Professional Documents

Culture Documents

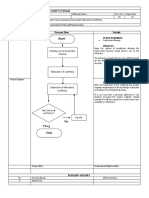

Work Instruction - Installation of Underwater - Tailshaft and Propeller

Work Instruction - Installation of Underwater - Tailshaft and Propeller

Uploaded by

Aaron Perez0 ratings0% found this document useful (0 votes)

36 views2 pagesThe document provides work instructions for installing a tailshaft and propeller. It outlines cleaning and preparing the stern tube and bearings before inserting the tailshaft. The tailshaft should be cleaned and inserted into the stern tube at the proper angle and insertion distance. Then the propeller is installed on the tailshaft by securing it with a lock nut. Finally, the coupling flanges are attached to the inboard end of the tailshaft to complete the installation.

Original Description:

Original Title

Work Instruction_Installation of Underwater_Tailshaft and Propeller

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides work instructions for installing a tailshaft and propeller. It outlines cleaning and preparing the stern tube and bearings before inserting the tailshaft. The tailshaft should be cleaned and inserted into the stern tube at the proper angle and insertion distance. Then the propeller is installed on the tailshaft by securing it with a lock nut. Finally, the coupling flanges are attached to the inboard end of the tailshaft to complete the installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

36 views2 pagesWork Instruction - Installation of Underwater - Tailshaft and Propeller

Work Instruction - Installation of Underwater - Tailshaft and Propeller

Uploaded by

Aaron PerezThe document provides work instructions for installing a tailshaft and propeller. It outlines cleaning and preparing the stern tube and bearings before inserting the tailshaft. The tailshaft should be cleaned and inserted into the stern tube at the proper angle and insertion distance. Then the propeller is installed on the tailshaft by securing it with a lock nut. Finally, the coupling flanges are attached to the inboard end of the tailshaft to complete the installation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

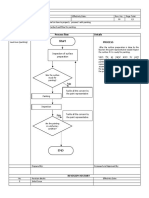

Work Instruction Title:

INSTALLATION OF UNDERWATER: TAILSHAFT & PROPELLER

WI. Ref NO Effectivity Date: Rev. No.: Page Total:

WI-RAJT-11 09.01.2020 00 1/2

PURPOSE: : To Inform operation personnel on how to properly proceed with installation of tailshaft and propeller.

SCOPE: : This procedure covers the standard way of tailshaft and propeller installation.

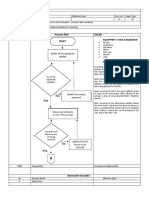

Responsible Process flow Details

Project Engineer

Construction Forman TOOLS/EQUIPMENT REQUIRED

Start Chain block

Lifting sling

Grease

Stern tube preparation

PROCESS

Clean the stern tube inboard and outboard

boss install and fit the bearings to their

respective housing. After installation do a final

checking on the inside diameter of the bearing

to ensure that they would not be loose/too

Installation of bearing and tight

surface preparation

Clean the inside surface of the bearings;

remove any dirt or grime and apply grease if

necessary

Clean the tail shaft free from any dirt or

Insertion of tail shaft foreign particles. For twin screw propellers;

determine which tail shaft is designated to

each stern tube. For clockwise turning

propellers, the stern tube outboard has left

handed threads and vice versa.

Verification of the

insertion distance Lift the tail shaft using chain blocks and align

properly before inserting. Check positioning

and angle for the duration of installation to

prevent any damage to the tail shaft or

Yes bearings. Attach any temporary lifting pad

eyes to the ships bottom if necessary

No Verify the final position by measuring the

clearance between the stern tube and the

Satisfactory? location of the forward end propeller hub. Less

Rectify clearance is preferable to lessen the

probability of rope coiling and getting stuck in

No between.

Install the propeller key into the shaft keyway

and secure it into place by means of locking

A screws

Determine which propeller is designated to

each propeller. Insert propeller into the tail

shaft until it is seated on the shaft tapered

length. Install propeller lock nut.

Prepared by: Reviewed and Approved By:

JOHN ANGELO D. TULIAO ALLEN JAMES C. TULIAO

Operations Head Director

REVISION HISTORY

No. Revision details: Effectivity Date:

0 Initial Issue 09.01.2020

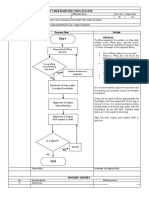

Work Instruction Title:

INSTALLATION OF UNDERWATER: TAILSHAFT & PROPELLER

WI. Ref NO Effectivity Date: Rev. No.: Page Total:

WI-RAJT-11 09.01.2020 00 2/2

PURPOSE: : To Inform operation personnel on how to properly proceed with installation of tail shaft and propeller.

