Professional Documents

Culture Documents

Installation Imbalance Sensor

Installation Imbalance Sensor

Uploaded by

JanCopyright:

Available Formats

You might also like

- 2.11.2 Project - Performance Task - The Parallax Problem (Project)Document7 pages2.11.2 Project - Performance Task - The Parallax Problem (Project)Tyler West100% (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Discovering Statistics Using IBM SPSS Stat - Andy FieldDocument2 pagesDiscovering Statistics Using IBM SPSS Stat - Andy Fieldfebty kuswantiNo ratings yet

- Printbar RemovalDocument21 pagesPrintbar RemovalTaur1968100% (1)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualWilliam John DavisonNo ratings yet

- Mission U500 Service ManualDocument67 pagesMission U500 Service ManualJanNo ratings yet

- Creality Ender-3 3D Printer User ManualDocument38 pagesCreality Ender-3 3D Printer User ManualPablo Ortiz Tobar100% (1)

- Tesla Model S Rear Door Handle ReplacementDocument12 pagesTesla Model S Rear Door Handle ReplacementAnonymous TjcIWjNo ratings yet

- ATRA 41TE Rebuild (Chrysler A 604)Document115 pagesATRA 41TE Rebuild (Chrysler A 604)Patricio Bacigalupi100% (4)

- GT Letter Writing Guide PDFDocument14 pagesGT Letter Writing Guide PDFDean ArigNo ratings yet

- QX MaintenanceDocument24 pagesQX MaintenancePa-jokey Espinoza GutierrezNo ratings yet

- Wrangler JeepDocument81 pagesWrangler Jeepjalvarez_385073No ratings yet

- CanrigBJWPC ICO Manual PDFDocument42 pagesCanrigBJWPC ICO Manual PDFCarlos Patiño SuarezNo ratings yet

- Apple PowerBook G4 Aluminum 15Document51 pagesApple PowerBook G4 Aluminum 15partybymartyNo ratings yet

- Caliber Compass PatriotDocument69 pagesCaliber Compass Patriotjalvarez_385073No ratings yet

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 pagesRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoNo ratings yet

- Disassembly Procedures LoResDocument24 pagesDisassembly Procedures LoResddeppenjr0% (1)

- Paddle Shift Install Instructions V5aDocument9 pagesPaddle Shift Install Instructions V5apenavi5687No ratings yet

- Installation Manual Bizhub Pro 1050Document19 pagesInstallation Manual Bizhub Pro 1050Hugo Luis Escalante100% (2)

- Suspension - FrontDocument5 pagesSuspension - FrontHans OosthuizenNo ratings yet

- Installation Instructions: Parts ListDocument5 pagesInstallation Instructions: Parts Listd-fbuser-93366182No ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Bike Harness Installation Kawasaki Type 13a 2016 2017 ZX10R ZX10RR v02Document20 pagesBike Harness Installation Kawasaki Type 13a 2016 2017 ZX10R ZX10RR v02Anas KhanNo ratings yet

- Installation RP-507 ComputerDocument19 pagesInstallation RP-507 ComputerJanNo ratings yet

- Ibm 4019Document2 pagesIbm 4019Jan SoukupNo ratings yet

- Apple Powerbook G4 Aluminum 12" Repair ManualDocument72 pagesApple Powerbook G4 Aluminum 12" Repair ManualhberbariNo ratings yet

- Installation ManualDocument11 pagesInstallation ManualSándor SzabóNo ratings yet

- Remanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesDocument8 pagesRemanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesservicerNo ratings yet

- Distox2 Assembly ManualDocument6 pagesDistox2 Assembly ManualVlad AdrianNo ratings yet

- 055.180.100.099-07 TECHART Tagfahrlicht ENUS 12-2011Document16 pages055.180.100.099-07 TECHART Tagfahrlicht ENUS 12-2011anuarmaukenovNo ratings yet

- Performance Computer Chip Installation Instructions: 325i/is/ix 325ic 525i 535i 635csi 735i/ilDocument4 pagesPerformance Computer Chip Installation Instructions: 325i/is/ix 325ic 525i 535i 635csi 735i/ilandrija_ganzbergerNo ratings yet

- Prestige - Medical - 2100 - Service - Manual Steam SterilizerDocument13 pagesPrestige - Medical - 2100 - Service - Manual Steam SterilizerGigi CostelusNo ratings yet

- Synth EsDocument36 pagesSynth EsFrank QuitianNo ratings yet

- iCR 3600 Flat Gear and Motor Replacement: WarningDocument13 pagesiCR 3600 Flat Gear and Motor Replacement: WarningEliana Caceres TorricoNo ratings yet

