Professional Documents

Culture Documents

Qap B7 - 2H

Qap B7 - 2H

Uploaded by

JJ VAPIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qap B7 - 2H

Qap B7 - 2H

Uploaded by

JJ VAPICopyright:

Available Formats

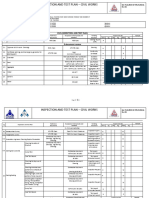

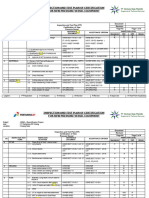

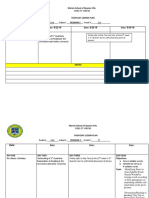

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-001 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B7/ SA-194 GR 2H BOLTING MATERIAL

A. Scope : This Inspection and test plan covers the minimum testing requirements for SA-193 Gr B7/

SA-194 Gr 2H bolting material

B. Reference Docs : Standard- ASME BPVC sec IIA- SA193 Gr B7/ SA 194 Gr 2H/ AES-3563/ PO/PR/ Job

specifications / Approved documents.

Inspection & Test Requirements for Manufacturer

Scope of

Reference inspection

Sl Characteristics/ Type Quantum

Stage/ Activity standard/ Record

No of check of check

Acceptance Norms Supplier TPIA

Test

Marking and ASME BPVC sec IIA-

Raw material certificate,

1 correlation with test 100% SA193 Gr B7/ SA H R

inspection inspection

certificate 194 Gr 2H

report

Chemical composition

one ASME BPVC sec IIA-

/ Macro/ Mechanical Inspection

sample SA193 Gr B7/ SA H R

Properties/internal report

Raw material per heat 194 Gr 2H

2 soundness

inspection

ASME BPVC sec IIA-

Inspection

Spectro analysis 100% SA193 Gr B7/ SA H R

report

194 Gr 2H

Inspection

report, Heat

Heat treatment cycle ASME BPVC sec IIA-

treatment

3 Heat treatment (time and 100% SA193 Gr B7/ SA H R

charts &

temperature) 194 Gr 2H

Calibration

records

Thread Rolling, ASME BPVC sec IIA-

In Process Inspection

4 Forging Of Nuts, 100% SA193 Gr B7/ SA H _

Inspection report

Machining 194 Gr 2H

Each HT

ASME BPVC sec IIA-

Selection of Lot/ Each Inspection

5 Test piece marking SA193 Gr B7/ SA H W

samples Heat No/ report

194 Gr 2H

Size

Each HT As per PO/ASME

Nondestructive Surface and internal Lot/ Each BPVC sec IIA- SA193 Inspection

6 H RW

testing imperfections Heat No/ Gr B7/ SA 194 Gr 2H report

Size / ASME Sec V

Each HT

Mechanical properties ASME BPVC sec IIA-

Destructive Lot/ Each Inspection

7 YS, UTS, RA, SA193 Gr B7/ SA H H

testing Heat No/ report

Elongation ,Proof Load 194 Gr 2H

Size

100% by

Positive material supplier As per PO/ASME

8 PMI identification (only for and at BPVC sec IIA- SA193 PMI report P RW

AS & SS components) 10% by Gr B7/ SA 194 Gr 2H

TPIA

Visual, Dimensional 100% by

As per PO/ Inspection

9 Final inspection check, Threads Check supplier H H

Stamping Of report

by GO-NOGO gauge, and at

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 2 of 4

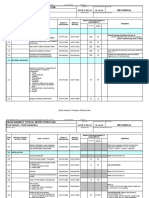

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-001 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B7/ SA-194 GR 2H BOLTING MATERIAL

