Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsSimulator Tests

Simulator Tests

Uploaded by

GF(1) A simulator test was conducted to evaluate the impact of wing surface contamination on take-off performance using a DC-8 simulator. Tests were flown with clean wings and with simulated contamination.

(2) With contaminated wings, take-offs resulted in stalls at higher speeds than with clean wings when pitch was increased above 10-15 degrees.

(3) The tests found that wing contamination deteriorated aircraft performance on take-off and increased the risk of stall. By itself, lower take-off speeds or weights would likely not cause a stall but surface contamination combined with these factors increased this risk.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Assignment A 3Document6 pagesAssignment A 3amir yousefiNo ratings yet

- NTSB Report On B-17 Crash at Bradley International AirportDocument24 pagesNTSB Report On B-17 Crash at Bradley International AirportPatrick JohnsonNo ratings yet

- Exam AERO4306 2005december PDFDocument4 pagesExam AERO4306 2005december PDFjonthemesNo ratings yet

- CARDS - Circle Theorems Match UpDocument2 pagesCARDS - Circle Theorems Match UpPablo CuevasNo ratings yet

- INHERITANCE (Exclusive Preview) by Christopher PaoliniDocument2 pagesINHERITANCE (Exclusive Preview) by Christopher PaoliniRandomHouseAU0% (1)

- Aircraft Operations From Runways With Inclined Ramps (Skijump)Document19 pagesAircraft Operations From Runways With Inclined Ramps (Skijump)hheussinger3893No ratings yet

- Tanjung Kupang DisasterDocument8 pagesTanjung Kupang DisasterShazwan Hazim Mohd Aznor0% (1)

- Airplane and Engine Responses To Abrupt Throttle Steps As Determined From Flight Tests of Eight Jet-Propelled AirplanesDocument47 pagesAirplane and Engine Responses To Abrupt Throttle Steps As Determined From Flight Tests of Eight Jet-Propelled AirplanesStorebrorNo ratings yet

- Bu 131 Jungmann Spins ReportDocument20 pagesBu 131 Jungmann Spins ReportRoslimizal KamarozamanNo ratings yet

- Assignment 4Document4 pagesAssignment 4José A. Montiel QuirósNo ratings yet

- NTSB BAC Final AAB0401 - 001010Document32 pagesNTSB BAC Final AAB0401 - 001010bombardierwatchNo ratings yet

- TSB A17O0243 Jazz Q400 YTZDocument7 pagesTSB A17O0243 Jazz Q400 YTZGFNo ratings yet

- Aviation Investigation Report A00P0244Document6 pagesAviation Investigation Report A00P0244vonmanoNo ratings yet

- Aeroplane EssaysDocument12 pagesAeroplane EssayscollinsNo ratings yet

- Air Canada Simulator EvaluationDocument19 pagesAir Canada Simulator EvaluationGFNo ratings yet

- Flight Test Validation of The Rq-4 Block 20 Global Hawk Aerodynamic and Propulsive ModelsDocument20 pagesFlight Test Validation of The Rq-4 Block 20 Global Hawk Aerodynamic and Propulsive Modelsj dnNo ratings yet

- G-Opfe (1996)Document4 pagesG-Opfe (1996)GFNo ratings yet

- FlightTestLog Bell-412EPI HX4146AcceptanceFlt 20210707Document3 pagesFlightTestLog Bell-412EPI HX4146AcceptanceFlt 20210707Reza Setyo PermadiNo ratings yet

- NTSB - Final Pitt. Co 2022 Plane Crash ReportDocument13 pagesNTSB - Final Pitt. Co 2022 Plane Crash ReportWSLSNo ratings yet

- Flight Test #1 ReportDocument41 pagesFlight Test #1 ReportBsharrellNo ratings yet

- OV-10 Bronco Cylinder FlapDocument173 pagesOV-10 Bronco Cylinder Flapawiator02100% (1)

- Ntps Fte CourseDocument20 pagesNtps Fte CourseShirat MohsinNo ratings yet

- Airbus A319 - Inadvertent Selection of Parking Brake On LandingDocument4 pagesAirbus A319 - Inadvertent Selection of Parking Brake On LandingReggie JoshuaNo ratings yet

- Flight Test of GL-1 Glider Half Scale PrototypeDocument14 pagesFlight Test of GL-1 Glider Half Scale Prototypericardo pelinNo ratings yet

- Army Aviation Digest - Sep 1961Document40 pagesArmy Aviation Digest - Sep 1961Aviation/Space History Library100% (1)

- NTSB Final ReportDocument10 pagesNTSB Final ReportABC15 NewsNo ratings yet

- NTSB BAC 050309 Probable CauseDocument2 pagesNTSB BAC 050309 Probable CausebombardierwatchNo ratings yet

- Criticalstudyofs00brow BWDocument36 pagesCriticalstudyofs00brow BWPuru-the-braveNo ratings yet

- Kline-Fogleman Airfoil Comparison Study 2-1Document8 pagesKline-Fogleman Airfoil Comparison Study 2-1shibin874141No ratings yet

