Professional Documents

Culture Documents

Batch Dryer Demo Guide

Batch Dryer Demo Guide

Uploaded by

Ghochapon MongkhonsiriCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yabatech Post Utme Past QuestionDocument25 pagesYabatech Post Utme Past QuestionFaithNo ratings yet

- CH 7 SULCOL For Tray and PackingDocument20 pagesCH 7 SULCOL For Tray and PackingGhochapon MongkhonsiriNo ratings yet

- 3.can Circular Bioeconomy Be Fueled by Waste Biorefineries - A Closer LookDocument11 pages3.can Circular Bioeconomy Be Fueled by Waste Biorefineries - A Closer LookGhochapon MongkhonsiriNo ratings yet

- Paring The Ability To Compete in The Export of Oil PalmDocument12 pagesParing The Ability To Compete in The Export of Oil PalmGhochapon MongkhonsiriNo ratings yet

- 3.linking The Bioeconomy To The Sustainable Development Agenda Can SDG Indicators Be Used To Monitor Progress Towards A Sustainable BioeconomyDocument10 pages3.linking The Bioeconomy To The Sustainable Development Agenda Can SDG Indicators Be Used To Monitor Progress Towards A Sustainable BioeconomyGhochapon MongkhonsiriNo ratings yet

- 1.foley Science MagazineDocument3 pages1.foley Science MagazineGhochapon MongkhonsiriNo ratings yet

- Belt Dryer Demo GuideDocument35 pagesBelt Dryer Demo GuideGhochapon MongkhonsiriNo ratings yet

- Bioethanol From CornDocument13 pagesBioethanol From CornGhochapon MongkhonsiriNo ratings yet

- 1.planetary Demands Redefining Sustainable Development and Sustainable Entrepreneurship-Journal of Cleaner Production 278 (2021)Document11 pages1.planetary Demands Redefining Sustainable Development and Sustainable Entrepreneurship-Journal of Cleaner Production 278 (2021)Ghochapon MongkhonsiriNo ratings yet

- IgccDocument19 pagesIgccGhochapon MongkhonsiriNo ratings yet

- PipelinegasDocument17 pagesPipelinegasGhochapon MongkhonsiriNo ratings yet

- Tiw - ChemAb-Post-combustion CO2 Recovery - Potassium Carbonate AbsorptionDocument13 pagesTiw - ChemAb-Post-combustion CO2 Recovery - Potassium Carbonate AbsorptionGhochapon MongkhonsiriNo ratings yet

- Molten Carbonate Fuel Cells For 90% Post Combustion CO2 Capture From A New Build CCGTDocument6 pagesMolten Carbonate Fuel Cells For 90% Post Combustion CO2 Capture From A New Build CCGTGhochapon MongkhonsiriNo ratings yet

- EfW ScenarioDocument4 pagesEfW ScenarioGhochapon MongkhonsiriNo ratings yet

- Amine Guideline - Carbon Capture Aspen Simulation - 2013 - LuybenDocument23 pagesAmine Guideline - Carbon Capture Aspen Simulation - 2013 - LuybenGhochapon MongkhonsiriNo ratings yet

- CaL-Calcium Looping Cycle For CO2 Capture Performance, Cost and Feasibility AnalysisDocument8 pagesCaL-Calcium Looping Cycle For CO2 Capture Performance, Cost and Feasibility AnalysisGhochapon MongkhonsiriNo ratings yet

- HPC-CO2 Capsol ForretningscaseDocument18 pagesHPC-CO2 Capsol ForretningscaseGhochapon MongkhonsiriNo ratings yet

- Review Amine Based Capture Review - IChemE - PartA - Full - Paper - V9 - 28may2010Document23 pagesReview Amine Based Capture Review - IChemE - PartA - Full - Paper - V9 - 28may2010Ghochapon MongkhonsiriNo ratings yet

