Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

30 viewsN2 Tank STEM 1 Checklist

N2 Tank STEM 1 Checklist

Uploaded by

JIHED PRIMA PHONESTOREThe document provides a checklist for inspecting a nitrogen tank skid. The checklist contains 22 inspection points to check the cleanliness, integrity and functionality of the tank, piping, valves, gauges and other components. Any issues found during inspection should be documented in the comments section.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Petrol Station Checklist AuditDocument10 pagesPetrol Station Checklist AuditrizamryNo ratings yet

- Land Rig Acceptance MasterDocument17 pagesLand Rig Acceptance Masterislam atif100% (1)

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)From EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)No ratings yet

- AST ChecklistsDocument16 pagesAST ChecklistsGary WoodsideNo ratings yet

- Location: Split A/C No.: Monthly PM Check List For SPLIT A/C'sDocument1 pageLocation: Split A/C No.: Monthly PM Check List For SPLIT A/C'ssiruslara6491100% (1)

- Audiolab 8000A Owner's Manual PDFDocument10 pagesAudiolab 8000A Owner's Manual PDFRastko ManojlovicNo ratings yet

- Primus Programming Manual PDFDocument82 pagesPrimus Programming Manual PDFMohamed ClioNo ratings yet

- Datasheet Aritco PublicLift Access 2021 en v1Document2 pagesDatasheet Aritco PublicLift Access 2021 en v1Lê Văn HoạtNo ratings yet

- Swab Tanker - Daily Checklist - Blue-WhiteDocument2 pagesSwab Tanker - Daily Checklist - Blue-WhitePCSL TransportNo ratings yet

- Loadline SurveyDocument8 pagesLoadline SurveyAmit Kumar SenNo ratings yet

- 019 - Tank Box Up ChecklistDocument1 page019 - Tank Box Up ChecklistDelil Ozan67% (6)

- High Pressure Lines PDFDocument3 pagesHigh Pressure Lines PDFKaleem UllahNo ratings yet

- Standard Operating Procedure: Operation and Preventive Maintenance of TransformersDocument5 pagesStandard Operating Procedure: Operation and Preventive Maintenance of TransformersMaryanthony NamyaloNo ratings yet

- PRES-M-08 Rotating Equipment - Compressors PackageDocument2 pagesPRES-M-08 Rotating Equipment - Compressors PackagesalamlinNo ratings yet

- ABB Substation Condition Monitoring ScheduleDocument16 pagesABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- Service and Maintenace Report FormDocument1 pageService and Maintenace Report Formmj santosNo ratings yet

- Reference Tank Handbook PDFDocument10 pagesReference Tank Handbook PDFIvan AvilesNo ratings yet

- PRES-M-09 Rotating Equipment - Gas TurbinesDocument2 pagesPRES-M-09 Rotating Equipment - Gas Turbinessalamlin100% (1)

- OPS 30 Crane Operation ChecklistDocument1 pageOPS 30 Crane Operation ChecklistDmitriyNo ratings yet

- Tank Inspection Standard Operating Procedures PDFDocument3 pagesTank Inspection Standard Operating Procedures PDFIfroz KhanNo ratings yet

- Equipment Group:: Intermediate Inspection Criteria, Well Control EquipmentDocument2 pagesEquipment Group:: Intermediate Inspection Criteria, Well Control Equipmentkaleem ullah jan100% (2)

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- TEC 08 - Bunkering Operations Checklist PDFDocument5 pagesTEC 08 - Bunkering Operations Checklist PDFnmospan100% (1)

- Fire Tank PPMDocument1 pageFire Tank PPMzwarrior333No ratings yet

- Parking Brake TPMDocument1 pageParking Brake TPMisash123No ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- PRES-M-07 Rotating EquipmentDocument2 pagesPRES-M-07 Rotating EquipmentsalamlinNo ratings yet

- 17 - Check Sheet of GT Air Inlet Filter House InspectionDocument5 pages17 - Check Sheet of GT Air Inlet Filter House InspectionSiraj AhmedNo ratings yet

- Warman-Flow System Maintenance ChecklistDocument2 pagesWarman-Flow System Maintenance ChecklistWilliam EvansNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- Sta Filter 1M ProdDocument2 pagesSta Filter 1M ProdMeng Kiat SawNo ratings yet

