Professional Documents

Culture Documents

Trio Impact Horizontal Crushers Brochure

Trio Impact Horizontal Crushers Brochure

Uploaded by

Oliver CabanillasCopyright:

Available Formats

You might also like

- Andrea Larosa 4 Weeks Calisthenics Training Program (Beginner)Document26 pagesAndrea Larosa 4 Weeks Calisthenics Training Program (Beginner)Dimitry Donaire Flores100% (8)

- YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesYL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- RX 60 30 Still ManualDocument6 pagesRX 60 30 Still ManualDavid Klachuk50% (2)

- PBH-PBM_EN-2Document20 pagesPBH-PBM_EN-2DAVID F. GARCIANo ratings yet

- Recycling MachinesDocument22 pagesRecycling MachinesDuško LaštroNo ratings yet

- Shaping Machines: Machine Tool Exporters To The World Since 1940Document4 pagesShaping Machines: Machine Tool Exporters To The World Since 1940pedjaNo ratings yet

- TNN CNC Lathe Machine CatalogueDocument3 pagesTNN CNC Lathe Machine Catalogueneda100% (1)

- Drills 7 TappersDocument10 pagesDrills 7 TappersBe HappyNo ratings yet

- Trelleborg Elastomeric Bridge Bearings PDFDocument4 pagesTrelleborg Elastomeric Bridge Bearings PDFMad WonderNo ratings yet

- Belt Cleaner: Head PulleyDocument7 pagesBelt Cleaner: Head PulleyAgung Pandega PutraNo ratings yet

- HP Strongdrain FRP Cover PL 10-10-2018Document1 pageHP Strongdrain FRP Cover PL 10-10-2018AMOLNo ratings yet

- 1610454833nowicki Bowl CuttersDocument20 pages1610454833nowicki Bowl Cuttersjanna ibrahimNo ratings yet

- Schiavi Enc Met Page097Document1 pageSchiavi Enc Met Page097Adel AdelNo ratings yet

- NEW Gelen Catalog-EnglishDocument40 pagesNEW Gelen Catalog-Englishsam saminNo ratings yet

- Base Hinged Masts Technical Data PDFDocument1 pageBase Hinged Masts Technical Data PDFgarpheetNo ratings yet

- 4e HydraulischePressen PDFDocument28 pages4e HydraulischePressen PDFDenis Yasmin AlineNo ratings yet

- BIDAPRO 600x600Document9 pagesBIDAPRO 600x600deborazoletNo ratings yet

- CNC Glass Cutting TableDocument6 pagesCNC Glass Cutting TableMarcel PiersonNo ratings yet

- Stone Jaw CrusherDocument2 pagesStone Jaw CrusherKarin AndersonNo ratings yet

- Material HandlingDocument36 pagesMaterial HandlingvishnusankarNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- SNXR Series - 2023Document2 pagesSNXR Series - 2023isgectraineeNo ratings yet

- Amafilter Cricketfilter For Wet Cake Discharge 20210414Document2 pagesAmafilter Cricketfilter For Wet Cake Discharge 20210414virus40No ratings yet

- Agarwalla: Bpa Projects PVT LTDDocument16 pagesAgarwalla: Bpa Projects PVT LTDKarin Anderson100% (1)

- Sevak Price ListDocument14 pagesSevak Price ListPentagon LeadNo ratings yet

- Vtech Catalog Scissor Lifts, Dock Leveler, Baling PressDocument4 pagesVtech Catalog Scissor Lifts, Dock Leveler, Baling PressORDER REPORTNo ratings yet

- Wittur Range of Systems: Machine Roomless EfficiencyDocument16 pagesWittur Range of Systems: Machine Roomless EfficiencyLe Huynh LongNo ratings yet

- Trio Grizzly Feeders - TF Series: Product CollectionDocument2 pagesTrio Grizzly Feeders - TF Series: Product CollectionEnso E Rosales FNo ratings yet

- MC Injection Spec2023Document1 pageMC Injection Spec2023anandan777No ratings yet