- Effect of Sand-to-Cement Ratio On Mechanical Properties of Foam ConcreteDocument14 pagesEffect of Sand-to-Cement Ratio On Mechanical Properties of Foam ConcreteGhochapon MongkhonsiriNo ratings yet

- Lecture 4 Distillation Column-5192-16142479047124Document95 pagesLecture 4 Distillation Column-5192-16142479047124Ghochapon MongkhonsiriNo ratings yet

- Troy2016 - Article - Life Cycle Assessment of Membrane-Based Carbon CaptureDocument14 pagesTroy2016 - Article - Life Cycle Assessment of Membrane-Based Carbon CaptureGhochapon MongkhonsiriNo ratings yet

- LCsoft ManualDocument68 pagesLCsoft ManualGhochapon MongkhonsiriNo ratings yet

- Insights Into The Regional Greenhouse Gas (GHG) Emission of Industrial Processes: A Case Study of Shenyang, ChinaDocument18 pagesInsights Into The Regional Greenhouse Gas (GHG) Emission of Industrial Processes: A Case Study of Shenyang, ChinaGhochapon MongkhonsiriNo ratings yet

- Demonstrating Full-Scale Post-Combustion CO2 Capture For Coal-Fired Power Plants Through Dynamic Modelling and SimulationDocument14 pagesDemonstrating Full-Scale Post-Combustion CO2 Capture For Coal-Fired Power Plants Through Dynamic Modelling and SimulationGhochapon MongkhonsiriNo ratings yet

- LAB REPORT - Discharge Over WeirsDocument9 pagesLAB REPORT - Discharge Over WeirsLuli LolNo ratings yet

- RBIEE-SCIENCE 9-OUTPUT-by-PBGalizaDocument8 pagesRBIEE-SCIENCE 9-OUTPUT-by-PBGalizaGold Aziphil GalizaNo ratings yet

- Candidate 1 (Reservoir Engineering Panel) : ONGC SAMPLE INTERVIEW QUESTIONS (Based Upon Memory of Appeared Candidates)Document3 pagesCandidate 1 (Reservoir Engineering Panel) : ONGC SAMPLE INTERVIEW QUESTIONS (Based Upon Memory of Appeared Candidates)Neha AhiraoNo ratings yet

- Falling Objects Exam Style QuestionsDocument3 pagesFalling Objects Exam Style QuestionsMr. SuitNo ratings yet

- Chapter II B Force Systems 3D: Engineering MechanicsDocument36 pagesChapter II B Force Systems 3D: Engineering MechanicsYue FeiNo ratings yet

- Craymul 2145Document1 pageCraymul 2145jamesBTNo ratings yet

- Plane Trigonometry ModuleDocument4 pagesPlane Trigonometry ModuleCarla Mae Panagdato100% (1)

- PB2000105994 PDFDocument198 pagesPB2000105994 PDFFirdaus ImanNo ratings yet

- ENSC3003 Asst2 S1 13Document5 pagesENSC3003 Asst2 S1 13louis_parker_5553No ratings yet

- Bachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersDocument10 pagesBachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersMufeesNo ratings yet

- Permeability, Group 5aDocument21 pagesPermeability, Group 5aComfort MaccarthyNo ratings yet

- The Molecular Basis of Specific HeatDocument7 pagesThe Molecular Basis of Specific HeatJACOB SANCHEZNo ratings yet

- 01.04 Lab Worksheet: Part One: The LabDocument2 pages01.04 Lab Worksheet: Part One: The LabLia WoodNo ratings yet

- Piezoelectricity-Induced High Temperature SuperconductorDocument14 pagesPiezoelectricity-Induced High Temperature SuperconductoraquilesanchezNo ratings yet

- Advances in Cognitive Neurodynamics V Proceedings of The Fifth International Conference On Cognitive Neurodynamics 2015 1st Edition Rubin WangDocument54 pagesAdvances in Cognitive Neurodynamics V Proceedings of The Fifth International Conference On Cognitive Neurodynamics 2015 1st Edition Rubin Wangoscar.warner960100% (5)

