Professional Documents

Culture Documents

Tank Shell & SE Head

Tank Shell & SE Head

Uploaded by

massive850 ratings0% found this document useful (0 votes)

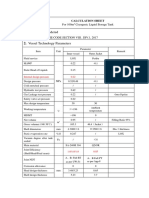

31 views1 pageThis document provides design specifications for an internal vessel component, including:

- An internal design pressure of 0.007 MPa with a design temperature of 40°C.

- Material specifications for the elliptical heads, including maximum allowable stresses of 113 MPa and 128 MPa.

- Dimensions for the elliptical heads, including an internal diameter of 2190 mm.

- A minimum required thickness calculation for the elliptical heads showing the 6 mm nominal thickness is satisfactory.

Original Description:

Tank shell & SE head calculation as per API

Original Title

Tank Shell & SE head

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides design specifications for an internal vessel component, including:

- An internal design pressure of 0.007 MPa with a design temperature of 40°C.

- Material specifications for the elliptical heads, including maximum allowable stresses of 113 MPa and 128 MPa.

- Dimensions for the elliptical heads, including an internal diameter of 2190 mm.

- A minimum required thickness calculation for the elliptical heads showing the 6 mm nominal thickness is satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

31 views1 pageTank Shell & SE Head

Tank Shell & SE Head

Uploaded by

massive85This document provides design specifications for an internal vessel component, including:

- An internal design pressure of 0.007 MPa with a design temperature of 40°C.

- Material specifications for the elliptical heads, including maximum allowable stresses of 113 MPa and 128 MPa.

- Dimensions for the elliptical heads, including an internal diameter of 2190 mm.

- A minimum required thickness calculation for the elliptical heads showing the 6 mm nominal thickness is satisfactory.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

???

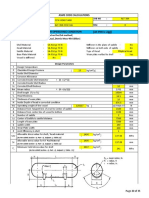

Internal Design Pressure P 0.003 Mpa

Specific Gravity Internals g 1

Liquid/ Packing Head Pressure Ph 0.004 Mpa

Design Pressure Including Head P 0.007 Mpa

o

Design Temperature for Internal Pressure 40 C

Internal Corrosion Allowance c.a 0 mm

Radiography None

P.W.H.T No

Impact Tests No

Head Data Material SS 304

(Heads 2:1 Semi-Ellipsoidal)

Maximum Allowable Stress (@ Design temp) UG-23 & ASME II Sd 113 MPa

Maximum Allowable Stress (@ Test Temp) UG-23 & ASME II Sa 128 MPa

Longitudinal Joint Factor E 0.7

Inside length of major axis (Internal Diameter New) Di 2190 mm

Inside length of the major axis (Internal Diameter Corroded) D 2190 mm

Estimated Thinning Allowance 7 %

Plate Undertolerance 1 mm

Comments:

Per ASME VIII Division 1 UG-16(e) - "The dimensional symbols used in design formulas throughout this division represent

2 : 1 Ellipsoidal Head Design UG-32 (d)

With Static Head Pressure

Nominal Thickness 6 mm

Nominal Thickness Minus Thinning Allowance & Plate Undertolerance tmin 4.58 mm

Minimum required thickness after forming = P D K / (2SE - 0.2P) t 0.10 mm

(where K = 1) t+c 0.10 mm

(Since t min > t + c, The thickness used is SATISFACTORY) Use 6 mm

You might also like

- Crack Width As Per ACI 318 - SpreadsheetDocument2 pagesCrack Width As Per ACI 318 - Spreadsheetmassive8590% (10)

- Ranger - Manual de Peças M5R1 M5R2 RKEDocument6 pagesRanger - Manual de Peças M5R1 M5R2 RKEWanderson Wadjô100% (3)

- PV External Pressure Spreadsheet ASME VIII Div 1Document1 pagePV External Pressure Spreadsheet ASME VIII Div 1Gohar ZamanNo ratings yet

- 13 - MDU, Rohtak B.E. - B.tech OrdinanceDocument5 pages13 - MDU, Rohtak B.E. - B.tech OrdinanceSanjay SinghNo ratings yet