- Emp Appendix 10 - Marine Fuel Procedures Feb 2020Document32 pagesEmp Appendix 10 - Marine Fuel Procedures Feb 2020majdi jerbiNo ratings yet

- Annual Inspection: Container RefrigerationDocument30 pagesAnnual Inspection: Container RefrigerationJuan Pablo Muñoz CortezNo ratings yet

- GRP SAILING Yacht CHECKLIST INSPECTIONDocument18 pagesGRP SAILING Yacht CHECKLIST INSPECTIONSang ThanhNo ratings yet

- Check List: Checklist For Column FormworkDocument1 pageCheck List: Checklist For Column FormworkPULAGARA SATISHNo ratings yet

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNo ratings yet

- Service Station Operators ChecklistDocument6 pagesService Station Operators Checklistdkishore28100% (1)

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESDocument3 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESkaleem ullah janNo ratings yet

- Saf51 Monthly Oily Overboard Discharge Systems Functionality TestDocument3 pagesSaf51 Monthly Oily Overboard Discharge Systems Functionality TestDmytroNo ratings yet

- Sprinkler Test 2Document5 pagesSprinkler Test 2nag_2004No ratings yet

- PTI CheckList20230804052203Document2 pagesPTI CheckList20230804052203sowntharyagbmNo ratings yet

- 50mva TRAFO#1 BAY#106Document19 pages50mva TRAFO#1 BAY#106Balaji DevathaNo ratings yet

- A Uh 0417Document17 pagesA Uh 0417Murugan ShanmugaiahNo ratings yet

- 2017checklist - Gas Terminal InspectionDocument3 pages2017checklist - Gas Terminal InspectionTushar SorteNo ratings yet

- Survey Checklist ANCODocument23 pagesSurvey Checklist ANCOkonstadine100% (1)

- Air Compressor RegisterDocument1 pageAir Compressor RegisterMcbride NdjaoNo ratings yet

- Service Station Operators ChecklistDocument6 pagesService Station Operators Checklistkwasi BoatengNo ratings yet

- Deep Oil - Flowback and Well Testing UnitDocument11 pagesDeep Oil - Flowback and Well Testing UnitADRIAN SOTONo ratings yet

- Fire Fighting ChecklistDocument10 pagesFire Fighting ChecklistSrikanth Shanmugam0% (1)

- JIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)Document6 pagesJIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)GomathyselviNo ratings yet

- Hydro Static Test Procedure: VD-211-Gen-PCJ-005Document12 pagesHydro Static Test Procedure: VD-211-Gen-PCJ-005arianaseriNo ratings yet

- Checklist For Inspection of RCDs On Indian RailwaysDocument11 pagesChecklist For Inspection of RCDs On Indian RailwaysHanuma ReddyNo ratings yet

- Air Handling Units COB AHU-10ADocument3 pagesAir Handling Units COB AHU-10AHernan RomeroNo ratings yet

- Air Compressor Inspection Checklist: Doc Ref: CL/01Document1 pageAir Compressor Inspection Checklist: Doc Ref: CL/01Muhammad NurNo ratings yet

- PRES-J-02 Instrument EquipmentDocument2 pagesPRES-J-02 Instrument EquipmentsalamlinNo ratings yet

- EXAMPLE SERVICE CHARTS For Low Pressure Co2 SystemDocument1 pageEXAMPLE SERVICE CHARTS For Low Pressure Co2 Systemijas ahmedNo ratings yet

- Feild Inspection of Shell and Tube Heat ExchangersDocument4 pagesFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNo ratings yet

- Compressor ChecklistDocument1 pageCompressor ChecklistRolando DaclanNo ratings yet

- F-LLS-02c - International Loadline Survey ChecklistDocument3 pagesF-LLS-02c - International Loadline Survey Checklistmtgeneral3cobNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 21 40Document20 pages21 40JIHED PRIMA PHONESTORENo ratings yet

- Fbos 5Document1 pageFbos 5JIHED PRIMA PHONESTORENo ratings yet

- KELLY HEXAGO FBOS Rig B1 IDA-14764Document1 pageKELLY HEXAGO FBOS Rig B1 IDA-14764JIHED PRIMA PHONESTORENo ratings yet

