Professional Documents

Culture Documents

10in 1500 MOV Datasheet

10in 1500 MOV Datasheet

Uploaded by

karthik0 ratings0% found this document useful (0 votes)

45 views1 pageThis document provides specifications for a motor operated valve (MOV) used in a discharge process. It lists over 50 details regarding the valve and actuator tag number, location, materials, pressure and temperature ratings, certifications, and actuator specifications including power supply, enclosure type, and configuration. The valve is a 10" trunnion mounted ball valve used for isolation in brackish water service at a pumping station.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a motor operated valve (MOV) used in a discharge process. It lists over 50 details regarding the valve and actuator tag number, location, materials, pressure and temperature ratings, certifications, and actuator specifications including power supply, enclosure type, and configuration. The valve is a 10" trunnion mounted ball valve used for isolation in brackish water service at a pumping station.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

45 views1 page10in 1500 MOV Datasheet

10in 1500 MOV Datasheet

Uploaded by

karthikThis document provides specifications for a motor operated valve (MOV) used in a discharge process. It lists over 50 details regarding the valve and actuator tag number, location, materials, pressure and temperature ratings, certifications, and actuator specifications including power supply, enclosure type, and configuration. The valve is a 10" trunnion mounted ball valve used for isolation in brackish water service at a pumping station.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

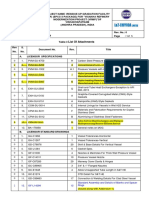

DATASHEET - MOTOR OPERATED VALVE (MOV)

1 Tag Number CPXX-900-MOV-0102 / 0202 / 0302 / 0402

2 Service Discharge MOV

3 Location Cluster Pumping Stations

GENERAL 4 P&ID TBA

5 Hazardous Area Classification Zone 1

6 Line size 10"

7 Line Number TBA

8 Process Medium Phase Brackish Water Liquid

9 Pressure Min / Norm / Max barg 7.0 8.0 45.0

10 Temperature Min / Norm / Max °C 30 70 70

PROCESS DATA

11 Design Pressure barg 255 (AS PER ASME B16.34)

12 Design Temperature °C -2 to +100

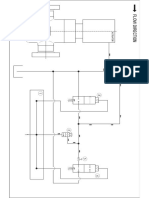

13 Valve Function MOV Isolation

14 Valve Type Trunnion Mounted, End entry, Metal seated Ball Valve, Bi-directional, Anti-Static, Anti Blowout

stem

15 Nominal Size / Rating Port Size 10" / 1500# per ASME B16.5 Full Bore

16 Design Specification / Criticality Rating API 6D / ISO14313 / CR-2

17 Design Pressure Fully Rated as per ASME B16.34

18 End Connections Flanged - ASME B16.5 Ring Type Joint

19 Body Material LTCS ASTM A350 LF2 CL.1 + Inconel 625 overlay on all wetted areas (3mm min.) (Note 12)

20 Bonnet / Trunnion Material ASTM A182 F51

21 Ball Material ASTM A182 F51+TCC

22 Seat Material ASTM A182 F51+TCC

23 Stem Material INCONEL 718

24 Gasket Material Spiral wound S.S. / Graphite

25 Seals Material VITON O-RING (Note 7) + PTFE Back-up rings

26 Bushing / Bearing Material Stainless Steel Backed DU (Note 2)

VALVE DATA 27 Studbolts & Nuts Material ASTM A193 B7M/ A194 2HM HOT DIP GALV. TO ASTM F2329

