Professional Documents

Culture Documents

Tutorial 4

Tutorial 4

Uploaded by

raisCopyright:

Available Formats

You might also like

- Tutorial 3Document3 pagesTutorial 3raisNo ratings yet

- Chemical EngineeringDocument9 pagesChemical EngineeringanushafiNo ratings yet

- Automotive Pollution Control and Alternative Fuels (AAE 4152) RCS (MAKE UP)Document2 pagesAutomotive Pollution Control and Alternative Fuels (AAE 4152) RCS (MAKE UP)Shantmanu KarnaNo ratings yet

- BTT304 - Ktu QbankDocument9 pagesBTT304 - Ktu QbankAnn JohnNo ratings yet

- College: Jyothi Engineering College, Cheruthuruthy: Answer Any Three Full Questions, Each Carries 7 MarksDocument3 pagesCollege: Jyothi Engineering College, Cheruthuruthy: Answer Any Three Full Questions, Each Carries 7 Marks11715070 JOSHWIN EMMANUEL JOHNSONNo ratings yet

- Tutorial 1Document4 pagesTutorial 1raisNo ratings yet

- Powerplant QPDocument3 pagesPowerplant QPsrimuthu_22100% (1)

- Res (E) - Ee16354Document2 pagesRes (E) - Ee16354Vivek ReddyNo ratings yet

- R05 Set No. 2Document4 pagesR05 Set No. 2c5221No ratings yet

- PP 2021Document2 pagesPP 2021GuriNo ratings yet

- University of Mauritius University of Mauritius University of Mauritius University of MauritiusDocument4 pagesUniversity of Mauritius University of Mauritius University of Mauritius University of MauritiusPriyam RamsokulNo ratings yet

- MEHB403 1920S2 Mid Term - SolutionDocument7 pagesMEHB403 1920S2 Mid Term - SolutionfoxypixelsmyNo ratings yet

- CHT312 - Ktu QbankDocument7 pagesCHT312 - Ktu QbankJeevandersh SNo ratings yet

- 2020 Sept. CH304-EDocument1 page2020 Sept. CH304-EDr ChemistNo ratings yet

- Project (Exergy Analysis of Steam Power Plant)Document76 pagesProject (Exergy Analysis of Steam Power Plant)Shashi Bhushan Patel88% (8)

- Fgscicj06 Codeandnameof Course: CHNG 1002 Applied Chemistry IiDocument6 pagesFgscicj06 Codeandnameof Course: CHNG 1002 Applied Chemistry IiJCNo ratings yet

- Advance Ic Me2401Document2 pagesAdvance Ic Me2401Magesh WaranNo ratings yet

- SCH 2106 - Introduction To Industrial Chemistryprint ReadyDocument4 pagesSCH 2106 - Introduction To Industrial Chemistryprint Readyallanshimoli09No ratings yet

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDocument1 pageB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyMilan MottaNo ratings yet

- Intership Report SampleDocument55 pagesIntership Report SampleKritagyaNo ratings yet

- Metal 3D Printing Technology For Functional Integration of Catalytic SystemDocument8 pagesMetal 3D Printing Technology For Functional Integration of Catalytic SystemUtkarsh AnandNo ratings yet

- AICTE Model Curriculum Scheme2020-2021 - 06.02.2021Document55 pagesAICTE Model Curriculum Scheme2020-2021 - 06.02.2021Deedad SaleemNo ratings yet

- Theoretical Modelling and Experimental Validation of Combustion in DI Diesel Engine by Using Diesel - RKDocument5 pagesTheoretical Modelling and Experimental Validation of Combustion in DI Diesel Engine by Using Diesel - RKmoath farrajNo ratings yet

- Meen40030Document4 pagesMeen40030jayakrishnan.plamthundilsuNo ratings yet

- Che Cycle Test IiDocument3 pagesChe Cycle Test IiSwakin manakshaNo ratings yet

- Modeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Document38 pagesModeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Diyar AliNo ratings yet

