Professional Documents

Culture Documents

Apw8804e Anpec

Apw8804e Anpec

Uploaded by

Ruan RomãoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apw8804e Anpec

Apw8804e Anpec

Uploaded by

Ruan RomãoCopyright:

Available Formats

APW8804E

3A 5V 1MHz Synchronous Buck Converter

Features General Description

• High Efficiency up to 95% APW8804E is a 3A synchronous buck converter with inte-

- Automatic PFM/PWM Mode Operation grated 65mΩ high side and 55mΩ low side power

• Adjustable Output Voltage from 0.6V to VPVDD MOSFETs. The APW8804E, design with a current-mode

• Integrated 65mΩ High Side / 55mΩ Low Side control scheme, can convert wide input voltage of 2.6V to

5.5V to the output voltage adjustable from 0.6V to 5.5V to

MOSFETs

provide excellent output voltage regulation.

• Low Dropout Operation: 100% Duty Cycle

The APW8804E is equipped with an automatic PFM/PWM

• Stable with Low ESR Ceramic Capacitors

mode operation. At light load , the IC operates in the PFM

• Power-On-Reset Detection on VDD and PVDD mode to reduce the switching losses. At heavy load, the

• Integrated Soft-Start and Soft-Stop IC works in PWM mode. At PWM mode, the switching

• Over-Temperature Protection frequency is set by the external resistor.

• Over-Voltage Protection The APW8804E is also equipped with Power-on-reset,

• Under-Voltage Protection soft-start, soft-stop, and whole protections (under-voltage,

• High/ Low Side Current Limit over-voltage, over-temperature and current-limit) into a

single package.

• Power Good Indication

This device, available TDFN3x3-10 , provides a very com-

• Enable/Shutdown Function

pact system solution external components and PCB area.

• TDFN3x3-10 Package

• Lead Free and Green Devices Available

(RoHS Compliant)

Simplified Application Circuit

Applications

VIN VOUT

PVDD LX

• Notebook Computer & UMPC

• LCD Monitor/TV VDD FB

• Set-Top Box APW8804E

• DSL, Switch HUBr POK

• Portable Instrument ON GND

OFF EN

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp. 1 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Ordering and Marking Information

APW8804E Package Code

QB : TDFN3x3-10

Assembly Material Operating Ambient Temperature Range

I : -40 to 85 oC

Handling Code Handling Code

Temperature Range TR : Tape & Reel

Assembly Material

Package Code G : Halogen and Lead Free Device

APW

APW8804E QB : 8804E XXXXX - Date Code

XXXXX

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020D for

MSL classification at lead-free peak reflow temperature. ANPEC defines “Green” to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

Pin Configuration

APW8804E

NC 1 10 PVDD

LX 2 9 PVDD

LX 3 11 8 VDD

POK 4 GND 7 NC

EN 5 6 FB

TDFN 3X3-10

(Top View)

11

GND Exposed pad

Absolute Maximum Ratings (Note 1)

Symbol Parameter Rating Unit

VPVDD, VVDD Input Supply Voltage -0.3 ~ 6.5 V

<30ns pulse width -3 ~VPVDD+3 V

VLX LX to GND Voltage

>30ns pulse width -1 ~VPVDD+0.3 V

POK, FB, EN to GND Voltage -0.3 ~ 6.5 V

PD Power Dissipation 2 W

o

TJ Junction Temperature 150 C

o

TSTG Storage Temperature -65 ~ 150 C

o

TSDR Maximum Lead Soldering Temperature, 10 Seconds 260 C

Note1: Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are

stress ratings only and functional operation of the device at these or any other conditions beyond those indicated under "recom-

mended operating conditions" is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device

reliability.

Copyright ANPEC Electronics Corp. 2 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Thermal Characteristics

Symbol Parameter Typical Value Unit

(Note 2)

Junction-to-Ambient Resistance in Free Air

θJA o

C/W

TDFN3x3-10 50

Junction-to-Case Resistance in Free Air o

θJC C/W

TDFN3x3-10 10

Note 2: θJA is measured with the component mounted on a high effective thermal conductivity test board in free air. The exposed pad

of TDFN3x3-10 is soldered directly on the PCB.