- Double Walled Vessel IntroductionDocument14 pagesDouble Walled Vessel IntroductionChanchal GuptaNo ratings yet

- 100 Kva Caterpillar Branded FG Wilson DG SetDocument4 pages100 Kva Caterpillar Branded FG Wilson DG SetMaintenance Unit Anil GroupNo ratings yet

- 나완수 전자기학 - 중간Document1 page나완수 전자기학 - 중간전호정No ratings yet

- Name: Vishik Pruthviraj Chavan Subject: (ECI) Semester: 3rd Sem Branch: EE Subject TeacherDocument10 pagesName: Vishik Pruthviraj Chavan Subject: (ECI) Semester: 3rd Sem Branch: EE Subject TeacherVishi MalikNo ratings yet

- Technical Design Report For Engine Powered Airplane, AIAA GIKI ChapterDocument70 pagesTechnical Design Report For Engine Powered Airplane, AIAA GIKI ChapterkostarasNo ratings yet

- Full Download pdf of (Original PDF) A Graphical Approach to Precalculus with Limits, 7th Edition all chapterDocument43 pagesFull Download pdf of (Original PDF) A Graphical Approach to Precalculus with Limits, 7th Edition all chaptertevijavae10100% (5)

- IAAC Pre Final Round 2022 Nbt158ofh37xhDocument9 pagesIAAC Pre Final Round 2022 Nbt158ofh37xhPodcast PeepsNo ratings yet

- C-5 One Way Two Way SlabDocument34 pagesC-5 One Way Two Way SlabBoopathi Yoganathan100% (2)

- Vibration Welding 2009Document11 pagesVibration Welding 2009Rodrigo ToasaNo ratings yet

- 1 - Molecular FluxDocument44 pages1 - Molecular FluxJason RoyNo ratings yet

- Gce O' Level Mathematics: Scheme of AssessmentDocument1 pageGce O' Level Mathematics: Scheme of AssessmentMohammad AshfaqNo ratings yet

- Sheer Wall PDFDocument142 pagesSheer Wall PDFemrubel100% (1)

- WB CH40Document8 pagesWB CH40arwaNo ratings yet

- June 2020 QP IAL Mechanics 2Document32 pagesJune 2020 QP IAL Mechanics 2Daniel KimNo ratings yet

Batch Dryer Demo Guide

Batch Dryer Demo Guide

Uploaded by

Ghochapon MongkhonsiriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batch Dryer Demo Guide

Batch Dryer Demo Guide

Uploaded by

Ghochapon MongkhonsiriCopyright:

Available Formats

Batch Drying

Guide to the Batch Dryer Demo

Aspen Technology

Bedford, MA

2013

© 2013 Aspen Technology, Inc. All rights reserved

Batch modeling with Aspen Plus

Example - Batch Drying

Fluidization Air, Moisture

& Fines

Wet solids

(batch feed)

Dry solids

(batch)

Dry Fluidization

Air

Commercial Pilot-Scale

Batch Fluid Bed Dryer

(with Cyclone)

© 2013 Aspen Technology, Inc. All rights reserved | 2

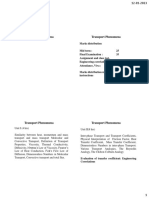

How does the model work?

Take very small steps – fixed step integrator

Sensitivity

GASOUT

“Clock”

Moisture out

Step I from 1 to 60

INITIAL Residence time

C ALCULATOR EACHSTEP

C ALCULATOR

Use feed to specify

initial condition

Calculator

DRYER

of the solid stream

“EachStep”

Integrates time and water

FEED PRODUCT removal

Tn = Tn-1 + Tstep

W n = W n-1 + W step

STEPFEED

TR ANS FER

After each time step, the ‘product’

GASIN

solids are copied back to the ‘feed’

Moisture in

© 2013 Aspen Technology, Inc. All rights reserved | 3

Open the File “Batch Drying.bkp”

© 2013 Aspen Technology, Inc. All rights reserved | 4

Review the Model Setup

1. Calculator “INITIAL” is

called to initialize parameters

counter and time

2. Loop consisting of:

- Sensitivity

- Dryer

- Calculator (each step)

- Transfer block is executed until the defined

counter has reached its upper limit (60 in the

present case)

© 2013 Aspen Technology, Inc. All rights reserved | 5

Review the Model Setup

Calculator

“INITIAL” sets

counter and time

to zero

© 2013 Aspen Technology, Inc. All rights reserved | 6

Review Model Setup

Sensitivity is used as “clock”.