- Inspection Tally Sheet of For Summary Report #001Document1 pageInspection Tally Sheet of For Summary Report #001JIHED PRIMA PHONESTORENo ratings yet

- 176 Jts DP 5 1-2 VAM EIS Class II + RejectedDocument10 pages176 Jts DP 5 1-2 VAM EIS Class II + RejectedJIHED PRIMA PHONESTORENo ratings yet

- 189 Jts DP 5 1-2 Vam Eis Premium0000Document11 pages189 Jts DP 5 1-2 Vam Eis Premium0000JIHED PRIMA PHONESTORENo ratings yet

- Niser 2Document1 pageNiser 2JIHED PRIMA PHONESTORENo ratings yet

- Atag PDFDocument37 pagesAtag PDFEmilianMarginaNo ratings yet

- ZXSDR BS8900A Quick Installation Guide - R1.0 - CH - ENDocument49 pagesZXSDR BS8900A Quick Installation Guide - R1.0 - CH - ENNnaji MauriceNo ratings yet

- Danfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZDocument11 pagesDanfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZclopez5556No ratings yet

- PSP Lab ManualDocument35 pagesPSP Lab ManualPriya SaxenaNo ratings yet

- Manual Mitsubishi Pajero 4x4 Propeler ShaftDocument8 pagesManual Mitsubishi Pajero 4x4 Propeler ShaftGIAN CARLO MAMANI GILES.No ratings yet

- Date Project Location Project Id em Asset Number Equipment NumberDocument8 pagesDate Project Location Project Id em Asset Number Equipment NumberAbdi Doni SetiaNo ratings yet

- Tut2 On Distribution System ReliabilityDocument1 pageTut2 On Distribution System ReliabilityKarma ThinleyNo ratings yet

- RS2LAN Refrigeration Installation Manual 1.4Document54 pagesRS2LAN Refrigeration Installation Manual 1.4Vinnicius100% (2)

- CAT24C44: 256-Bit Serial Nonvolatile CMOS Static RAMDocument8 pagesCAT24C44: 256-Bit Serial Nonvolatile CMOS Static RAMvanmarteNo ratings yet

- 1 0 50 HSL Connector PortfolioDocument2 pages1 0 50 HSL Connector PortfoliomykedindealNo ratings yet

- What Is Direct Memory Access MDADocument1 pageWhat Is Direct Memory Access MDAJuan Ortega GuerraNo ratings yet

- Parts Guide Manual: Ineo+ 454e A5C0121Document149 pagesParts Guide Manual: Ineo+ 454e A5C0121OFBA srlNo ratings yet

- Owner'S Manual: RCSP-XLDocument28 pagesOwner'S Manual: RCSP-XLCarlos Gabriel EstergaardNo ratings yet

- Grundfos Machine SelectionDocument8 pagesGrundfos Machine SelectionMussie BekeleNo ratings yet

- Mains Dimmable LED Strip Drivers, 45W12vDCD 45W24VDCDDocument4 pagesMains Dimmable LED Strip Drivers, 45W12vDCD 45W24VDCDsstockwell1411No ratings yet

- KS3 Electricity 1Document95 pagesKS3 Electricity 1Dominic Wynes-DevlinNo ratings yet

- Technical Specifications01Document14 pagesTechnical Specifications01Sokol ShoshiNo ratings yet

- Spyder Vents - Installation Guide - Clean VersionDocument10 pagesSpyder Vents - Installation Guide - Clean VersionohshafiNo ratings yet

- Solatek 3KW 24 5KW 48Document1 pageSolatek 3KW 24 5KW 48Dammika KarunasingheNo ratings yet

- Im 40muaa 02Document32 pagesIm 40muaa 02hpinetNo ratings yet

- Atari STE TOS Upgrade v2Document3 pagesAtari STE TOS Upgrade v2greenious100% (1)

- Protection and Control Ieds: Selection GuideDocument7 pagesProtection and Control Ieds: Selection Guide男は私 彼女のNo ratings yet

- PCHardwarHbk2ndEdSH PDFDocument132 pagesPCHardwarHbk2ndEdSH PDFAlexis78No ratings yet