- PEL-03-CPL-A CAAT Edited Jan 19Document3 pagesPEL-03-CPL-A CAAT Edited Jan 19Nat ChuenjumlongNo ratings yet

- CAAT Private Pilot LicensingDocument3 pagesCAAT Private Pilot LicensingNat ChuenjumlongNo ratings yet

- NTSB ReportDocument7 pagesNTSB ReportDan ShepardNo ratings yet

- Exercises Lecture 3: How Aircraft FlyDocument6 pagesExercises Lecture 3: How Aircraft FlyJosé A. Montiel QuirósNo ratings yet

- Experimental Measurement Moment of InertiaDocument34 pagesExperimental Measurement Moment of InertiayogagaNo ratings yet

- Module-Iv: Flight Testing-17Ae831 Tutorial - IiiDocument2 pagesModule-Iv: Flight Testing-17Ae831 Tutorial - IiiNithinNo ratings yet

- NTSB LJ 020830 Probable CauseDocument3 pagesNTSB LJ 020830 Probable CausebombardierwatchNo ratings yet

- "Systems Phase Planning Guide" (1995)Document255 pages"Systems Phase Planning Guide" (1995)Ali NajmaldinNo ratings yet

- Piper CubDocument84 pagesPiper CubDavid Scott100% (1)

- Chuck Yeagers Advanced Flight Trainer - Manual MacDocument30 pagesChuck Yeagers Advanced Flight Trainer - Manual MacEffat MokhtarNo ratings yet

- 1979 11 11 UsDocument35 pages1979 11 11 UsEduardo RochaNo ratings yet

- National Transportation Safety Board Aviation Incident Final ReportDocument7 pagesNational Transportation Safety Board Aviation Incident Final Reportnestorin111No ratings yet

- Flight Training ManualDocument218 pagesFlight Training ManualaugvydasNo ratings yet

- Ad 0422034Document92 pagesAd 0422034dmmeta80No ratings yet

- February 2005 BulletinDocument80 pagesFebruary 2005 BulletinFlamingo FlamejanteNo ratings yet

- Bombardier CL-600-2B16 604 D-AAAY 02-24Document31 pagesBombardier CL-600-2B16 604 D-AAAY 02-24johnpriceNo ratings yet

- MAE 4350 - Lab 4 AerodynamicsDocument45 pagesMAE 4350 - Lab 4 AerodynamicsjonolioNo ratings yet

- TSBC Bac 050607 A05p0132Document9 pagesTSBC Bac 050607 A05p0132bombardierwatchNo ratings yet

- NASA 120309main FS-055-DFRCDocument3 pagesNASA 120309main FS-055-DFRCNASAdocumentsNo ratings yet

- NTSB Galloping Ghost Photo AnalysisDocument27 pagesNTSB Galloping Ghost Photo AnalysisMiguel Poduje VarasNo ratings yet

- Final Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeDocument28 pagesFinal Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeMorgen GumpNo ratings yet

- Aircraft PerformanceDocument17 pagesAircraft PerformanceGFNo ratings yet

- AINsight - Fatal In-Flight Upset Poses Important Lessons - Business Aviation - Aviation International NewsDocument3 pagesAINsight - Fatal In-Flight Upset Poses Important Lessons - Business Aviation - Aviation International NewstmuthukumarNo ratings yet

- FQ Breguet MD 188Document84 pagesFQ Breguet MD 188dagger21100% (2)

- KJFKDocument29 pagesKJFKSridhar Eswaran100% (1)

- Adp ReportDocument98 pagesAdp ReportSeenu CnuNo ratings yet

- Douglas DC 8 52 ZK NZBDocument31 pagesDouglas DC 8 52 ZK NZBGFNo ratings yet

- Team ID: 6098: Air Crash Investigation Report 101Document6 pagesTeam ID: 6098: Air Crash Investigation Report 101Humesh SNo ratings yet

- NACA TN 116 Comparative Performance With Direct and Geared EnginesDocument13 pagesNACA TN 116 Comparative Performance With Direct and Geared EnginesMark Evan SalutinNo ratings yet

- VH SuzDocument23 pagesVH SuzfrgonzalezNo ratings yet

- Air Crash Investigations - Cracked Solder Joint - The Crash of Indonesia Air Asia Flight 8501From EverandAir Crash Investigations - Cracked Solder Joint - The Crash of Indonesia Air Asia Flight 8501No ratings yet

