Professional Documents

Culture Documents

12282A - Expansion Joints Datasheet

12282A - Expansion Joints Datasheet

Uploaded by

Gaurav TripathiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12282A - Expansion Joints Datasheet

12282A - Expansion Joints Datasheet

Uploaded by

Gaurav TripathiCopyright:

Available Formats

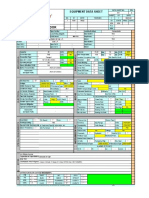

ISSUE PRD BY CKD BY APPD BY DATE

CLIENT : BHARAT PETROLEUM CORPORATION LIMITED JOB NO. : P0 MSN NSB NKN 22/04/2022

R0

PROJECT : EPCM Services for 2G Bio-Ethanol & 1G Bio-Ethanol Refinery Project at Bargarh Orissa. TCE.12282A

SECTION :

Doc No. 12282A-00-000-PP08DS-012 SPECIFICATION AND BOQ FOR EXPANSION JOINT

SHEET 1 OF 1

OPERATING CONDITION DESIGN CONDITION END CONNECTION / RATING BELLOW STIFFNESSES (Note 1.0)

TIE ROD

TIE ROD EFFECTIVE

Bellow SIZE Stress System PID NO. BELLOW MOC SERVICE EXPANSION GAP LENGTH (MM)

SR.NO. Tag No. LINE NO. LENGTH* ID QUANTITY (Nos.) REMARK

(Inch) NO. (NOTE-2) PRESSURE TEMPERATURE PRESSURE TEMPERATURE FLUID BELLOW TYPE (AXIAL) (NOTE-4) Translational BENDING TORSIONAL

FROM TO (mm) (mm) AXIAL (kg/cm)

kg/cm² (g) (Deg.C.) kg/cm² (g) (Deg.C.) (mm) (Kg/cm) (Kg.m/deg) (Kg.m/deg)

1 EJ-950219-01 24"-TSV-101-950219-A3K-3"H-02EV 24 9500-CA-0001 9502 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 476 641.516 355 12316 46138 1

2 EJ-950125-01 24"-TSV-101-950125-A3K-2.5"H-02EV/B1 24 9500-CA-0001 9501 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 476 641.516 354.895 12316 66138 1

3 EJ-950619-01 60"-TSV-101-950619-A3K-3"-H 60 9500-CA-0004 9506 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 367 85 647 66625 807926 1

4 EJ-950619-02 60"-TSV-101-950619-A3K-3"-H 60 9500-CA-0004 9506 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 433 85 324 8328 403963 1

5 EJ-950520-01 44"-TSV-101-950520-A3K-3"-H-02EV 44 9500-CA-0004 9505 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 273 1151.795 184 7403 133084 1

6 EJ-950420-01 24"-TSV-101-950420-A3K-3"-H-02EV 24 9500-CA-0004 9504 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 473 641.516 532 41566 69207 1

7 EJ-950320-01 20"-TSV-101-950320-A3K-2.5"H-02EV 20 9500-CA-0004 9503 SS 1 120 4 145 V Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 568 47 1338 18825 62343 1

8 EJ-950613-01 48"-TSV-101-950613-A3K-3"-H-02EV 48 9500-CA-0004 9506 SS 7.0/0.1 120 9 131 L Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 717 954.883 514.356 7267 91794 1

9 EJ-950613-02 48"-TSV-101-950613-A3K-3"-H-02EV 48 9500-CA-0004 9506 SS 7.0/0.1 120 9 131 L Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 762 954.883 450.188 4869 80320 1

10 EJ-950513-01 32"-TSV-101-950513-A3K-3"-H-02EV 32 9500-CA-0004 9505 SS 7.0/0.1 120 9 131 V Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 495 853.111 1596 2205 225645 1

11 EJ-950513-02 32"-TSV-101-950513-A3K-3"-H-02EV 32 9500-CA-0004 9505 SS 7.0/0.1 120 9 131 V Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 762 853.111 399 3447 56411 1

9509 Universal Tied

12 EJ-950901-01 32"-TSL-101-950901-A3K-3"H-02EV 32 9500-CA-0008 SS 7.0/0.1 120 9 131 L Slip-on/150# Slip-on/150# By Vendor 0 1550 853.111 399 3448 56434 1

Bellow

9508 Universal Tied

13 EJ-950801-02 32"-TSL-101-950801-A3K-3"H-02EV 32 9500-CA-0008 SS 7.0/0.1 120 9 131 L Slip-on/150# Slip-on/150# By Vendor 0 1550 853.111 399 3448 56434 1