28 Face to Face Face to Face Dimension-ASME B16.10 Long Pattern

29 Body Cavity Relief Required

30 Vent / Drain Manufacturer's Standard

31 Seat Injection N/A

32 Stem Injection N/A

33 NACE Compliance Leakage Class NACE MR0175 / ISO 15156 API 6D / ISO 14313

34 Corrosion Allowance 3 mm

35 Hydrostatic / Air Pressure Test API 6D / ISO14313 38.5MPa (Shell), 28.2MPa seat, 0.6MPa Air seat

36 Gas Test N/A

37 External Painting As per 0000RP-C-G0-G000-ML-SPC-0002

38 Material Certification 3.2 Certs for Pressurised Parts, 3.1 Certs for other parts

39 PMI As per 0000RP-C-G0-G000-PE-SPC-0017

40 Fire Test Certification Design certified in accordance with ISO 10497/ API 6FA / API 607

41 Spring Material INCONEL X-750

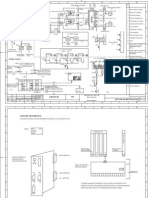

42 ACTUATOR DATA ROTORK IQ20/IW82

43 Actuator Manufacturer Model number Rotork IQ

44 Actuator Type Electric

45 Duty Classification On-Off & Inching

46 Size Actuator Activation 20 Standard

47 Power Supply Volts 400

48 Phase 3

49 Frequency Hz 50

50 Speed rpm 96

51 Wiring Diagram 101B0000-6

52 Enclosure (Hazardous) II2 GD EXD IIB T4

53 Enclosure (Environmental) IP68 Nema 4X

54 Handwheel Ratio Yes Geared 13.3:1

55 Handwheel Orientation Side

56 Conduit / Cable Entries 3 x M25 plus 1 x M40

57 ACTUATOR CONFIGURATION

58 Direction to Close Turns Clockwise Rotation 90

59 FUNCTIONAL DATA (Gearbox)

60 Unit Size IW82

61 Max Motor Duty Nm 37000

62 Torque Manual Duty Nm 48100

ACTUATOR DATA 63 Max Input Torque Motor Nm 196

64 Nom ratio Nominal MA 480 189

65 Weight Kg 222

66 OPTIONAL EXTRAS

67 CPT YES

68 CPT Supply 4-20 mA

69 CPT Open Signal 20 mA

70 SPECIAL REQUIREMENTS

71 NACE Requirements NO

72 Fire Proof Requirement NO

73 Certificates Requirement YES

74 Special Requirements for Application NO

75 SIL Capability NO

76 Lubricator NO

77 Lock-up Valve NO

78 Full Stroke Time (C→O / O→C) sec By MFR

79 Instrument Air Pressure Supply barg N/A

80 Ambient Temperature °C 2 55

81 Ambient Humidity % 25 84

82 Test Certificates Ex Certificates YES YES

83 Leakage Test STD ANSI FCI 70-2

84 Hydrostatic Testing STD ISA S75.19

85 Supplier VTA

86 Manufacturer (Valve) VTA

PURCHASE

87 Model No. Valve VTA

88 Model No. Actuator VTA

Notes:-

1. Full Function Testing required for valve / gearbox / actuator assembly, 15 cycles min.

2. Valve stem to be supported by Stainless Steel backed DU bush at lower and upper locations.

3. Valves to be supplied with a SS nameplate showing manufacturers name, serial number, size, rating, certification data and tag.

4. Refer to 0000RP-C-G0-G000-PE-SPC-0017 Specification for Piping Valves Technical Requirements.

5. Applicable Piping Class A15E2B.

6. Actuator sized to 1.5 x valve BTO.

7. All seal materials shall be resistant to explosive decompression and suitable for the services/temperatures.

8. Valves, to comply with the requirements of NACE MR-0175/ISO-15156 latest edition and be resistant to high H2S and sulphide.

9. Vendor shall provide all required certification as per Material Traceability and Certification Specification - 0000RP-C-G0-G000- QA-PRO-0003 for Actuator and Valve.

10. The Actuator and other pressure retaining parts shall be designed and manufactured in accordance with ASME VIII.

11. Vendor to select appropriate actuator size: Rotork IQ20 / IW82. Vendor to advise if alternative size of Rotork is required.

12. Inconel 625 weld overlay to be 3mm minimum thickness after final machining.

12. General Assembly drawing showing inconel 625 overlaid areas with full parts list and materials required at Technical bid stage.