- L1011 QRHDocument57 pagesL1011 QRHGFNo ratings yet

- CYOWDocument26 pagesCYOWGFNo ratings yet

- TowersDocument27 pagesTowersGFNo ratings yet

- CYLWDocument17 pagesCYLWGFNo ratings yet

- YYC Ceiling MapDocument4 pagesYYC Ceiling MapGFNo ratings yet

- CYQBDocument19 pagesCYQBGFNo ratings yet

- CYLTDocument6 pagesCYLTGFNo ratings yet

- CYJTDocument9 pagesCYJTGFNo ratings yet

- Yo 101Document25 pagesYo 101GFNo ratings yet

- Drawing 10-50000-RDocument1 pageDrawing 10-50000-RGFNo ratings yet

- CYHZDocument28 pagesCYHZGFNo ratings yet

- CYFIDocument10 pagesCYFIGFNo ratings yet

- CYHMDocument18 pagesCYHMGFNo ratings yet

- CYDFDocument10 pagesCYDFGFNo ratings yet

- CYEUDocument7 pagesCYEUGFNo ratings yet

- BKPRDocument22 pagesBKPRGFNo ratings yet

- CYGLDocument10 pagesCYGLGFNo ratings yet

- CYCLDocument7 pagesCYCLGFNo ratings yet

- CYFCDocument14 pagesCYFCGFNo ratings yet

- CYEGDocument35 pagesCYEGGFNo ratings yet

- CYFBDocument10 pagesCYFBGFNo ratings yet

- CYEVDocument7 pagesCYEVGFNo ratings yet

- Drawing 10-58030-RDocument1 pageDrawing 10-58030-RGFNo ratings yet

- CYBGDocument13 pagesCYBGGFNo ratings yet

- AIB Report F 15C TN 86 0176 - FINAL - SIGNEDDocument35 pagesAIB Report F 15C TN 86 0176 - FINAL - SIGNEDGFNo ratings yet

- Drawing 10-41000-RDocument1 pageDrawing 10-41000-RGFNo ratings yet

- Operational Factors Human Performance - Attachment 20 - Audit Report-RelDocument23 pagesOperational Factors Human Performance - Attachment 20 - Audit Report-RelGFNo ratings yet

- Operational Factors Human Performance - Attachment 18 - Transair Administration Manual (Excerpts) - RelDocument17 pagesOperational Factors Human Performance - Attachment 18 - Transair Administration Manual (Excerpts) - RelGFNo ratings yet

- Operational Factors Human Performance - Attachment 19 - Transair SEIMl (Excerpts) - Redacted-RelDocument37 pagesOperational Factors Human Performance - Attachment 19 - Transair SEIMl (Excerpts) - Redacted-RelGFNo ratings yet

- Operational Factors Human Performance - Attachment 17 - Rhoades Aviation Operational Specification Manual (Excerpts) - Redacted-RelDocument20 pagesOperational Factors Human Performance - Attachment 17 - Rhoades Aviation Operational Specification Manual (Excerpts) - Redacted-RelGFNo ratings yet

- Quantum-Like Networks: An Approach To Neural Behavior Through Their Mathematics and Logic 1st Edition Stephen A. SelesnickDocument70 pagesQuantum-Like Networks: An Approach To Neural Behavior Through Their Mathematics and Logic 1st Edition Stephen A. Selesnickamberavila557619100% (5)

- Credit and Saving Management SystemDocument96 pagesCredit and Saving Management SystemFitsum TesfayeNo ratings yet

- ICETIT Proceeding Book 2012Document31 pagesICETIT Proceeding Book 2012sudhakarcjNo ratings yet

- Boolean and Logic GatesDocument56 pagesBoolean and Logic Gatesmitparikh1046No ratings yet

- Jurnal Belimbing WuluhDocument6 pagesJurnal Belimbing WuluhPuspitasari NurulNo ratings yet

- Planning A Code-Compliant, Off-Grid PV System: John WilesDocument6 pagesPlanning A Code-Compliant, Off-Grid PV System: John WilesDaniel MilosevskiNo ratings yet

- Red Box Hack 2Document22 pagesRed Box Hack 2jgregors8683No ratings yet

- Formulas Physics B CH 11, 12, 22, 23, 24, 25 WavesDocument6 pagesFormulas Physics B CH 11, 12, 22, 23, 24, 25 WavesEpic WinNo ratings yet

- Tunnel Lighting 2Document4 pagesTunnel Lighting 2dimaomarNo ratings yet

- Classification and Epidemiology of Communicable DiseasesDocument40 pagesClassification and Epidemiology of Communicable DiseasesRwapembe StephenNo ratings yet

- q1 Week 1 PhilosophyDocument22 pagesq1 Week 1 PhilosophyStiffany FlordelizaNo ratings yet

- Properties of Ideal Transformer & Phasor DiagramDocument2 pagesProperties of Ideal Transformer & Phasor DiagramterNo ratings yet

- Academic Press - Advances in Heat Transfer, Volume 26 - (1995)Document347 pagesAcademic Press - Advances in Heat Transfer, Volume 26 - (1995)jmprtaNo ratings yet

- This Study Resource Was: Demand AnalysisDocument6 pagesThis Study Resource Was: Demand Analysisbest One0% (1)

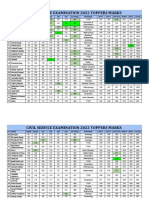

- Selected Candidates Marks CSE 2022Document6 pagesSelected Candidates Marks CSE 2022hara vardhan reddy naruNo ratings yet

- Sales Final ExamDocument1 pageSales Final ExamIan PangNo ratings yet

- Exploded Parts List VTB 370Document2 pagesExploded Parts List VTB 370Dusan MilosevicNo ratings yet