Bellow

9507 Universal Tied

14 EJ-950701-01 32"-TSL-101-950701-A3K-3"H-02EV 32 9500-CA-0008 SS 7.0/0.1 120 9 131 L Slip-on/150# Slip-on/150# By Vendor 0 1550 853.111 798.469 6896 116796 1

Bellow

15 EJ-950413-01 18"-TSV-101-950413-A3K-2.5"H-02EV 18 9500-CA-0004 9504 SS 7.0/0.1 120 9 131 V Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 298 48 1238.423 43397 72334 1

16 EJ-920201-01 26"-CSL1-101-920201-A1N-3"-H-02PH 26 9200-CA-0001 9202 SS 4 125 6 150 L Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 355 35 1000.726 22959 68459 1

17 EJ-920203-01 26"-CSL1-101-920203-A1N-1"-H-02PH 26 9200-CA-0001 9202 SS 4 125 6 150 L Slip-on/150# Slip-on/150# Un-Tied Bellow By Vendor 355 35 1000.726 22959 68459 1

18 EJ-920207-01 28"-FLV1-101-920207-A1N-3"-H-02PH 28 9200-CA-0002 9202 SS 2 100 4 150 V Slip-on/150# Slip-on/150# Tied Bellow By Vendor 0 832 747.932 1510.23 25641 136588 1

Notes:

1 For End connection refer piping material specification and Equipment GA Drawing.

2 Vendor to provide the actual bellow stiffnesses data and the effective ID and confirm final length as per vendor design/ Calculation and code requirments.

3 The bellow material of construction shall be of suitable grade to meets the stiffness as well as the specification requirements.

4 The expansion bellow design and material selection shall be such that it meets the expected design life cycle of 7000 cycles.

5 The tie-rods of tied bellows shall be designed for full pressure thrust expected in the system as well as for local bending, if any.

6 The design of expansion joint components and assemby shall conform to the requirements of EJMA / ASME B31.3 and specification.

7 Vendor to offer bellows with minimum possible length./ The expansion bellows and all its components shall be designed for maximum loads especially for weld strength check and buckling check for tie-rods.

8 The MOC of other accessories shall be compatible with the bellow MOC and fluid sevice being handled.

9 Metallic bellows are required 100% radiography.

10 All "*" should be confirmed by vendor

11 Quantity of number of Bellows mentioned above subject to change in subsequent revision based on further engineering.

You might also like

- IGT Game King 044 Video CTRL Board Schematics (757-044-10)Document24 pagesIGT Game King 044 Video CTRL Board Schematics (757-044-10)Turko Alejandro50% (2)

- Rotating Equipment API StandardsDocument1 pageRotating Equipment API StandardsGaurav Tripathi100% (2)

- Rotating Equipment API StandardsDocument1 pageRotating Equipment API StandardsGaurav Tripathi100% (2)

- DLL Empowerment Technologies Week 1Document3 pagesDLL Empowerment Technologies Week 1Brynard Garbosa100% (2)

- Ele Vir Flush Ring 160 0001 To 0008Document16 pagesEle Vir Flush Ring 160 0001 To 0008rahul o gNo ratings yet

- SUbmission - R2/Annexure - 1 Design Calculatoin Mechanical/Annexure - 1Document11 pagesSUbmission - R2/Annexure - 1 Design Calculatoin Mechanical/Annexure - 1mehtaabhi99_27916695No ratings yet

- Expansion Joint For EvaporateurDocument2 pagesExpansion Joint For EvaporateurLAKHTIRINo ratings yet

- 9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyDocument2 pages9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyANIL PLAMOOTTILNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- Bato-Cogon Pertcpm (Final)Document1 pageBato-Cogon Pertcpm (Final)MANNY CARAJAYNo ratings yet

- JPC C DWG BF 01 PDFDocument3 pagesJPC C DWG BF 01 PDFHendri HermawanNo ratings yet

- Diesel Plant Facility-ModelDocument1 pageDiesel Plant Facility-ModelJohn Phillip Lopez MasagcaNo ratings yet

- Process Overview 240108 223527Document1 pageProcess Overview 240108 223527thiago.fcouto23No ratings yet

- Index: Signature Not VerifiedDocument8 pagesIndex: Signature Not VerifiedAMJAD KHANNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectKuwait Gulf CircleNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- Outline Drawing of Segment Lining (Basic Design) - V2Document51 pagesOutline Drawing of Segment Lining (Basic Design) - V2know netNo ratings yet