Steps parameter I from 1 to 60

Each time step the

controller is called to

calculate:

- The new time

At each time step, the listed - The drying rate

variables are sampled - the cumulative

moisture loss

© 2013 Aspen Technology, Inc. All rights reserved | 7

Review Parameterization of

the Dryer

Flow pattern: Cross-flow

Solids Flow: ideal mixed

Mass transfer described by given

Sherwood number

Second drying period

described by normalized Heat transfer coefficient calculated

drying rate based on mass transfer coefficient

using the Lewis correlation.

© 2013 Aspen Technology, Inc. All rights reserved | 8

Review Model Setup

Calculator

“EACHSTEP” is

called to

calculate:

- The new time

- The drying rate

- the cumulative

moisture loss

© 2013 Aspen Technology, Inc. All rights reserved | 9

Review Model Setup

Transfer block

“STEPFEED” is called

to copy the product

of the dryer back to

its solid feed

© 2013 Aspen Technology, Inc. All rights reserved | 10

Run the model

Run the model

Open the layout “plots”

© 2013 Aspen Technology, Inc. All rights reserved | 11

Review Results

solids moisture content

as function of time

cumulative water removal

as function of time

gas and solid Drying rate as

temperature function of time

function of time

© 2013 Aspen Technology, Inc. All rights reserved | 12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yabatech Post Utme Past QuestionDocument25 pagesYabatech Post Utme Past QuestionFaithNo ratings yet

- CH 7 SULCOL For Tray and PackingDocument20 pagesCH 7 SULCOL For Tray and PackingGhochapon MongkhonsiriNo ratings yet

- 3.can Circular Bioeconomy Be Fueled by Waste Biorefineries - A Closer LookDocument11 pages3.can Circular Bioeconomy Be Fueled by Waste Biorefineries - A Closer LookGhochapon MongkhonsiriNo ratings yet

- Paring The Ability To Compete in The Export of Oil PalmDocument12 pagesParing The Ability To Compete in The Export of Oil PalmGhochapon MongkhonsiriNo ratings yet

- 3.linking The Bioeconomy To The Sustainable Development Agenda Can SDG Indicators Be Used To Monitor Progress Towards A Sustainable BioeconomyDocument10 pages3.linking The Bioeconomy To The Sustainable Development Agenda Can SDG Indicators Be Used To Monitor Progress Towards A Sustainable BioeconomyGhochapon MongkhonsiriNo ratings yet

- 1.foley Science MagazineDocument3 pages1.foley Science MagazineGhochapon MongkhonsiriNo ratings yet

- Belt Dryer Demo GuideDocument35 pagesBelt Dryer Demo GuideGhochapon MongkhonsiriNo ratings yet

- Bioethanol From CornDocument13 pagesBioethanol From CornGhochapon MongkhonsiriNo ratings yet

- 1.planetary Demands Redefining Sustainable Development and Sustainable Entrepreneurship-Journal of Cleaner Production 278 (2021)Document11 pages1.planetary Demands Redefining Sustainable Development and Sustainable Entrepreneurship-Journal of Cleaner Production 278 (2021)Ghochapon MongkhonsiriNo ratings yet

- IgccDocument19 pagesIgccGhochapon MongkhonsiriNo ratings yet

- PipelinegasDocument17 pagesPipelinegasGhochapon MongkhonsiriNo ratings yet

- Tiw - ChemAb-Post-combustion CO2 Recovery - Potassium Carbonate AbsorptionDocument13 pagesTiw - ChemAb-Post-combustion CO2 Recovery - Potassium Carbonate AbsorptionGhochapon MongkhonsiriNo ratings yet

