Professional Documents

Culture Documents

ZBT 10004759517 en

ZBT 10004759517 en

Uploaded by

RENE PADUA AGUIAROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZBT 10004759517 en

ZBT 10004759517 en

Uploaded by

RENE PADUA AGUIARCopyright:

Available Formats

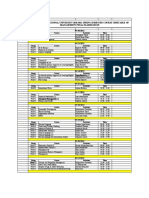

T E CHNICA L INF O RM A T IO NS – PO W DE R CO A T ING S

POLITHERM 26 R SM BLACK 70840 MA

PRODUCT: 10005903

DESCRIPTION / USES: Metallic parts coating for outdoor use.

CHARACTERISTI CS:

Resin: Polyester

Specific gravity: 1,63 ± 0,10 g/cm3

Stability: 12 month (max. 30ºC)

Observations: Free of heavy metals and other substances provided for

in Directive 2015/863 EU of 03/31/2015 (RoHS).

APPLICATION CHARACTERISTICS:

Surface: Ferrous and non-ferrous

Surface preparation: Ferrous : Phosphatization

Non-ferrous: Chromatization or phosphatization*

Cure conditions: 10 minutes at 200 ºC**

Thickness: 60 – 80 µm

Application system: Electrostatic gun

AFTER CURE CHARACTERISTICS :***

TEST METHOD SPECIFICATION

ADHESION WPS-3905 : GR0

GLOSS @ 60° WPS-3854 : 28 ± 5 UB

IMPACT (REVERSE) WPS-4130 : Min 50 kg X cm

FLEXIBILITY (CONIC MANDREL) WPS-4856 : Max 3 mm

CHEMICAL RESISTANCE ***

Salt spray: : Min. 500 h (ASTM B117 – 03)

Hum idity: : Min. 1000 h (35ºC)

* For non-ferrous metals phosphatizing, please contact our technical service.

** After stabilization on correct temperature (metal temperature).

*** The tests w ere conducted on degreased steel panels in accordance with the cure and thickness specifications. The results may

vary, depending on the surface characteristics. For chemical resistance testing, panels w ere degreased and treated with tricationic

phosphat.

IMPORTANT: This coating, w hen properly applied and cured is suitable for the use of adhesives and sealants. How ever, because of

the different products on the market, it requires prior testing by the user in order to select the adhesive and / or sealant appropriate.

If is not possible the use of the product according to the directions given above w e ask you to contact our technical service .

STORAGE: Fresh, dry and covered place.

C O P Y F O R I N F O R M AT I O N

Review : 00 Date: 08/04/20

You might also like

- SAP Press Ebooks Collection ListDocument3 pagesSAP Press Ebooks Collection ListKishor Boda40% (5)

- ZBT 10004759365 enDocument1 pageZBT 10004759365 enRicardo FernandesNo ratings yet

- Paint Technical File RAL 3000Document2 pagesPaint Technical File RAL 3000Bruno MarquesNo ratings yet

- TDS M30 REV2 Apr14 A4Document2 pagesTDS M30 REV2 Apr14 A4dakidofdaboomNo ratings yet

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoNo ratings yet

- Driscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValueDocument2 pagesDriscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValuemariannyNo ratings yet

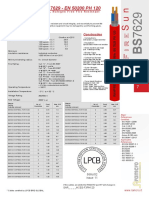

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- PMET 273 - Amorphous AlloyDocument1 pagePMET 273 - Amorphous Alloy.xNo ratings yet

- Product Specification - Apcoshield Py905sg Grey Ral 7016 20kgDocument1 pageProduct Specification - Apcoshield Py905sg Grey Ral 7016 20kgVenkatraman SubramaniamNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- p635 Construction Pu Sealant Tds EnDocument3 pagesp635 Construction Pu Sealant Tds Enscribdme123No ratings yet

- RR 1.5 SQ MM FR-LSH (DRJ-220000868)Document1 pageRR 1.5 SQ MM FR-LSH (DRJ-220000868)Govind NataniNo ratings yet

- Rebar Coupler SpecificationDocument7 pagesRebar Coupler SpecificationÇïvílìåñ ÑâvîñNo ratings yet

- PW100 Technical Data SheetDocument1 pagePW100 Technical Data SheetPartagon PowNo ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Black 2 Coat TDSDocument1 pageBlack 2 Coat TDSradiantpappuNo ratings yet

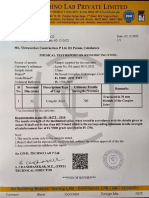

- Mr-001 Test CertificateDocument1 pageMr-001 Test Certificatesai sudheerNo ratings yet

