Professional Documents

Culture Documents

Durostone PCB Solder e

Durostone PCB Solder e

Uploaded by

aisyahhamidCopyright:

Available Formats

You might also like

- Chem 136-LAB EDocument5 pagesChem 136-LAB Esidro12382% (11)

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- Balancing Chemical EquationDocument4 pagesBalancing Chemical Equationamin_zaman100% (1)

- Astm B686 PDFDocument8 pagesAstm B686 PDFpicnarukNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Specification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541Document2 pagesSpecification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541ex4182No ratings yet

- Araldite 2014-2: Advanced MaterialsDocument6 pagesAraldite 2014-2: Advanced MaterialsAnonymous r3MoX2ZMTNo ratings yet

- Alloy321 SpecSheetDocument2 pagesAlloy321 SpecSheetVinod tiwariNo ratings yet

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvNo ratings yet

- Araldite FT 420 AB ENDocument5 pagesAraldite FT 420 AB ENantoine DelesvauxNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- AV138M Araldite HV998 HardDocument6 pagesAV138M Araldite HV998 HardFilipe Alberto De MagalhãesNo ratings yet

- TIS 1665 e PDFDocument5 pagesTIS 1665 e PDFeduardo rochaNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Technical Data Sheet: Primerless MMA AdhesivesDocument3 pagesTechnical Data Sheet: Primerless MMA AdhesivespronavNo ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Araldit-STANDARD Datasheet PDFDocument3 pagesAraldit-STANDARD Datasheet PDFsiva shanmugamNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- Nci Test DataDocument21 pagesNci Test DataPig DookNo ratings yet

- How To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesDocument11 pagesHow To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesdNo ratings yet

- COLLANTE FCB 130 - Araldite - FT - AV138M-1 - HV998 - ENDocument4 pagesCOLLANTE FCB 130 - Araldite - FT - AV138M-1 - HV998 - ENMax SalogniNo ratings yet

- Araldite AV 138M-1 With Hardener HV 998: Advanced MaterialsDocument4 pagesAraldite AV 138M-1 With Hardener HV 998: Advanced MaterialsMajid TorabiNo ratings yet

- Araldite 2047-1: Advanced MaterialsDocument6 pagesAraldite 2047-1: Advanced MaterialsLiberio AragaoNo ratings yet

- MG Chemicals MARKERSDocument6 pagesMG Chemicals MARKERSMantasPuskoriusNo ratings yet

- SP-1386 Jun 2023Document5 pagesSP-1386 Jun 2023huicholeNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenNo ratings yet

- Brochure AlphaRod SuckerRodsDocument8 pagesBrochure AlphaRod SuckerRodsRicardo Pulido RamìrezNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Hardox 450 Plate: General Product DescriptionDocument2 pagesHardox 450 Plate: General Product Descriptiongorane11No ratings yet

- SikaAnchorFix2Arctic PdsDocument4 pagesSikaAnchorFix2Arctic PdsDragoș SturzoiuNo ratings yet

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Document8 pagesDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriNo ratings yet

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

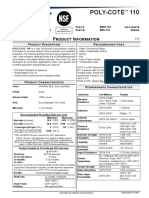

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 pagesArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- CATALOG - Final - Low ResulotionDocument66 pagesCATALOG - Final - Low ResulotionKadiri El MoustaphaNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- RTV160, RTV162 and RTV167 Electronic Grade Silicone Adhesive SealantsDocument4 pagesRTV160, RTV162 and RTV167 Electronic Grade Silicone Adhesive SealantspokleNo ratings yet

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- Hardox® 450: General Product DescriptionDocument2 pagesHardox® 450: General Product DescriptionAmal RajNo ratings yet

- 203-010 Griswold 6100 Family Product Data SheetDocument1 page203-010 Griswold 6100 Family Product Data Sheetjuan davidNo ratings yet