- Senr9414senr9414-01 SisDocument9 pagesSenr9414senr9414-01 SisPablo Gaspar D'Agostini AmengualNo ratings yet

- Intesisbox: Interface KNX For Hitachi Air-To-WaterDocument4 pagesIntesisbox: Interface KNX For Hitachi Air-To-WaternajibNo ratings yet

- A6V14163548 enDocument9 pagesA6V14163548 enhk.waa2020No ratings yet

- HoltekDocument96 pagesHoltekZhan AinabekovNo ratings yet

N2 Tank STEM 1 Checklist

N2 Tank STEM 1 Checklist

Uploaded by

JIHED PRIMA PHONESTORE0 ratings0% found this document useful (0 votes)

30 views1 pageThe document provides a checklist for inspecting a nitrogen tank skid. The checklist contains 22 inspection points to check the cleanliness, integrity and functionality of the tank, piping, valves, gauges and other components. Any issues found during inspection should be documented in the comments section.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a checklist for inspecting a nitrogen tank skid. The checklist contains 22 inspection points to check the cleanliness, integrity and functionality of the tank, piping, valves, gauges and other components. Any issues found during inspection should be documented in the comments section.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

30 views1 pageN2 Tank STEM 1 Checklist

N2 Tank STEM 1 Checklist

Uploaded by

JIHED PRIMA PHONESTOREThe document provides a checklist for inspecting a nitrogen tank skid. The checklist contains 22 inspection points to check the cleanliness, integrity and functionality of the tank, piping, valves, gauges and other components. Any issues found during inspection should be documented in the comments section.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Record checks and inspection results in all the white sections, and in the order listed.

Document any unsolved issues, repairs or replacements.

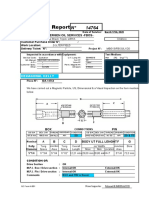

STEM 1 Checklist for Nitrogen Tank Skid

Nitrogen Tank Operator

Date:

Unit Number: Name:

Location/Rig:

Mark the individual checkpoints with a V if the task is completed as specified and with the expected result.

Use an X to indicate otherwise and note your comments below, with a reference to the line number. V/X

1 Ensure that the tank is clean

2 Visually inspect the tank to ensure there are no corroded or partially painted areas on the tank itself.

3 Visually inspect the tank for dents, cracks and other signs of damage.

4 Visually inpsect the roof for damage and loose nuts/bolts

5 Visually inspect the skid and frame to ensure there are no cracks or heavily corroded areas.

6 Visually inspect all piping and valves on the unit to ensure these are undamaged and without leaks.

7 Visually inspect all valves to ensure they are correctly labeled and uniqueliy identifiable.

8 Visually inspect the complete unit including drip pan and roof for signs of damage or loose objects.

9 Record the latest certification dates physically marked on the data plates for these three certifications:

IMO major IMO intermediate

10 Lifting Sling/Container DNV 2.7-1:

5 year certification: 2.5 year control:

11 Verift that the tank is labeled with warning signs for cold temperatures and nitrogen content.

12 Visually inspect the tank vacuum burst disc to ensure it shows no signs of damage or failure.

13 Operate all valve handles to verify that they are in good condtion and can be easily opened and closed.

14 Verify that there are no teflon caps on the unit, and that all pipe ends are plugged with a brass cap.

15 Verify that all brass caps are secured to the unit/piping with a chain or wire.

16 Visually inspect all gauges and relief valves for signs of damage or failure.

17 Record the last STEM2/STEM3 date

18 Verify that the PRV's are not frozen up with ice.

19 Test vaporizer and lines for leaks.

20 Verify transport PRV and instrument valves are working.

21 Ensure earth/ground cable is present and in good condition

Open the transport valve, and verify that all other valves are closed. Pressure valve V7 and liquid valve

22

V8 is open, equalizing valve V9 is closed.

Comments and notes

Signatures:

Operator: ERL/MSV/OAS/MM: Date:

This is a live document, and the latest version of this checklist is available in the Maintenance index on SharePoint.