Recommended Operating Conditions (Note 3)

Symbol P arame ter Range Unit

V VDD Con tro l a nd Drive r Supp ly Voltage 2.6~ 5.5 V

V PVDD Inpu t Sup ply Vo ltag e 2~5 .5 V

L Indu ctance 1~3 .3 µH

I OUT Con ver ter Output Cur rent 0~3 A

o

TA Am bient Temp erature -40 ~ 85 C

o

TJ Jun ction Tempera tu re - 40 ~ 125 C

Note 3: Refer to the typical application circuit.

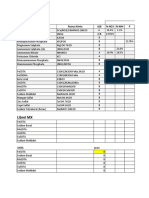

Electrical Characteristics

Unless otherwise specified, these specifications apply over VVDD=VPVDD=5V, TA=25oC.

APW8804E

Symbo Parameter Test Conditions Unit

Min. Typ. Max.

SUPPLY CURRENT

I VDD VDD Supply Current V FB=0.7V - 65 - µA

I VDD_SDH VDD Shutdown Supply Current EN=GND - - 1 µA

POWER-ON-RESET (POR)

VDD POR Voltage Threshold V VDD Rising 2.3 2.4 2.5 V

VDD POR Hysteresis - 0.2 - V

PVDD POR Voltage Threshold 2.3 2.4 2.5 V

PVDD POR Hysteresis - 0.2 - V

REFERENCE VOLTAGE

- 0.6 - V

VREF Reference Voltage

All temperature -1 - +1 %

Output Accuracy I OUT=10mA~3A, VVDD=2.6~5V -1.5 - +1.5 %

Copyright ANPEC Electronics Corp. 3 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Electrical Characteristics (Cont.)

Unless otherwise specified, these specifications apply over VVDD=VPVDD=5V, TA=25oC.

APW880 4E

S ym bo Parameter Tes t Condit ions Unit

Min. Typ. Max.

OSCILLATOR AND DUTY CYCLE

F OSC Oscillator Frequ ency 0.85 1 1.15 MHz

Minimum on Time - 70 - ns

POWER MOSFET

o

High Si de P-MOS FET Resistance VVD D=5 V, I LX=0 .5 A, T A=2 5 C - 65 80 mΩ

Lo w Sid e N-MOSFET Resistance VVD D=5 V, I LX=0 .5 A, T A=2 5 o C - 55 75 mΩ

High/Lo w Sid e MO SFET Leakage

- - 1 µA

Curre nt

PROTECTIONS

Pe ak Curre nt, VIN=2.6~5.5V

I LIM High Si de MOSFET cur rent-limit o 4 5 6 A

T A= -40 ~125 C

Over- tem perature Trip Po int

T OTP - 160 - °C

(Resoft start after OTP)

Over- tem perature Hyster esis - 50 - °C

Over- Voltage Protectio n thre sh old VOUT Rising 12 0 125 1 30 %V REF

Unde r-Vol tag e Protecti on th reshold 57 66 75 %V REF

Over- Voltage Protectio n debo unce

- 25 - µs

time

Lo w Sid e Switch Curre nt-Limit From Drain to S ource - -1 - A

SOFT-START, ENABLE, AND INPUT CURRENTS

So ft-Start Time - 0.8 - ms

EN Ena ble Threshold VEN rising voltage to enab le device - - 1.4 V

VEN fallin g voltage to shutdown

EN Shu tdo wn Thresh old 0 .5 - - V

device

EN Pull L ow Curre nt - 0.5 1 µA

PO K in from Lo we r

82.5 8 7.5 92.5 %VOUT

(PO K Goe s High)

PO K Low Hyste resis

- 5 - %VOUT

(PO K Goe s Low)

PO K Th reshold

PO K in from High er

12 0 125 1 30 %VOUT

(PO K Goe s High)

PO K Hi gh Hysteresis

- 5 - %VOUT

(PO K Goe s Low)

Po we r Good Pu ll Low Re sistance - 100 - Ω

Po we r Good Debo unce High to low - 20 - us

Copyright ANPEC Electronics Corp. 4 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Pin Description

PIN

FUNCTION

NO. NAME

1 NC No Connection.

Power Switching Output. LX is the Junction of the high-side and low-side Power MOSFETs to

2,3 LX supply power to the output LC filter.