- Project Sizes - Small, Medium and LargeDocument2 pagesProject Sizes - Small, Medium and Large1105195794100% (1)

- FRP Vessel Calc Asme RTP 1Document7 pagesFRP Vessel Calc Asme RTP 1GautamNo ratings yet

- 809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Document2 pages809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Sebastiano OrofinoNo ratings yet

- Saddle-Design-Operating - FinalDocument17 pagesSaddle-Design-Operating - FinalSiva baalan75% (4)

- Design Data: 2" Threadolet CalculationDocument2 pagesDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Anchor Bolt DesignDocument2 pagesAnchor Bolt Designmassive85No ratings yet

- CPI Site-Activities PDFDocument30 pagesCPI Site-Activities PDFmassive85No ratings yet

- Tasks Engl 9 11 Yarik Mun 17 8Document27 pagesTasks Engl 9 11 Yarik Mun 17 8Dragon SlayerNo ratings yet

- Nes 747Document252 pagesNes 747Soumya Ranjan Subudhi100% (1)

- VMC Programing ManualDocument171 pagesVMC Programing Manualsujoylud100% (2)

- Author: Partha Das Sharma, B.Tech (Hons.) in Mining Engineering, E.mail:, Blogs/WebsitesDocument16 pagesAuthor: Partha Das Sharma, B.Tech (Hons.) in Mining Engineering, E.mail:, Blogs/Websitespartha das sharma100% (1)

- Design Calculations For Pressure VesselsDocument43 pagesDesign Calculations For Pressure VesselsMoises Alvarez LeandroNo ratings yet

- External Pressure-Dish Head and Shell-Taiwan TankDocument1 pageExternal Pressure-Dish Head and Shell-Taiwan TanknaimNo ratings yet

- CA LPG 5b STD 0 RepairedDocument27 pagesCA LPG 5b STD 0 RepairedMadiaw NajaNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- Final ExaminationDocument7 pagesFinal ExaminationAwanNo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- 100 KL Old CalDocument8 pages100 KL Old CalpavanNo ratings yet

- 3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of ComponentsDocument1 page3" NB PIPE Thickness Check (Design Condition) : Asme B31.3: Section 304 Pressure Design of Components7761430No ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- MAWP Calculation SpreadsheetDocument9 pagesMAWP Calculation SpreadsheetLawrence Osuvwe OfuokuNo ratings yet

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- Saddle Design at Operating ConditionDocument17 pagesSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- SHELLDocument6 pagesSHELLSalz EngineeringNo ratings yet

- New PA Column - THK CalcDocument8 pagesNew PA Column - THK CalcSabariMechyNo ratings yet

- Thickness Calculations For - 406.4 MM Dia of Pipe For Pressure MainDocument1 pageThickness Calculations For - 406.4 MM Dia of Pipe For Pressure MainRamsuNo ratings yet

- Code Calcs Rev1Document11 pagesCode Calcs Rev1Tauqeer AhmedNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- Pressure Vessel Calculation Report PDFDocument12 pagesPressure Vessel Calculation Report PDFVictor Fakoya50% (2)

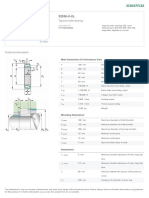

- GE180-UK-2RS: Spherical Plain BearingDocument1 pageGE180-UK-2RS: Spherical Plain BearingVõ Quang LânNo ratings yet

- Body Flange DesignDocument4 pagesBody Flange DesignRajesh KumarNo ratings yet

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- Thickness Calculation of Cylindrical Shell and TubeDocument1 pageThickness Calculation of Cylindrical Shell and TubeThanhNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- MP Condensate Flash VesselDocument4 pagesMP Condensate Flash VesselGanesh BhardwajNo ratings yet

- Design Pipeline Wall Thickness 2) Hydrostatic Collapse PressureDocument6 pagesDesign Pipeline Wall Thickness 2) Hydrostatic Collapse PressureNurul Ameera SaparuddinNo ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Main Shell Calculation: UG-27 (1) CB-3.13Document7 pagesMain Shell Calculation: UG-27 (1) CB-3.13RajdeepsinhNo ratings yet