SCOPE: : This procedure covers the standard way of tail shaft and propeller installation.

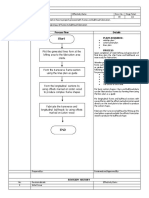

Responsible Process flow Details

Project Engineer

Construction Forman PROCESS

A Tighten propeller lock nut using fabricated

propeller nut wrench. The direction of

tightening is opposite of the intended propeller

rotation; for right -handed propellers

tightening direction is counter-clockwise and

vice versa. The propeller hub should sit tightly

on the tailshaft tapered end.

Installation of propeller

Secure the propeller nut by tightening the lock

screws.

Insert key into the shaft keyway for the

gearbox coupling flange for the inboard ends

followed by the installation of coupling

End flanges. Install coupling lock nuts.

Tighten using fabricated lock nut wrench. The

direction of tightening is opposite of the

operational rotation; for right handed

propellers tightening direction is counter

clockwise and vice versa.

Secure the propeller nut by tightening the lock

screws.

Tighten using fabricated lock nut wrench. The

direction of tightening is opposite of the

operational rotation; for right handed

propellers tightening direction is counter

clockwise and vice versa.

Prepared by: Reviewed and Approved By:

JOHN ANGELO D. TULIAO ALLEN JAMES C. TULIAO

Operations Head Director

REVISION HISTORY

No. Revision details: Effectivity Date:

0 Initial Issue 09.01.2020

You might also like

- Qf-Fsc-Le-002 - Ship Repair AgreementDocument2 pagesQf-Fsc-Le-002 - Ship Repair AgreementAaron PerezNo ratings yet

- BR3 001 - Rex 2000,3000,5000,9000 Series Roller BearDocument5 pagesBR3 001 - Rex 2000,3000,5000,9000 Series Roller BearRodrigo Jechéla BarriosNo ratings yet

- Manual Reductor Dodge Tep PDFDocument232 pagesManual Reductor Dodge Tep PDFraulNo ratings yet

- RTL Sleevoil Instruction Manual 499970Document11 pagesRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाNo ratings yet

- Work Instruction LaunchingDocument3 pagesWork Instruction LaunchingAaron PerezNo ratings yet

- Eaton Clutch Installation Guide EMEA CLIG-0050 0416Document32 pagesEaton Clutch Installation Guide EMEA CLIG-0050 0416Daniel EscobarNo ratings yet

- Work Instruction - Keel LayingDocument1 pageWork Instruction - Keel LayingAaron PerezNo ratings yet

- Dodge® Sleevoil®Rtl Pillow Blocks Sizes 3-7/16" Thru 12": Pre-Assembly InstructionsDocument8 pagesDodge® Sleevoil®Rtl Pillow Blocks Sizes 3-7/16" Thru 12": Pre-Assembly Instructionsjhgjhgjhgj100% (1)

- para Montar Los RodamientosDocument9 pagespara Montar Los Rodamientosbobkanabis79No ratings yet

- V-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612Document9 pagesV-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612pablo7890No ratings yet

- Super Fishing Jar: Instruction Manual 4100Document21 pagesSuper Fishing Jar: Instruction Manual 4100Foros IscNo ratings yet

- Lead Seal Casing Patches: Instruction Manual 6400Document9 pagesLead Seal Casing Patches: Instruction Manual 6400Ragui StephanosNo ratings yet

- F40 561 End Suction Pumps IOIDocument16 pagesF40 561 End Suction Pumps IOIAUX PRESUPUESTONo ratings yet

- Installation & Maintenance: 2.5.7 Tilt (Clearance)Document2 pagesInstallation & Maintenance: 2.5.7 Tilt (Clearance)Depriwangga OMNo ratings yet

- Gleason - Submresible Pump Cable ReelDocument4 pagesGleason - Submresible Pump Cable ReelIgor GrytsenkoNo ratings yet

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsDocument4 pagesWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETNo ratings yet

- F43 560 HSC Fire Pumps IandODocument16 pagesF43 560 HSC Fire Pumps IandOAhmad AliNo ratings yet