- IEC 61000-4-4 Burst Electrical Fast Transient / Burst Immunity TestDocument64 pagesIEC 61000-4-4 Burst Electrical Fast Transient / Burst Immunity TestopinzonNo ratings yet

- Lecture 20Document24 pagesLecture 20Trix CCNo ratings yet

- Date of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)Document65 pagesDate of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)GaneshNo ratings yet

- Lecture Poultry Chicken NC IiDocument34 pagesLecture Poultry Chicken NC IiNichole Kyla Enriquez100% (1)

- Ion PropulsionDocument16 pagesIon PropulsionMimsisiNo ratings yet

- Aggmax: Integrated Scrubbing SystemDocument15 pagesAggmax: Integrated Scrubbing SystemPoyaNo ratings yet

- Sources of Stem CellsDocument13 pagesSources of Stem CellsAnshi AroraNo ratings yet

- 1811 Dictionary of The Vulgar TongueDocument315 pages1811 Dictionary of The Vulgar TonguelivehardNo ratings yet

- Nuclear EnergyDocument6 pagesNuclear EnergyDENNIS KIHUNGINo ratings yet

- Never On SundayDocument4 pagesNever On Sundaybrigitte jacquotNo ratings yet

- Public Health Aspect in Respiratory Health Problem (COPD Case)Document17 pagesPublic Health Aspect in Respiratory Health Problem (COPD Case)Anditri WeningtyasNo ratings yet

Simulator Tests

Simulator Tests

Uploaded by

GF0 ratings0% found this document useful (0 votes)

15 views4 pages(1) A simulator test was conducted to evaluate the impact of wing surface contamination on take-off performance using a DC-8 simulator. Tests were flown with clean wings and with simulated contamination.

(2) With contaminated wings, take-offs resulted in stalls at higher speeds than with clean wings when pitch was increased above 10-15 degrees.

(3) The tests found that wing contamination deteriorated aircraft performance on take-off and increased the risk of stall. By itself, lower take-off speeds or weights would likely not cause a stall but surface contamination combined with these factors increased this risk.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document(1) A simulator test was conducted to evaluate the impact of wing surface contamination on take-off performance using a DC-8 simulator. Tests were flown with clean wings and with simulated contamination.

(2) With contaminated wings, take-offs resulted in stalls at higher speeds than with clean wings when pitch was increased above 10-15 degrees.

(3) The tests found that wing contamination deteriorated aircraft performance on take-off and increased the risk of stall. By itself, lower take-off speeds or weights would likely not cause a stall but surface contamination combined with these factors increased this risk.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views4 pagesSimulator Tests

Simulator Tests

Uploaded by

GF(1) A simulator test was conducted to evaluate the impact of wing surface contamination on take-off performance using a DC-8 simulator. Tests were flown with clean wings and with simulated contamination.

(2) With contaminated wings, take-offs resulted in stalls at higher speeds than with clean wings when pitch was increased above 10-15 degrees.

(3) The tests found that wing contamination deteriorated aircraft performance on take-off and increased the risk of stall. By itself, lower take-off speeds or weights would likely not cause a stall but surface contamination combined with these factors increased this risk.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

MiMb

ARROW AIR

DAT1: October 14, 1986 '<<\

TO: Don Swing f ~) I j f ' ^ , V;

'L

FROM: John Cce ' ^0 <j

* • &

Rl: Report on DC8-63 Simulator Tests, October 7/8, 1986

LOCATION: Sterling Training Center, Copenhagen, Denmark

PARTICIPANTS: David J. McNair

Investigator

Canadian Aviation Safety Board

Robert D. Cook

Accident Investigation & Coordination Branch

FAA j

Jeffrey L. Gorney

Air Safety Investigator

NTS3

Alfred J. Sweeney

Customer Maintenance Engineer

Pratt & Whitney

F.E. (Phil) Blum

Engineering Test Pilot

McDonnell Douglas

T. Z. Ellison

Staff Engineer - Aircraft Performance

McDonnell Douglas

John T. Coe

« DC-8 Line Captain

Arrow Air

SUMMARY OF EVENTS:

The objective was to fly the simulator with a clean wing sur-

face, doing various take-off scenarios, and then introduce

wing surface contamination and fly the same take-off profiles.

) ')

Page 2 (DC-8 Simulator Tests)

Prior to conducting the tests, Dave McNair developed an

outline of criteria and various take-off profiles that

he wanted to have flown. All of the flying was performed

by myself and Phil Blum of McDonnel Douglas. The take-offs

were made from the right seat. All of the take-offs were

recorded by McNair on video tape. He filmed the co-pilots

flight instruments for each test.

Before the take-off tests were conducted, Phil Blum and

I each made several normal take-offs to get the feel of

the simulator, and to determine if there were any unusual

characteristics about this simulator. We also did complete

aerodynamic stalls to establish a stall speed at 345,000.

