Professional Documents

Culture Documents

Good Weighing in Pharma - 2

Good Weighing in Pharma - 2

Uploaded by

RainMan750 ratings0% found this document useful (0 votes)

11 views3 pagesThis document discusses weighing accuracy and precision in the pharmaceutical industry. It defines key terms like accuracy, precision, and trueness in measuring mass. Accuracy refers to how close a measurement is to the true value, precision refers to the repeatability of measurements, and trueness is how close the average of repeated measurements is to the true value. The document notes that mass measurement is important in pharmaceutical manufacturing processes and that companies set acceptance criteria and weighing recommendations to help ensure product quality and safety.

Original Description:

Good Weighing in Pharma - 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses weighing accuracy and precision in the pharmaceutical industry. It defines key terms like accuracy, precision, and trueness in measuring mass. Accuracy refers to how close a measurement is to the true value, precision refers to the repeatability of measurements, and trueness is how close the average of repeated measurements is to the true value. The document notes that mass measurement is important in pharmaceutical manufacturing processes and that companies set acceptance criteria and weighing recommendations to help ensure product quality and safety.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views3 pagesGood Weighing in Pharma - 2

Good Weighing in Pharma - 2

Uploaded by

RainMan75This document discusses weighing accuracy and precision in the pharmaceutical industry. It defines key terms like accuracy, precision, and trueness in measuring mass. Accuracy refers to how close a measurement is to the true value, precision refers to the repeatability of measurements, and trueness is how close the average of repeated measurements is to the true value. The document notes that mass measurement is important in pharmaceutical manufacturing processes and that companies set acceptance criteria and weighing recommendations to help ensure product quality and safety.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

Good Weighing in Pharma -2

2.3. Random error

Random error is a measurement error component, which changes in unpredictable way

during

repeatable measurements. Random measurement error is equal to: measurement error

minus

systematic measurement error.

International Vocabulary of Terms in Legal Metrology -2.19 ( 3.13)

Random error results from various incidental factors (like for instance: temperature

oscillations, air movements in close distance from the measuring instrument). If

measuring results

of the same quantity are not repeatable, than it is caused by random error occurrence.

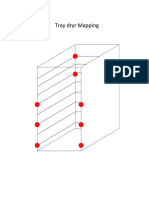

Fig 1. An instance of balance indications dispersion

2.4. Balance accuracy and precision

Evaluation of balances refers to terms and definitions like accuracy, precision and

trueness.

Proper utilization of these terms is required for proper control of balances.

Definition: accuracy

_ closeness of agreement between a measured quantity value and a true quantity value of

a

measurand. VIM *

_ difference between measurements average value and the real value according to USP**

-6-

Definition: precision

_ closeness of agreement between indications or measured quantity values obtained by

replicate measurements on the same or similar objects under specified conditions. VIM

Definition: trueness

_ closeness of agreement between the average of an infinite number of replicate

measured

quantity values and a reference quantity value according to VIM 2010

Below figures represent graphic interpretation of above definitions.

imprecisely, accurately

(values are wide-spread)

imprecisely, inaccurately

(values are wide-spread)

precise, inaccurately

(good balance repeatability)

precise, accurately

(good balance repeatability)

Fig 4 Balance accuracy and precision

(*) VIM – International Vocabulary of Terms in Legal Metrology

(**) USP – United States Pharmacopeia

-7-

3. Mass measurement in pharmaceutical industry

Manufacturing process of medicines has been and still is connected with smaller or

bigger risk

of error occurrence. In this case, the risk refers to introducing to market a medicine that is

harmful

for a patient. In order to avoid such situation, special attention has been paid for years to

quality

control process and its extension. However, it did not caused error elimination. Recently,

the

manufacturers opt for a concept of high quality medicines obtained through its design

“Quality by

Design”, and not control process of ready product. When describing Quality, it should

not be

evaluated by product test, but is should be “implemented into the product” or

guaranteed by

project design.

During most processes intended for formula elaborating, mass measurement should be

performed. The weighing quality significantly influences the quality of final result.

Therefore

acceptance criteria are defined by pharmaceutical companies and recommendations for

weighing

process are presented by American Pharmacopoeia*. Such recommendations are not

contained in

European Pharmacopoeia and that is why the companies that are not subordinate to

American

requirements, use their own balance estimation criteria.

(*) Pharmacopoeia, pharmacy code – the official list of medicines in a given country or

in the

market, and fortified by the same regulations inventory of substances for the manual

preparation of

some of the drugs in the pharmacy (prescription drugs). In Poland, official

pharmacopoeia is

Polish Pharmacopoeia, issued by Drugs, Medical Products and Bio-killers Register

Office. At

present, Polish Pharmacopoeia VIII is valid, edited in 2008,which is European

Pharmacopoeia 6.0

translated to Polish.