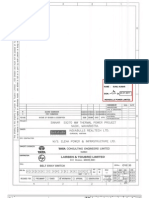

CPS DISCHARGE MOV - 10" 1500#

DATA SHEET FOR MOTOR OPERATED VALVE

No. By: N.W. Date: 18-Oct-21 Revision 0 Spec.: Doc. No.: DOC-1129-ROO-08-21 Rev. 0

# Caterpillar: Confidential Green

You might also like

- t1080s ManualDocument191 pagest1080s ManualMorena Estatal Arizona100% (5)

- DB Schedule 2 BHKDocument4 pagesDB Schedule 2 BHKAnsal KhanNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- TR0038-3 - Valve-ActuatorsDocument49 pagesTR0038-3 - Valve-ActuatorsMaffone NumerounoNo ratings yet

- Kei PDFDocument48 pagesKei PDFvasanthi8025No ratings yet

- 225121000-05-906 Level Switch RevDocument3 pages225121000-05-906 Level Switch RevAlaa RamadanNo ratings yet

- MOV DatasheetDocument98 pagesMOV Datasheetsrik11No ratings yet

- EGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatorDocument4 pagesEGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatordrkongalaNo ratings yet

- MOV Data SheetDocument2 pagesMOV Data SheetMathivanan AnbazhaganNo ratings yet

- Project Prafful Company / Customer 10088D2000 CommentDocument830 pagesProject Prafful Company / Customer 10088D2000 CommentAnish SinghNo ratings yet

- A307 5880 1253 Enq Rev0Document827 pagesA307 5880 1253 Enq Rev0Sunil VaishnavNo ratings yet

- TABLE-3 LIST OF ATTACHMENTS - Rev 0Document5 pagesTABLE-3 LIST OF ATTACHMENTS - Rev 0Anonymous AyDvqgNo ratings yet

- Mov EIL SpecsDocument10 pagesMov EIL SpecsveenaNo ratings yet

- P11218 SPE ME 00 - 005 RevB Spec For Pressure VesselDocument17 pagesP11218 SPE ME 00 - 005 RevB Spec For Pressure VesselBukhory TajudinNo ratings yet

- 9034975-250-00-Td-00-Uop R0Document8 pages9034975-250-00-Td-00-Uop R0TATA STEELNo ratings yet

- Electrical Io ListDocument15 pagesElectrical Io ListRahulNo ratings yet

- CO AnalyzerDocument1 pageCO AnalyzeruzairNo ratings yet

- 421FN 6se38028+l08Document64 pages421FN 6se38028+l082003vinay0% (1)

- Anubar SpecDocument8 pagesAnubar SpecSHIVAJI CHOUDHURYNo ratings yet

- Differential Pressure Transmitter (Smart)Document6 pagesDifferential Pressure Transmitter (Smart)JKKNo ratings yet

- GE-103002, Waste Oil Transfer Pumps, P-102A&BDocument4 pagesGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerNo ratings yet

- Temprature GaugeDocument1 pageTemprature GaugeKenneth EmbeleNo ratings yet

- PLC System ArchitectureDocument14 pagesPLC System ArchitectureFikriNo ratings yet

- GA Drawing Deluge Valve System - R2Document4 pagesGA Drawing Deluge Valve System - R2Keannu Radhika Putra WibowoNo ratings yet

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Document28 pagesSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaNo ratings yet

- Technical Specification For Motor Operated ValvesDocument6 pagesTechnical Specification For Motor Operated ValvesĐặng Trung AnhNo ratings yet

- Marshalling CabinetsDocument6 pagesMarshalling CabinetsBike To WorkNo ratings yet

- Belt Sway Switch-Nasik R1-Final Sent On 04.01.11Document4 pagesBelt Sway Switch-Nasik R1-Final Sent On 04.01.11atulbhogare7No ratings yet

- E 7 Elec Spec ListDocument3 pagesE 7 Elec Spec ListMARIMUTHUNo ratings yet

- A415 5120 1021 Enq Rev0Document443 pagesA415 5120 1021 Enq Rev0Apoorv GoenkaNo ratings yet

- Amnit in 300 Wir 1003 Ded C Junction Box Schedule AppDocument46 pagesAmnit in 300 Wir 1003 Ded C Junction Box Schedule Appzaraki kenpachiNo ratings yet

- Tube Bundle Detail Drawing 1200-E-4006: Document TitleDocument2 pagesTube Bundle Detail Drawing 1200-E-4006: Document TitleAnwar SadatNo ratings yet