- WL115 0117 PE4710 Water PipeDocument8 pagesWL115 0117 PE4710 Water PipeEdwin MariacaNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALDocument8 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALAkbar Perwira UtamaNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- Midas Civil2013v3Document18 pagesMidas Civil2013v3silvereyes18No ratings yet

- Mds TPODocument3 pagesMds TPORicardo Andres Ojeda VidalNo ratings yet

- Plastics 2Document121 pagesPlastics 2AMIT PRAJAPATINo ratings yet

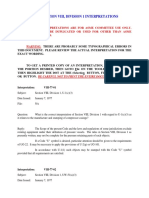

- Asme Section Viii, Division 1 InterpretationsDocument1,148 pagesAsme Section Viii, Division 1 InterpretationsajitNo ratings yet

- Comparison of Pipe Flow EquationsDocument6 pagesComparison of Pipe Flow EquationsJohn HarkenNo ratings yet

- Mill Lines by FlSmidthDocument4 pagesMill Lines by FlSmidthIrving Dirzo CarrilloNo ratings yet

- Brochure Polyurethane Materials For Vibration Isolation ENDocument12 pagesBrochure Polyurethane Materials For Vibration Isolation ENymukhtar897No ratings yet

- Beam Force Detail Summary: Beam L/C D FX Fy FZ MX My MZDocument1 pageBeam Force Detail Summary: Beam L/C D FX Fy FZ MX My MZThakshayani SellavelNo ratings yet

- 2 Manjunath-2018Document11 pages2 Manjunath-2018Nórida Pájaro GómezNo ratings yet

- Shark SC630 Manual enDocument23 pagesShark SC630 Manual enkrievkalnsgNo ratings yet

- Narra Park Residence - Two StoreyDocument11 pagesNarra Park Residence - Two StoreyJofel Jay Dumogho BarnuevoNo ratings yet

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument3 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingAriel FernandezNo ratings yet

- PD (Solmax Advanced Product Series)Document3 pagesPD (Solmax Advanced Product Series)kertaningNo ratings yet

- Portable Cabin Steel Porta Cabin Consist of With One Room and VerandahDocument7 pagesPortable Cabin Steel Porta Cabin Consist of With One Room and VerandahCivil TAPS34No ratings yet

- VFCS 21 7 FilterSeparatorDocument2 pagesVFCS 21 7 FilterSeparatorBruno HauckNo ratings yet

- Falling Film Transition and Heat Transfer On Horizontal Circular CylindersDocument4 pagesFalling Film Transition and Heat Transfer On Horizontal Circular CylindersAvijit KarmakarNo ratings yet

- Quarter 1 Module 7 - Concentration of SolutionsDocument16 pagesQuarter 1 Module 7 - Concentration of SolutionsJeline MacallaNo ratings yet

- Review of Related Literature: Performance Evaluation of Corn Cob-Derived Activated Carbon On The Removal of Mercury and Lead On Contaminated WaterDocument10 pagesReview of Related Literature: Performance Evaluation of Corn Cob-Derived Activated Carbon On The Removal of Mercury and Lead On Contaminated WaterKenneth John Anthony TabagNo ratings yet

- GE Dishwasher ManualDocument48 pagesGE Dishwasher ManualBrian KoenigbergNo ratings yet

- Fertilizer Catalogue (UreaN46 & DAP 18:46:0)Document7 pagesFertilizer Catalogue (UreaN46 & DAP 18:46:0)Ajay PandeyNo ratings yet

- UNIT # 1 Final Report of WDADocument38 pagesUNIT # 1 Final Report of WDArashmi006kiit8417No ratings yet

- Post-Tensioning Systems European Technical AssessmentDocument84 pagesPost-Tensioning Systems European Technical AssessmentMangisi Haryanto ParapatNo ratings yet

- Heat TreatmentDocument2 pagesHeat TreatmentAnonymous VRspXsmNo ratings yet

- College Roll No: Total No. of Printed Pages: 2: Semester: 5 Sub: Machining Science & TechnologyDocument2 pagesCollege Roll No: Total No. of Printed Pages: 2: Semester: 5 Sub: Machining Science & TechnologyPrabina PatnaikNo ratings yet