- 00016-32901y-Toyota KeylessDocument12 pages00016-32901y-Toyota KeylessalexandytaNo ratings yet

- Nilfisk GM 80 - GM 80iDocument28 pagesNilfisk GM 80 - GM 80iAngel De la TorreNo ratings yet

- CM200 Opertional ManualDocument21 pagesCM200 Opertional ManualZahid AnwerNo ratings yet

- XL2 Disassembly Procedure: Wayne Minter 9/30/2009Document23 pagesXL2 Disassembly Procedure: Wayne Minter 9/30/2009MAmarNo ratings yet

- INSTALL GUIDE - 991 & 991.2 Turbo Valvetronic ControllerDocument10 pagesINSTALL GUIDE - 991 & 991.2 Turbo Valvetronic Controllerirfaan2133No ratings yet

- Z UTEC User Manual 23-1Document66 pagesZ UTEC User Manual 23-1TeeJay RexNo ratings yet

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 pagesRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoNo ratings yet

- DDM 30658116 Cleaning ProcedureDocument7 pagesDDM 30658116 Cleaning ProcedurePawluchNo ratings yet

- Torre Secadora MABEDocument46 pagesTorre Secadora MABEDoris RojasNo ratings yet

- Chapter Seven: GS Ohlins Installation, Adjustment Tips & TricksDocument29 pagesChapter Seven: GS Ohlins Installation, Adjustment Tips & TricksWhattonNo ratings yet

- Installing Ipad Wi-Fi LCDDocument8 pagesInstalling Ipad Wi-Fi LCDАлександрNo ratings yet

- Filtro Onga Series IIDocument24 pagesFiltro Onga Series IIRicardo Cesar Bueno BertichevicNo ratings yet

- Adaptive Cruise Installation Guide (Edited)Document9 pagesAdaptive Cruise Installation Guide (Edited)Night WolfNo ratings yet

- Manual - Service - PB560 - English (148-160)Document13 pagesManual - Service - PB560 - English (148-160)STEPHANY VANESSA LOMBANA ROJASNo ratings yet

- Pull Off Test MumbaiDocument5 pagesPull Off Test MumbaiVpln SarmaNo ratings yet

- ROUSH AirBags Upgrade 97581-01-01Document4 pagesROUSH AirBags Upgrade 97581-01-01joecosta77No ratings yet

- Samsung ML 1610 - 4521 4725 Fml-2010 Xerox Phaser 3117 Cambio de Drum y RecargaDocument5 pagesSamsung ML 1610 - 4521 4725 Fml-2010 Xerox Phaser 3117 Cambio de Drum y RecargaComotu IgualNo ratings yet

- 1952 Delco Remy Generator Bearing and Brush Replacement Step by Step.Document13 pages1952 Delco Remy Generator Bearing and Brush Replacement Step by Step.Daner3No ratings yet

- Arosa 5i Spark Detector ACM Module Manual 2020Document23 pagesArosa 5i Spark Detector ACM Module Manual 2020mamuntextileNo ratings yet

- HA Plug-And-Play Car Harness InstallationDocument32 pagesHA Plug-And-Play Car Harness InstallationalftoyNo ratings yet

- Installation Manual Bizhub c450Document15 pagesInstallation Manual Bizhub c450Hugo Luis EscalanteNo ratings yet

- OKI C911 / 931 / 941: Disassembly & Reassembly ProceduresDocument40 pagesOKI C911 / 931 / 941: Disassembly & Reassembly Proceduresmo30mai08No ratings yet

- User's Manual: Item# 891340 Electric Pipe Cutting ThreaderDocument13 pagesUser's Manual: Item# 891340 Electric Pipe Cutting ThreaderRanj Japs0% (1)

- VW Jetta, Golf, New Beetle 1.9L Tdi Unichip PNP Installation InstructionsDocument5 pagesVW Jetta, Golf, New Beetle 1.9L Tdi Unichip PNP Installation InstructionsAdina CamfortNo ratings yet

- Honda CR-V 2012-2016 V3G.1.2aDocument17 pagesHonda CR-V 2012-2016 V3G.1.2aBarry GravesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- LX-VX-FX Service Manual-R2Document25 pagesLX-VX-FX Service Manual-R2Jan100% (1)

- Sweat Testing: Macroduct® AdvancedDocument4 pagesSweat Testing: Macroduct® AdvancedJanNo ratings yet