You might also like

- SOP For Room Particle Count TestDocument3 pagesSOP For Room Particle Count TestRainMan75100% (1)

- SOP For Airflow Velocity and Uniformity TestDocument3 pagesSOP For Airflow Velocity and Uniformity TestRainMan75100% (2)

- Sop of Cleaning and Operation of Dispensing BoothDocument3 pagesSop of Cleaning and Operation of Dispensing BoothRainMan7575% (4)

- Measurement of UncertaintyDocument27 pagesMeasurement of Uncertaintydrs_mdu48No ratings yet

- Blend Uniformity AnalysisDocument16 pagesBlend Uniformity AnalysisUrsula Hille100% (1)

- List of Pharmaceutical Companies in INDIA (Address and Phone NO) - PharmexcelDocument22 pagesList of Pharmaceutical Companies in INDIA (Address and Phone NO) - PharmexcelKarthikeyan radhakrishnan75% (4)

- Good Weighing in Pharma - 4Document6 pagesGood Weighing in Pharma - 4RainMan75No ratings yet

- PHAP AssignmentDocument9 pagesPHAP Assignmentarmand bayoranNo ratings yet

- Good Weighing in Pharma - 5Document4 pagesGood Weighing in Pharma - 5RainMan75No ratings yet

- Working Paper Series: College of Business Administration University of Rhode IslandDocument25 pagesWorking Paper Series: College of Business Administration University of Rhode IslandDeivid Zharatte Enry QuezNo ratings yet

- Acceptance Criteria 8Document11 pagesAcceptance Criteria 8abdelaziz_ismail685662No ratings yet

- 8.2.2 LAP Guidance On The Estimation of Uncertainty of Measurement - R1Document18 pages8.2.2 LAP Guidance On The Estimation of Uncertainty of Measurement - R1Catalina CiocanNo ratings yet

- Why You Never Really Validate Your Analytical Method Unless You Use The Total Error Approach (Part I: Concept)Document10 pagesWhy You Never Really Validate Your Analytical Method Unless You Use The Total Error Approach (Part I: Concept)ConnieNo ratings yet

- Basic Principles of Engineering MetrologyDocument25 pagesBasic Principles of Engineering MetrologyRay DebashishNo ratings yet

- Estimating and Reporting Measurement Uncertainty of Chemical Test ResultsDocument13 pagesEstimating and Reporting Measurement Uncertainty of Chemical Test ResultsTandhi_WahyonoNo ratings yet

- Hemwati Nandan Bahuguna Garhwal University (A Central University) Srinagar Garhwal, Uttarakhand, 246174Document10 pagesHemwati Nandan Bahuguna Garhwal University (A Central University) Srinagar Garhwal, Uttarakhand, 246174aadrika negiNo ratings yet

- SMEA1301Document137 pagesSMEA1301Nandha Gopal SenthilnathanNo ratings yet

- Pharmaceutical MeasurementDocument9 pagesPharmaceutical Measurementmematugoldahmunu21No ratings yet

- Risk Benefit FinalDocument7 pagesRisk Benefit FinalgoaltechNo ratings yet

- STUCOR - ME8501-SF MM 2 PDFDocument148 pagesSTUCOR - ME8501-SF MM 2 PDFHema TharunNo ratings yet

- Guidelines For Estimating and Reporting Measurement Uncertainty of Chemical Test ResultsDocument11 pagesGuidelines For Estimating and Reporting Measurement Uncertainty of Chemical Test ResultsAlexandr ChuvakovNo ratings yet

- Pharmacoeconomics LceDocument118 pagesPharmacoeconomics LceHope GemidaNo ratings yet

- Pharmacoeconomics in HealthcareDocument8 pagesPharmacoeconomics in HealthcareDyah Ayuwati WaluyoNo ratings yet

- QC & QA Lecture Week 2-4Document24 pagesQC & QA Lecture Week 2-4Richard Simon KisituNo ratings yet

- Safety Data GenerationDocument10 pagesSafety Data Generationaadrika negiNo ratings yet

- CXG - 054e 2021Document7 pagesCXG - 054e 2021Nguyen Hien Duc HienNo ratings yet

- Technical Note 33Document13 pagesTechnical Note 33toantranpro100% (1)

- Evaluation of IPMDocument23 pagesEvaluation of IPMJerzon VillacencioNo ratings yet