This speed was 144 knots. We also did a couple of take-offs

with engine failure after V]_. During all of the tests

the motion part of the simulator was not used. McNair

felt this might cause a problem with so many people observing,

if the simulator were crashed. t

The simulator was set up with the following criteria: I

Ambient Conditions: Temp: -4°c

Wind: 290V04 kts

Press. Alt: 550 ft.

Altim.: 29.85

Aircraft: Engine anti-ice: On

AOW: 3 4 5,000 lbs

Flaps: 18° % MAC: 26%

Gear: Down Stab: 4.3 ANU

Engine #4: T.O. Power - 40°c (.1 EPR)

Each test exercise to be terminated at 300ft.

AGL or brake release + 2 minutes.

«

During the first simulator session, we performed the follow-

ing clean aircraft tests:

(1) Normal T.O. with the V speeds found

on the co-pilot's A.S. indicator. V^ »

129 V R = 145 V 2 - 158 V F = 183

(2) Take-off with lower V speeds and engine

#4 failure at VR.

(3) Take-off with lower V speeds and engine

#4 failure after V 1#

\

Page 3 (DC-8 Simulator Tests)

(4) Take-off with lower V speeds and engine

#4 idle reverse at V R .

(5) All of the tests 1-4 were also performed

at the correct V speeds for 345,000 lbs;

Vi • 138 V R = 158 V 2 = 166

My impression from flying the simulator under these condi-

tions* was that the airplane was controllable. At the lower

V speed take-offs the airplane felt more sluggish and did

not climb as rapidly. We tried a couple of additional

tests that were not included in the test program outline.

A take-off was made with #4 engine failure after Vj_, without

any rudder input to control direction; only aileron input.

The first one resulted in a crash due to extreme control

wheel deflection at the lower speeds. Subsequent take-offs

were made allowing speed to build up after rotation, and

also allowing aircraft to turn into the failed engine. Under

these circumstances, the airplane was controllable.

We also attempted to pull the spoiler handle instead of

the gear, by mistake, to see if the spoiler handle would

cause 44 engine throttle to be pulled back. This test

did net affect the #4 engine throttle, and was discounted

as a possibility.

On the second simulator session, the simulator was reprogram-

med to simulate wing contamination of 1.4 4mm thickness

of wing surface contamination. Data for these changes

was provided by the University of Dayton, through lift/drag

curves, which were constructed for various conditions of

smooth and rough wing surfaces. Additional drag coefficient

curves provided by McDonnell Douglas were used to develop

the program changes.

The contaminated aircraft tests were performed under the

same conditions as listed previously, with the exception

of the addition of wing surface contamination. The various

tests performed were the same as the clean airplane tests.

The initial take-off was made by a DC-8 rated pilot from

Sterling. He was not told about the wing surface contamina-

tion. On his initial T.O. with the lower V speeds after

rotation and lift off, as the airplane accelerated to 166

kts, he increased the pitch above 10-11° and the aircraft

stalled. The result was a rapid break in pitch attitude

to a nose down 20°. There was no stick shaker, or aircraft

buffetting prior to the stall. At the higher V speed take-

off, the aircraft stalled at 170 kt when the pitch was

increased above 10° to establish V2 + 10 climb pitch attitude.

)

page 4 (DC-8 Simulator Tests)

There were some adjustments made to the drag coefficient,

before I flew, because it was felt that what was originally

programmed was excessive. Even with less drag, above a

certain pitch attitude (12-15°), the airplane would stall.

An additional test we performed with a clean wing was a

complete hydraulic failure during take-off (llOkt), with

#4 engine failure after V. There was no real noticeable

difference in controllability, other than increased rudder

pressure.

i

My personal impression of the second session was that,

if within the parameters that we were working, the introduc-

tion of wing surface contamination had a definite deteriorat-

ing affect on aircraft performance. By themselves, the

lower V speeds, higher take-off weight, or possible surface

contamination, would not have caused the aircraft to stall.

McNair seemed to be pleased with the way the tests went.

Additionally, the other representatives present indicated j

they felt the tests were a positive input to the investiga- (

tion. McNair told us at the debriefing, which was also i

video taped, that information from these tests would be

submitted in a report to the CASB, and that a copy of it

would be made available upon request.

John T. Coe

CaDtain - DC-3

You might also like

- Assignment A 3Document6 pagesAssignment A 3amir yousefiNo ratings yet

- NTSB Report On B-17 Crash at Bradley International AirportDocument24 pagesNTSB Report On B-17 Crash at Bradley International AirportPatrick JohnsonNo ratings yet

- Exam AERO4306 2005december PDFDocument4 pagesExam AERO4306 2005december PDFjonthemesNo ratings yet

- CARDS - Circle Theorems Match UpDocument2 pagesCARDS - Circle Theorems Match UpPablo CuevasNo ratings yet

- INHERITANCE (Exclusive Preview) by Christopher PaoliniDocument2 pagesINHERITANCE (Exclusive Preview) by Christopher PaoliniRandomHouseAU0% (1)