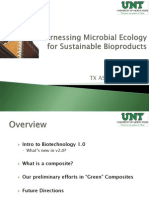

- UNT Kenaf ResearchDocument22 pagesUNT Kenaf Researchjmartin4800No ratings yet

- Die Max Die SpringsDocument16 pagesDie Max Die SpringsCarlos GranadaNo ratings yet

Durostone PCB Solder e

Durostone PCB Solder e

Uploaded by

aisyahhamidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Durostone PCB Solder e

Durostone PCB Solder e

Uploaded by

aisyahhamidCopyright:

Available Formats

Durostone® – PCB Solder Pallet Materials

High performance composite materials

specifically designed for the

PCB assembly process

Durostone®

Fibre reinforced plastics

Durostone®

PCB Solder Pallet Materials

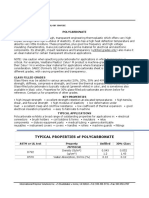

Durostone® materials have been developed for all

procedures within the PCB assembly process. There

are three main grades which are suitable for use

in the SMT reflow and wave soldering processes,

Durostone® CHP760, CAS761 & CAG762.

These materials offer the following features:

• Excellent mechanical properties at elevated

temperatures including the lead-free process.

• Low thermal conductivity.

• Excellent machining properties enabling the

manufacture of complex design solder pallets.

• Good resistance to chemicals used in

modern fluxes.

CHP760 CAS761 CAG762

2 | Röchling Engineering Plastics

Durostone®

Harsh environments

A combination of flux, temperature and process CFR767

cycles can result in the degradation of the standard

Durostone® grades of material.

The solution is Durostone® CFR767 which has

been specifically formulated for use with aggressive

fluxes and high process temperatures.

The resin used to produce Durostone® CFR767 can

withstand temperatures up to 300°C. The decision

to use Durostone® CFR767 over one of the standard

grades is made when the solder bath temperature

exceeds 265°C and the bottom side PCB pre-heat

exceeds 140°C.

Durostone® CFR767 has excellent flux resistance.

When fluxes containing halides or dicarboxylic

acids are used in high volume production the lifespan

of the standard grades of material can be reduced so

Durostone® CFR767 is an ideal solution.

Röchling Engineering Plastics | 3

Durostone®

Material Selector

The following flow chart Durostone®

enables the correct Material Selector

choice of material grade

depending on the

process parameters.

Does it contain ?

• halides (JSTD-004 types ORH1, ORM1)

Is the flux corrosive ? • succinic or adipic acid

(see MSDS, CAS n°: 110 -15 -6

No and 124 - 04 -9)

Yes

Does the solder bath Does the bottom side

exceed 265 °C ? Yes PCB pre-heat temperature Yes

exceed 140 °C ? Durostone®

CFR767

No

No

Are anti-static properties

required ?

Yes Does the material have to

be optically reflective for

infra-red sensors ?

No No Yes

Durostone® Durostone® Durostone®

CHP760 CAS761 CAG762

Röchling Engineering Plastics | 4

Technical Data CHP760 CAS761 CAG762 CFR767

Grade Standard Anti-Static Anti-Static Optical Flux Resistant

Colour Blue Black Grey Bordeaux (Red)

Density (g/cm 3) 1.90 1.90 1.90 1.80

@ 23°C 360 360 360 380

Flexural Strength

3 point support @ 150°C 180 180 180 260

(MPa)

@ 185°C – – – 150

@ 23°C 18,000 18,000 18,000 18,000

Modulus of Elasticity

(MPa)

@ 150°C 9,000 9,000 9,000 14,000

@185°C – – – 10,000

Water Absorption (%) < 0.20 < 0.20 < 0.20 < 0.20

Coefficient of Linear Expansion (10-6/K)

between 30°C & 200°C

13 11 11 11

Thermal Conductivity (W/m°K) 0.25 0.25 0.25 0.23

Maximum Operating Temperature (°C)