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- Main Head Calculation (Left Head & Right Head)Document1 pageMain Head Calculation (Left Head & Right Head)vietsdsNo ratings yet

- Ge40 Fo 2RSDocument1 pageGe40 Fo 2RSrakhikishore143No ratings yet

- IBR Calualations (28.12.22)Document10 pagesIBR Calualations (28.12.22)Sumit MishraNo ratings yet

- Input ValuesDocument5 pagesInput ValuesmasoodNo ratings yet

- Tapered Roller Bearing: Schaeffler IDDocument2 pagesTapered Roller Bearing: Schaeffler IDSabaresan :: PolymersNo ratings yet

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- Input ValuesDocument38 pagesInput ValuesArjunNo ratings yet

- Deep Groove Ball Bearing: Main Dimensions & Performance DataDocument1 pageDeep Groove Ball Bearing: Main Dimensions & Performance DataCutberto MartinezNo ratings yet

- Base Plate Design With AnchorsDocument1 pageBase Plate Design With AnchorsAamirShabbirNo ratings yet

- PTB E4.3.3 Spherical ShellDocument2 pagesPTB E4.3.3 Spherical ShellNicolaSaviliNo ratings yet

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Ge45 Fo 2RSDocument1 pageGe45 Fo 2RSEngin YasharNo ratings yet

- Api 650 RF Pad CalculationDocument1 pageApi 650 RF Pad Calculationfauzy2504No ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- Data Sheet of Process Equipment CalculationDocument24 pagesData Sheet of Process Equipment Calculation于子超No ratings yet

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 pagesDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012No ratings yet

- Apa-Zhd-Pr-Cal-026 14Document1 pageApa-Zhd-Pr-Cal-026 14behnam fallahNo ratings yet

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 pagesR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- Tapered Roller Bearing: Schaeffler IDDocument2 pagesTapered Roller Bearing: Schaeffler IDFlorian GhioculescuNo ratings yet

- Design of Storage Tanks For Internal PressureDocument7 pagesDesign of Storage Tanks For Internal Pressuremanish318No ratings yet

- Deep Groove Ball Bearing: Main Dimensions & Performance DataDocument1 pageDeep Groove Ball Bearing: Main Dimensions & Performance DataCutberto MartinezNo ratings yet

- Ge45 FW 2RS A PDFDocument1 pageGe45 FW 2RS A PDFshashibagewadiNo ratings yet

- InputDocument5 pagesInputTrần Văn NhânNo ratings yet

- Notes:: Supporting Beam Supported ColumnDocument2 pagesNotes:: Supporting Beam Supported Columnmassive85No ratings yet

- Roof Drain-Tank DesignDocument3 pagesRoof Drain-Tank Designmassive85No ratings yet

- Dybamic Design Analysis of Foundtison Wiell Help Us To Do All Things For Stuff and Help Peoples Fndna N Dnajjhaja IncludingDocument1 pageDybamic Design Analysis of Foundtison Wiell Help Us To Do All Things For Stuff and Help Peoples Fndna N Dnajjhaja Includingmassive85No ratings yet

- Retaining Wall CalculationDocument7 pagesRetaining Wall Calculationmassive85No ratings yet

- Vent Calculation API STD 2000Document2 pagesVent Calculation API STD 2000massive85No ratings yet

- Pipeline Anchor Force CalculationDocument1 pagePipeline Anchor Force Calculationmassive85No ratings yet

- FOUNDATION Design Calculations Check ListDocument1 pageFOUNDATION Design Calculations Check Listmassive85No ratings yet

- Structural Steel Design ChecklistDocument2 pagesStructural Steel Design Checklistmassive85100% (4)

- Vertical Equation Foundation-Spread Sheet PDFDocument6 pagesVertical Equation Foundation-Spread Sheet PDFmassive85No ratings yet

- Early Thermal Cracking CalculationsDocument1 pageEarly Thermal Cracking Calculationsmassive85No ratings yet

- Design Calculation: Base Pressure OkayDocument2 pagesDesign Calculation: Base Pressure Okaymassive85No ratings yet