- Aircraft Operations From Runways With Inclined Ramps (Skijump)Document19 pagesAircraft Operations From Runways With Inclined Ramps (Skijump)hheussinger3893No ratings yet

- Tanjung Kupang DisasterDocument8 pagesTanjung Kupang DisasterShazwan Hazim Mohd Aznor0% (1)

- Airplane and Engine Responses To Abrupt Throttle Steps As Determined From Flight Tests of Eight Jet-Propelled AirplanesDocument47 pagesAirplane and Engine Responses To Abrupt Throttle Steps As Determined From Flight Tests of Eight Jet-Propelled AirplanesStorebrorNo ratings yet

- Bu 131 Jungmann Spins ReportDocument20 pagesBu 131 Jungmann Spins ReportRoslimizal KamarozamanNo ratings yet

- Assignment 4Document4 pagesAssignment 4José A. Montiel QuirósNo ratings yet

- NTSB BAC Final AAB0401 - 001010Document32 pagesNTSB BAC Final AAB0401 - 001010bombardierwatchNo ratings yet

- TSB A17O0243 Jazz Q400 YTZDocument7 pagesTSB A17O0243 Jazz Q400 YTZGFNo ratings yet

- Aviation Investigation Report A00P0244Document6 pagesAviation Investigation Report A00P0244vonmanoNo ratings yet

- Aeroplane EssaysDocument12 pagesAeroplane EssayscollinsNo ratings yet

- Air Canada Simulator EvaluationDocument19 pagesAir Canada Simulator EvaluationGFNo ratings yet

- Flight Test Validation of The Rq-4 Block 20 Global Hawk Aerodynamic and Propulsive ModelsDocument20 pagesFlight Test Validation of The Rq-4 Block 20 Global Hawk Aerodynamic and Propulsive Modelsj dnNo ratings yet

- G-Opfe (1996)Document4 pagesG-Opfe (1996)GFNo ratings yet

- FlightTestLog Bell-412EPI HX4146AcceptanceFlt 20210707Document3 pagesFlightTestLog Bell-412EPI HX4146AcceptanceFlt 20210707Reza Setyo PermadiNo ratings yet

- NTSB - Final Pitt. Co 2022 Plane Crash ReportDocument13 pagesNTSB - Final Pitt. Co 2022 Plane Crash ReportWSLSNo ratings yet

- Flight Test #1 ReportDocument41 pagesFlight Test #1 ReportBsharrellNo ratings yet

- OV-10 Bronco Cylinder FlapDocument173 pagesOV-10 Bronco Cylinder Flapawiator02100% (1)

- Ntps Fte CourseDocument20 pagesNtps Fte CourseShirat MohsinNo ratings yet

- Airbus A319 - Inadvertent Selection of Parking Brake On LandingDocument4 pagesAirbus A319 - Inadvertent Selection of Parking Brake On LandingReggie JoshuaNo ratings yet

- Flight Test of GL-1 Glider Half Scale PrototypeDocument14 pagesFlight Test of GL-1 Glider Half Scale Prototypericardo pelinNo ratings yet

- Army Aviation Digest - Sep 1961Document40 pagesArmy Aviation Digest - Sep 1961Aviation/Space History Library100% (1)

- NTSB Final ReportDocument10 pagesNTSB Final ReportABC15 NewsNo ratings yet

- NTSB BAC 050309 Probable CauseDocument2 pagesNTSB BAC 050309 Probable CausebombardierwatchNo ratings yet

- Criticalstudyofs00brow BWDocument36 pagesCriticalstudyofs00brow BWPuru-the-braveNo ratings yet

- Kline-Fogleman Airfoil Comparison Study 2-1Document8 pagesKline-Fogleman Airfoil Comparison Study 2-1shibin874141No ratings yet

- PEL-03-CPL-A CAAT Edited Jan 19Document3 pagesPEL-03-CPL-A CAAT Edited Jan 19Nat ChuenjumlongNo ratings yet

- CAAT Private Pilot LicensingDocument3 pagesCAAT Private Pilot LicensingNat ChuenjumlongNo ratings yet

- NTSB ReportDocument7 pagesNTSB ReportDan ShepardNo ratings yet

- Exercises Lecture 3: How Aircraft FlyDocument6 pagesExercises Lecture 3: How Aircraft FlyJosé A. Montiel QuirósNo ratings yet

- Experimental Measurement Moment of InertiaDocument34 pagesExperimental Measurement Moment of InertiayogagaNo ratings yet

- Module-Iv: Flight Testing-17Ae831 Tutorial - IiiDocument2 pagesModule-Iv: Flight Testing-17Ae831 Tutorial - IiiNithinNo ratings yet

- NTSB LJ 020830 Probable CauseDocument3 pagesNTSB LJ 020830 Probable CausebombardierwatchNo ratings yet

- "Systems Phase Planning Guide" (1995)Document255 pages"Systems Phase Planning Guide" (1995)Ali NajmaldinNo ratings yet

- Piper CubDocument84 pagesPiper CubDavid Scott100% (1)