- Core Tools: Measurement Systems Analysis (MSA)Document6 pagesCore Tools: Measurement Systems Analysis (MSA)Salvador Hernandez ColoradoNo ratings yet

- Use Pharmaceutical Calculation Techniques and TerminologiesDocument62 pagesUse Pharmaceutical Calculation Techniques and TerminologiesKena Samuel100% (3)

- UCM092149Document6 pagesUCM092149rpbpaNo ratings yet

- Identification of Demand Forecasting Model Considering Key Factors in The Context of Healthcare ProductsDocument5 pagesIdentification of Demand Forecasting Model Considering Key Factors in The Context of Healthcare ProductsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- EPA Ireland Agency Requirements For Applying Measurement Uncertainty MU To Periodic Air MonitoringDocument6 pagesEPA Ireland Agency Requirements For Applying Measurement Uncertainty MU To Periodic Air MonitoringHelder DuraoNo ratings yet

- FME UNIT-5 Notes Part-1Document44 pagesFME UNIT-5 Notes Part-1Neel's Official100% (1)

- Environmental Monitoring Risk AssessmentDocument22 pagesEnvironmental Monitoring Risk AssessmentMarcelo CarvalhoNo ratings yet

- J Diabetes Sci Technol 2009 Ginsberg 903 13Document11 pagesJ Diabetes Sci Technol 2009 Ginsberg 903 13Ninosk Mendoza SolisNo ratings yet

- Concepto de InertidumbreDocument6 pagesConcepto de InertidumbrePaul Avelino CallupeNo ratings yet

- Paper6 Actuarial Methodology For Evaluating DMDocument30 pagesPaper6 Actuarial Methodology For Evaluating DMImran AhsanNo ratings yet

- Peer-Reviewed: Submitted: Nov. 21, 2017. Accepted: Jan. 4, 2018Document3 pagesPeer-Reviewed: Submitted: Nov. 21, 2017. Accepted: Jan. 4, 2018Catrinescu OanaNo ratings yet

- VALIDACIJA TechnicalNote17apr09Document9 pagesVALIDACIJA TechnicalNote17apr09dabicdarioNo ratings yet

- Measurement & MetrologyDocument106 pagesMeasurement & MetrologyMURSELIM ALINo ratings yet

- What Is Pharmacoeconomics?Document4 pagesWhat Is Pharmacoeconomics?pinto princeNo ratings yet

- The Use of Control ChartsDocument16 pagesThe Use of Control ChartsAmeer MuhammadNo ratings yet

- Bland Altman Measuring Comparison StudiesDocument27 pagesBland Altman Measuring Comparison StudiesirdinamarchsyaNo ratings yet

- Making Sense of Trueness, Precision, Accuracy, and UncertaintyDocument5 pagesMaking Sense of Trueness, Precision, Accuracy, and UncertaintyJoe Luis Villa MedinaNo ratings yet

- Ema - Noel & NoaelDocument3 pagesEma - Noel & NoaelMahesh GavasaneNo ratings yet

- Smart Review of Marketing Authorisation Applications and Product Lifecycle Management: Future and ChallengesDocument8 pagesSmart Review of Marketing Authorisation Applications and Product Lifecycle Management: Future and ChallengesRAPPORTS DE PHARMACIENo ratings yet

- The Epidemiology of Medication Errors: The Methodological DifficultiesDocument7 pagesThe Epidemiology of Medication Errors: The Methodological DifficultiesgabyvaleNo ratings yet

- Analytic Method Development and Validation: MT MVDocument2 pagesAnalytic Method Development and Validation: MT MVRaja AbhilashNo ratings yet

- Risk Management in The IndustryDocument13 pagesRisk Management in The IndustryLetchmy NathanNo ratings yet

- Principles of PharmacoeconomicsDocument9 pagesPrinciples of Pharmacoeconomicsshafinaz12No ratings yet

- Control Banding B NaumannDocument11 pagesControl Banding B NaumannipliprensNo ratings yet

- Measurement Systems Analysis (MSA) : What Are Measurement Data and Measurement Variation?Document12 pagesMeasurement Systems Analysis (MSA) : What Are Measurement Data and Measurement Variation?Harika KalluriNo ratings yet

- Public Health BNNNDocument8 pagesPublic Health BNNNOmpal SinghNo ratings yet

- Accuracy and PrecisionDocument4 pagesAccuracy and PrecisionbismashakilsNo ratings yet

- Clinical Safety Data Management AE SAE ADR ReportingDocument10 pagesClinical Safety Data Management AE SAE ADR ReportingIvan KolevNo ratings yet