- Installation SoftwareDocument13 pagesInstallation SoftwareJanNo ratings yet

- Aerospray TB Model 7722Document106 pagesAerospray TB Model 7722JanNo ratings yet

- Installation RP-507 ComputerDocument19 pagesInstallation RP-507 ComputerJanNo ratings yet

- Mission U500 Improvement Data Transfer Package Insert-02232017Document1 pageMission U500 Improvement Data Transfer Package Insert-02232017JanNo ratings yet

- Aerospray Model 7622Document53 pagesAerospray Model 7622JanNo ratings yet

- Aerospray Stat 7122Document97 pagesAerospray Stat 7122JanNo ratings yet

- Aerospray Cytology 7522Document102 pagesAerospray Cytology 7522JanNo ratings yet

- Listening Test: Directions: For Each Question in This Part, You Will Hear Four Statements About A Picture in YourDocument40 pagesListening Test: Directions: For Each Question in This Part, You Will Hear Four Statements About A Picture in YourTrương Hữu LộcNo ratings yet

- Chicco Cortina CX Stroller ManualDocument22 pagesChicco Cortina CX Stroller ManualRRNo ratings yet

- Training Topics: Differentiating InstructionDocument7 pagesTraining Topics: Differentiating InstructionarisuNo ratings yet

- 02 Topically P3 A4 M10Document43 pages02 Topically P3 A4 M10Ir HeriawanNo ratings yet

- PDU-G1, 2: UHF Sensor For Partial Discharge Monitoring of GIS/GILDocument2 pagesPDU-G1, 2: UHF Sensor For Partial Discharge Monitoring of GIS/GILHafiziAhmadNo ratings yet

- Inovasi Minuman Berbasis WheyDocument8 pagesInovasi Minuman Berbasis WheyRizki Zulfan NurNo ratings yet

- CcnaDocument324 pagesCcnapratik11886100% (2)

- Environmental Impact Assessment EIA ﻲﺌﻴﺒﻟا ﺮﺛﻷا ﻢﻴﻴﻘﺗ ﺔﻴﺌﻴﺒﻟا ىوﺪﺠﻟا ﺔﺳاردDocument28 pagesEnvironmental Impact Assessment EIA ﻲﺌﻴﺒﻟا ﺮﺛﻷا ﻢﻴﻴﻘﺗ ﺔﻴﺌﻴﺒﻟا ىوﺪﺠﻟا ﺔﺳاردAsala CosmeticsNo ratings yet

- ML Lab Manual-2019Document85 pagesML Lab Manual-2019ManjulaNo ratings yet

- Awaring Presentation On Ethiopian Standards ES 3961 2 June 2017Document36 pagesAwaring Presentation On Ethiopian Standards ES 3961 2 June 2017berekajimma100% (4)

- Subject Availability - IalDocument11 pagesSubject Availability - IalDaianna PeirisNo ratings yet

- Mannuru Et Al 2023 Artificial Intelligence in Developing Countries The Impact of Generative Artificial Intelligence AiDocument20 pagesMannuru Et Al 2023 Artificial Intelligence in Developing Countries The Impact of Generative Artificial Intelligence AiDr. Muhammad Zaman ZahidNo ratings yet

- 2015-06-15 17.25.49 ErrorDocument19 pages2015-06-15 17.25.49 ErrorMilkovic91No ratings yet

- 99 Minute Millionaire - The Simp - Scott Alan Turner PDFDocument576 pages99 Minute Millionaire - The Simp - Scott Alan Turner PDFhasitha100% (2)

- UNIT-1: Linear Wave ShapingDocument24 pagesUNIT-1: Linear Wave Shapingmahender1987No ratings yet

- QUVANCHBEK QILICHEV SHAMILOVICH New 1Document3 pagesQUVANCHBEK QILICHEV SHAMILOVICH New 1Rassl AmrullaevichNo ratings yet

- Module 1 Lesson 4Document10 pagesModule 1 Lesson 4Trisha Marie Nalla TallodarNo ratings yet

- Make in India SpeechDocument1 pageMake in India SpeechRohith BalajiNo ratings yet

- Topic Wise Test Schedule For Gate MT & Xe-C 2022: Week - 1Document5 pagesTopic Wise Test Schedule For Gate MT & Xe-C 2022: Week - 1FawofoNo ratings yet

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDocument2 pages16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinNo ratings yet

- Linux PracticalDocument18 pagesLinux PracticalAnonymous x6UDQVBHawNo ratings yet

- HEC-HMS Users Manual 3.5Document318 pagesHEC-HMS Users Manual 3.5Rosendo Zuñiga100% (1)