- 2A UAG Dimensions EN81-1Document1 page2A UAG Dimensions EN81-1engineer63No ratings yet

- Brochure Mistral eDocument2 pagesBrochure Mistral ecelia.miguel.martinsNo ratings yet

- Roller Beds at PEMADocument8 pagesRoller Beds at PEMASadashiva sahooNo ratings yet

- Elektra 315 EngDocument8 pagesElektra 315 EngNitesh SinghNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- Rolling 3Document2 pagesRolling 3danaandrei74No ratings yet

- Neco Hubless CI Pipe Price List 2022Document1 pageNeco Hubless CI Pipe Price List 2022Kevin MaldeNo ratings yet

- Covers Whip SockDocument1 pageCovers Whip SockMichaël AlbaneseNo ratings yet

- Telescopic Forks, Type TFP: Cap. 2500 - 5000 (KG)Document2 pagesTelescopic Forks, Type TFP: Cap. 2500 - 5000 (KG)kumbrovNo ratings yet

- ByStar Fiber Datasheet Eng Original 14278Document2 pagesByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhNo ratings yet

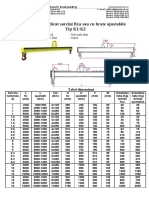

- Grinda de Ridicat Cu Brate Ajustabile K1K2Document1 pageGrinda de Ridicat Cu Brate Ajustabile K1K2Cristina CojocariuNo ratings yet

- Model Jaw Vertical ConeDocument4 pagesModel Jaw Vertical ConerianNo ratings yet

- Cricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Document2 pagesCricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Dwi Agus DermawanNo ratings yet

- Centamax B CouplingDocument6 pagesCentamax B Couplingmecanicas alaynaNo ratings yet

- Load CHRT CLMNDocument2 pagesLoad CHRT CLMNVivekNo ratings yet

- Spech - GranatesDocument4 pagesSpech - GranatesSUBHASH NAIRNo ratings yet

- UntitledDocument12 pagesUntitledAngel Rodriguez PizarroNo ratings yet

- UPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber SimplexDocument4 pagesUPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber Simplexwaqasasad408No ratings yet

- Seal 'N Devices 2018 CatalogueDocument13 pagesSeal 'N Devices 2018 CatalogueBarryNo ratings yet

- Scissor LiftDocument2 pagesScissor Liftnaswc.jiooNo ratings yet

- Erke Catalog enDocument52 pagesErke Catalog enKarbonKale100% (1)

- LICODocument16 pagesLICOAmrNo ratings yet

- Cosmos Imtex Die MouldDocument2 pagesCosmos Imtex Die MouldAbhishek Velaga100% (2)

- Horizontal Boring MillsDocument2 pagesHorizontal Boring MillsRaluca UrseNo ratings yet

- Bus Bar Selection Chart AluminiumDocument1 pageBus Bar Selection Chart AluminiumJit0% (1)

- JP Balancer Catalog 2022-LDocument19 pagesJP Balancer Catalog 2022-Lisidromundarain67No ratings yet

- Cooler CopmaritiveDocument3 pagesCooler Copmaritiveirfan.ali0463No ratings yet

- 02 PRO Series Jaw Crushers 2Document2 pages02 PRO Series Jaw Crushers 2gopinath chitturiNo ratings yet

- 2022 New Catalog - JP BalancerDocument19 pages2022 New Catalog - JP Balancerdiwa tataNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Iala Model Course: L2.1.8 Aids To Navigation - Technician Training Module 1 Element 8 Level 2 - Buoy CleaningDocument9 pagesIala Model Course: L2.1.8 Aids To Navigation - Technician Training Module 1 Element 8 Level 2 - Buoy CleaningRodrigo BaienseNo ratings yet

- Conversion of Units of Volume and Capacity: WorkedDocument1 pageConversion of Units of Volume and Capacity: WorkedPaul TurnerNo ratings yet

- User Analysis SampleDocument8 pagesUser Analysis Samplecece vergieNo ratings yet