- Chuck Yeagers Advanced Flight Trainer - Manual MacDocument30 pagesChuck Yeagers Advanced Flight Trainer - Manual MacEffat MokhtarNo ratings yet

- 1979 11 11 UsDocument35 pages1979 11 11 UsEduardo RochaNo ratings yet

- National Transportation Safety Board Aviation Incident Final ReportDocument7 pagesNational Transportation Safety Board Aviation Incident Final Reportnestorin111No ratings yet

- Flight Training ManualDocument218 pagesFlight Training ManualaugvydasNo ratings yet

- Ad 0422034Document92 pagesAd 0422034dmmeta80No ratings yet

- February 2005 BulletinDocument80 pagesFebruary 2005 BulletinFlamingo FlamejanteNo ratings yet

- Bombardier CL-600-2B16 604 D-AAAY 02-24Document31 pagesBombardier CL-600-2B16 604 D-AAAY 02-24johnpriceNo ratings yet

- MAE 4350 - Lab 4 AerodynamicsDocument45 pagesMAE 4350 - Lab 4 AerodynamicsjonolioNo ratings yet

- TSBC Bac 050607 A05p0132Document9 pagesTSBC Bac 050607 A05p0132bombardierwatchNo ratings yet

- NASA 120309main FS-055-DFRCDocument3 pagesNASA 120309main FS-055-DFRCNASAdocumentsNo ratings yet

- NTSB Galloping Ghost Photo AnalysisDocument27 pagesNTSB Galloping Ghost Photo AnalysisMiguel Poduje VarasNo ratings yet

- Final Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeDocument28 pagesFinal Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeMorgen GumpNo ratings yet

- Aircraft PerformanceDocument17 pagesAircraft PerformanceGFNo ratings yet

- AINsight - Fatal In-Flight Upset Poses Important Lessons - Business Aviation - Aviation International NewsDocument3 pagesAINsight - Fatal In-Flight Upset Poses Important Lessons - Business Aviation - Aviation International NewstmuthukumarNo ratings yet

- FQ Breguet MD 188Document84 pagesFQ Breguet MD 188dagger21100% (2)

- KJFKDocument29 pagesKJFKSridhar Eswaran100% (1)

- Adp ReportDocument98 pagesAdp ReportSeenu CnuNo ratings yet

- Douglas DC 8 52 ZK NZBDocument31 pagesDouglas DC 8 52 ZK NZBGFNo ratings yet

- Team ID: 6098: Air Crash Investigation Report 101Document6 pagesTeam ID: 6098: Air Crash Investigation Report 101Humesh SNo ratings yet

- NACA TN 116 Comparative Performance With Direct and Geared EnginesDocument13 pagesNACA TN 116 Comparative Performance With Direct and Geared EnginesMark Evan SalutinNo ratings yet

- VH SuzDocument23 pagesVH SuzfrgonzalezNo ratings yet

- Air Crash Investigations - Cracked Solder Joint - The Crash of Indonesia Air Asia Flight 8501From EverandAir Crash Investigations - Cracked Solder Joint - The Crash of Indonesia Air Asia Flight 8501No ratings yet

- L1011 QRHDocument57 pagesL1011 QRHGFNo ratings yet

- CYOWDocument26 pagesCYOWGFNo ratings yet

- TowersDocument27 pagesTowersGFNo ratings yet

- CYLWDocument17 pagesCYLWGFNo ratings yet

- YYC Ceiling MapDocument4 pagesYYC Ceiling MapGFNo ratings yet

- CYQBDocument19 pagesCYQBGFNo ratings yet

- CYLTDocument6 pagesCYLTGFNo ratings yet

- CYJTDocument9 pagesCYJTGFNo ratings yet

- Yo 101Document25 pagesYo 101GFNo ratings yet

- Drawing 10-50000-RDocument1 pageDrawing 10-50000-RGFNo ratings yet

- CYHZDocument28 pagesCYHZGFNo ratings yet

- CYFIDocument10 pagesCYFIGFNo ratings yet

- CYHMDocument18 pagesCYHMGFNo ratings yet

- CYDFDocument10 pagesCYDFGFNo ratings yet

- CYEUDocument7 pagesCYEUGFNo ratings yet

- BKPRDocument22 pagesBKPRGFNo ratings yet

- CYGLDocument10 pagesCYGLGFNo ratings yet

- CYCLDocument7 pagesCYCLGFNo ratings yet

- CYFCDocument14 pagesCYFCGFNo ratings yet

- CYEGDocument35 pagesCYEGGFNo ratings yet

- CYFBDocument10 pagesCYFBGFNo ratings yet

- CYEVDocument7 pagesCYEVGFNo ratings yet

- Drawing 10-58030-RDocument1 pageDrawing 10-58030-RGFNo ratings yet

- CYBGDocument13 pagesCYBGGFNo ratings yet

- AIB Report F 15C TN 86 0176 - FINAL - SIGNEDDocument35 pagesAIB Report F 15C TN 86 0176 - FINAL - SIGNEDGFNo ratings yet