- Acknowledgement AbstractDocument6 pagesAcknowledgement AbstractNarendra ReddyNo ratings yet

- 6.334 Power Electronics: Mit OpencoursewareDocument4 pages6.334 Power Electronics: Mit OpencoursewareLocalized Prayer AppNo ratings yet

- Davidson Et Al-2019-Journal of Applied Behavior AnalysisDocument14 pagesDavidson Et Al-2019-Journal of Applied Behavior Analysisnermal93No ratings yet

- Article 1500408825Document7 pagesArticle 1500408825fennilubisNo ratings yet

- S11 1321 01aDocument20 pagesS11 1321 01aMarsKwokNo ratings yet

Installation Imbalance Sensor

Installation Imbalance Sensor

Uploaded by

JanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Imbalance Sensor

Installation Imbalance Sensor

Uploaded by

JanCopyright:

Available Formats

2015-05-19

Service Bulletin - Instructions:

Installing Imbalance Sensor, RP-515

Aerospray / Cytopro Series 2

Required Equipment:

Vibration sensor

Drive hub seal

100% pure silicone sealant

Tools needed for installation

#1 and #2 Phillips screw drivers

Small flat blade screwdriver

Pair of plyers

1/8” hex wrench

Torque wrench (in. lbs)

Instructions:

1. If the instrument has been in use turn the power switch on the back of the instrument to the off (O) position, and unplug the power cord.

File DOC-01136A.docx Page 1 of 17 ELITechGroup Inc.

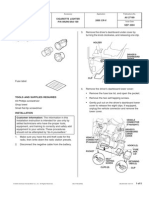

2. Remove the reagent tray mounting screws (7 places) and lift the reagent tray away from the instrument.

3. Remove the case front bottom and top screws (7 places). Let the case front down gently to rest on the counter top.

4. Remove the right side panel bottom and top screws (4 places). Gently lay the side panel down onto the reagent tray mounting plate.

File DOC-01136A.docx Page 2 of 17 ELITechGroup Inc.

5. Remove the solenoid PCB mounting screws (4 places) and let it hang free.

6. Remove the left side panel bottom and top screws (4 places). Set the side panel out of the way.

7. Disconnect the cables from the lock sensor PCB located on the lid lock assembly and the lock motor J16 on the main PCB.

File DOC-01136A.docx Page 3 of 17 ELITechGroup Inc.

8. Disconnect the lid sensor cable from the lid sensor PCB.

9. Remove the drive hub center label with a small screw driver taking care not to damage the drive hub.

10. With a 1/8” hex wrench loosen the drive hub mounting screw and then lift the drive hub to remove it from the motor coupler.

File DOC-01136A.docx Page 4 of 17 ELITechGroup Inc.

11. Remove the case top front and rear screws (5 places).

12. Using a pair of plyers compress the internal drain tube wire clamps and slide them down the drain hose one at a time. Using a slight twisting

motion slide the drain tube off of the nipple.

13. Using a slight twisting motion remove the vent hose from the spigot vent port. Rub or peel away the cured silicone off of the outside of the

spigot and the inside of the vent hose.

File DOC-01136A.docx Page 5 of 17 ELITechGroup Inc.

14. Place some protective foam over the right side panel.

15. Lift the instruments top assembly up slightly then disconnect the carousel sensor cable from the sensor PCB. Lift the instrument top assembly

while rotating it over and to the right laying it on top of the protective foam. Take care not to pinch or damage the solenoid PCB and

connected tubing.

16. Disconnect the imbalance sensor cable by pressing in on the locking tab and gently pulling it out of the connector.

File DOC-01136A.docx Page 6 of 17 ELITechGroup Inc.

17. Remove the imbalance sensor mounting screws (4 places) and remove the sensor from the motor mount top plate assembly.

18. Install the new vibration sensor onto the motor mount top plate using the previously removed screws. Install the imbalance sensor cable into

the connector of the new sensor. Make sure that it is completely seated and the locking tab locks into position.

19. Check the fluid deflector to make sure it has not been pressed down and is not touching the motor mount top plate. The motor will not turn if

it is rubbing on anything. Rotate the motor shaft to make sure it rotates freely before reassembly.

File DOC-01136A.docx Page 7 of 17 ELITechGroup Inc.

20. Lift and rotate the instrument top assembly over to the original assembled position, taking care not to pull or pinch any of the tubing.

21. Connect the carousel sensor cable to the carousel sensor that is mounted to the bowl.

22. Align the instrument top assembly into its correct positon. Check that the lid sensor is not resting on the black plastic shield to the right of the

sensor and that the tubing on the right side of the instrument is not being pinched or kinked.

