantu BiswaaNo ratings yet

- Shared Information ModelDocument16 pagesShared Information Modelrohitchawandke100% (1)

- SOC FlyerDocument2 pagesSOC Flyersammer1985No ratings yet

- Arithmetic MeansDocument8 pagesArithmetic MeansMargie Ballesteros ManzanoNo ratings yet

- Calcaneus Fracture: Randy SusantoDocument32 pagesCalcaneus Fracture: Randy SusantoRandy SusantoNo ratings yet

- Cs 20Document45 pagesCs 20INTEGRAL100% (2)

- A Project Report On CustomerDocument13 pagesA Project Report On CustomerDrishti BhushanNo ratings yet

- Department of Applied Physics Applied Physics Question Bank Session - 2012-13Document4 pagesDepartment of Applied Physics Applied Physics Question Bank Session - 2012-13Sajid Ur RehmanNo ratings yet

- Developing On AwsDocument7 pagesDeveloping On Awsalton032No ratings yet

- Fault Diagnosis of Power Transformer Based On Multi-Layer SVM ClassifierDocument7 pagesFault Diagnosis of Power Transformer Based On Multi-Layer SVM ClassifierFelipe KaewNo ratings yet

- InventoryrrgDocument31 pagesInventoryrrgPiyush KumarNo ratings yet

- An Information Silo: Management System Information System InformationDocument5 pagesAn Information Silo: Management System Information System InformationGeetanjaliNo ratings yet

- UFOs Caught in A Web of DeceptionDocument30 pagesUFOs Caught in A Web of DeceptionMarko CankarNo ratings yet

- Prospective vs. Retrospective Delay Analysis: Rohit Singhal, Shishir Kant & Adarsh KumarDocument10 pagesProspective vs. Retrospective Delay Analysis: Rohit Singhal, Shishir Kant & Adarsh KumarKevin DonNo ratings yet

- HR 109 - Review of MWSS Contracts With Maynilad and Manila WatersDocument3 pagesHR 109 - Review of MWSS Contracts With Maynilad and Manila WatersanakpawispartylistNo ratings yet

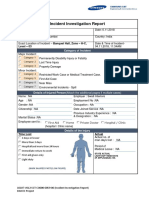

- Incident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsDocument4 pagesIncident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsMobin Thomas AbrahamNo ratings yet

- ALEOS 4.17.0 Software Configuration Guide For RV50Document580 pagesALEOS 4.17.0 Software Configuration Guide For RV50venginesNo ratings yet

- Fifty Selected Piano-Studies v1 1000050100Document48 pagesFifty Selected Piano-Studies v1 1000050100Lizzie Allan60% (5)

- JAMB English Language Past Questions and Answers 2010 - 2018Document84 pagesJAMB English Language Past Questions and Answers 2010 - 2018Joel Adams100% (6)

- Assignment Name: Identifying Characteristics of Some Family With 5 ExamplesDocument4 pagesAssignment Name: Identifying Characteristics of Some Family With 5 ExamplesAbdullah Al MamunNo ratings yet

- Make and Grow Money The Right Way (Free Sample)Document12 pagesMake and Grow Money The Right Way (Free Sample)Ankit ChawlaNo ratings yet