- Motor Operated Valve List, Datasheet and Drawings: Enersur S.ADocument50 pagesMotor Operated Valve List, Datasheet and Drawings: Enersur S.AJuan ShunaNo ratings yet

- 104 08655 000 Esp J 007 - 0 Ultrasonic and Radar Level TransmittersDocument8 pages104 08655 000 Esp J 007 - 0 Ultrasonic and Radar Level TransmittersCristian RománNo ratings yet

- s10332300-3007 - 0 Process Flow MeteringDocument11 pagess10332300-3007 - 0 Process Flow Meteringappril26No ratings yet

- 21010-BAE-70000-In-SP-0028 Tech Spec For Inst. and Control CablesDocument43 pages21010-BAE-70000-In-SP-0028 Tech Spec For Inst. and Control CablesJignesh BanavaNo ratings yet

- Positioner SpecsDocument1 pagePositioner Specsbiswasdipankar05No ratings yet

- 20100PE-DW02-0005 Rev0 11-SD-2121-4Document1 page20100PE-DW02-0005 Rev0 11-SD-2121-4Jovit BeaNo ratings yet

- UPS Power SupplyDocument10 pagesUPS Power SupplyNageswar MakalaNo ratings yet

- Project: Korba Super Thermal Power Project Wagon Tippler Conveying Plant Package OwnerDocument2 pagesProject: Korba Super Thermal Power Project Wagon Tippler Conveying Plant Package Ownerrajatkatiyar2416No ratings yet

- ABB Drive and Motor Selector ACS880-04 Module PDFDocument3 pagesABB Drive and Motor Selector ACS880-04 Module PDFBataa BatsuuriNo ratings yet

- Price List MSRP For WEB PDFDocument3 pagesPrice List MSRP For WEB PDFnavneetNo ratings yet

- Chiyoda Malaysia Sdn. BHD.: Anuj Maifeng Winms Anuj Maifeng WinmsDocument4 pagesChiyoda Malaysia Sdn. BHD.: Anuj Maifeng Winms Anuj Maifeng WinmsmeeNo ratings yet

- Tas PD 000 Document ListDocument9 pagesTas PD 000 Document ListsswahyudiNo ratings yet

- QDR-GCS-ESJ-REP-1000 RevADocument31 pagesQDR-GCS-ESJ-REP-1000 RevAshaheen iqbal100% (2)

- LT-DC-LE130733-1-CI-503, RevFDocument28 pagesLT-DC-LE130733-1-CI-503, RevFSUSOVAN BISWASNo ratings yet

- Datasheet of HCSD VFD TransformerDocument15 pagesDatasheet of HCSD VFD TransformerdevasshuklaNo ratings yet

- Selection Guide EmersonDocument16 pagesSelection Guide Emersonmmrjbi9412No ratings yet

- s10332300-3011 - 0 Process AnalyzerDocument14 pagess10332300-3011 - 0 Process Analyzerappril26No ratings yet

- 6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFDocument34 pages6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFharmlesdragon100% (1)

- Tds Tcs Tata Krishnapatnam Rev.r0Document46 pagesTds Tcs Tata Krishnapatnam Rev.r0SupriyaRongNo ratings yet

- E 7403-9002g Motor List CustomerDocument5 pagesE 7403-9002g Motor List Customerraobabar21No ratings yet

- A537 - 0500 - 1 - ENQ - REV0Power TransformerDocument155 pagesA537 - 0500 - 1 - ENQ - REV0Power TransformerRitaban R. BanerjeeNo ratings yet

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDocument6 pagesR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Actuator Sizing ProgramDocument11 pagesActuator Sizing ProgramAttyubNo ratings yet

- FM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetDocument8 pagesFM012-EMC-DS-A0 - Closed Drain Submersible Pump DatasheetAmr TarekNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- 15250-192-EN02-LM-001 Rev-D Load ListDocument7 pages15250-192-EN02-LM-001 Rev-D Load Listmusab shabbirNo ratings yet

- AMNIT-IN-800-LST-1002 Cable Schedule Rev C-1 (2) 1912Document4 pagesAMNIT-IN-800-LST-1002 Cable Schedule Rev C-1 (2) 1912zaraki kenpachiNo ratings yet