File DOC-01136A.docx Page 8 of 17 ELITechGroup Inc.

23. Attach the case top assembly with the previously removed screws (5 places).

24. Apply a small bead of silicone sealant around the inside of the vent hose then spread it evenly with a gloved finger.

25. Compress the vent hose slightly and slide the end over the bowl spigot. Slide the end of the vent hose down the spigot approximately halfway.

Gently press with your fingers all the way around the vent hose to ensure a complete seal.

File DOC-01136A.docx Page 9 of 17 ELITechGroup Inc.

26. Slide the internal drain hose onto the spigot nipple and then slide the wire clamps back up into place on the drain hose.

27. Install the left side panel using the previously removed screws (4 places).

File DOC-01136A.docx Page 10 of 17 ELITechGroup Inc.

28. Lift the solenoid PCB up into place and attach it with the previously removed screws (4 places).

29. Check to make sure there are no kinks or damaged tubing before installing the right side panel.

30. Lift the right side panel into place while tucking the reagent tubing underneath the solenoid PCB.

File DOC-01136A.docx Page 11 of 17 ELITechGroup Inc.

31. Install the right side panel with the previously removed screws (4 places).

32. Install the drive hub onto the motor coupler, align the slot in the drive hub with the pin in the coupler. Tighten the drive hub mounting screw

with a 1/8“ hex wrench until snug.

File DOC-01136A.docx Page 12 of 17 ELITechGroup Inc.

33. Connect the cable to the lock sensor PCB and the lock motor cable J16 on the main PCB.

34. Connect the lid sensor cable to the lid sensor PCB.

35. Raise the case front up into place and attach it with the previously removed top and bottom screws (7 places).

File DOC-01136A.docx Page 13 of 17 ELITechGroup Inc.

36. Set the reagent tray into position and loosely install all of the reagent tray screws (7 places). Torque screws to 15 in. lbs in the order illustrated

below. If no torque wrench is available tighten the screws as evenly as possible in the order shown.

37. Connect the power cord into the back of the instrument and turn the power switch to the on (I) position.

38. Press the CYTO button on the touch screen to access the Cytocentrifuge mode.

File DOC-01136A.docx Page 14 of 17 ELITechGroup Inc.

39. Place two chambers with slides next to each other in a cytocentrifuge rotor to simulate an out of balance condition. Place the cytocentrifuge

rotor onto the drive hub of the instrument. Note: If no Cytocentrifuge rotor is available, skip to step 45.

40. Run a cytocentrifuge program with the speed set at 1000 rpm or the default program if available. Closed the lid and press the start button. The

instrument should start to run and then shut down with an Imbalance Error 0001.

41. Remove the chambers and slides from the cytocentrifuge rotor and run the same program as before.

File DOC-01136A.docx Page 15 of 17 ELITechGroup Inc.

42. The instrument should speed up to the programmed 1000 rpm and the timer should start to count down. Press the stop button to cancel the

run. The imbalance sensor is functioning correctly.

43. Peel the paper backing off of the drive hub label and press the label into place on the center of the drive hub.

44. The instrument is now ready to use.

45. If no Cytocentrifuge rotor is available the imbalance sensor can be tested to make sure it is communicating with the computer and not failing.

Press the CYTO button on the touch screen. Program a speed to 1000 rpm or run the default program if available.

File DOC-01136A.docx Page 16 of 17 ELITechGroup Inc.

46. With no rotor installed on the drive hub close the lid and press the Start button. The machine will start to run then shut down with a Wrong

rotor 0003 error. This shows that the imbalance sensor is communicating with the computer. The instrument should run correctly.

47. Peel the paper backing off of the drive hub label and press the label into place on the center of the drive hub.

48. The instrument is now ready to use.

END

File DOC-01136A.docx Page 17 of 17 ELITechGroup Inc.