- Drawing 10-41000-RDocument1 pageDrawing 10-41000-RGFNo ratings yet

- Operational Factors Human Performance - Attachment 20 - Audit Report-RelDocument23 pagesOperational Factors Human Performance - Attachment 20 - Audit Report-RelGFNo ratings yet

- Operational Factors Human Performance - Attachment 18 - Transair Administration Manual (Excerpts) - RelDocument17 pagesOperational Factors Human Performance - Attachment 18 - Transair Administration Manual (Excerpts) - RelGFNo ratings yet

- Operational Factors Human Performance - Attachment 19 - Transair SEIMl (Excerpts) - Redacted-RelDocument37 pagesOperational Factors Human Performance - Attachment 19 - Transair SEIMl (Excerpts) - Redacted-RelGFNo ratings yet

- Operational Factors Human Performance - Attachment 17 - Rhoades Aviation Operational Specification Manual (Excerpts) - Redacted-RelDocument20 pagesOperational Factors Human Performance - Attachment 17 - Rhoades Aviation Operational Specification Manual (Excerpts) - Redacted-RelGFNo ratings yet

- Quantum-Like Networks: An Approach To Neural Behavior Through Their Mathematics and Logic 1st Edition Stephen A. SelesnickDocument70 pagesQuantum-Like Networks: An Approach To Neural Behavior Through Their Mathematics and Logic 1st Edition Stephen A. Selesnickamberavila557619100% (5)

- Credit and Saving Management SystemDocument96 pagesCredit and Saving Management SystemFitsum TesfayeNo ratings yet

- ICETIT Proceeding Book 2012Document31 pagesICETIT Proceeding Book 2012sudhakarcjNo ratings yet

- Boolean and Logic GatesDocument56 pagesBoolean and Logic Gatesmitparikh1046No ratings yet

- Jurnal Belimbing WuluhDocument6 pagesJurnal Belimbing WuluhPuspitasari NurulNo ratings yet

- Planning A Code-Compliant, Off-Grid PV System: John WilesDocument6 pagesPlanning A Code-Compliant, Off-Grid PV System: John WilesDaniel MilosevskiNo ratings yet

- Red Box Hack 2Document22 pagesRed Box Hack 2jgregors8683No ratings yet

- Formulas Physics B CH 11, 12, 22, 23, 24, 25 WavesDocument6 pagesFormulas Physics B CH 11, 12, 22, 23, 24, 25 WavesEpic WinNo ratings yet

- Tunnel Lighting 2Document4 pagesTunnel Lighting 2dimaomarNo ratings yet

- Classification and Epidemiology of Communicable DiseasesDocument40 pagesClassification and Epidemiology of Communicable DiseasesRwapembe StephenNo ratings yet

- q1 Week 1 PhilosophyDocument22 pagesq1 Week 1 PhilosophyStiffany FlordelizaNo ratings yet

- Properties of Ideal Transformer & Phasor DiagramDocument2 pagesProperties of Ideal Transformer & Phasor DiagramterNo ratings yet

- Academic Press - Advances in Heat Transfer, Volume 26 - (1995)Document347 pagesAcademic Press - Advances in Heat Transfer, Volume 26 - (1995)jmprtaNo ratings yet

- This Study Resource Was: Demand AnalysisDocument6 pagesThis Study Resource Was: Demand Analysisbest One0% (1)

- Selected Candidates Marks CSE 2022Document6 pagesSelected Candidates Marks CSE 2022hara vardhan reddy naruNo ratings yet

- Sales Final ExamDocument1 pageSales Final ExamIan PangNo ratings yet

- Exploded Parts List VTB 370Document2 pagesExploded Parts List VTB 370Dusan MilosevicNo ratings yet

- IEC 61000-4-4 Burst Electrical Fast Transient / Burst Immunity TestDocument64 pagesIEC 61000-4-4 Burst Electrical Fast Transient / Burst Immunity TestopinzonNo ratings yet

- Lecture 20Document24 pagesLecture 20Trix CCNo ratings yet

- Date of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)Document65 pagesDate of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)GaneshNo ratings yet

- Lecture Poultry Chicken NC IiDocument34 pagesLecture Poultry Chicken NC IiNichole Kyla Enriquez100% (1)

- Ion PropulsionDocument16 pagesIon PropulsionMimsisiNo ratings yet

- Aggmax: Integrated Scrubbing SystemDocument15 pagesAggmax: Integrated Scrubbing SystemPoyaNo ratings yet

- Sources of Stem CellsDocument13 pagesSources of Stem CellsAnshi AroraNo ratings yet

- 1811 Dictionary of The Vulgar TongueDocument315 pages1811 Dictionary of The Vulgar TonguelivehardNo ratings yet

- Nuclear EnergyDocument6 pagesNuclear EnergyDENNIS KIHUNGINo ratings yet

- Never On SundayDocument4 pagesNever On Sundaybrigitte jacquotNo ratings yet

- Public Health Aspect in Respiratory Health Problem (COPD Case)Document17 pagesPublic Health Aspect in Respiratory Health Problem (COPD Case)Anditri WeningtyasNo ratings yet