- Structural Steel (Coatings) PDFDocument30 pagesStructural Steel (Coatings) PDFmassive85No ratings yet

- Code For Anchor BoltDocument15 pagesCode For Anchor Boltmassive85No ratings yet

- 2016 To 2010 Spec Comparison - Final PDFDocument42 pages2016 To 2010 Spec Comparison - Final PDFmassive85No ratings yet

- Structural Steel (Coatings) PDFDocument30 pagesStructural Steel (Coatings) PDFmassive85No ratings yet

- Structural Shapes Database v15.0Document3 pagesStructural Shapes Database v15.0massive85No ratings yet

- Moment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71Document3 pagesMoment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71massive85No ratings yet

- List of Civil PIP CodesDocument1 pageList of Civil PIP Codesmassive85100% (1)

- Aisc Shapes Database v15.0Document14 pagesAisc Shapes Database v15.0ErickSimonNo ratings yet

- Material Selection Lecture-1Document50 pagesMaterial Selection Lecture-1Hassan HabibNo ratings yet

- Meeting 7 Unsupervised LearnignDocument95 pagesMeeting 7 Unsupervised LearnignAntonio VictoryNo ratings yet

- Examples PythonDocument276 pagesExamples PythonsandeeptaraNo ratings yet

- Lehm0088 01 1Document2 pagesLehm0088 01 1Becirspahic AlmirNo ratings yet

- Econogauge-Brochure-1 (1) - 220415 - 080434Document2 pagesEconogauge-Brochure-1 (1) - 220415 - 080434Antonio PereiraNo ratings yet

- BENDY AND THE INK MACHINE SONG (Ft. OR3O) Absolutely Anything (SFM) CG5 - YouTube PDFDocument1 pageBENDY AND THE INK MACHINE SONG (Ft. OR3O) Absolutely Anything (SFM) CG5 - YouTube PDFAlexisNo ratings yet

- Bulk Density of BricksDocument1 pageBulk Density of BrickssuryakantameNo ratings yet

- Midterm 11 So LsDocument7 pagesMidterm 11 So LsMohamedNo ratings yet

- Revista PTQ Refineria-PetroquimicaDocument132 pagesRevista PTQ Refineria-PetroquimicaElimar RojasNo ratings yet

- Thompson Proto US1425810Document4 pagesThompson Proto US1425810apoorva singhNo ratings yet

- Standard Label MW Ioh 2022Document11 pagesStandard Label MW Ioh 2022Febry Hisbullah NurmanNo ratings yet

- FlywheelDocument8 pagesFlywheelAidil Syawani Kun100% (1)

- Lista Aspectelor de Mediu IdentificateDocument7 pagesLista Aspectelor de Mediu IdentificateLuminita GrecuNo ratings yet

- EEG Machine Troubleshooting: Symptom Reasons Troubleshooting ActionDocument1 pageEEG Machine Troubleshooting: Symptom Reasons Troubleshooting ActionBiomed TNo ratings yet

- Geberit PluviaDocument8 pagesGeberit PluviaszeestherNo ratings yet

- JPerf and IPerfDocument5 pagesJPerf and IPerfjuharieNo ratings yet

- Aerotbx Ug PDFDocument542 pagesAerotbx Ug PDFਰਾਜਬੀਰNo ratings yet

- Chapter 2 RRLDocument18 pagesChapter 2 RRLcelmae150% (1)

- Ritchey 2016 ECatalog IntlDocument113 pagesRitchey 2016 ECatalog IntlBas VolkswagenNo ratings yet

- Mining Equipment Maintenance PDFDocument93 pagesMining Equipment Maintenance PDFGanapati Hegde100% (1)

- Gics 2010Document476 pagesGics 2010rranjan27No ratings yet

- CASE STUDY - Collapsed Wind Tower - A Root Cause Investigation (Element Materials Technology)Document3 pagesCASE STUDY - Collapsed Wind Tower - A Root Cause Investigation (Element Materials Technology)engrrahman3135No ratings yet

- Travis Duvier, Kevin Carter (Topic: Gmos)Document2 pagesTravis Duvier, Kevin Carter (Topic: Gmos)Brent M. HunterNo ratings yet