You might also like

- 2.11.2 Project - Performance Task - The Parallax Problem (Project)Document7 pages2.11.2 Project - Performance Task - The Parallax Problem (Project)Tyler West100% (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Discovering Statistics Using IBM SPSS Stat - Andy FieldDocument2 pagesDiscovering Statistics Using IBM SPSS Stat - Andy Fieldfebty kuswantiNo ratings yet

- Printbar RemovalDocument21 pagesPrintbar RemovalTaur1968100% (1)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualWilliam John DavisonNo ratings yet

- Mission U500 Service ManualDocument67 pagesMission U500 Service ManualJanNo ratings yet

- Creality Ender-3 3D Printer User ManualDocument38 pagesCreality Ender-3 3D Printer User ManualPablo Ortiz Tobar100% (1)

- Tesla Model S Rear Door Handle ReplacementDocument12 pagesTesla Model S Rear Door Handle ReplacementAnonymous TjcIWjNo ratings yet

- ATRA 41TE Rebuild (Chrysler A 604)Document115 pagesATRA 41TE Rebuild (Chrysler A 604)Patricio Bacigalupi100% (4)

- GT Letter Writing Guide PDFDocument14 pagesGT Letter Writing Guide PDFDean ArigNo ratings yet

- QX MaintenanceDocument24 pagesQX MaintenancePa-jokey Espinoza GutierrezNo ratings yet

- Wrangler JeepDocument81 pagesWrangler Jeepjalvarez_385073No ratings yet

- CanrigBJWPC ICO Manual PDFDocument42 pagesCanrigBJWPC ICO Manual PDFCarlos Patiño SuarezNo ratings yet

- Apple PowerBook G4 Aluminum 15Document51 pagesApple PowerBook G4 Aluminum 15partybymartyNo ratings yet

- Caliber Compass PatriotDocument69 pagesCaliber Compass Patriotjalvarez_385073No ratings yet

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 pagesRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoNo ratings yet

- Disassembly Procedures LoResDocument24 pagesDisassembly Procedures LoResddeppenjr0% (1)

- Paddle Shift Install Instructions V5aDocument9 pagesPaddle Shift Install Instructions V5apenavi5687No ratings yet

- Installation Manual Bizhub Pro 1050Document19 pagesInstallation Manual Bizhub Pro 1050Hugo Luis Escalante100% (2)

- Suspension - FrontDocument5 pagesSuspension - FrontHans OosthuizenNo ratings yet

- Installation Instructions: Parts ListDocument5 pagesInstallation Instructions: Parts Listd-fbuser-93366182No ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Bike Harness Installation Kawasaki Type 13a 2016 2017 ZX10R ZX10RR v02Document20 pagesBike Harness Installation Kawasaki Type 13a 2016 2017 ZX10R ZX10RR v02Anas KhanNo ratings yet

- Installation RP-507 ComputerDocument19 pagesInstallation RP-507 ComputerJanNo ratings yet

- Ibm 4019Document2 pagesIbm 4019Jan SoukupNo ratings yet

- Apple Powerbook G4 Aluminum 12" Repair ManualDocument72 pagesApple Powerbook G4 Aluminum 12" Repair ManualhberbariNo ratings yet

- Installation ManualDocument11 pagesInstallation ManualSándor SzabóNo ratings yet

- Remanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesDocument8 pagesRemanufacturing The Dell 1100/ Samsung ML-2010D3 Laser CartridgesservicerNo ratings yet

- Distox2 Assembly ManualDocument6 pagesDistox2 Assembly ManualVlad AdrianNo ratings yet

- 055.180.100.099-07 TECHART Tagfahrlicht ENUS 12-2011Document16 pages055.180.100.099-07 TECHART Tagfahrlicht ENUS 12-2011anuarmaukenovNo ratings yet

- Performance Computer Chip Installation Instructions: 325i/is/ix 325ic 525i 535i 635csi 735i/ilDocument4 pagesPerformance Computer Chip Installation Instructions: 325i/is/ix 325ic 525i 535i 635csi 735i/ilandrija_ganzbergerNo ratings yet

- Prestige - Medical - 2100 - Service - Manual Steam SterilizerDocument13 pagesPrestige - Medical - 2100 - Service - Manual Steam SterilizerGigi CostelusNo ratings yet

- Synth EsDocument36 pagesSynth EsFrank QuitianNo ratings yet

- iCR 3600 Flat Gear and Motor Replacement: WarningDocument13 pagesiCR 3600 Flat Gear and Motor Replacement: WarningEliana Caceres TorricoNo ratings yet

- 00016-32901y-Toyota KeylessDocument12 pages00016-32901y-Toyota KeylessalexandytaNo ratings yet

- Nilfisk GM 80 - GM 80iDocument28 pagesNilfisk GM 80 - GM 80iAngel De la TorreNo ratings yet

- CM200 Opertional ManualDocument21 pagesCM200 Opertional ManualZahid AnwerNo ratings yet

- XL2 Disassembly Procedure: Wayne Minter 9/30/2009Document23 pagesXL2 Disassembly Procedure: Wayne Minter 9/30/2009MAmarNo ratings yet