Power Good Output. This pin is open-drain logic output that is pulled to the ground when the output

4 POK

voltage is out of regulation point.

Enable Input. EN is a digital input that turns the regulator on or off. Drive EN high to turn on the

5 EN

regulator, drive it low to turn it off.

Output Feedback Input. The APW8804E senses the feedback voltage via FB and regulates the

6 FB voltage at 0.6V. Connecting FB with a resistor-divider from the converter’s output sets the output

voltage.

7 NC No connection.

Signal Input. VDD supplies the control circuitry, gate drivers. Connecting a ceramic bypass

8 VDD

capacitor from VDD to GND to eliminate switching noise and voltage ripple on the input to the IC.

Power Input. PVDD supplies the step-down converter switches. Connecting a ceramic bypass

9,10 PVDD

capacitor from PVDD to GND to eliminate switching noise and voltage ripple on the input to the IC.

GND Ground and Exposed pad. Connect the exposed pad to the system ground plan with large copper

11

(Exposed Pad) area for dissipating heat into the ambient air.

Copyright ANPEC Electronics Corp. 5 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Typical Operating Characteristics

Efficiency vs. Output Current Reference Voltage vs. VIN Voltage

100 0.65

95 0.64

Reference Voltage, VREF(V)

90 0.63

85 0.62

Efficiency(%)

80 0.61

75 0.6

VOUT=1.8V

70 0.59

65 0.58

60 0.57

VIN=5V

55 0.56

50 0.55

0.01 0.1 1 10 2.5 3 3.5 4 4.5 5 5.5

Output Current, IOUT(A) VIN Voltage, VIN(V)

High Side MOSFET Current Limit vs.

VIN Voltage VIN Supply Current vs. VIN Voltage

High Side MOSFET Current Limit, ILIM(A)

7 150

VIN Supply Current, IDD(uA)

6 125

5

100

4

75

3

50

2

25

1

0 0

2.5 3 3.5 4 4.5 5 5.5 2.5 3 3.5 4 4.5 5 5.5

VIN Voltage, VIN(V) VIN Voltage, VIN(V)

Copyright ANPEC Electronics Corp. 6 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Operating Waveforms

Refer to the typical application circuit. The test condition is VIN=5V, TA= 25oC unless otherwise specified.

Enable without Loading Shutdown without Loading

V EN V EN

1 1

VOUT V OUT

2 2

V POK

VPOK

3 3

IL

IL 4

CH1: VEN , 5V/Div, DC CH1: VEN, 5V/Div, DC

CH2: VOUT, 1V/Div, DC CH2: VOUT, 1V/Div, DC

CH3: VPOK, 5V/Div, DC CH3: VPOK, 5V/Div, DC

CH4: IL, 1A/Div, DC CH4: IL, 1A/Div, DC

TIME: 500µs/Div TIME: 200µs/Div

Current Limit Over Voltage Protection

VOUT

VOUT

1

VPOK

VPOK

2 1

2

IL

IL 3

CH1: VOUT, 1V/Div, DC CH1: V OUT, 1V/Div, DC

CH2: VPOK, 5V/Div, DC CH2: V POK, 5V/Div, DC

CH3: IL, 2A/Div, DC CH3: IL, 2A/Div, DC

TIME: 200µs/Div TIME: 200µs/Div

Copyright ANPEC Electronics Corp. 7 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Operating Waveforms

Refer to the typical application circuit. The test condition is VIN=5V, TA= 25oC unless otherwise specified.