- Jabsco Marine Product Guide 2006.Document24 pagesJabsco Marine Product Guide 2006.m_najmanNo ratings yet

- Colligative Freezing Point DeppressionDocument40 pagesColligative Freezing Point Deppressiongillianmarie.perez.pharmaNo ratings yet

- TỔNG HỢP CÁC ĐỀ CHUYÊN ANH QUỐC HỌC CÁC NĂMDocument61 pagesTỔNG HỢP CÁC ĐỀ CHUYÊN ANH QUỐC HỌC CÁC NĂMLan Phong TranNo ratings yet

- 780B-780C Spec (99014) D.1Document1 page780B-780C Spec (99014) D.1Cristobal ArayaNo ratings yet

- Acp CBC 1Document52 pagesAcp CBC 1Danny R. SalvadorNo ratings yet

- CVDocument3 pagesCVshahbaz akramNo ratings yet

- PDF SSCP Systems Security Certified Practitioner All in One Exam Guide 3Rd Edition Gibson Ebook Full ChapterDocument53 pagesPDF SSCP Systems Security Certified Practitioner All in One Exam Guide 3Rd Edition Gibson Ebook Full Chapterdiane.vant368100% (2)

- Engelhardt BioethicsDocument9 pagesEngelhardt BioethicsAaron Lee WiegmannNo ratings yet

- Mitchell 2005Document8 pagesMitchell 2005DianNo ratings yet

- Vocabulary 3Document5 pagesVocabulary 3Huyền ThuNo ratings yet

- Information Technology System Applicable To Nursing PracticeDocument56 pagesInformation Technology System Applicable To Nursing PracticeKristle Ann VillarealNo ratings yet

- Scope and Sequence - Cookery - 10Document1 pageScope and Sequence - Cookery - 10JP AballeNo ratings yet

- The Antibacterial Mechanism of Silver Nanoparticles and Its Application in DentistryDocument8 pagesThe Antibacterial Mechanism of Silver Nanoparticles and Its Application in DentistryabdulrazaqNo ratings yet

- Biotech DirectoryDocument56 pagesBiotech DirectorySreesanth SaruvilNo ratings yet

- Autoclave - Kaizen ImperialDocument3 pagesAutoclave - Kaizen ImperialAnaThomasNo ratings yet

- GlyphosateDocument7 pagesGlyphosateantonio leonNo ratings yet

- Gadget Building 2016Document36 pagesGadget Building 2016Kelvin MsafiriNo ratings yet

- Pbl-Gin Urine Test (Feme)Document11 pagesPbl-Gin Urine Test (Feme)KarthigaRamanNo ratings yet

- CourseDocument2 pagesCourseRNo ratings yet

- Reviews of Environmental Contamination and Toxicology - Continuation of Residue ReviewsDocument232 pagesReviews of Environmental Contamination and Toxicology - Continuation of Residue ReviewsYoNo ratings yet

- Is QualityDocument14 pagesIs QualityArathy VikramNo ratings yet

- Dup TemplateDocument5 pagesDup TemplateJoshua SouthNo ratings yet

- Navi Gi PolicyDocumentSA006T0VDocument25 pagesNavi Gi PolicyDocumentSA006T0Vdattam venkateswarluNo ratings yet

- Definition of Biomedical Model of HealthDocument4 pagesDefinition of Biomedical Model of Healthتالیہ مرادNo ratings yet

- 07 Gyproc Eas-Fill COSHH Ass'tDocument2 pages07 Gyproc Eas-Fill COSHH Ass'tphil.jacksonNo ratings yet

- UV Curing Inkjet IssuesDocument7 pagesUV Curing Inkjet IssuesAshish Jain100% (1)

Trio Impact Horizontal Crushers Brochure

Trio Impact Horizontal Crushers Brochure

Uploaded by

Oliver CabanillasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trio Impact Horizontal Crushers Brochure

Trio Impact Horizontal Crushers Brochure

Uploaded by

Oliver CabanillasCopyright:

Available Formats

2012

TRIO APP and APS Series

Horizontal Shaft Impact Crushers

Versatile, High Production Crushers

Building Solutions Together

WWW.TRIOPRODUCTS.COM

Rugged Primary and Secondary Jaw Crushers Horizontal Shaft Impact Crushers

ROTOR SIZE POWER WEIGHT SPEED CAPACITY

TRIO offers two configurations of impact crushers: the APP Series for high-production primary and recycling MODELS INCH MM HP KW LBS KG RPM TPH

applications, and the APS Series for high production secondary or recycling applications. All models are available APP4354 43"x54" 1100x1370 250 160-200 38500 17500 350-600 200-350

as bare units, and as stationary and portable configurations. APP5148 51"x48" 1295x1220 300 200-250 48500 22050 350-600 200-500

APP5560 55"x60" 1400x1525 500 315-355 56595 25665 350-600 375-700

APP6384 63"x84" 1600x2130 350x2 315x2-355x2 101800 46273 350-500 500-1050

The machines are all equipped with solid rotors in either 2, 3 or 4 row blow bar configurations. These extra-heavy

APP8084 80"x84" 2030x2130 1400 1000-1200 26756 59000 250-400 600-2000

duty solid rotor units provide the mass and strength necessary to crush feed material up to 36”. Comparisons with

APS3030 30"x30" 760x760 75 50 9218 4190 700-1000 Varies

other brands will show that TRIO crushers are among the most heavy-duty machines available. Important features APS4034 40"x34" 1015x865 150 90-110 20730 9400 450-700 100-250

to consider are: bearing size, shaft diameter, total machine weight and blow bar weight. APS4054 40"x54" 1015x1370 250 132-160 29110 13200 450-700 120-300

APS5148 51"x48" 1295x1220 300 200-250 40700 18500 450-650 160-350

Applications APS5160 51"x60" 1295x1525 350 250-315 48800 22130 450-650 200-400

• Primary & secondary hard rock crushing • Asphalt APS6084 60"x84" 1525x2135 350x2 400-250x2 93760 42620 300-500 320-600

• Mixed demolition debris • River rock

• Crushed or broken concrete • Industrial applications Primary Impact Crushers

Open Circuit Maximum Capacity (TPH)

D max Inch-MM 24”(600) 32"(800) 40”(1000)

d 90 < Inch-MM 4"-100 8"-200 4"-100 8"-200 10"-250 4"-100 8"-200 10"-250 12"-300

APP4354 190 300

APP5148 200 320 220 320 350 200 250 300 350

APP5160 250 400 280 400 430 250 280 350 430

Average

Impact work APP5184 350 550 400 570 600 300 350 400 600

Index - 18

APP6060 380 500 480 660 510 320 390 460 600

APP6084 525 700 480 660 700 450 550 650 850

APP6096 600 800 550 750 800 510 630 740 970

APP4354 250 360 220 320

APP5148 280 400 240 360 400 240 280 360 400

APP5160 350 500 300 450 500 300 350 450 500

Average

Impact work APP5184 500 700 400 600 700 400 500 600 700

Index - 14

APP6060 400 600 400 540 650 450 500 600 720

APP6084 700 840 650 750 900 620 700 840 1000

APP6096 800 960 740 860 1030 720 800 960 1150

Product Gradations (Percent Passing)

d 90= 4” 6” 8” 10” 12” 4” 6” 8” 10” 12”

Inch-MM 100MM 150MM 200MM 250MM 300MM 100MM 150MM 200MM 250MM 300MM

>12”(300) 100 100 100 100

12”(300) 100 94 90 100 95 90

10”(250) 100 95 a 82 100 96 90 82

8”(200) 96 90 82 75 98 90 82 75

7”(175) 93 80 75 62 94 80 75 62

APP & APS Series Features 6”(150) 100 90 70 65 55 100 90 70 65 55

• Versatile selection satisfies most applications • Rotor designed to minimize likelihood of 5”(125) 96 82 60 55 42 96 85 60 55 42