- INSTALL GUIDE - 991 & 991.2 Turbo Valvetronic ControllerDocument10 pagesINSTALL GUIDE - 991 & 991.2 Turbo Valvetronic Controllerirfaan2133No ratings yet

- Z UTEC User Manual 23-1Document66 pagesZ UTEC User Manual 23-1TeeJay RexNo ratings yet

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Document2 pagesRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoNo ratings yet

- DDM 30658116 Cleaning ProcedureDocument7 pagesDDM 30658116 Cleaning ProcedurePawluchNo ratings yet

- Torre Secadora MABEDocument46 pagesTorre Secadora MABEDoris RojasNo ratings yet

- Chapter Seven: GS Ohlins Installation, Adjustment Tips & TricksDocument29 pagesChapter Seven: GS Ohlins Installation, Adjustment Tips & TricksWhattonNo ratings yet

- Installing Ipad Wi-Fi LCDDocument8 pagesInstalling Ipad Wi-Fi LCDАлександрNo ratings yet

- Filtro Onga Series IIDocument24 pagesFiltro Onga Series IIRicardo Cesar Bueno BertichevicNo ratings yet

- Adaptive Cruise Installation Guide (Edited)Document9 pagesAdaptive Cruise Installation Guide (Edited)Night WolfNo ratings yet

- Manual - Service - PB560 - English (148-160)Document13 pagesManual - Service - PB560 - English (148-160)STEPHANY VANESSA LOMBANA ROJASNo ratings yet

- Pull Off Test MumbaiDocument5 pagesPull Off Test MumbaiVpln SarmaNo ratings yet

- ROUSH AirBags Upgrade 97581-01-01Document4 pagesROUSH AirBags Upgrade 97581-01-01joecosta77No ratings yet

- Samsung ML 1610 - 4521 4725 Fml-2010 Xerox Phaser 3117 Cambio de Drum y RecargaDocument5 pagesSamsung ML 1610 - 4521 4725 Fml-2010 Xerox Phaser 3117 Cambio de Drum y RecargaComotu IgualNo ratings yet

- 1952 Delco Remy Generator Bearing and Brush Replacement Step by Step.Document13 pages1952 Delco Remy Generator Bearing and Brush Replacement Step by Step.Daner3No ratings yet

- Arosa 5i Spark Detector ACM Module Manual 2020Document23 pagesArosa 5i Spark Detector ACM Module Manual 2020mamuntextileNo ratings yet

- HA Plug-And-Play Car Harness InstallationDocument32 pagesHA Plug-And-Play Car Harness InstallationalftoyNo ratings yet

- Installation Manual Bizhub c450Document15 pagesInstallation Manual Bizhub c450Hugo Luis EscalanteNo ratings yet

- OKI C911 / 931 / 941: Disassembly & Reassembly ProceduresDocument40 pagesOKI C911 / 931 / 941: Disassembly & Reassembly Proceduresmo30mai08No ratings yet

- User's Manual: Item# 891340 Electric Pipe Cutting ThreaderDocument13 pagesUser's Manual: Item# 891340 Electric Pipe Cutting ThreaderRanj Japs0% (1)

- VW Jetta, Golf, New Beetle 1.9L Tdi Unichip PNP Installation InstructionsDocument5 pagesVW Jetta, Golf, New Beetle 1.9L Tdi Unichip PNP Installation InstructionsAdina CamfortNo ratings yet

- Honda CR-V 2012-2016 V3G.1.2aDocument17 pagesHonda CR-V 2012-2016 V3G.1.2aBarry GravesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- LX-VX-FX Service Manual-R2Document25 pagesLX-VX-FX Service Manual-R2Jan100% (1)

- Sweat Testing: Macroduct® AdvancedDocument4 pagesSweat Testing: Macroduct® AdvancedJanNo ratings yet

- Installation SoftwareDocument13 pagesInstallation SoftwareJanNo ratings yet

- Aerospray TB Model 7722Document106 pagesAerospray TB Model 7722JanNo ratings yet

- Installation RP-507 ComputerDocument19 pagesInstallation RP-507 ComputerJanNo ratings yet

- Mission U500 Improvement Data Transfer Package Insert-02232017Document1 pageMission U500 Improvement Data Transfer Package Insert-02232017JanNo ratings yet

- Aerospray Model 7622Document53 pagesAerospray Model 7622JanNo ratings yet

- Aerospray Stat 7122Document97 pagesAerospray Stat 7122JanNo ratings yet

- Aerospray Cytology 7522Document102 pagesAerospray Cytology 7522JanNo ratings yet