- Outline Drawing of Segment Lining (Basic Design) - V2Document51 pagesOutline Drawing of Segment Lining (Basic Design) - V2know netNo ratings yet

- Tanque: Equipment Data SheetDocument1 pageTanque: Equipment Data SheetAlonso DIAZNo ratings yet

- Equipment ListDocument7 pagesEquipment Listyadav yadavNo ratings yet

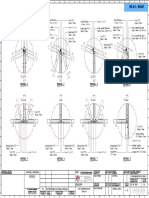

- Detail - 1 Detail - 2 Detail - 3 Detail - 4: Aproval DrawingDocument1 pageDetail - 1 Detail - 2 Detail - 3 Detail - 4: Aproval DrawingSyahrul RomadhonNo ratings yet

- EPC-1A Hot Tappings Post-Site-Visit Master 23nov2020Document1 pageEPC-1A Hot Tappings Post-Site-Visit Master 23nov2020Joseley D'souzaNo ratings yet

- Low SupportDocument1 pageLow SupportMDhana SekarNo ratings yet

- Piping DetailsDocument16 pagesPiping DetailsSasi MesthiriNo ratings yet

- Khu - 11 - G - Bac20 - Ea - 004 - 2Document18 pagesKhu - 11 - G - Bac20 - Ea - 004 - 2Shafiqul IslamNo ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- NDT SpecsDocument3 pagesNDT SpecsRam Shankar SahuNo ratings yet

- Helliptical Head Design Calculation ASMEVIII-DIV I-141F Rev1Document2 pagesHelliptical Head Design Calculation ASMEVIII-DIV I-141F Rev1Hicham SaadiNo ratings yet

- Actuve Raileay Pulling PipebookDocument2 pagesActuve Raileay Pulling Pipebookatulpatil99No ratings yet

- D-200-MAC-GEN-LLP-001 - RevC1 Line List - 24 Oct (After Issued)Document17 pagesD-200-MAC-GEN-LLP-001 - RevC1 Line List - 24 Oct (After Issued)abduhNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataShubham kgc100% (1)

- Khu - 11 - G - Bac20 - DS - 001 - 2Document2 pagesKhu - 11 - G - Bac20 - DS - 001 - 2Shafiqul IslamNo ratings yet

- Mega-Lntiel-Stn-Ns-Sbrs-Str-Dd-S199-R0-Pms-Numeration Detail of Steel Staircase From Concourse Level To Platform Level-Sh 2 of 2Document1 pageMega-Lntiel-Stn-Ns-Sbrs-Str-Dd-S199-R0-Pms-Numeration Detail of Steel Staircase From Concourse Level To Platform Level-Sh 2 of 2Suresh BabuNo ratings yet

- Abcd 001 0007Document13 pagesAbcd 001 0007bishalNo ratings yet

- Heat Stress Management PlanDocument18 pagesHeat Stress Management Planjaydyishiah1234No ratings yet

- 20GHA85BR006Document1 page20GHA85BR006NITHIN MATHEWNo ratings yet

- Tsr216 DifferentialDocument3 pagesTsr216 Differentialdwi supraptoNo ratings yet

- Vaporizador: Equipment Data SheetDocument1 pageVaporizador: Equipment Data SheetAlonso DIAZNo ratings yet

- 140 C 001Document11 pages140 C 001Goutam GiriNo ratings yet

- Plano Hidraulico Filtracion FinaDocument2 pagesPlano Hidraulico Filtracion Finanilton acNo ratings yet

- D EHP: Nidec Sankyo Project M-AC-3 3P4W-380/220VACDocument1 pageD EHP: Nidec Sankyo Project M-AC-3 3P4W-380/220VACHoang TungNo ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 17-Mar-16 TWR-01 14-Mar-17Document1 pageWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 17-Mar-16 TWR-01 14-Mar-17abdullaNo ratings yet

- DAILY REJECTION DATA (Jan 2024)Document8 pagesDAILY REJECTION DATA (Jan 2024)rahulkumarqa01No ratings yet

- Схема пульта управленияDocument1 pageСхема пульта управленияДенис УмеренкоNo ratings yet

- 9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Document15 pages9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Pottem VanithareddyNo ratings yet

- Pioneer 15 m3 ETP Level ElivationDocument1 pagePioneer 15 m3 ETP Level ElivationAdam DevidNo ratings yet

- Hdpe 81aDocument1 pageHdpe 81aAli RaheemNo ratings yet

- Aproval Drawing: PT - Aiko Negara DahaDocument1 pageAproval Drawing: PT - Aiko Negara DahaSyahrul RomadhonNo ratings yet