4”(100) 90 68 50 45 30 90 70 50 45 30

and operator preferences catastrophic damage by blow bar breakage

3 1/8 “(80) 70 58 42 37 28 78 60 42 37 28

• Routinely installed in stationary and portable • Greased oversize bearings 2 1/2”(63) 55 42 35 30 20 65 48 35 30 20

crushing systems • Hydraulically operated hoods 2”(50) 40 32 28 23 15 48 40 28 23 15

• Extra heavy duty solid rotor construction • Blow bars availablev in manganese and 1 9⁄16”(40) 30 25 15 18 10 40 32 22 18 10

• Two, three and four-row configurations various compositions of chrome steels 1”(25) 20 15 8 5 3 30 25 15 10 4

• Hydraulic adjustment mechanisms for • Improved service life of critical components 4#(4.75) 5 3 1 0 0 10 8 5 3 0

primary and secondary curtains • Lower maintenance & operating costs

• Operator friendly centrifugal wedge system APP and APS SERIES SHAFT IMPACT CRUSHER TRIOPRODUCTS.COM

www.trioproducts.com

Data for marketing purposes only. Please contact TRIO for product information. Capacities are suggested only and wholly dependent on material type and condition. Data for marketing purposes only. Please contact TRIO for product information. Capacities are suggested only and wholly dependent on material type and condition.

Secondary Impact Crushers

Open Circuit Maximum Capacity (TPH)

D max Inch-MM 24”(600) 32"(800) 40”(1000)

d 90 < Inch-MM 4"-100 8"-200 4"-100 8"-200 10"-250 4"-100 8"-200 10"-250 12"-300

APS4034 100 170 75 150 60 100

APS4054 130 250 120 200 110 180

APS4334 145 275 132 220 120 200 110 165

Average

Impact work APS5148 190 280 160 270 150 230 120 200 110 200 220

Index - 18

APS5160 250 350 220 350 200 300 150 250 140 220 280

APS5180

APS5184 350 480 300 450 270 400 200 350 200 300 400

APS4034 120 200 100 180 80 150 70 130 60 100 150

APS4054 180 300 150 260 120 220 100 200 85 150 200

APS4354 230 320 210 300 200 280 160 240 120 200 280

Average

Impact work APS5148 230 320 210 300 200 280 160 240 120 200 280

Index - 14

APS5160 300 400 280 380 250 350 200 300 150 250 350

APS5180

APS5184 400 550 350 500 320 450 250 400 200 320 450

Product Gradations (Percent Passing)

d 90= 5⁄8” 3⁄4” 1” 1 3⁄16” 1 9⁄16” 2” 2 3⁄8” 5⁄8” 3⁄4” 1” 1 3⁄16” 1 9⁄16” 2” 2 3⁄8”

Inch-MM 16MM 20MM 25MM 30MM 40MM 50MM 60MM 16MM 20MM 25MM 30MM 40MM 50MM 60MM

>4” (100)