- SyllabusDocument6 pagesSyllabuselsonpaulNo ratings yet

- AE Course PlanDocument6 pagesAE Course PlanrameshszrNo ratings yet

- MET478 PPE SyllabusDocument7 pagesMET478 PPE SyllabusAnoof M.SNo ratings yet

- Power Plant Engineerng: Rajalakshmi Engineering College Deparment of Mechanical EngineeringDocument4 pagesPower Plant Engineerng: Rajalakshmi Engineering College Deparment of Mechanical EngineeringDeepak Kumar0% (1)

- Me 2403 Power Plant Engineering - Model ExamDocument2 pagesMe 2403 Power Plant Engineering - Model ExamBIBIN CHIDAMBARANATHANNo ratings yet

- Engineering Chemistry: Inst Ruct Ions T O Candidat EsDocument2 pagesEngineering Chemistry: Inst Ruct Ions T O Candidat EsJaskaran SinghNo ratings yet

- Power Plant Engg 2 Mark Question OnlyDocument7 pagesPower Plant Engg 2 Mark Question OnlyM.ThirunavukkarasuNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityRohit patelNo ratings yet

- Advance Ic Engine 2 Question PaperDocument2 pagesAdvance Ic Engine 2 Question PaperushaNo ratings yet

- M Pharm PDFDocument49 pagesM Pharm PDFkothi hemaraniNo ratings yet

- Ic Enginecombustion & PollutionDocument6 pagesIc Enginecombustion & PollutionsajithukNo ratings yet

- AL Biology Past Paper 91-03 (PART I) ADocument58 pagesAL Biology Past Paper 91-03 (PART I) ARainbow WongNo ratings yet

- Part-Ii: Federal Public Service CommissionDocument3 pagesPart-Ii: Federal Public Service Commissionaneela.kanwalNo ratings yet

- Polymer Blends and Composites: Chemistry and TechnologyFrom EverandPolymer Blends and Composites: Chemistry and TechnologyNo ratings yet

- Advanced Energy EngineeringDocument6 pagesAdvanced Energy Engineeringnaifmansoor101No ratings yet

- Spray ModellingDocument28 pagesSpray Modellingsrinivas krishnaNo ratings yet

- Experimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionDocument10 pagesExperimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionkannanjbrNo ratings yet

- Study Tribological Properties of Modtc and Its Interactions With Metal DetergentsDocument11 pagesStudy Tribological Properties of Modtc and Its Interactions With Metal DetergentsMarcos Dantas dos SantosNo ratings yet

- MIDTERM - 2008 Third Year Ft-373 Waste Management (Food Technology) Time: 2 HR Marks 50Document8 pagesMIDTERM - 2008 Third Year Ft-373 Waste Management (Food Technology) Time: 2 HR Marks 50munirftNo ratings yet

- Power Plant Engineering 2 & 16 Mark QuestionDocument7 pagesPower Plant Engineering 2 & 16 Mark QuestionKanagaraj Chelladurai100% (1)

- At AssignmentsDocument2 pagesAt AssignmentsBharathiraja MoorthyNo ratings yet

- ME404 Industrial Engineering, May 2019Document2 pagesME404 Industrial Engineering, May 2019Mohammed SalaNo ratings yet

- Nov Dec 2016 PPC Question Paper PDFDocument21 pagesNov Dec 2016 PPC Question Paper PDFrajNo ratings yet

- BME203007 IC ProjectDocument29 pagesBME203007 IC ProjectHamza AliNo ratings yet

- Iii B.tech I Sem Question Bank For R18Document22 pagesIii B.tech I Sem Question Bank For R18saiharish634No ratings yet

- 2021 August CH409-FDocument2 pages2021 August CH409-FDr ChemistNo ratings yet

- Engineering Failure Analysis: Rui Yu, Jinxiang LiuDocument7 pagesEngineering Failure Analysis: Rui Yu, Jinxiang LiuPrasad GharatNo ratings yet