- 3827-E10-067 - High Performance Butterfly Valve - BDocument2 pages3827-E10-067 - High Performance Butterfly Valve - BMohamed Elsaid El ShallNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument12 pagesLarsen & Toubro Limited: ECC Division - EDRCEngr. Nabid Rayhan KhalequeNo ratings yet

- Recipiente: Equipment Data SheetDocument1 pageRecipiente: Equipment Data SheetAlonso DIAZNo ratings yet

- Piping Class PDFDocument4 pagesPiping Class PDFanil pkNo ratings yet

- Rotating Equipment List: A. ProcessDocument2 pagesRotating Equipment List: A. ProcesshungNo ratings yet

- Production 712906: Installation Outline Drawing, Fl500Document2 pagesProduction 712906: Installation Outline Drawing, Fl500gerardo.serco19No ratings yet

- PZV Pressurerelief ValveDocument3 pagesPZV Pressurerelief Valvepraveenice23No ratings yet

- PTT Public Company Limited 7Th Gas Separation Plant ProjectDocument2 pagesPTT Public Company Limited 7Th Gas Separation Plant ProjectThane SkinnerNo ratings yet

- TSR Sd22e Bd108Document3 pagesTSR Sd22e Bd108dwi supraptoNo ratings yet

- Dol 0000 Ppi 00001 - Z19Document1 pageDol 0000 Ppi 00001 - Z19ywahyudiNo ratings yet

- PFD Dry Beneficiation - 015E20019 - 00Document1 pagePFD Dry Beneficiation - 015E20019 - 00Bondan BagusNo ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- A554 D A2111 DWG A05 501Document1 pageA554 D A2111 DWG A05 501Non Etabas GadnatamNo ratings yet

- 5/2 Air Operated, Spring/ Return Valve: Series: 32PDocument2 pages5/2 Air Operated, Spring/ Return Valve: Series: 32PGaurav TripathiNo ratings yet

- Project Control GuideDocument13 pagesProject Control GuideGaurav TripathiNo ratings yet

- Age 9 10 Vol1 Print Learn CenterDocument101 pagesAge 9 10 Vol1 Print Learn CenterGaurav TripathiNo ratings yet

- 5/2 Pilot Operated, Single/ Double Solenoid, Subbase Mounted ValveDocument4 pages5/2 Pilot Operated, Single/ Double Solenoid, Subbase Mounted ValveGaurav TripathiNo ratings yet

- 5/3 Internal Pilot Operated, Center Off Poppet Solenoid ValveDocument2 pages5/3 Internal Pilot Operated, Center Off Poppet Solenoid ValveGaurav TripathiNo ratings yet

- 20111111114204001Document3 pages20111111114204001Gaurav TripathiNo ratings yet

- Age 4 5 Vol1 Print Learn CenterDocument101 pagesAge 4 5 Vol1 Print Learn CenterGaurav TripathiNo ratings yet

- Brief Scope of Supply For Reciprocating Gas Compressor PackageDocument1 pageBrief Scope of Supply For Reciprocating Gas Compressor PackageGaurav TripathiNo ratings yet

- Age 10 11 Vol1 Print Learn CenterDocument101 pagesAge 10 11 Vol1 Print Learn CenterGaurav TripathiNo ratings yet

- STD Iv - Ek Thi SwatiDocument3 pagesSTD Iv - Ek Thi SwatiGaurav TripathiNo ratings yet

- Activities Performed in ONGCDocument31 pagesActivities Performed in ONGCGaurav TripathiNo ratings yet

- Job Description: Position Grade Function Reporting To Key Activities / AccountabilitiesDocument3 pagesJob Description: Position Grade Function Reporting To Key Activities / AccountabilitiesGaurav TripathiNo ratings yet

- Mess Bill September To OctoberDocument4 pagesMess Bill September To OctoberGaurav TripathiNo ratings yet

- Age 4 5 Vol1 Print Learn CenterDocument101 pagesAge 4 5 Vol1 Print Learn CenterGaurav TripathiNo ratings yet

- Brief Scope of Supply For Reciprocating Gas Compressor PackageDocument2 pagesBrief Scope of Supply For Reciprocating Gas Compressor PackageGaurav TripathiNo ratings yet

- Suvidya Institute of Technology Pvt. LTD.: Mechanical Design of Process Equipment (Full Time) Batch No. 053Document2 pagesSuvidya Institute of Technology Pvt. LTD.: Mechanical Design of Process Equipment (Full Time) Batch No. 053Gaurav TripathiNo ratings yet