4” (100) 100 100

3 1⁄8” (80) 100 97 100 97

2 1⁄2" (63) 100 95 92 100 95 92

2 3⁄8” (60) 100 98 93 90 100 98 93 90

2” (50) 97 94 90 75 97 94 90 80

1 9⁄16” (40) 100 93 90 74 65 100 93 90 80 70

1 3⁄16” (30) 100 95 90 76 58 55 100 95 90 80 70 60

1” (25) 100 95 90 78 62 50 47 100 95 90 80 71 60 54

3⁄4” (20) 94 90 78 65 50 42 40 94 90 82 72 62 53 47

5⁄8” (16) 90 76 65 52 42 40 35 90 82 71 63 53 47 39

1/2” (12.5) 75 62 55 42 38 35 30 80 73 62 54 46 40 32

3⁄8” (10) 60 50 45 35 33 30 24 68 63 54 45 40 33 25

5/16” (8) 50 40 38 30 29 26 20 55 52 46 40 35 28 20

1.4” (6.3) 40 30 30 26 22 20 15 48 42 38 33 30 22 17

4# (4.75) 30 20 26 20 15 12 7 40 36 30 25 20 15 10

6# (3.4) 20 16 14 10 7 6 3 33 30 24 20 16 12 8

8# (2.4) 15 11 9 5 4 3 1 25 20 16 13 11 8 6

16# (1.2) 8 6 4 2 2 1 13 10 8 7 6 4 2

30# (0.6) 4 2 1 1 7 5 4 3 2 1

50# (0.3) 1 4 3 1

100# (0.16) 2 1

VISIT WWW.TRIOPRODUCTS.COM FOR MORE INFORMATION

US +1 626 851 3966 EU +353 57 86 61333 China +86 21 39979708 India +91 9899110184

You might also like

- Andrea Larosa 4 Weeks Calisthenics Training Program (Beginner)Document26 pagesAndrea Larosa 4 Weeks Calisthenics Training Program (Beginner)Dimitry Donaire Flores100% (8)

- YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesYL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- RX 60 30 Still ManualDocument6 pagesRX 60 30 Still ManualDavid Klachuk50% (2)

- PBH-PBM_EN-2Document20 pagesPBH-PBM_EN-2DAVID F. GARCIANo ratings yet

- Recycling MachinesDocument22 pagesRecycling MachinesDuško LaštroNo ratings yet

- Shaping Machines: Machine Tool Exporters To The World Since 1940Document4 pagesShaping Machines: Machine Tool Exporters To The World Since 1940pedjaNo ratings yet

- TNN CNC Lathe Machine CatalogueDocument3 pagesTNN CNC Lathe Machine Catalogueneda100% (1)

- Drills 7 TappersDocument10 pagesDrills 7 TappersBe HappyNo ratings yet

- Trelleborg Elastomeric Bridge Bearings PDFDocument4 pagesTrelleborg Elastomeric Bridge Bearings PDFMad WonderNo ratings yet

- Belt Cleaner: Head PulleyDocument7 pagesBelt Cleaner: Head PulleyAgung Pandega PutraNo ratings yet

- HP Strongdrain FRP Cover PL 10-10-2018Document1 pageHP Strongdrain FRP Cover PL 10-10-2018AMOLNo ratings yet

- 1610454833nowicki Bowl CuttersDocument20 pages1610454833nowicki Bowl Cuttersjanna ibrahimNo ratings yet

- Schiavi Enc Met Page097Document1 pageSchiavi Enc Met Page097Adel AdelNo ratings yet

- NEW Gelen Catalog-EnglishDocument40 pagesNEW Gelen Catalog-Englishsam saminNo ratings yet

- Base Hinged Masts Technical Data PDFDocument1 pageBase Hinged Masts Technical Data PDFgarpheetNo ratings yet

- 4e HydraulischePressen PDFDocument28 pages4e HydraulischePressen PDFDenis Yasmin AlineNo ratings yet

- BIDAPRO 600x600Document9 pagesBIDAPRO 600x600deborazoletNo ratings yet

- CNC Glass Cutting TableDocument6 pagesCNC Glass Cutting TableMarcel PiersonNo ratings yet

- Stone Jaw CrusherDocument2 pagesStone Jaw CrusherKarin AndersonNo ratings yet

- Material HandlingDocument36 pagesMaterial HandlingvishnusankarNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- SNXR Series - 2023Document2 pagesSNXR Series - 2023isgectraineeNo ratings yet

- Amafilter Cricketfilter For Wet Cake Discharge 20210414Document2 pagesAmafilter Cricketfilter For Wet Cake Discharge 20210414virus40No ratings yet

- Agarwalla: Bpa Projects PVT LTDDocument16 pagesAgarwalla: Bpa Projects PVT LTDKarin Anderson100% (1)

- Sevak Price ListDocument14 pagesSevak Price ListPentagon LeadNo ratings yet

- Vtech Catalog Scissor Lifts, Dock Leveler, Baling PressDocument4 pagesVtech Catalog Scissor Lifts, Dock Leveler, Baling PressORDER REPORTNo ratings yet