300 300 300 380

10 – 20 seconds

Standard Operating Temperature (°C) 260 260 260 300

Surface Resistivity (ohms) – 10 5 - 10 9 10 5 - 10 9 10 5 - 10 9

Chemical Resistance Good Good Good Excellent

Sheet Size (mm) 2440 x 1220

Thickness’ available (mm) 3, 4, 5, 6, 8, 10, 12 5, 6, 8, 10

Thickness Tolerance 3 mm -0 / +0.10

Thickness Tolerance 4 – 12 mm -0 / +0.20

Flatness Tolerance

0.20

(for a panel size of 300 x 300)

Parallelism 0.10

• All the values are average values.

are insulative (1012 Ω). According to JEDEC standard JESD625B, a static dissipative material

• Material is considered as not electrostatic dissipative (ESD) if more than 5 measurements / m²

is a material having a surface resistance between 104 and 1011 Ω.

• Cosmetic defects are not considered as non-conformities.

Due to the nature of glass fiber composite, the colour repartition is not guaranteed.

5 | Röchling Engineering Plastics

Röchling Röchling Roechling

Permali Composites S.A.S. Lützen SE & Co. KG Engineering Plastics (India) Pvt. Ltd.

8, Rue André Fruchard Planckstraße 3 302, A Wing

B.P.12, Maxéville 06686 Lützen/Germany Leo, 24th Road

54527 LAXOU Cedex/France Tel. +49 34444 308-0 Khar West, Mumbai - 400 052/India

Tel. +33 383 34 24 24 Fax +49 34444 308-10 Tel. +91 22 2648 22 61 or -62

Fax +33 383 32 23 18 kontakt@roechling-luetzen.de Fax +91 22 2648 22 63

info@permali.com www.roechling-luetzen.de durostone@roechling-india.com

www.permali.com/pallets

Röchling Roechling

Roechling Engineering Plastics (UK) Ltd. International (Shanghai) Co., Ltd.

Engineering Plastics Pte. Ltd. Waterwells Business Park 26/F Shanghai Times Square

No. 14 Tuas Avenue 8 Waterwells Drive Office Tower,

Singapore 639229/Singapore Gloucester GL2 4AA/Great Britain 93 Huai Hai Zhong Road

Tel. +65 6 863 18 77 Tel. +44 1452 72-7900 Shanghai 200021/P.R. China

Fax +65 6 863 17 66 Fax +44 1452 72-8056 Tel. +86 21 5117 6360

rep@roechling.com.sg sales@roechling-plastics.co.uk Fax +86 21 5117 7963

www.roechling-asia.com www.roechling-plastics.co.uk ris@roechling-plastics.com.cn

www.roechling-asia.com

Röchling Machined Plastics Röchling

161 Westec Drive Machined Plastics Italia s.r.l. Röchling Plásticos Técnicos, S.A.U.

Mount Pleasant, PA 15666/USA Via Boldrocchi 5/7 Ctra. Villena, s/n Apartado 34

Tel. +1 724 696-5200 20046 Biassono, Milano/Italy 46880 – Bocairent (Valencia) /Spain

Fax +1 724 696-5300 Tel. +39 039 2324324 Tel. +34 962 350 165

www.roechling.biz Fax +39 039 2324331 Fax +34 962 351 025

rmp@roechling.biz compositi@roechling.it commercial@roechling-plastics.es

www.roechling.it www.roechling-plastics.es

Durostone® stocking locations

grafikdesign/1110032/215.3 (GB)

You might also like

- Chem 136-LAB EDocument5 pagesChem 136-LAB Esidro12382% (11)

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- Balancing Chemical EquationDocument4 pagesBalancing Chemical Equationamin_zaman100% (1)