- EuTronic Arc Spray 595ASDocument2 pagesEuTronic Arc Spray 595ASEdwinNo ratings yet

- PMET 292 Nano AlloyDocument1 pagePMET 292 Nano Alloy.xNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- Material Data Sheet: Type Test Method Imperial MetricDocument1 pageMaterial Data Sheet: Type Test Method Imperial MetricGufran AhmadNo ratings yet

- Test Report C5Document1 pageTest Report C5janakaNo ratings yet

- (201207) (PDS) Ex4700Document3 pages(201207) (PDS) Ex4700Abdelrahman AwadallahNo ratings yet

- Datasheet: EnglishDocument1 pageDatasheet: Englisha.anticlickNo ratings yet

- Berger Paints India LimitedDocument2 pagesBerger Paints India LimiteddipeshlodhiqseplNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- Nitoflor RT6000 UTDocument4 pagesNitoflor RT6000 UTAndrew KasanaNo ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- Siare Technologies - Test ReportDocument1 pageSiare Technologies - Test ReportnikhilbhorNo ratings yet

- Ramfireco CableDocument1 pageRamfireco CableahsanNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- Datasheet SaphirAS 2016 EN v1Document2 pagesDatasheet SaphirAS 2016 EN v1André CardosoNo ratings yet

- MTC VG-40-9080942Document1 pageMTC VG-40-9080942vyzjhxypdcNo ratings yet

- TSP Truseal Polymer, IndustrialDocument1 pageTSP Truseal Polymer, IndustrialCosmin PuniNo ratings yet

- TS 15130Document1 pageTS 15130GiveawayNo ratings yet

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 pagesALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucNo ratings yet

- HD00108WBK Technical Data Sheet 20240227105749Document1 pageHD00108WBK Technical Data Sheet 20240227105749phanplastic299No ratings yet

- Powergrout-Ns3: High Performance Precision GroutDocument2 pagesPowergrout-Ns3: High Performance Precision GroutHemamathiNo ratings yet

- Din933 A4l 8 X 80 MMDocument1 pageDin933 A4l 8 X 80 MMM K ANBUDURAINo ratings yet

- MR-001 Test CertificateDocument1 pageMR-001 Test Certificatesai sudheerNo ratings yet

- 1604-01 Simatherm HR Primer ATP 600CDocument2 pages1604-01 Simatherm HR Primer ATP 600CBagusRekaNo ratings yet

- Esd Jotun PaintDocument3 pagesEsd Jotun PaintMohd Ridzuan Abdul AzizNo ratings yet

- A F 984 Technical Data SheetDocument1 pageA F 984 Technical Data SheetdneradNo ratings yet

- Product Data Sheet EP CC 301Document1 pageProduct Data Sheet EP CC 301David Arturo Ramos GajardoNo ratings yet

- Deep F.C KitDocument6 pagesDeep F.C KitVipul SharmaNo ratings yet

- SECCO S2040: Polypropylene, HomopolymerDocument2 pagesSECCO S2040: Polypropylene, HomopolymerManuel Lopez100% (1)

- MR 230 231 232 233 234 - en - PiDocument3 pagesMR 230 231 232 233 234 - en - Picoronado777No ratings yet

- Wire Harness - BizlinkDocument6 pagesWire Harness - BizlinkDaniel GnanaselvamNo ratings yet

- EluCad InstructionsDocument2 pagesEluCad InstructionsIng Admir MatoshiNo ratings yet

- VRM 2 UT and MPT ReportsDocument3 pagesVRM 2 UT and MPT ReportsSunny G CNo ratings yet

- TDS Nitoflor SL3000 UT IndiaDocument4 pagesTDS Nitoflor SL3000 UT IndiaqmsudhirNo ratings yet

- HOSTAPHAN® Polyester films..PETDocument10 pagesHOSTAPHAN® Polyester films..PETsreeeragNo ratings yet

- UltraTech Powergrout NS2Document2 pagesUltraTech Powergrout NS2Savalia HardikNo ratings yet

- Intime Co2 4.5 WT MSDocument2 pagesIntime Co2 4.5 WT MSuday245No ratings yet

- Ceiling Insulation-K FlexDocument1 pageCeiling Insulation-K FlexdesignNo ratings yet

- Especificaciones Tecnicas eSUN - eASA-FilamentDocument2 pagesEspecificaciones Tecnicas eSUN - eASA-FilamentDiego TellezNo ratings yet