- Wittur Range of Systems: Machine Roomless EfficiencyDocument16 pagesWittur Range of Systems: Machine Roomless EfficiencyLe Huynh LongNo ratings yet

- Trio Grizzly Feeders - TF Series: Product CollectionDocument2 pagesTrio Grizzly Feeders - TF Series: Product CollectionEnso E Rosales FNo ratings yet

- MC Injection Spec2023Document1 pageMC Injection Spec2023anandan777No ratings yet

- 2A UAG Dimensions EN81-1Document1 page2A UAG Dimensions EN81-1engineer63No ratings yet

- Brochure Mistral eDocument2 pagesBrochure Mistral ecelia.miguel.martinsNo ratings yet

- Roller Beds at PEMADocument8 pagesRoller Beds at PEMASadashiva sahooNo ratings yet

- Elektra 315 EngDocument8 pagesElektra 315 EngNitesh SinghNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- Rolling 3Document2 pagesRolling 3danaandrei74No ratings yet

- Neco Hubless CI Pipe Price List 2022Document1 pageNeco Hubless CI Pipe Price List 2022Kevin MaldeNo ratings yet

- Covers Whip SockDocument1 pageCovers Whip SockMichaël AlbaneseNo ratings yet

- Telescopic Forks, Type TFP: Cap. 2500 - 5000 (KG)Document2 pagesTelescopic Forks, Type TFP: Cap. 2500 - 5000 (KG)kumbrovNo ratings yet

- ByStar Fiber Datasheet Eng Original 14278Document2 pagesByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhNo ratings yet

- Grinda de Ridicat Cu Brate Ajustabile K1K2Document1 pageGrinda de Ridicat Cu Brate Ajustabile K1K2Cristina CojocariuNo ratings yet

- Model Jaw Vertical ConeDocument4 pagesModel Jaw Vertical ConerianNo ratings yet

- Cricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Document2 pagesCricketfilter With Wet Cake Discharge: Technical Bulletin E-8012Dwi Agus DermawanNo ratings yet

- Centamax B CouplingDocument6 pagesCentamax B Couplingmecanicas alaynaNo ratings yet

- Load CHRT CLMNDocument2 pagesLoad CHRT CLMNVivekNo ratings yet

- Spech - GranatesDocument4 pagesSpech - GranatesSUBHASH NAIRNo ratings yet

- UntitledDocument12 pagesUntitledAngel Rodriguez PizarroNo ratings yet

- UPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber SimplexDocument4 pagesUPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber Simplexwaqasasad408No ratings yet

- Seal 'N Devices 2018 CatalogueDocument13 pagesSeal 'N Devices 2018 CatalogueBarryNo ratings yet

- Scissor LiftDocument2 pagesScissor Liftnaswc.jiooNo ratings yet

- Erke Catalog enDocument52 pagesErke Catalog enKarbonKale100% (1)

- LICODocument16 pagesLICOAmrNo ratings yet

- Cosmos Imtex Die MouldDocument2 pagesCosmos Imtex Die MouldAbhishek Velaga100% (2)

- Horizontal Boring MillsDocument2 pagesHorizontal Boring MillsRaluca UrseNo ratings yet

- Bus Bar Selection Chart AluminiumDocument1 pageBus Bar Selection Chart AluminiumJit0% (1)

- JP Balancer Catalog 2022-LDocument19 pagesJP Balancer Catalog 2022-Lisidromundarain67No ratings yet

- Cooler CopmaritiveDocument3 pagesCooler Copmaritiveirfan.ali0463No ratings yet

- 02 PRO Series Jaw Crushers 2Document2 pages02 PRO Series Jaw Crushers 2gopinath chitturiNo ratings yet

- 2022 New Catalog - JP BalancerDocument19 pages2022 New Catalog - JP Balancerdiwa tataNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Iala Model Course: L2.1.8 Aids To Navigation - Technician Training Module 1 Element 8 Level 2 - Buoy CleaningDocument9 pagesIala Model Course: L2.1.8 Aids To Navigation - Technician Training Module 1 Element 8 Level 2 - Buoy CleaningRodrigo BaienseNo ratings yet