- Molten Carbonate Fuel Cells For 90% Post Combustion CO2 Capture From A New Build CCGTDocument6 pagesMolten Carbonate Fuel Cells For 90% Post Combustion CO2 Capture From A New Build CCGTGhochapon MongkhonsiriNo ratings yet

- EfW ScenarioDocument4 pagesEfW ScenarioGhochapon MongkhonsiriNo ratings yet

- Amine Guideline - Carbon Capture Aspen Simulation - 2013 - LuybenDocument23 pagesAmine Guideline - Carbon Capture Aspen Simulation - 2013 - LuybenGhochapon MongkhonsiriNo ratings yet

- CaL-Calcium Looping Cycle For CO2 Capture Performance, Cost and Feasibility AnalysisDocument8 pagesCaL-Calcium Looping Cycle For CO2 Capture Performance, Cost and Feasibility AnalysisGhochapon MongkhonsiriNo ratings yet

- HPC-CO2 Capsol ForretningscaseDocument18 pagesHPC-CO2 Capsol ForretningscaseGhochapon MongkhonsiriNo ratings yet

- Review Amine Based Capture Review - IChemE - PartA - Full - Paper - V9 - 28may2010Document23 pagesReview Amine Based Capture Review - IChemE - PartA - Full - Paper - V9 - 28may2010Ghochapon MongkhonsiriNo ratings yet

- Effect of Sand-to-Cement Ratio On Mechanical Properties of Foam ConcreteDocument14 pagesEffect of Sand-to-Cement Ratio On Mechanical Properties of Foam ConcreteGhochapon MongkhonsiriNo ratings yet

- Lecture 4 Distillation Column-5192-16142479047124Document95 pagesLecture 4 Distillation Column-5192-16142479047124Ghochapon MongkhonsiriNo ratings yet

- Troy2016 - Article - Life Cycle Assessment of Membrane-Based Carbon CaptureDocument14 pagesTroy2016 - Article - Life Cycle Assessment of Membrane-Based Carbon CaptureGhochapon MongkhonsiriNo ratings yet

- LCsoft ManualDocument68 pagesLCsoft ManualGhochapon MongkhonsiriNo ratings yet

- Insights Into The Regional Greenhouse Gas (GHG) Emission of Industrial Processes: A Case Study of Shenyang, ChinaDocument18 pagesInsights Into The Regional Greenhouse Gas (GHG) Emission of Industrial Processes: A Case Study of Shenyang, ChinaGhochapon MongkhonsiriNo ratings yet

- Demonstrating Full-Scale Post-Combustion CO2 Capture For Coal-Fired Power Plants Through Dynamic Modelling and SimulationDocument14 pagesDemonstrating Full-Scale Post-Combustion CO2 Capture For Coal-Fired Power Plants Through Dynamic Modelling and SimulationGhochapon MongkhonsiriNo ratings yet

- LAB REPORT - Discharge Over WeirsDocument9 pagesLAB REPORT - Discharge Over WeirsLuli LolNo ratings yet

- RBIEE-SCIENCE 9-OUTPUT-by-PBGalizaDocument8 pagesRBIEE-SCIENCE 9-OUTPUT-by-PBGalizaGold Aziphil GalizaNo ratings yet

- Candidate 1 (Reservoir Engineering Panel) : ONGC SAMPLE INTERVIEW QUESTIONS (Based Upon Memory of Appeared Candidates)Document3 pagesCandidate 1 (Reservoir Engineering Panel) : ONGC SAMPLE INTERVIEW QUESTIONS (Based Upon Memory of Appeared Candidates)Neha AhiraoNo ratings yet

- Falling Objects Exam Style QuestionsDocument3 pagesFalling Objects Exam Style QuestionsMr. SuitNo ratings yet