Scope of

Reference inspection

Sl Characteristics/ Type Quantum

Stage/ Activity standard/ Record

No of check of check

Acceptance Norms Supplier TPIA

Color coding, Final 10% by Accepted Bolting

Stamping, Grade TPIA Material

punch check,

lubrication

100% by

Verification of supplier

Coating (If As per PO / PR / Inspection

10 galvanized coating & and at H RW

Applicable) Applicable Standard report

galvanizing thickness 10% by

TPIA

Verification of Test

material test As per PO / PR / certificate

Documentation

11 certificate, test report, 100% Material (EN 10204 H H

& Release

inspection reports & specification 3.2), Reports,

Issue of Release Note IRN

Inspection & Test Requirements for Traders /Stockist

Reference Scope of

Sl Characterist

Quantum standard and inspection

N Stage / Activity ics / Type of Record

of check Acceptance

o check Supplier TPIA

norms

MTC review for the physical ASME BPVC sec

1 and chemical test, heat Verify MTC 100% IIA- SA193 Gr Mill TC R R

treatment, NDT B7/ SA 194 Gr 2H

Physical co-relation of MTC Verify Heat

ASME BPVC sec Mill TC & TPI

Heat no./Batch no. to the no./Batch Each Heat

2 IIA- SA193 Gr Inspection P RW

fasteners under scope of no. to the No. / Lot

B7/ SA 194 Gr 2H report

supply. MTC

Chemical

composition

One

/ Macro/ ASME BPVC sec

Sample selection & Check Sample per

3 Mechanical IIA- SA193 Gr Test report H W

Testing Heat / Per

Properties/I B7/ SA 194 Gr 2H

Size

nternal

soundness

100% by ASME BPVC sec

Dimensional checking Dimensional

Measureme supplier IIA- SA193 Gr

4 (including Threads Check by inspection P RW

nt and at 10% B7/ SA 194 Gr 2H

GO-NOGO gauge) report

by TPIA / P.O.

Visible

ASME BPVC sec

Visual inspection and surface 100% by

IIA- SA193 Gr Internal

Verification of Marking of defect / supplier

5 B7/ SA 194 Gr 2H Inspection P RW

Material spec./ Grade / Corrosion. and at 10%

/ Std. engg. report

Heat No. / Lot No. / Size etc. Verification by TPIA

Practice / PO

with respect

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 3 of 4

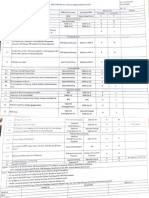

BHARAT PETROLEUM CORPORATION LIMITED, KOCHI REFINERY

ADVISORY SERVICES DEPARTMENT File No: KR.AS.INSP.9.03:900:08:2

QUALITY ASSURANCE PLAN Doc No: BPCL/KR/AS-ITP-001 Rev : 0

INSPECTION TEST PLAN FOR SA-193 GR B7/ SA-194 GR 2H BOLTING MATERIAL

Reference Scope of

Sl Characterist

Quantum standard and inspection

N Stage / Activity ics / Type of Record

of check Acceptance

o check Supplier TPIA

norms

to Test

Certificate

Positive

material

100% by As per PO/ASME

identificatio

supplier BPVC sec IIA-

6 PMI n (only for PMI report P RW

and at 10% SA193 Gr B7/ SA

AS & SS

by TPIA 194 Gr 2H

components

)

Verification

of

galvanized P.O. / Std. engg. Inspection

7 Coating (If Applicable) Each item H RW

coating & practice Report

galvanizing

thickness

Separate

TPIA stamping on all stamping for the

Each item Inspection

8 certified items of the Verification whole lot and for H H

of PO Report

inspected lot under the PO. the actual

witnessed items.

Verification

of

Inspection As per PO / PR / Test

9 Documentation & Release Reports, 100% Material certificate -- H

MTC & Issue specification Reports, IRN

of Release

Note

Legend

H - Hold (Do not proceed without approval), P-Perform, RW - Random Witness (As specified or 10% (min.1 No. of

each size and type of Bulk item), R-review, W-Witness (Give due notice, work may proceed after scheduled date).

Notes

1. This ITP contains the minimum inspection requirements. Vendor to comply all other requirements (if any) as per PO / PR.

2. In case of raw material supplied by sub suppliers/vendors; chemical composition / Macro/ Mechanical Properties/internal

soundness/ spectro analysis shall be performed by them and shall be witnessed by supplier as mentioned in Sl No-2

2. Hardness for studs/nuts shall be in range of 250-300 HBW.

3. As per AES-3563 REV 3, magnetic particle inspection has to be carried out on 10% of each heat on finished bolts (1 number

minimum and maximum 20 numbers per size) in accordance with ASTM-E-709. (This is a supplementary requirement and shall not

apply unless specified in the PO).

4. Raw material or finished fastener macro etch examination to be verified by TPIA.

5. B7 bolt and 2H nuts metallurgy must be punched on both ends of the studs and at the two end faces of nuts on both ends of the

studs and at two locations on the nuts.