- Final B Cud ReportDocument37 pagesFinal B Cud ReportsubburajsNo ratings yet

- BCM614Document10 pagesBCM614Nuri AbdullahNo ratings yet

- BE MechanicalDocument162 pagesBE Mechanicalsatish kurraNo ratings yet

- Ee1252 - Power Plant Engineering: Question Bank Unit I - Thermal Power Plants PART A (2 Marks)Document4 pagesEe1252 - Power Plant Engineering: Question Bank Unit I - Thermal Power Plants PART A (2 Marks)Vivek BendreNo ratings yet

- Assignment Submission Details: Program / Semester Specialization Course Name Course CodeDocument1 pageAssignment Submission Details: Program / Semester Specialization Course Name Course Codemalika_00No ratings yet

- PapersDocument40 pagesPapersBilalNo ratings yet

- Tutorial 2Document3 pagesTutorial 2raisNo ratings yet

- Tutorial 1Document4 pagesTutorial 1raisNo ratings yet

- Crude DistillationDocument35 pagesCrude DistillationraisNo ratings yet

- Tutorial 3Document3 pagesTutorial 3raisNo ratings yet

Tutorial 4

Tutorial 4

Uploaded by

raisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial 4

Tutorial 4

Uploaded by

raisCopyright:

Available Formats

CPE656

PETROLEUM REFINING

ENGINEERING

TUTORIAL 4

IR. TS. MOHD FADHIL BIN MAJNIS

SCHOOL OF CHEMICAL ENGINEERING

COLLEGE OF ENGINEERING

UNIVERSITI TEKNOLOGI MARA (UiTM)

https://www.linkedin.com/in/fadhilmajnis/

1

Question 1

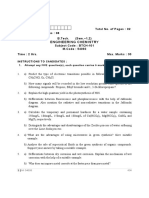

Figure 1 illustrates the schematic flow diagram of a fluid catalytic cracker which is arranged in a side-by-side configuration. It was built

up of three major components, which are labelled as (i), (ii) and (iii), respectively, in Figure 1.

a) Outline the respective functions of components (i), (ii) and (iii) in this cracking unit. (6 marks)

b) Different types of feed are catalytically cracked. The properties of the feed and the composition of the cracked products are

summarized in Table 1 and Table 2, respectively. Based on the results above, deduce the influence of the feedstock towards the

performances of the catalytic cracking process. Support your deduction with three (3) reasonable explanations. (4 marks)

Table 1: Feed properties of aromatic feed and hydrotreated feed.

Table 2: FCC yield for cracking of aromatic and hydrotreated feed.

Figure 1: Fluidized catalytic cracking unit.

Question 2

Write a comparison of different coking processes, delayed coking and fluid

coking in terms of operating condition, feedstock, product and process

purpose. (12 marks)

Question 3

Describe the differences between fluid coking and fluid catalytic cracking

unit's design/configuration and their working principle with a proper process

flow diagram. (10 marks)

Question 4

Engineering variables affect the performance of delayed coking process.

Support the statement with a proper description on how engineering

variables in terms of mode of operation, unit capacity, and coke removal and

handling equipment affect the process performance. (9 marks)

You might also like

- Tutorial 3Document3 pagesTutorial 3raisNo ratings yet

- Chemical EngineeringDocument9 pagesChemical EngineeringanushafiNo ratings yet

- Automotive Pollution Control and Alternative Fuels (AAE 4152) RCS (MAKE UP)Document2 pagesAutomotive Pollution Control and Alternative Fuels (AAE 4152) RCS (MAKE UP)Shantmanu KarnaNo ratings yet

- BTT304 - Ktu QbankDocument9 pagesBTT304 - Ktu QbankAnn JohnNo ratings yet

- College: Jyothi Engineering College, Cheruthuruthy: Answer Any Three Full Questions, Each Carries 7 MarksDocument3 pagesCollege: Jyothi Engineering College, Cheruthuruthy: Answer Any Three Full Questions, Each Carries 7 Marks11715070 JOSHWIN EMMANUEL JOHNSONNo ratings yet