- Roots Universal RAI Rotary Positive Blowers: Frames 22 Thru 718Document2 pagesRoots Universal RAI Rotary Positive Blowers: Frames 22 Thru 718Alberto Velosa RoaNo ratings yet

- Super Fishing Jar: Instruction Manual 4100Document24 pagesSuper Fishing Jar: Instruction Manual 4100Teodor Ioan Ghinet Ghinet DorinaNo ratings yet

- Mariners Repository - Propeller Inspection, Defects and RepairsDocument13 pagesMariners Repository - Propeller Inspection, Defects and RepairsATT2016No ratings yet

- Winegard FreeVision Sensar HV AntennaDocument9 pagesWinegard FreeVision Sensar HV Antennabigrob2No ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- 11 2E 后悬架Document15 pages11 2E 后悬架Alexander cesar neyra sotoNo ratings yet

- Installation and Operating Instructions: Horizontal Split Case Fire PumpsDocument16 pagesInstallation and Operating Instructions: Horizontal Split Case Fire Pumpsyesid rodriguezNo ratings yet

- MN4027 PDFDocument4 pagesMN4027 PDFAntonio Juan AntonioNo ratings yet

- TDS-11SA Rig Up ChecklistDocument2 pagesTDS-11SA Rig Up Checklistluis lopezNo ratings yet

- Tas 85 Manual 1Document4 pagesTas 85 Manual 1Mauricio Ariel H. OrellanaNo ratings yet

- Rt540E Operator'S Manual Set-Up and InstallationDocument13 pagesRt540E Operator'S Manual Set-Up and InstallationYuri FaroNo ratings yet

- Resilient Seated Wedge Gate Valve: Installation, Operation & Maintenance InstructionsDocument2 pagesResilient Seated Wedge Gate Valve: Installation, Operation & Maintenance InstructionsshahqazwsxNo ratings yet

- CRAFT Installation-Guide For Split Bearings PDFDocument7 pagesCRAFT Installation-Guide For Split Bearings PDFAdrian CantaragiuNo ratings yet

- E-Brake-Adjust-Instructions 1Document1 pageE-Brake-Adjust-Instructions 1greg titanNo ratings yet

- Overdrive & Intermediate Servo Pin Bore Sleeve Kit: Ford 5R55N/W/SDocument2 pagesOverdrive & Intermediate Servo Pin Bore Sleeve Kit: Ford 5R55N/W/SAndrei valençaNo ratings yet

- KF Series 31 Checkvalves: Installation, Operation, and MaintenanceDocument2 pagesKF Series 31 Checkvalves: Installation, Operation, and MaintenanceVictor LopezNo ratings yet

- Mounting Adjusting Pump UnitDocument2 pagesMounting Adjusting Pump UnitRalf JonesNo ratings yet

- Basic Mechanical Seal Installation: By: Dewi Tri HandayaniDocument9 pagesBasic Mechanical Seal Installation: By: Dewi Tri HandayaniPermana DediNo ratings yet

- Nstructions OR Amshaft Earing OOL: I F C B TDocument2 pagesNstructions OR Amshaft Earing OOL: I F C B TcunNo ratings yet

- Jar Intensifiers: Instruction Manual 4019Document20 pagesJar Intensifiers: Instruction Manual 4019bilalpearltecNo ratings yet

- Pressure Balanced Drilling Bumper Sub: Instruction Manual 4410Document17 pagesPressure Balanced Drilling Bumper Sub: Instruction Manual 4410Foros IscNo ratings yet

- 46 SOP - Fuel Tap ServicingDocument3 pages46 SOP - Fuel Tap ServicingAnonymous O9TX7YlNo ratings yet

- Belt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationDocument8 pagesBelt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationKenji LacambraNo ratings yet

- 102015-8-Ring and Pinion GearDocument5 pages102015-8-Ring and Pinion GearKyaw MinAungNo ratings yet

- Size Overlap: Figure 2 - Non-Ducted Inlet ClearanceDocument3 pagesSize Overlap: Figure 2 - Non-Ducted Inlet ClearanceScott CameronNo ratings yet

- Duco Reaction Beam Air Disc Brake: Maintenance Manual For C and D VariantsDocument36 pagesDuco Reaction Beam Air Disc Brake: Maintenance Manual For C and D VariantsLUKASNo ratings yet

- Excel Components For Symons Templates PDFDocument1 pageExcel Components For Symons Templates PDFAnonymous 8t0V9SNo ratings yet