- Listening Test: Directions: For Each Question in This Part, You Will Hear Four Statements About A Picture in YourDocument40 pagesListening Test: Directions: For Each Question in This Part, You Will Hear Four Statements About A Picture in YourTrương Hữu LộcNo ratings yet

- Chicco Cortina CX Stroller ManualDocument22 pagesChicco Cortina CX Stroller ManualRRNo ratings yet

- Training Topics: Differentiating InstructionDocument7 pagesTraining Topics: Differentiating InstructionarisuNo ratings yet

- 02 Topically P3 A4 M10Document43 pages02 Topically P3 A4 M10Ir HeriawanNo ratings yet

- PDU-G1, 2: UHF Sensor For Partial Discharge Monitoring of GIS/GILDocument2 pagesPDU-G1, 2: UHF Sensor For Partial Discharge Monitoring of GIS/GILHafiziAhmadNo ratings yet

- Inovasi Minuman Berbasis WheyDocument8 pagesInovasi Minuman Berbasis WheyRizki Zulfan NurNo ratings yet

- CcnaDocument324 pagesCcnapratik11886100% (2)

- Environmental Impact Assessment EIA ﻲﺌﻴﺒﻟا ﺮﺛﻷا ﻢﻴﻴﻘﺗ ﺔﻴﺌﻴﺒﻟا ىوﺪﺠﻟا ﺔﺳاردDocument28 pagesEnvironmental Impact Assessment EIA ﻲﺌﻴﺒﻟا ﺮﺛﻷا ﻢﻴﻴﻘﺗ ﺔﻴﺌﻴﺒﻟا ىوﺪﺠﻟا ﺔﺳاردAsala CosmeticsNo ratings yet

- ML Lab Manual-2019Document85 pagesML Lab Manual-2019ManjulaNo ratings yet

- Awaring Presentation On Ethiopian Standards ES 3961 2 June 2017Document36 pagesAwaring Presentation On Ethiopian Standards ES 3961 2 June 2017berekajimma100% (4)

- Subject Availability - IalDocument11 pagesSubject Availability - IalDaianna PeirisNo ratings yet

- Mannuru Et Al 2023 Artificial Intelligence in Developing Countries The Impact of Generative Artificial Intelligence AiDocument20 pagesMannuru Et Al 2023 Artificial Intelligence in Developing Countries The Impact of Generative Artificial Intelligence AiDr. Muhammad Zaman ZahidNo ratings yet

- 2015-06-15 17.25.49 ErrorDocument19 pages2015-06-15 17.25.49 ErrorMilkovic91No ratings yet

- 99 Minute Millionaire - The Simp - Scott Alan Turner PDFDocument576 pages99 Minute Millionaire - The Simp - Scott Alan Turner PDFhasitha100% (2)

- UNIT-1: Linear Wave ShapingDocument24 pagesUNIT-1: Linear Wave Shapingmahender1987No ratings yet

- QUVANCHBEK QILICHEV SHAMILOVICH New 1Document3 pagesQUVANCHBEK QILICHEV SHAMILOVICH New 1Rassl AmrullaevichNo ratings yet

- Module 1 Lesson 4Document10 pagesModule 1 Lesson 4Trisha Marie Nalla TallodarNo ratings yet

- Make in India SpeechDocument1 pageMake in India SpeechRohith BalajiNo ratings yet

- Topic Wise Test Schedule For Gate MT & Xe-C 2022: Week - 1Document5 pagesTopic Wise Test Schedule For Gate MT & Xe-C 2022: Week - 1FawofoNo ratings yet

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDocument2 pages16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinNo ratings yet

- Linux PracticalDocument18 pagesLinux PracticalAnonymous x6UDQVBHawNo ratings yet

- HEC-HMS Users Manual 3.5Document318 pagesHEC-HMS Users Manual 3.5Rosendo Zuñiga100% (1)

- Acknowledgement AbstractDocument6 pagesAcknowledgement AbstractNarendra ReddyNo ratings yet

- 6.334 Power Electronics: Mit OpencoursewareDocument4 pages6.334 Power Electronics: Mit OpencoursewareLocalized Prayer AppNo ratings yet

- Davidson Et Al-2019-Journal of Applied Behavior AnalysisDocument14 pagesDavidson Et Al-2019-Journal of Applied Behavior Analysisnermal93No ratings yet

- Article 1500408825Document7 pagesArticle 1500408825fennilubisNo ratings yet

- S11 1321 01aDocument20 pagesS11 1321 01aMarsKwokNo ratings yet