- Appendices PDFDocument96 pagesAppendices PDFGaurav TripathiNo ratings yet

- EOI - Replacement of CSU & OGC at UranDocument7 pagesEOI - Replacement of CSU & OGC at UranGaurav TripathiNo ratings yet

- PFD ModelDocument23 pagesPFD ModelGaurav TripathiNo ratings yet

- Cálculo Flange ASME VIII 1 Apendice 2Document5 pagesCálculo Flange ASME VIII 1 Apendice 2Anonymous gfR3btyUNo ratings yet

- Leroy Somer Alternator Products PDFDocument20 pagesLeroy Somer Alternator Products PDFfirdNo ratings yet

- Teseo Liv3flDocument34 pagesTeseo Liv3flАртем ВитальевичNo ratings yet

- Preparation - Form 3: Please SelectDocument2 pagesPreparation - Form 3: Please SelectAjay PawarNo ratings yet

- Lecture 1: Introduction To Network SecurityDocument40 pagesLecture 1: Introduction To Network SecurityPinnamaneni_Dh_1228No ratings yet

- Citibank, N.A. Fraud Prevention PO BOX 769027-9027 SAN ANTONIO TX 78245-9963Document2 pagesCitibank, N.A. Fraud Prevention PO BOX 769027-9027 SAN ANTONIO TX 78245-9963Munir El FakihNo ratings yet

- 04 Signal Cond Bridge SystemsDocument35 pages04 Signal Cond Bridge SystemsSohaib M. AlameenNo ratings yet

- 13-Chapter 13 - TransistorsDocument28 pages13-Chapter 13 - Transistorssrinu247100% (3)

- BEM 126 Mikroskop Digital - V2 English - Win10Document40 pagesBEM 126 Mikroskop Digital - V2 English - Win10Jeven Hanbert JeremyNo ratings yet

- S.Achudhan: Automotive-Sales EngineerDocument2 pagesS.Achudhan: Automotive-Sales EngineerSobbyNo ratings yet

- UNIT-1 Design Considerations of Electrical InstallationsDocument4 pagesUNIT-1 Design Considerations of Electrical InstallationspradeepNo ratings yet

- ProNet Plus User S Manual V1 03Document216 pagesProNet Plus User S Manual V1 03Cesar Sn Juan100% (1)

- Wa0018.Document4,101 pagesWa0018.Ria SharmaNo ratings yet

- Aircraft Radio Navigation Communication SystemsDocument192 pagesAircraft Radio Navigation Communication Systemspontoo100% (16)

- Seguridad Electronica Control de AccesoDocument39 pagesSeguridad Electronica Control de AccesoChristians Pacco TaipeNo ratings yet

- Bumper Sizing Codes and CalculationsDocument4 pagesBumper Sizing Codes and CalculationssarochimNo ratings yet

- HIMA TrainingDocument26 pagesHIMA TrainingmshahabahmadNo ratings yet

- NodeMCU TutorialDocument49 pagesNodeMCU Tutorialv_ananthuNo ratings yet

- Polymers 14 00274Document28 pagesPolymers 14 00274MECHANICAL SHORTS Gate Technical ExamNo ratings yet

- CO2 Fire Suppression SystemsDocument18 pagesCO2 Fire Suppression Systemsmarpaung saberindoNo ratings yet

- UCCE BK S5AE1622 00 Staging-GuideDocument146 pagesUCCE BK S5AE1622 00 Staging-GuidedasramjithNo ratings yet

- DXXXX-QSOP - Well Control DrillDocument7 pagesDXXXX-QSOP - Well Control Drillharry mulyafitNo ratings yet

- Toshiba Catalogue-AirCondDocument8 pagesToshiba Catalogue-AirCondashraful alhanyNo ratings yet

- Lenovo RecoveryDocument6 pagesLenovo RecoverycNo ratings yet

- Resume of Nmac711Document2 pagesResume of Nmac711api-23719279No ratings yet

- Mercruiser Shift CablesDocument9 pagesMercruiser Shift CablesJSMarine Parts ChinaNo ratings yet

- Tips For Preventing Damage To Digital Multimeters: Ensure Proper GroundingDocument2 pagesTips For Preventing Damage To Digital Multimeters: Ensure Proper GroundingYidnekachwe MekuriaNo ratings yet

- Ford ObdDocument235 pagesFord ObdLuciane Vaghetti100% (5)

- VLSIDocument12 pagesVLSIPeer MohamedNo ratings yet

- WcdmaDocument14 pagesWcdmadangdoan2008No ratings yet