- ASCBZ-S-4041 Rev ADocument1 pageASCBZ-S-4041 Rev AVivek JoshiNo ratings yet

- 4510678501-50 GadDocument1 page4510678501-50 GadJamsurf DeanNo ratings yet

- Page 4 PDFDocument1 pagePage 4 PDFkarthikNo ratings yet

- Mentor Consent FormDocument1 pageMentor Consent FormkarthikNo ratings yet

- Drawings - WE1609.061 - E1942Document3 pagesDrawings - WE1609.061 - E1942karthikNo ratings yet

- Dwg-We0067-013-002 Rev.0Document1 pageDwg-We0067-013-002 Rev.0karthikNo ratings yet

- Dwg-We0067-013-001 Rev.0Document1 pageDwg-We0067-013-001 Rev.0karthikNo ratings yet

- AsfaqDocument2 pagesAsfaqkarthikNo ratings yet

- Hall TicketDocument2 pagesHall TicketkarthikNo ratings yet

- Handwriting Check PDFDocument1 pageHandwriting Check PDFkarthikNo ratings yet

- Q4 From BrainlyDocument5 pagesQ4 From BrainlykarthikNo ratings yet

- WE1917.010 - Eng Request - REV1Document1 pageWE1917.010 - Eng Request - REV1karthikNo ratings yet

- Application FormDocument2 pagesApplication FormkarthikNo ratings yet

- WE2319 - E2006 - Radial-Seal-CalculationsDocument1 pageWE2319 - E2006 - Radial-Seal-CalculationskarthikNo ratings yet

- WE2118.001 - Eng RequestDocument1 pageWE2118.001 - Eng RequestkarthikNo ratings yet

- WE1917.006 - Eng RequestDocument1 pageWE1917.006 - Eng RequestkarthikNo ratings yet

- WE1609.061 - Eng RequestDocument1 pageWE1609.061 - Eng RequestkarthikNo ratings yet

- NPT Gewinde NPT Nach ASME B1.20.1Document1 pageNPT Gewinde NPT Nach ASME B1.20.1karthikNo ratings yet

- WE2319 - E2007 - Radial-Seal-CalculationsDocument1 pageWE2319 - E2007 - Radial-Seal-CalculationskarthikNo ratings yet

- Senthilkumar Pay Slip Aug.2022Document1 pageSenthilkumar Pay Slip Aug.2022karthikNo ratings yet

- Solankikirankumar Fateshisinhmr - 4 - 3Document2 pagesSolankikirankumar Fateshisinhmr - 4 - 3karthikNo ratings yet

- Factsheet PPL DXB 10415Document2 pagesFactsheet PPL DXB 10415karthikNo ratings yet

- Table CDocument12 pagesTable CkarthikNo ratings yet

- SS-H 4HL2Document2 pagesSS-H 4HL2karthikNo ratings yet

- ObjectiveDocument4 pagesObjectivekarthikNo ratings yet

- Dwg-E1675-11 R1Document1 pageDwg-E1675-11 R1karthikNo ratings yet

- Final Laboratory Report: 32 Years 2239041054Document1 pageFinal Laboratory Report: 32 Years 2239041054karthikNo ratings yet

- HLR - 7790BPM Velocity Check Valve PagesDocument3 pagesHLR - 7790BPM Velocity Check Valve PageskarthikNo ratings yet

- Ima ssv3Document1 pageIma ssv3karthikNo ratings yet

- Ima ssv2Document1 pageIma ssv2karthikNo ratings yet

- Shalin VK - Mechanical Engineer - Resume PDFDocument3 pagesShalin VK - Mechanical Engineer - Resume PDFkarthik100% (1)

- International SOS App: Caterpillar: Confidential GreenDocument1 pageInternational SOS App: Caterpillar: Confidential GreenkarthikNo ratings yet

- EEMG Manual RevisedDocument277 pagesEEMG Manual RevisedsridharNo ratings yet

- Born-Oppenheimer ApproximationDocument6 pagesBorn-Oppenheimer ApproximationSup FansNo ratings yet