Page 1 of 1 Revised 10/09-20

You might also like

- Petrol Station Checklist AuditDocument10 pagesPetrol Station Checklist AuditrizamryNo ratings yet

- Land Rig Acceptance MasterDocument17 pagesLand Rig Acceptance Masterislam atif100% (1)

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)From EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)No ratings yet

- AST ChecklistsDocument16 pagesAST ChecklistsGary WoodsideNo ratings yet

- Location: Split A/C No.: Monthly PM Check List For SPLIT A/C'sDocument1 pageLocation: Split A/C No.: Monthly PM Check List For SPLIT A/C'ssiruslara6491100% (1)

- Audiolab 8000A Owner's Manual PDFDocument10 pagesAudiolab 8000A Owner's Manual PDFRastko ManojlovicNo ratings yet

- Primus Programming Manual PDFDocument82 pagesPrimus Programming Manual PDFMohamed ClioNo ratings yet

- Datasheet Aritco PublicLift Access 2021 en v1Document2 pagesDatasheet Aritco PublicLift Access 2021 en v1Lê Văn HoạtNo ratings yet

- Swab Tanker - Daily Checklist - Blue-WhiteDocument2 pagesSwab Tanker - Daily Checklist - Blue-WhitePCSL TransportNo ratings yet

- Loadline SurveyDocument8 pagesLoadline SurveyAmit Kumar SenNo ratings yet

- 019 - Tank Box Up ChecklistDocument1 page019 - Tank Box Up ChecklistDelil Ozan67% (6)

- High Pressure Lines PDFDocument3 pagesHigh Pressure Lines PDFKaleem UllahNo ratings yet

- Standard Operating Procedure: Operation and Preventive Maintenance of TransformersDocument5 pagesStandard Operating Procedure: Operation and Preventive Maintenance of TransformersMaryanthony NamyaloNo ratings yet

- PRES-M-08 Rotating Equipment - Compressors PackageDocument2 pagesPRES-M-08 Rotating Equipment - Compressors PackagesalamlinNo ratings yet

- ABB Substation Condition Monitoring ScheduleDocument16 pagesABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- Service and Maintenace Report FormDocument1 pageService and Maintenace Report Formmj santosNo ratings yet

- Reference Tank Handbook PDFDocument10 pagesReference Tank Handbook PDFIvan AvilesNo ratings yet

- PRES-M-09 Rotating Equipment - Gas TurbinesDocument2 pagesPRES-M-09 Rotating Equipment - Gas Turbinessalamlin100% (1)

- OPS 30 Crane Operation ChecklistDocument1 pageOPS 30 Crane Operation ChecklistDmitriyNo ratings yet

- Tank Inspection Standard Operating Procedures PDFDocument3 pagesTank Inspection Standard Operating Procedures PDFIfroz KhanNo ratings yet

- Equipment Group:: Intermediate Inspection Criteria, Well Control EquipmentDocument2 pagesEquipment Group:: Intermediate Inspection Criteria, Well Control Equipmentkaleem ullah jan100% (2)

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- TEC 08 - Bunkering Operations Checklist PDFDocument5 pagesTEC 08 - Bunkering Operations Checklist PDFnmospan100% (1)

- Fire Tank PPMDocument1 pageFire Tank PPMzwarrior333No ratings yet

- Parking Brake TPMDocument1 pageParking Brake TPMisash123No ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- PRES-M-07 Rotating EquipmentDocument2 pagesPRES-M-07 Rotating EquipmentsalamlinNo ratings yet

- 17 - Check Sheet of GT Air Inlet Filter House InspectionDocument5 pages17 - Check Sheet of GT Air Inlet Filter House InspectionSiraj AhmedNo ratings yet

- Warman-Flow System Maintenance ChecklistDocument2 pagesWarman-Flow System Maintenance ChecklistWilliam EvansNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- Sta Filter 1M ProdDocument2 pagesSta Filter 1M ProdMeng Kiat SawNo ratings yet

- Emp Appendix 10 - Marine Fuel Procedures Feb 2020Document32 pagesEmp Appendix 10 - Marine Fuel Procedures Feb 2020majdi jerbiNo ratings yet

- Annual Inspection: Container RefrigerationDocument30 pagesAnnual Inspection: Container RefrigerationJuan Pablo Muñoz CortezNo ratings yet

- GRP SAILING Yacht CHECKLIST INSPECTIONDocument18 pagesGRP SAILING Yacht CHECKLIST INSPECTIONSang ThanhNo ratings yet