- Bulk and Sterile ManufacturingDocument18 pagesBulk and Sterile ManufacturingRobert PonziNo ratings yet

- Quality Risk Management PharmDocument9 pagesQuality Risk Management Pharmagarciah15891No ratings yet

- Measurement System AnalysisDocument7 pagesMeasurement System AnalysisselvamNo ratings yet

- 97 Statistical Control of The Measurement ProcessDocument9 pages97 Statistical Control of The Measurement ProcesseuszkoNo ratings yet

- 1 StabilityDocument20 pages1 StabilitykanhaiyabattaseNo ratings yet

- Quality Risk Management SopDocument9 pagesQuality Risk Management Sopselinasimpson1301100% (1)

- The Duty for Sponor Oversight in Clinical Trials: Practical Guide: 2nd Edition Clinical Data ReviewFrom EverandThe Duty for Sponor Oversight in Clinical Trials: Practical Guide: 2nd Edition Clinical Data ReviewNo ratings yet

- SOP On Transferring Finished Products To Finished Goods StoresDocument3 pagesSOP On Transferring Finished Products To Finished Goods StoresRainMan7567% (3)

- PW Specification USPDocument2 pagesPW Specification USPRainMan75No ratings yet

- SOP On Operating Procedure For Conveyor BeltDocument2 pagesSOP On Operating Procedure For Conveyor BeltRainMan75No ratings yet

- SOP For Disintegration Test ApparatusDocument4 pagesSOP For Disintegration Test ApparatusRainMan75No ratings yet

- Laminar Air Flow SpecificationDocument2 pagesLaminar Air Flow SpecificationRainMan75No ratings yet

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75No ratings yet

- Sampling Procedure by ISO KineticDocument2 pagesSampling Procedure by ISO KineticRainMan75No ratings yet

- Types of Lubricants Used For Phrmaceutical MachinesDocument2 pagesTypes of Lubricants Used For Phrmaceutical MachinesRainMan75No ratings yet

- Try DryerDocument2 pagesTry DryerRainMan75No ratings yet

- CAPA Corrective and Preventive Action in PharmaceuticalDocument5 pagesCAPA Corrective and Preventive Action in PharmaceuticalRainMan75No ratings yet

- Aseptic and Sterile in PharmaceuticalDocument2 pagesAseptic and Sterile in PharmaceuticalRainMan75No ratings yet

- SOP OF Operating and Cleaning Procedure For Vacuum CleanerDocument2 pagesSOP OF Operating and Cleaning Procedure For Vacuum CleanerRainMan75No ratings yet

- Sop of Operation & Cleaning of Distillation AssemblyDocument2 pagesSop of Operation & Cleaning of Distillation AssemblyRainMan75No ratings yet

- SOP For Installed Filter Leakage TestDocument2 pagesSOP For Installed Filter Leakage TestRainMan75100% (1)

- Sop of Operation and Cleaning of Mechanical StirrerDocument3 pagesSop of Operation and Cleaning of Mechanical StirrerRainMan75100% (1)

- Procedure For Planned Internal Quality Audits in PharmaDocument5 pagesProcedure For Planned Internal Quality Audits in PharmaRainMan75No ratings yet

- Sop of Operating Procedure For Operation and Cleaning of Insect Killer EquipmentDocument2 pagesSop of Operating Procedure For Operation and Cleaning of Insect Killer EquipmentRainMan75100% (1)

- SOP On Storage and Labeling of Raw and Packing MaterialsDocument2 pagesSOP On Storage and Labeling of Raw and Packing MaterialsRainMan75No ratings yet

- Training SOP Part - 1Document4 pagesTraining SOP Part - 1RainMan75No ratings yet

- Training SOP Part - 3Document4 pagesTraining SOP Part - 3RainMan75No ratings yet

- Entry Exit Procedure SOPDocument4 pagesEntry Exit Procedure SOPRainMan75100% (1)

- Training SOP Part - 2Document3 pagesTraining SOP Part - 2RainMan75No ratings yet

- Good Weighing in Pharma - 4Document6 pagesGood Weighing in Pharma - 4RainMan75No ratings yet

- SOP For Hot Air Oven Cleaning, Operation & Calibration of Hot Air OvenDocument3 pagesSOP For Hot Air Oven Cleaning, Operation & Calibration of Hot Air OvenRainMan75100% (1)

- Good Weighing in Pharma - 5Document4 pagesGood Weighing in Pharma - 5RainMan75No ratings yet