- Astm B686 PDFDocument8 pagesAstm B686 PDFpicnarukNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Specification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541Document2 pagesSpecification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541ex4182No ratings yet

- Araldite 2014-2: Advanced MaterialsDocument6 pagesAraldite 2014-2: Advanced MaterialsAnonymous r3MoX2ZMTNo ratings yet

- Alloy321 SpecSheetDocument2 pagesAlloy321 SpecSheetVinod tiwariNo ratings yet

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvNo ratings yet

- Araldite FT 420 AB ENDocument5 pagesAraldite FT 420 AB ENantoine DelesvauxNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- AV138M Araldite HV998 HardDocument6 pagesAV138M Araldite HV998 HardFilipe Alberto De MagalhãesNo ratings yet

- TIS 1665 e PDFDocument5 pagesTIS 1665 e PDFeduardo rochaNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Technical Data Sheet: Primerless MMA AdhesivesDocument3 pagesTechnical Data Sheet: Primerless MMA AdhesivespronavNo ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Araldit-STANDARD Datasheet PDFDocument3 pagesAraldit-STANDARD Datasheet PDFsiva shanmugamNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- Nci Test DataDocument21 pagesNci Test DataPig DookNo ratings yet

- How To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesDocument11 pagesHow To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesdNo ratings yet

- COLLANTE FCB 130 - Araldite - FT - AV138M-1 - HV998 - ENDocument4 pagesCOLLANTE FCB 130 - Araldite - FT - AV138M-1 - HV998 - ENMax SalogniNo ratings yet

- Araldite AV 138M-1 With Hardener HV 998: Advanced MaterialsDocument4 pagesAraldite AV 138M-1 With Hardener HV 998: Advanced MaterialsMajid TorabiNo ratings yet

- Araldite 2047-1: Advanced MaterialsDocument6 pagesAraldite 2047-1: Advanced MaterialsLiberio AragaoNo ratings yet

- MG Chemicals MARKERSDocument6 pagesMG Chemicals MARKERSMantasPuskoriusNo ratings yet

- SP-1386 Jun 2023Document5 pagesSP-1386 Jun 2023huicholeNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenNo ratings yet

- Brochure AlphaRod SuckerRodsDocument8 pagesBrochure AlphaRod SuckerRodsRicardo Pulido RamìrezNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Hardox 450 Plate: General Product DescriptionDocument2 pagesHardox 450 Plate: General Product Descriptiongorane11No ratings yet

- SikaAnchorFix2Arctic PdsDocument4 pagesSikaAnchorFix2Arctic PdsDragoș SturzoiuNo ratings yet

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Document8 pagesDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriNo ratings yet

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNo ratings yet

- Bronze Putty: Technical Data SheetDocument2 pagesBronze Putty: Technical Data SheetSharad ShahNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 pagesArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- CATALOG - Final - Low ResulotionDocument66 pagesCATALOG - Final - Low ResulotionKadiri El MoustaphaNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Iso Dis 23936-2appendix+a08Document33 pagesIso Dis 23936-2appendix+a08Abel Lopez JoachinNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- RTV160, RTV162 and RTV167 Electronic Grade Silicone Adhesive SealantsDocument4 pagesRTV160, RTV162 and RTV167 Electronic Grade Silicone Adhesive SealantspokleNo ratings yet

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- Hardox® 450: General Product DescriptionDocument2 pagesHardox® 450: General Product DescriptionAmal RajNo ratings yet

- 203-010 Griswold 6100 Family Product Data SheetDocument1 page203-010 Griswold 6100 Family Product Data Sheetjuan davidNo ratings yet

- WL115 0117 PE4710 Water PipeDocument8 pagesWL115 0117 PE4710 Water PipeEdwin MariacaNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALDocument8 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALAkbar Perwira UtamaNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- Midas Civil2013v3Document18 pagesMidas Civil2013v3silvereyes18No ratings yet