- Chapter II B Force Systems 3D: Engineering MechanicsDocument36 pagesChapter II B Force Systems 3D: Engineering MechanicsYue FeiNo ratings yet

- Craymul 2145Document1 pageCraymul 2145jamesBTNo ratings yet

- Plane Trigonometry ModuleDocument4 pagesPlane Trigonometry ModuleCarla Mae Panagdato100% (1)

- PB2000105994 PDFDocument198 pagesPB2000105994 PDFFirdaus ImanNo ratings yet

- ENSC3003 Asst2 S1 13Document5 pagesENSC3003 Asst2 S1 13louis_parker_5553No ratings yet

- Bachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersDocument10 pagesBachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersMufeesNo ratings yet

- Permeability, Group 5aDocument21 pagesPermeability, Group 5aComfort MaccarthyNo ratings yet

- The Molecular Basis of Specific HeatDocument7 pagesThe Molecular Basis of Specific HeatJACOB SANCHEZNo ratings yet

- 01.04 Lab Worksheet: Part One: The LabDocument2 pages01.04 Lab Worksheet: Part One: The LabLia WoodNo ratings yet

- Piezoelectricity-Induced High Temperature SuperconductorDocument14 pagesPiezoelectricity-Induced High Temperature SuperconductoraquilesanchezNo ratings yet

- Advances in Cognitive Neurodynamics V Proceedings of The Fifth International Conference On Cognitive Neurodynamics 2015 1st Edition Rubin WangDocument54 pagesAdvances in Cognitive Neurodynamics V Proceedings of The Fifth International Conference On Cognitive Neurodynamics 2015 1st Edition Rubin Wangoscar.warner960100% (5)

- Double Walled Vessel IntroductionDocument14 pagesDouble Walled Vessel IntroductionChanchal GuptaNo ratings yet

- 100 Kva Caterpillar Branded FG Wilson DG SetDocument4 pages100 Kva Caterpillar Branded FG Wilson DG SetMaintenance Unit Anil GroupNo ratings yet

- 나완수 전자기학 - 중간Document1 page나완수 전자기학 - 중간전호정No ratings yet

- Name: Vishik Pruthviraj Chavan Subject: (ECI) Semester: 3rd Sem Branch: EE Subject TeacherDocument10 pagesName: Vishik Pruthviraj Chavan Subject: (ECI) Semester: 3rd Sem Branch: EE Subject TeacherVishi MalikNo ratings yet

- Technical Design Report For Engine Powered Airplane, AIAA GIKI ChapterDocument70 pagesTechnical Design Report For Engine Powered Airplane, AIAA GIKI ChapterkostarasNo ratings yet

- Full Download pdf of (Original PDF) A Graphical Approach to Precalculus with Limits, 7th Edition all chapterDocument43 pagesFull Download pdf of (Original PDF) A Graphical Approach to Precalculus with Limits, 7th Edition all chaptertevijavae10100% (5)

- IAAC Pre Final Round 2022 Nbt158ofh37xhDocument9 pagesIAAC Pre Final Round 2022 Nbt158ofh37xhPodcast PeepsNo ratings yet

- C-5 One Way Two Way SlabDocument34 pagesC-5 One Way Two Way SlabBoopathi Yoganathan100% (2)

- Vibration Welding 2009Document11 pagesVibration Welding 2009Rodrigo ToasaNo ratings yet

- 1 - Molecular FluxDocument44 pages1 - Molecular FluxJason RoyNo ratings yet

- Gce O' Level Mathematics: Scheme of AssessmentDocument1 pageGce O' Level Mathematics: Scheme of AssessmentMohammad AshfaqNo ratings yet

- Sheer Wall PDFDocument142 pagesSheer Wall PDFemrubel100% (1)

- WB CH40Document8 pagesWB CH40arwaNo ratings yet

- June 2020 QP IAL Mechanics 2Document32 pagesJune 2020 QP IAL Mechanics 2Daniel KimNo ratings yet