- Ultrapaste Cu 12 SF - 2017 (E)Document1 pageUltrapaste Cu 12 SF - 2017 (E)HANIF AKBARNo ratings yet

- Ucrete MF AsDocument2 pagesUcrete MF AsDoby YuniardiNo ratings yet

- Under Ground RailwayDocument38 pagesUnder Ground RailwaySandip JagdaleNo ratings yet

- Apollonius of Rhodes - ArgonauticaDocument438 pagesApollonius of Rhodes - Argonauticajoaquin ojedaNo ratings yet

- System Wiring DiagramsDocument87 pagesSystem Wiring Diagramshcastens3989100% (1)

- Myanmar Community Security Cartoon Booklet EnglishDocument15 pagesMyanmar Community Security Cartoon Booklet EnglishSaw HsarNo ratings yet

- Palmer Propbank CLDocument33 pagesPalmer Propbank CLAtif RaufNo ratings yet

- Transport4 - High Electric Fields - Velocity SaturationDocument16 pagesTransport4 - High Electric Fields - Velocity SaturationMạnh Huy BùiNo ratings yet

- Principles and Theories of Language Acquisition and LearningDocument78 pagesPrinciples and Theories of Language Acquisition and LearningPrincess AlmarioNo ratings yet

- NEFRO4Document26 pagesNEFRO4carlosl123456No ratings yet

- Sportsmen and TechnologyDocument11 pagesSportsmen and TechnologyAkshita KapilNo ratings yet

- Print Supple Admit Card - I-EMS - EUBDocument1 pagePrint Supple Admit Card - I-EMS - EUBMustak JuliatNo ratings yet

- Syllabus - PAPER 1 - Application of Computer in MediaDocument39 pagesSyllabus - PAPER 1 - Application of Computer in MediaAbubakar shomarNo ratings yet

- Ala-Too International University 2020-2021 Spring Semester Course Timetable of Management Final ExaminationDocument8 pagesAla-Too International University 2020-2021 Spring Semester Course Timetable of Management Final ExaminationKunduz IbraevaNo ratings yet

- Metrology in Health A Pilot StudyDocument11 pagesMetrology in Health A Pilot StudyMarcos AguiarNo ratings yet

- Transmission: Section F Section FDocument1 pageTransmission: Section F Section FSzabolcs Ignátisin0% (1)

- Circuit Analysis Technique Mesh (Loop) Current Method (Maxwell's Method)Document8 pagesCircuit Analysis Technique Mesh (Loop) Current Method (Maxwell's Method)Rahma HanifaNo ratings yet

- Getting Started With Kubernetes - Sample ChapterDocument22 pagesGetting Started With Kubernetes - Sample ChapterPackt Publishing100% (1)

- Paint DeptDocument3 pagesPaint DeptYanelfi GuzmanNo ratings yet

- Pediatric Hospital PresentationDocument61 pagesPediatric Hospital PresentationLindsay Khryss Cendy MadahanNo ratings yet

- Rome of Augustus Study GuideDocument41 pagesRome of Augustus Study GuideTheo WilsonNo ratings yet

- 032055-06 01a PDFDocument150 pages032055-06 01a PDFmiscaelNo ratings yet

- 29primary AngleClosure GlauDocument9 pages29primary AngleClosure GlauShari' Si WahyuNo ratings yet

- Math 308 Solutions To Conceptual Problems - Chapter 1Document3 pagesMath 308 Solutions To Conceptual Problems - Chapter 1Mehul JoshiNo ratings yet

- Lab Report 2 Sku 3043Document7 pagesLab Report 2 Sku 3043Nelviana NahNo ratings yet

- Aspergers Boarding SchoolDocument4 pagesAspergers Boarding SchoolBrian HaraNo ratings yet

- Fen4702 Project 2019Document18 pagesFen4702 Project 2019Molebogeng MathibediNo ratings yet

- Christmas Fruit Cake - Kerala Plum CakeDocument2 pagesChristmas Fruit Cake - Kerala Plum Cakekevinkevz1No ratings yet

- Tubos de CalorDocument7 pagesTubos de CalorChristo AcostaNo ratings yet

- 4D Printing: Self-Assembly & Programmable MatterDocument18 pages4D Printing: Self-Assembly & Programmable MatterAnonymous iI88LtNo ratings yet

- Updated UHVPE Unit II Notes PDFDocument28 pagesUpdated UHVPE Unit II Notes PDFAditya SrivastavaNo ratings yet