- Check List: Checklist For Column FormworkDocument1 pageCheck List: Checklist For Column FormworkPULAGARA SATISHNo ratings yet

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNo ratings yet

- Service Station Operators ChecklistDocument6 pagesService Station Operators Checklistdkishore28100% (1)

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESDocument3 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESkaleem ullah janNo ratings yet

- Saf51 Monthly Oily Overboard Discharge Systems Functionality TestDocument3 pagesSaf51 Monthly Oily Overboard Discharge Systems Functionality TestDmytroNo ratings yet

- Sprinkler Test 2Document5 pagesSprinkler Test 2nag_2004No ratings yet

- PTI CheckList20230804052203Document2 pagesPTI CheckList20230804052203sowntharyagbmNo ratings yet

- 50mva TRAFO#1 BAY#106Document19 pages50mva TRAFO#1 BAY#106Balaji DevathaNo ratings yet

- A Uh 0417Document17 pagesA Uh 0417Murugan ShanmugaiahNo ratings yet

- 2017checklist - Gas Terminal InspectionDocument3 pages2017checklist - Gas Terminal InspectionTushar SorteNo ratings yet

- Survey Checklist ANCODocument23 pagesSurvey Checklist ANCOkonstadine100% (1)

- Air Compressor RegisterDocument1 pageAir Compressor RegisterMcbride NdjaoNo ratings yet

- Service Station Operators ChecklistDocument6 pagesService Station Operators Checklistkwasi BoatengNo ratings yet

- Deep Oil - Flowback and Well Testing UnitDocument11 pagesDeep Oil - Flowback and Well Testing UnitADRIAN SOTONo ratings yet

- Fire Fighting ChecklistDocument10 pagesFire Fighting ChecklistSrikanth Shanmugam0% (1)

- JIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)Document6 pagesJIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)GomathyselviNo ratings yet

- Hydro Static Test Procedure: VD-211-Gen-PCJ-005Document12 pagesHydro Static Test Procedure: VD-211-Gen-PCJ-005arianaseriNo ratings yet

- Checklist For Inspection of RCDs On Indian RailwaysDocument11 pagesChecklist For Inspection of RCDs On Indian RailwaysHanuma ReddyNo ratings yet

- Air Handling Units COB AHU-10ADocument3 pagesAir Handling Units COB AHU-10AHernan RomeroNo ratings yet

- Air Compressor Inspection Checklist: Doc Ref: CL/01Document1 pageAir Compressor Inspection Checklist: Doc Ref: CL/01Muhammad NurNo ratings yet

- PRES-J-02 Instrument EquipmentDocument2 pagesPRES-J-02 Instrument EquipmentsalamlinNo ratings yet

- EXAMPLE SERVICE CHARTS For Low Pressure Co2 SystemDocument1 pageEXAMPLE SERVICE CHARTS For Low Pressure Co2 Systemijas ahmedNo ratings yet

- Feild Inspection of Shell and Tube Heat ExchangersDocument4 pagesFeild Inspection of Shell and Tube Heat ExchangersMatthew BennettNo ratings yet

- Compressor ChecklistDocument1 pageCompressor ChecklistRolando DaclanNo ratings yet

- F-LLS-02c - International Loadline Survey ChecklistDocument3 pagesF-LLS-02c - International Loadline Survey Checklistmtgeneral3cobNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 21 40Document20 pages21 40JIHED PRIMA PHONESTORENo ratings yet

- Fbos 5Document1 pageFbos 5JIHED PRIMA PHONESTORENo ratings yet

- KELLY HEXAGO FBOS Rig B1 IDA-14764Document1 pageKELLY HEXAGO FBOS Rig B1 IDA-14764JIHED PRIMA PHONESTORENo ratings yet

- Inspection Tally Sheet of For Summary Report #001Document1 pageInspection Tally Sheet of For Summary Report #001JIHED PRIMA PHONESTORENo ratings yet

- 176 Jts DP 5 1-2 VAM EIS Class II + RejectedDocument10 pages176 Jts DP 5 1-2 VAM EIS Class II + RejectedJIHED PRIMA PHONESTORENo ratings yet