- Service Bulletin #TAS-129: Commercial Steering SystemsDocument4 pagesService Bulletin #TAS-129: Commercial Steering SystemsariaNo ratings yet

- Spin Valves - Dual Plate Wafer Check ValveDocument4 pagesSpin Valves - Dual Plate Wafer Check ValvePablo HurtubiaNo ratings yet

- Pre-Starting Checks: Avertissement DangerDocument2 pagesPre-Starting Checks: Avertissement DangerAquino ArviNo ratings yet

- Seam 1 Module 5Document46 pagesSeam 1 Module 5Rene Jan HilberoNo ratings yet

- Installation and Operating Instructions Series 4600 Horizontal Split Case PumpDocument4 pagesInstallation and Operating Instructions Series 4600 Horizontal Split Case Pumprkss100% (1)

- CH 8 Suspension & SteeringDocument41 pagesCH 8 Suspension & SteeringjustcheerfulNo ratings yet

- Pneumatische-Schwenkantriebe enDocument20 pagesPneumatische-Schwenkantriebe enSasawahyu WahyukuNo ratings yet

- CH4400 Controls Rev.2 IS 4400Document8 pagesCH4400 Controls Rev.2 IS 4400jpagustinNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument21 pagesGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNo ratings yet

- Attention: Installation GuideDocument2 pagesAttention: Installation GuideDaniel EcheverriaNo ratings yet

- Catalog TechnorollDocument24 pagesCatalog TechnorollSummA Learning CenterNo ratings yet

- ShaftpullerinstructionsDocument2 pagesShaftpullerinstructionsjitmarineNo ratings yet

- 4347 Instructions FRDocument4 pages4347 Instructions FRAllfrNo ratings yet

- SKF SAF and SAFS Installation and Maintenance OMs English 1 PDFDocument4 pagesSKF SAF and SAFS Installation and Maintenance OMs English 1 PDFjaime San Martin PulgarNo ratings yet

- Stereo Turntable: Operating InstructionsDocument10 pagesStereo Turntable: Operating InstructionsBarbaraNo ratings yet

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Po403 - FSC - Eco Ii Drydocking WorksDocument1 pagePo403 - FSC - Eco Ii Drydocking WorksAaron PerezNo ratings yet

- Astm19 0101Document4 pagesAstm19 0101Aaron PerezNo ratings yet

- Astm Volume 01 02Document8 pagesAstm Volume 01 02Aaron PerezNo ratings yet

- Work Instruction FabricationDocument1 pageWork Instruction FabricationAaron PerezNo ratings yet

- PG70ABDLDocument30 pagesPG70ABDLAaron PerezNo ratings yet

- Work Instruction - PaintingDocument1 pageWork Instruction - PaintingAaron PerezNo ratings yet

- Work Instruction - Installation of Machineries - Main EngineDocument1 pageWork Instruction - Installation of Machineries - Main EngineAaron PerezNo ratings yet

- Work Instruction - Fabrication of OutfittingsDocument1 pageWork Instruction - Fabrication of OutfittingsAaron PerezNo ratings yet

- Work Instruction - Keel LayingDocument1 pageWork Instruction - Keel LayingAaron PerezNo ratings yet

- Work Instruction LaunchingDocument3 pagesWork Instruction LaunchingAaron PerezNo ratings yet

- Work Instruction - Mold LoftingDocument2 pagesWork Instruction - Mold LoftingAaron PerezNo ratings yet

- JDM PRICELIST 2022 OCTOBER 05 For ClientsDocument55 pagesJDM PRICELIST 2022 OCTOBER 05 For ClientsAaron PerezNo ratings yet

- Work Instruction - WeldingDocument1 pageWork Instruction - WeldingAaron PerezNo ratings yet

- Church Program 1Document2 pagesChurch Program 1Aaron PerezNo ratings yet

- Class Items For Drydock 2022Document38 pagesClass Items For Drydock 2022Aaron PerezNo ratings yet

- Astm21 0303Document12 pagesAstm21 0303Aaron PerezNo ratings yet

- 218CH047Document6 pages218CH047Aaron PerezNo ratings yet

- Ardrox 970P25E 6.5.15Document2 pagesArdrox 970P25E 6.5.15Aaron PerezNo ratings yet

- TDS-Flaw Crack Detector SystemDocument2 pagesTDS-Flaw Crack Detector SystemAaron PerezNo ratings yet

- 216 NR - 2022 07Document363 pages216 NR - 2022 07Aaron PerezNo ratings yet