- SOP For Cleaning, Operation & Calibration of Hot Plate ApparatusDocument3 pagesSOP For Cleaning, Operation & Calibration of Hot Plate ApparatusRainMan75100% (1)

- Good Weighing in Pharma - 3Document4 pagesGood Weighing in Pharma - 3RainMan75No ratings yet

- Tracheostomy Techniques and ManagementDocument9 pagesTracheostomy Techniques and Managementtaner_soysuren100% (1)

- 4 Life TestimoniesDocument87 pages4 Life TestimoniesBhavin VoraNo ratings yet

- Role Play Asthma Bahasa Inggris: Disusun OlehDocument7 pagesRole Play Asthma Bahasa Inggris: Disusun OlehSiti lestarinurhamidahNo ratings yet

- 14.ergonomic Workstation Design For Science Laboratory (Norhafizah Rosman) PP 93-102Document10 pages14.ergonomic Workstation Design For Science Laboratory (Norhafizah Rosman) PP 93-102upenapahangNo ratings yet

- Courts Quietly Confirm MMR Vaccine Causes AutismDocument2 pagesCourts Quietly Confirm MMR Vaccine Causes AutismGordon LoganNo ratings yet

- Nurs 4011 Care Plan-Concept Map 2Document8 pagesNurs 4011 Care Plan-Concept Map 2api-650043935No ratings yet

- Inflammatory Lesions of The JawsDocument54 pagesInflammatory Lesions of The JawsAi Rafikah Nurpratiwi100% (1)

- DNB CetssDocument21 pagesDNB CetssRinku RinkuNo ratings yet

- Postinfectious Bronchiolitis Obliterans in Children.2020Document16 pagesPostinfectious Bronchiolitis Obliterans in Children.2020carlaNo ratings yet

- Dum SpiroDocument2 pagesDum SpiroSundaresan MNo ratings yet

- Cardiac AssessmentDocument11 pagesCardiac Assessmentwaqas_xsNo ratings yet

- presented By:-: Sujit R. Patel Department of Pharmaceutics, Maratha Mandal's College of Pharmacy, BelgaumDocument33 pagespresented By:-: Sujit R. Patel Department of Pharmaceutics, Maratha Mandal's College of Pharmacy, BelgaumBandameedi RamuNo ratings yet

- Patient-Centered Care at The End of Life.07Document52 pagesPatient-Centered Care at The End of Life.07api-3755169100% (1)

- Pharmacy Propos 2Document3 pagesPharmacy Propos 2Momo RhieNo ratings yet

- Orthopedic PDFDocument47 pagesOrthopedic PDFSiraj HaiderNo ratings yet

- Internet AddictionDocument6 pagesInternet AddictionstupidshitNo ratings yet

- Carcinoma Buccal Mucosa: Dr. Abhilash G JR-3Document47 pagesCarcinoma Buccal Mucosa: Dr. Abhilash G JR-3LingeshNo ratings yet

- IDJ Vol 7 1Document6 pagesIDJ Vol 7 1Saatvik AtriNo ratings yet

- Ddg.13546.Doc BenerDocument25 pagesDdg.13546.Doc Benernailatul fadhilaNo ratings yet

- English PresentationDocument24 pagesEnglish PresentationAnnaNo ratings yet

- A Study To Evaluate The Effectiveness of Video Assisted Teaching (VAT) On Knowledge Regarding Stroke Rehabilitation Among The Caregivers of Stroke Patients in Selected Hospitals, Hassan, KarnatakaDocument15 pagesA Study To Evaluate The Effectiveness of Video Assisted Teaching (VAT) On Knowledge Regarding Stroke Rehabilitation Among The Caregivers of Stroke Patients in Selected Hospitals, Hassan, KarnatakaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chapter 1Document8 pagesChapter 1Reynald Tracy C. MagnoNo ratings yet

- Hospital KPIDocument22 pagesHospital KPIjayeshEPGP100% (1)

- Good Practitioners Guide 2016Document52 pagesGood Practitioners Guide 2016savrasxNo ratings yet

- Hospital French PDFDocument52 pagesHospital French PDFDavina GaskinNo ratings yet

- Gastric PathologyDocument11 pagesGastric PathologyAndra BauerNo ratings yet

- Monthly & Weekly Report of Health PostDocument13 pagesMonthly & Weekly Report of Health PostDSK CAIDNo ratings yet

- (Oleaceae) Aedes AegyptiDocument23 pages(Oleaceae) Aedes AegyptiEmil Sasil VloggsNo ratings yet

- Memorial For The ComplainantDocument32 pagesMemorial For The ComplainantArpit BansalNo ratings yet