- 189 Jts DP 5 1-2 Vam Eis Premium0000Document11 pages189 Jts DP 5 1-2 Vam Eis Premium0000JIHED PRIMA PHONESTORENo ratings yet

- Niser 2Document1 pageNiser 2JIHED PRIMA PHONESTORENo ratings yet

- Atag PDFDocument37 pagesAtag PDFEmilianMarginaNo ratings yet

- ZXSDR BS8900A Quick Installation Guide - R1.0 - CH - ENDocument49 pagesZXSDR BS8900A Quick Installation Guide - R1.0 - CH - ENNnaji MauriceNo ratings yet

- Danfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZDocument11 pagesDanfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZclopez5556No ratings yet

- PSP Lab ManualDocument35 pagesPSP Lab ManualPriya SaxenaNo ratings yet

- Manual Mitsubishi Pajero 4x4 Propeler ShaftDocument8 pagesManual Mitsubishi Pajero 4x4 Propeler ShaftGIAN CARLO MAMANI GILES.No ratings yet

- Date Project Location Project Id em Asset Number Equipment NumberDocument8 pagesDate Project Location Project Id em Asset Number Equipment NumberAbdi Doni SetiaNo ratings yet

- Tut2 On Distribution System ReliabilityDocument1 pageTut2 On Distribution System ReliabilityKarma ThinleyNo ratings yet

- RS2LAN Refrigeration Installation Manual 1.4Document54 pagesRS2LAN Refrigeration Installation Manual 1.4Vinnicius100% (2)

- CAT24C44: 256-Bit Serial Nonvolatile CMOS Static RAMDocument8 pagesCAT24C44: 256-Bit Serial Nonvolatile CMOS Static RAMvanmarteNo ratings yet

- 1 0 50 HSL Connector PortfolioDocument2 pages1 0 50 HSL Connector PortfoliomykedindealNo ratings yet

- What Is Direct Memory Access MDADocument1 pageWhat Is Direct Memory Access MDAJuan Ortega GuerraNo ratings yet

- Parts Guide Manual: Ineo+ 454e A5C0121Document149 pagesParts Guide Manual: Ineo+ 454e A5C0121OFBA srlNo ratings yet

- Owner'S Manual: RCSP-XLDocument28 pagesOwner'S Manual: RCSP-XLCarlos Gabriel EstergaardNo ratings yet

- Grundfos Machine SelectionDocument8 pagesGrundfos Machine SelectionMussie BekeleNo ratings yet

- Mains Dimmable LED Strip Drivers, 45W12vDCD 45W24VDCDDocument4 pagesMains Dimmable LED Strip Drivers, 45W12vDCD 45W24VDCDsstockwell1411No ratings yet

- KS3 Electricity 1Document95 pagesKS3 Electricity 1Dominic Wynes-DevlinNo ratings yet

- Technical Specifications01Document14 pagesTechnical Specifications01Sokol ShoshiNo ratings yet

- Spyder Vents - Installation Guide - Clean VersionDocument10 pagesSpyder Vents - Installation Guide - Clean VersionohshafiNo ratings yet

- Solatek 3KW 24 5KW 48Document1 pageSolatek 3KW 24 5KW 48Dammika KarunasingheNo ratings yet

- Im 40muaa 02Document32 pagesIm 40muaa 02hpinetNo ratings yet

- Atari STE TOS Upgrade v2Document3 pagesAtari STE TOS Upgrade v2greenious100% (1)

- Protection and Control Ieds: Selection GuideDocument7 pagesProtection and Control Ieds: Selection Guide男は私 彼女のNo ratings yet

- PCHardwarHbk2ndEdSH PDFDocument132 pagesPCHardwarHbk2ndEdSH PDFAlexis78No ratings yet

- Senr9414senr9414-01 SisDocument9 pagesSenr9414senr9414-01 SisPablo Gaspar D'Agostini AmengualNo ratings yet

- Intesisbox: Interface KNX For Hitachi Air-To-WaterDocument4 pagesIntesisbox: Interface KNX For Hitachi Air-To-WaternajibNo ratings yet

- A6V14163548 enDocument9 pagesA6V14163548 enhk.waa2020No ratings yet

- HoltekDocument96 pagesHoltekZhan AinabekovNo ratings yet