- PHYS-20-Chapter-10-TemperatureHeatDocument29 pagesPHYS-20-Chapter-10-TemperatureHeatKent Estella AbatayoNo ratings yet

- Spare Parts List: Dusters/Misters 362M18, 2010-02Document12 pagesSpare Parts List: Dusters/Misters 362M18, 2010-02Jose Manuel Carpinteiro NuñezNo ratings yet

- Certificado EMC - EGT 50000 80000 MAXDocument3 pagesCertificado EMC - EGT 50000 80000 MAXLeonardo Flavio Silva Lima0% (1)

- Etherification of Glycerol For Improved Production of OxygenatesDocument7 pagesEtherification of Glycerol For Improved Production of OxygenatesVijaya GosuNo ratings yet

- ECE 027 - Simulation Activity 2.1 The Zener and Light Emitting DiodeDocument8 pagesECE 027 - Simulation Activity 2.1 The Zener and Light Emitting DiodeGong BoNo ratings yet

- EVM Global WarmingDocument14 pagesEVM Global WarmingRahul PurshottamNo ratings yet

- Prospects of Green Ammonia For Fertilizer Production: Dr. S. NandDocument2 pagesProspects of Green Ammonia For Fertilizer Production: Dr. S. NandMinhquang NgoNo ratings yet

- Photoelectric and Compton EffectDocument17 pagesPhotoelectric and Compton EffectRitam DattaNo ratings yet

- Chevron Product Guide Final Aug2019Document165 pagesChevron Product Guide Final Aug2019Shekhar SumanNo ratings yet

- Model: SZ185: Technical DataDocument6 pagesModel: SZ185: Technical DataAli AlchmreNo ratings yet

- 20PHD2161 Assignment 1Document4 pages20PHD2161 Assignment 1Elanthamil PandiNo ratings yet

- SBT MagnetismDocument383 pagesSBT Magnetismshree hariNo ratings yet

- Efficiency Maps of Electrical MachinesDocument9 pagesEfficiency Maps of Electrical Machinesmdht1556No ratings yet

- Trends in The Development of Desalination Plants For Use in Ship Energy Installations 2016-2022Document7 pagesTrends in The Development of Desalination Plants For Use in Ship Energy Installations 2016-2022SargeSarioNo ratings yet

- Types of Burners and Combustion Systems - HEATER TREATER IMPORTANTDocument5 pagesTypes of Burners and Combustion Systems - HEATER TREATER IMPORTANTadewunmi olufemiNo ratings yet

- MS FZR FZS SvhoDocument336 pagesMS FZR FZS SvhoBruno100% (2)

- SEE4121 (2023) - Basic Gas Engineering & Energy Market - Lecture 2 - 16 Jan 2023Document85 pagesSEE4121 (2023) - Basic Gas Engineering & Energy Market - Lecture 2 - 16 Jan 2023MelodyNo ratings yet

- Diesel Generator Set NT855 Series Engine: Specification SheetDocument4 pagesDiesel Generator Set NT855 Series Engine: Specification SheetFauzan AriqNo ratings yet

- MD Product Catalogue PROXIMITY ENGDocument194 pagesMD Product Catalogue PROXIMITY ENGETIENNENo ratings yet

- Physics Lab 6Document7 pagesPhysics Lab 6Tahsin RahmannNo ratings yet

- As Practice 2Document30 pagesAs Practice 2gytiheceNo ratings yet

- THARUN A Task 1Document29 pagesTHARUN A Task 1NANDHAKUMAR ANo ratings yet

- Laporan Mingguan 2023-1Document14 pagesLaporan Mingguan 2023-1Ok NawaNo ratings yet

- Grade 8 Physics - Presentation - T2Document1 pageGrade 8 Physics - Presentation - T2Vandana AbhiNo ratings yet

- EN590 10ppm SPECIFICATIONS PEGASUS OILDocument1 pageEN590 10ppm SPECIFICATIONS PEGASUS OILSephiwe Mafilika100% (1)

- Closed Loop by Geophires Residential PDFDocument21 pagesClosed Loop by Geophires Residential PDFvitaxnNo ratings yet

- JharkhandDocument57 pagesJharkhandDigitalsolar NoidaNo ratings yet