- Tutorial 1Document4 pagesTutorial 1raisNo ratings yet

- Powerplant QPDocument3 pagesPowerplant QPsrimuthu_22100% (1)

- Res (E) - Ee16354Document2 pagesRes (E) - Ee16354Vivek ReddyNo ratings yet

- R05 Set No. 2Document4 pagesR05 Set No. 2c5221No ratings yet

- PP 2021Document2 pagesPP 2021GuriNo ratings yet

- University of Mauritius University of Mauritius University of Mauritius University of MauritiusDocument4 pagesUniversity of Mauritius University of Mauritius University of Mauritius University of MauritiusPriyam RamsokulNo ratings yet

- MEHB403 1920S2 Mid Term - SolutionDocument7 pagesMEHB403 1920S2 Mid Term - SolutionfoxypixelsmyNo ratings yet

- CHT312 - Ktu QbankDocument7 pagesCHT312 - Ktu QbankJeevandersh SNo ratings yet

- 2020 Sept. CH304-EDocument1 page2020 Sept. CH304-EDr ChemistNo ratings yet

- Project (Exergy Analysis of Steam Power Plant)Document76 pagesProject (Exergy Analysis of Steam Power Plant)Shashi Bhushan Patel88% (8)

- Fgscicj06 Codeandnameof Course: CHNG 1002 Applied Chemistry IiDocument6 pagesFgscicj06 Codeandnameof Course: CHNG 1002 Applied Chemistry IiJCNo ratings yet

- Advance Ic Me2401Document2 pagesAdvance Ic Me2401Magesh WaranNo ratings yet

- SCH 2106 - Introduction To Industrial Chemistryprint ReadyDocument4 pagesSCH 2106 - Introduction To Industrial Chemistryprint Readyallanshimoli09No ratings yet

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDocument1 pageB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyMilan MottaNo ratings yet

- Intership Report SampleDocument55 pagesIntership Report SampleKritagyaNo ratings yet

- Metal 3D Printing Technology For Functional Integration of Catalytic SystemDocument8 pagesMetal 3D Printing Technology For Functional Integration of Catalytic SystemUtkarsh AnandNo ratings yet

- AICTE Model Curriculum Scheme2020-2021 - 06.02.2021Document55 pagesAICTE Model Curriculum Scheme2020-2021 - 06.02.2021Deedad SaleemNo ratings yet

- Theoretical Modelling and Experimental Validation of Combustion in DI Diesel Engine by Using Diesel - RKDocument5 pagesTheoretical Modelling and Experimental Validation of Combustion in DI Diesel Engine by Using Diesel - RKmoath farrajNo ratings yet

- Meen40030Document4 pagesMeen40030jayakrishnan.plamthundilsuNo ratings yet

- Che Cycle Test IiDocument3 pagesChe Cycle Test IiSwakin manakshaNo ratings yet

- Modeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Document38 pagesModeling and Simulation of Fluid Catalytic Cracking Unit: Reviews in Chemical Engineering January 2005Diyar AliNo ratings yet

- SyllabusDocument6 pagesSyllabuselsonpaulNo ratings yet

- AE Course PlanDocument6 pagesAE Course PlanrameshszrNo ratings yet

- MET478 PPE SyllabusDocument7 pagesMET478 PPE SyllabusAnoof M.SNo ratings yet

- Power Plant Engineerng: Rajalakshmi Engineering College Deparment of Mechanical EngineeringDocument4 pagesPower Plant Engineerng: Rajalakshmi Engineering College Deparment of Mechanical EngineeringDeepak Kumar0% (1)

- Me 2403 Power Plant Engineering - Model ExamDocument2 pagesMe 2403 Power Plant Engineering - Model ExamBIBIN CHIDAMBARANATHANNo ratings yet

- Engineering Chemistry: Inst Ruct Ions T O Candidat EsDocument2 pagesEngineering Chemistry: Inst Ruct Ions T O Candidat EsJaskaran SinghNo ratings yet

- Power Plant Engg 2 Mark Question OnlyDocument7 pagesPower Plant Engg 2 Mark Question OnlyM.ThirunavukkarasuNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityRohit patelNo ratings yet