6. All bolts shall be properly lubricated prior to dispatch/ supplying.

BPCL-KR/Advisory Services/ QAP/ File No: KR.AS.INSP.9.03:900:08:2 Page 4 of 4

You might also like

- 2020 WHO Classification of Soft Tissue and Bone TumoursDocument617 pages2020 WHO Classification of Soft Tissue and Bone TumoursOlteanu Dragos-Nicolae91% (11)

- Inspection and Test Plan For Gas Turbine PDFDocument5 pagesInspection and Test Plan For Gas Turbine PDFreza ebrahimi100% (1)

- Irvine Welsh Ecstasy Three Tales of Chemical RomanceDocument43 pagesIrvine Welsh Ecstasy Three Tales of Chemical RomanceClara RuizNo ratings yet

- Quality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular LimitedDocument2 pagesQuality Assurance Plan For Austenitic Stainless Steel Welded Pipe AS PER ASTM A 312, Latest Edtion Vendor: Jindal Quality Tubular Limitedamit rajputNo ratings yet

- ITP (Inspection Test Plan) For Tank ConstructionDocument6 pagesITP (Inspection Test Plan) For Tank ConstructionNuwan RanaweeraNo ratings yet

- Qap B7M - 2HMDocument4 pagesQap B7M - 2HMJJ VAPINo ratings yet

- Qap B16Document4 pagesQap B16JJ VAPINo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- Inspection and Test Plan For Gas TurbineDocument5 pagesInspection and Test Plan For Gas TurbineLiu YangtzeNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- Quality Assurance Plan FastnersDocument1 pageQuality Assurance Plan FastnersSuKHjiT SiNGhNo ratings yet

- Civil Inspection and Test PlanDocument5 pagesCivil Inspection and Test PlanWalid AmdouniNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- With Strainer, Piston QapDocument1 pageWith Strainer, Piston QapajmainNo ratings yet

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- TSP Adaptation Project No: Q3510: Inspection and Test Plan of Shop Fabricated Stainless Steel TanksDocument2 pagesTSP Adaptation Project No: Q3510: Inspection and Test Plan of Shop Fabricated Stainless Steel TanksfbellimamNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- WM65AJN200Document4 pagesWM65AJN200Shasin SolankiNo ratings yet

- Inspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok ADocument7 pagesInspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok AMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- Tube CS179 - MPSDocument3 pagesTube CS179 - MPSgaurangNo ratings yet

- Sample Quality Assurance Plan For Cs FlangesDocument2 pagesSample Quality Assurance Plan For Cs FlangesKaran BhanotNo ratings yet

- GS Peb QapDocument4 pagesGS Peb Qapshailendr12No ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Inspection and Test Plan-Geo-Technical Works C002Document3 pagesInspection and Test Plan-Geo-Technical Works C002Furqan0% (1)

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Satip F 001 01Document3 pagesSatip F 001 01Ansar Ali VemmullyNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Inspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)Document2 pagesInspection and Test Plan: Existing Metering System (MR/S Turbine & Rotary)iwan NugrohoNo ratings yet

- Scan 27 Sep 2020Document2 pagesScan 27 Sep 2020SURAJ PRSADNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- ATTACHMENTDocument10 pagesATTACHMENTAgus SuriptoNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- QAP Roofing SheetDocument3 pagesQAP Roofing SheetAMRIT PAL SINGHNo ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- Additional Control Valve QAP (Review 07-11-22)Document4 pagesAdditional Control Valve QAP (Review 07-11-22)PRADEEP GAIKWADNo ratings yet

- Qap Wo 7 r0 (Ion Exchange)Document1 pageQap Wo 7 r0 (Ion Exchange)KailasNo ratings yet

- Draft ITP PV NEW PEP ScrubberDocument4 pagesDraft ITP PV NEW PEP Scrubberinspectionzona11No ratings yet

- Quality Assurance Plan (Qap) For L.T.C.S. FittingsDocument2 pagesQuality Assurance Plan (Qap) For L.T.C.S. FittingsVIVEK TIWARINo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

- Tubacex-Prakash 10650T1 QapDocument3 pagesTubacex-Prakash 10650T1 Qaprabiprasad.iispl.comletedNo ratings yet

- Danem Engineering Works - WLL.: Quality Control & Inspection Test PlanDocument11 pagesDanem Engineering Works - WLL.: Quality Control & Inspection Test PlanRejoy babyNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDocument2 pagesTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanNo ratings yet

- UNQ-00-K-143b - 001-EQ-017 - Inspection and Test Plan For U.G. FuelGas Pipe InstallationDocument3 pagesUNQ-00-K-143b - 001-EQ-017 - Inspection and Test Plan For U.G. FuelGas Pipe InstallationrakibnjtechNo ratings yet