- Conversion of Units of Volume and Capacity: WorkedDocument1 pageConversion of Units of Volume and Capacity: WorkedPaul TurnerNo ratings yet

- User Analysis SampleDocument8 pagesUser Analysis Samplecece vergieNo ratings yet

- Jabsco Marine Product Guide 2006.Document24 pagesJabsco Marine Product Guide 2006.m_najmanNo ratings yet

- Colligative Freezing Point DeppressionDocument40 pagesColligative Freezing Point Deppressiongillianmarie.perez.pharmaNo ratings yet

- TỔNG HỢP CÁC ĐỀ CHUYÊN ANH QUỐC HỌC CÁC NĂMDocument61 pagesTỔNG HỢP CÁC ĐỀ CHUYÊN ANH QUỐC HỌC CÁC NĂMLan Phong TranNo ratings yet

- 780B-780C Spec (99014) D.1Document1 page780B-780C Spec (99014) D.1Cristobal ArayaNo ratings yet

- Acp CBC 1Document52 pagesAcp CBC 1Danny R. SalvadorNo ratings yet

- CVDocument3 pagesCVshahbaz akramNo ratings yet

- PDF SSCP Systems Security Certified Practitioner All in One Exam Guide 3Rd Edition Gibson Ebook Full ChapterDocument53 pagesPDF SSCP Systems Security Certified Practitioner All in One Exam Guide 3Rd Edition Gibson Ebook Full Chapterdiane.vant368100% (2)

- Engelhardt BioethicsDocument9 pagesEngelhardt BioethicsAaron Lee WiegmannNo ratings yet

- Mitchell 2005Document8 pagesMitchell 2005DianNo ratings yet

- Vocabulary 3Document5 pagesVocabulary 3Huyền ThuNo ratings yet

- Information Technology System Applicable To Nursing PracticeDocument56 pagesInformation Technology System Applicable To Nursing PracticeKristle Ann VillarealNo ratings yet

- Scope and Sequence - Cookery - 10Document1 pageScope and Sequence - Cookery - 10JP AballeNo ratings yet

- The Antibacterial Mechanism of Silver Nanoparticles and Its Application in DentistryDocument8 pagesThe Antibacterial Mechanism of Silver Nanoparticles and Its Application in DentistryabdulrazaqNo ratings yet

- Biotech DirectoryDocument56 pagesBiotech DirectorySreesanth SaruvilNo ratings yet

- Autoclave - Kaizen ImperialDocument3 pagesAutoclave - Kaizen ImperialAnaThomasNo ratings yet

- GlyphosateDocument7 pagesGlyphosateantonio leonNo ratings yet

- Gadget Building 2016Document36 pagesGadget Building 2016Kelvin MsafiriNo ratings yet

- Pbl-Gin Urine Test (Feme)Document11 pagesPbl-Gin Urine Test (Feme)KarthigaRamanNo ratings yet

- CourseDocument2 pagesCourseRNo ratings yet

- Reviews of Environmental Contamination and Toxicology - Continuation of Residue ReviewsDocument232 pagesReviews of Environmental Contamination and Toxicology - Continuation of Residue ReviewsYoNo ratings yet

- Is QualityDocument14 pagesIs QualityArathy VikramNo ratings yet

- Dup TemplateDocument5 pagesDup TemplateJoshua SouthNo ratings yet

- Navi Gi PolicyDocumentSA006T0VDocument25 pagesNavi Gi PolicyDocumentSA006T0Vdattam venkateswarluNo ratings yet

- Definition of Biomedical Model of HealthDocument4 pagesDefinition of Biomedical Model of Healthتالیہ مرادNo ratings yet

- 07 Gyproc Eas-Fill COSHH Ass'tDocument2 pages07 Gyproc Eas-Fill COSHH Ass'tphil.jacksonNo ratings yet

- UV Curing Inkjet IssuesDocument7 pagesUV Curing Inkjet IssuesAshish Jain100% (1)