- Mds TPODocument3 pagesMds TPORicardo Andres Ojeda VidalNo ratings yet

- Plastics 2Document121 pagesPlastics 2AMIT PRAJAPATINo ratings yet

- Asme Section Viii, Division 1 InterpretationsDocument1,148 pagesAsme Section Viii, Division 1 InterpretationsajitNo ratings yet

- Comparison of Pipe Flow EquationsDocument6 pagesComparison of Pipe Flow EquationsJohn HarkenNo ratings yet

- Mill Lines by FlSmidthDocument4 pagesMill Lines by FlSmidthIrving Dirzo CarrilloNo ratings yet

- Brochure Polyurethane Materials For Vibration Isolation ENDocument12 pagesBrochure Polyurethane Materials For Vibration Isolation ENymukhtar897No ratings yet

- Beam Force Detail Summary: Beam L/C D FX Fy FZ MX My MZDocument1 pageBeam Force Detail Summary: Beam L/C D FX Fy FZ MX My MZThakshayani SellavelNo ratings yet

- 2 Manjunath-2018Document11 pages2 Manjunath-2018Nórida Pájaro GómezNo ratings yet

- Shark SC630 Manual enDocument23 pagesShark SC630 Manual enkrievkalnsgNo ratings yet

- Narra Park Residence - Two StoreyDocument11 pagesNarra Park Residence - Two StoreyJofel Jay Dumogho BarnuevoNo ratings yet

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument3 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingAriel FernandezNo ratings yet

- PD (Solmax Advanced Product Series)Document3 pagesPD (Solmax Advanced Product Series)kertaningNo ratings yet

- Portable Cabin Steel Porta Cabin Consist of With One Room and VerandahDocument7 pagesPortable Cabin Steel Porta Cabin Consist of With One Room and VerandahCivil TAPS34No ratings yet

- VFCS 21 7 FilterSeparatorDocument2 pagesVFCS 21 7 FilterSeparatorBruno HauckNo ratings yet

- Falling Film Transition and Heat Transfer On Horizontal Circular CylindersDocument4 pagesFalling Film Transition and Heat Transfer On Horizontal Circular CylindersAvijit KarmakarNo ratings yet

- Quarter 1 Module 7 - Concentration of SolutionsDocument16 pagesQuarter 1 Module 7 - Concentration of SolutionsJeline MacallaNo ratings yet

- Review of Related Literature: Performance Evaluation of Corn Cob-Derived Activated Carbon On The Removal of Mercury and Lead On Contaminated WaterDocument10 pagesReview of Related Literature: Performance Evaluation of Corn Cob-Derived Activated Carbon On The Removal of Mercury and Lead On Contaminated WaterKenneth John Anthony TabagNo ratings yet

- GE Dishwasher ManualDocument48 pagesGE Dishwasher ManualBrian KoenigbergNo ratings yet

- Fertilizer Catalogue (UreaN46 & DAP 18:46:0)Document7 pagesFertilizer Catalogue (UreaN46 & DAP 18:46:0)Ajay PandeyNo ratings yet

- UNIT # 1 Final Report of WDADocument38 pagesUNIT # 1 Final Report of WDArashmi006kiit8417No ratings yet

- Post-Tensioning Systems European Technical AssessmentDocument84 pagesPost-Tensioning Systems European Technical AssessmentMangisi Haryanto ParapatNo ratings yet

- Heat TreatmentDocument2 pagesHeat TreatmentAnonymous VRspXsmNo ratings yet

- College Roll No: Total No. of Printed Pages: 2: Semester: 5 Sub: Machining Science & TechnologyDocument2 pagesCollege Roll No: Total No. of Printed Pages: 2: Semester: 5 Sub: Machining Science & TechnologyPrabina PatnaikNo ratings yet

- UNT Kenaf ResearchDocument22 pagesUNT Kenaf Researchjmartin4800No ratings yet

- Die Max Die SpringsDocument16 pagesDie Max Die SpringsCarlos GranadaNo ratings yet