- Advance Ic Engine 2 Question PaperDocument2 pagesAdvance Ic Engine 2 Question PaperushaNo ratings yet

- M Pharm PDFDocument49 pagesM Pharm PDFkothi hemaraniNo ratings yet

- Ic Enginecombustion & PollutionDocument6 pagesIc Enginecombustion & PollutionsajithukNo ratings yet

- AL Biology Past Paper 91-03 (PART I) ADocument58 pagesAL Biology Past Paper 91-03 (PART I) ARainbow WongNo ratings yet

- Part-Ii: Federal Public Service CommissionDocument3 pagesPart-Ii: Federal Public Service Commissionaneela.kanwalNo ratings yet

- Polymer Blends and Composites: Chemistry and TechnologyFrom EverandPolymer Blends and Composites: Chemistry and TechnologyNo ratings yet

- Advanced Energy EngineeringDocument6 pagesAdvanced Energy Engineeringnaifmansoor101No ratings yet

- Spray ModellingDocument28 pagesSpray Modellingsrinivas krishnaNo ratings yet

- Experimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionDocument10 pagesExperimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionkannanjbrNo ratings yet

- Study Tribological Properties of Modtc and Its Interactions With Metal DetergentsDocument11 pagesStudy Tribological Properties of Modtc and Its Interactions With Metal DetergentsMarcos Dantas dos SantosNo ratings yet

- MIDTERM - 2008 Third Year Ft-373 Waste Management (Food Technology) Time: 2 HR Marks 50Document8 pagesMIDTERM - 2008 Third Year Ft-373 Waste Management (Food Technology) Time: 2 HR Marks 50munirftNo ratings yet

- Power Plant Engineering 2 & 16 Mark QuestionDocument7 pagesPower Plant Engineering 2 & 16 Mark QuestionKanagaraj Chelladurai100% (1)

- At AssignmentsDocument2 pagesAt AssignmentsBharathiraja MoorthyNo ratings yet

- ME404 Industrial Engineering, May 2019Document2 pagesME404 Industrial Engineering, May 2019Mohammed SalaNo ratings yet

- Nov Dec 2016 PPC Question Paper PDFDocument21 pagesNov Dec 2016 PPC Question Paper PDFrajNo ratings yet

- BME203007 IC ProjectDocument29 pagesBME203007 IC ProjectHamza AliNo ratings yet

- Iii B.tech I Sem Question Bank For R18Document22 pagesIii B.tech I Sem Question Bank For R18saiharish634No ratings yet

- 2021 August CH409-FDocument2 pages2021 August CH409-FDr ChemistNo ratings yet

- Engineering Failure Analysis: Rui Yu, Jinxiang LiuDocument7 pagesEngineering Failure Analysis: Rui Yu, Jinxiang LiuPrasad GharatNo ratings yet

- Final B Cud ReportDocument37 pagesFinal B Cud ReportsubburajsNo ratings yet

- BCM614Document10 pagesBCM614Nuri AbdullahNo ratings yet

- BE MechanicalDocument162 pagesBE Mechanicalsatish kurraNo ratings yet

- Ee1252 - Power Plant Engineering: Question Bank Unit I - Thermal Power Plants PART A (2 Marks)Document4 pagesEe1252 - Power Plant Engineering: Question Bank Unit I - Thermal Power Plants PART A (2 Marks)Vivek BendreNo ratings yet

- Assignment Submission Details: Program / Semester Specialization Course Name Course CodeDocument1 pageAssignment Submission Details: Program / Semester Specialization Course Name Course Codemalika_00No ratings yet

- PapersDocument40 pagesPapersBilalNo ratings yet

- Tutorial 2Document3 pagesTutorial 2raisNo ratings yet

- Tutorial 1Document4 pagesTutorial 1raisNo ratings yet

- Crude DistillationDocument35 pagesCrude DistillationraisNo ratings yet

- Tutorial 3Document3 pagesTutorial 3raisNo ratings yet