- ValveDocument6 pagesValvetharmarajuNo ratings yet

- ITEM: Carbon Steel Seamless PipesDocument3 pagesITEM: Carbon Steel Seamless Pipesmanoj thakkarNo ratings yet

- Automated Stream Analysis for Process Control V2From EverandAutomated Stream Analysis for Process Control V2Dan MankaNo ratings yet

- Earth Compaction EquipmentDocument15 pagesEarth Compaction EquipmentÄmî Îíţ ŚHäh100% (1)

- Risk Based SupervisionDocument22 pagesRisk Based Supervisionsakshi819863200No ratings yet

- Fides Et Veritas: Marian School of Quezon CityDocument3 pagesFides Et Veritas: Marian School of Quezon Cityprecious alcantaraNo ratings yet

- Muscle Nerds Education: Nutrient GuideDocument24 pagesMuscle Nerds Education: Nutrient GuideAle AlessandroNo ratings yet

- Amersham RPCManualDocument86 pagesAmersham RPCManualRobertoNo ratings yet

- Female Reproductive SystemDocument8 pagesFemale Reproductive SystemEfanPutraNo ratings yet

- Economic BotanyDocument27 pagesEconomic BotanyAnanth Kulkarni0% (1)

- G8010 2GR PREMIUM - Molykote - g8010Document2 pagesG8010 2GR PREMIUM - Molykote - g8010Dicky PratamaNo ratings yet

- 1-Nitocote CM210Document4 pages1-Nitocote CM210Ahmed I. GhallabNo ratings yet

- Properties of TimberDocument44 pagesProperties of TimberMary Joy RuilesNo ratings yet

- K.S.Venkatraman: Core Competencies Brief OverviewDocument3 pagesK.S.Venkatraman: Core Competencies Brief OverviewHariNo ratings yet

- Ignition System Prototype Maintenance Manual and Safety ManualDocument15 pagesIgnition System Prototype Maintenance Manual and Safety ManualangeloNo ratings yet

- 1150-1155 Haybuster Parts SN0191 and Up Aug-2020Document306 pages1150-1155 Haybuster Parts SN0191 and Up Aug-2020Jason CrowleyNo ratings yet

- G.R. No. 198501 Kestrel Shipping Inc. v. MunarDocument12 pagesG.R. No. 198501 Kestrel Shipping Inc. v. MunarJa RuNo ratings yet

- Memorial HospitalDocument4 pagesMemorial HospitalShyqyrie Baci0% (2)

- FOMAR-QTN-2019-20-117 Kamat PDFDocument1 pageFOMAR-QTN-2019-20-117 Kamat PDFPriyesh KamatNo ratings yet

- Technical Specification For Sorghum GrainsDocument6 pagesTechnical Specification For Sorghum GrainsMohd SaifulNo ratings yet

- Problems Faced in Spoken English Among Learning Disabilities StudentsDocument12 pagesProblems Faced in Spoken English Among Learning Disabilities StudentsTompok ManggisNo ratings yet

- Vulvovaginitis: Find The Cause To Treat It: ReviewDocument10 pagesVulvovaginitis: Find The Cause To Treat It: ReviewMinati Yohana SiagianNo ratings yet

- Building With Alternative MaterialsDocument10 pagesBuilding With Alternative MaterialsCharmaine R. TaylorNo ratings yet

- Raj GeographyDocument42 pagesRaj Geographyhemant.niotNo ratings yet

- Ocular Injuries and EmergenciesDocument60 pagesOcular Injuries and Emergenciesarnol3090100% (1)

- LT Adm 14Document10 pagesLT Adm 14Bayani VicencioNo ratings yet

- Astm D5963-04Document9 pagesAstm D5963-04Sampath WeragodaNo ratings yet

- Via Character Strength SurveyDocument4 pagesVia Character Strength Surveyapi-276878497No ratings yet

- Sigmatherm™ 540 / PPG Hi-Temp™ 540: Product Data SheetDocument4 pagesSigmatherm™ 540 / PPG Hi-Temp™ 540: Product Data SheetSubodh KulkarniNo ratings yet

- Ware vs. Ciba-Geigy CorpDocument2 pagesWare vs. Ciba-Geigy CorpJann RosalesNo ratings yet

- Gas Oil: Section 1 - Chemical Product and Company IdentificationDocument10 pagesGas Oil: Section 1 - Chemical Product and Company Identificationasep supriyadiNo ratings yet