Normal Operation in Ligh Load Normal Operation in Heavy Load

VOUT

VOUT

1

1

V LX

VLX

2 2

IL

IL

3 3

IOUT=200mA IOUT=3A

CH1: VOUT, 50mV/Div, offset=1.8V CH1: VOUT, 50mV/Div, offset=1.8V

CH2: VLX, 5V/Div, DC CH2: VLX, 5V/Div, DC

CH3: IL, 1A/Div, DC CH3: IL, 2A/Div, DC

TIME: 2µs/Div TIME: 0.5µs/Div

Copyright ANPEC Electronics Corp. 8 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Block Diagram

VDD PVDD

Current Sense

LOC

Amplifier

Over Power-On- Current

Temperature Reset Limit Zero Crossing

Protection

Comparator

POR

125%VREF OTP

OVP

Fault

66%V RE Logics

F

UVP

Inhibit

Gate LX

125%VREF

Control

POK

Gate

90%VREF Current Driver

Error Compartor

Amplifier Gat

e

FB Gm

Soft-start VREF Slope LOC

0.6V Compensation

Current Sense

Oscillator Amplifier

Shutdown GND

EN POK

Copyright ANPEC Electronics Corp. 9 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Typical Application Circuit

VIN L1 VOUT

5V 1µH

1.8V/3A

PVDD LX

R1

R3 24k COUT

CIN

100k 22µF

VDD FB 22µFx2

APW8804E R2

POK 12k

ON GND

OFF EN

VIN L1 VOUT

1µH

2~5.5V 1V/3A

PVDD LX

VDD CIN R1

2.6~5.5V 22µF 10k COUT

VDD FB 22µFx2

R3 CVDD

100k 1µF APW8804E R2

POK 15k

ON GND

OFF EN

Copyright ANPEC Electronics Corp. 10 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Function Description

VDD and PVDD Power-On-Reset (POR) with a 50 oC hysteresis to lower the average TJ during

The APW8804E keeps monitoring the voltage on VDD continuous thermal overload conditions, increasing life-

and PVDD pins to prevent wrong logic operations which time of the APW8804E.

may occur when VDD or PVDD voltage is not high enough Current-Limit Protection

for internal control circuitry to operate. The VDD POR ris-

The APW8804E monitors the output current, flows through

ing threshold is 2.4V (typical) with 0.2V hysteresis and

the high-side and low-side power MOSFETs, and limits

PVDD POR rising threshold is 1.7V with 0.2V hysteresis.

the current peak at current-limit level to prevent the IC

During start-up, the VDD and PVDD voltage must exceed

from damaging during overload, short-circuit and over-

the POR threshold. Then, the IC starts a start-up process

voltage conditions. Typical high side power MOSFET cur-

and ramps up the output voltage to the voltage target.

rent limit is 5A, and low side MOSFET current limit is -1A.

Output Under-Voltage Protection (UVP)

Soft-Start

In the operational process, if a short-circuit occurs, the

output voltage will drop quickly. Before the current-limit The APW8804E has a built-in soft-start to control the rise

circuit responds, the output voltage will fall out of the re- rate of the output voltage and limit the input current surge

quired regulation range. The under-voltage continually during start-up. During soft-start, an internal voltage ramp

monitors the FB voltage after soft-start is completed. If a connected to one of the positive inputs of the error

load step is strong enough to pull the output voltage lower amplifier, rises up to replace the reference voltage (0.6V)

than the under-voltage threshold, the IC shuts down until the voltage ramp reaches the reference voltage. Dur-

converter’s output. ing soft-start without output over-voltage, the APW8804E

The under-voltage threshold is 66% of the nominal out- converter’s sinking capability is disabled until the output

put voltage. APW8804E will be latched after under-volt- voltage reaches the voltage target.

age protection.

Soft-Stop

At the moment of shutdown controlled by EN signal or

over-voltage event, the APW8804E initiates a soft-stop

Over-Voltage Protection (OVP) process to discharge the output voltage in the output

capacitors. Certainly, the load current also discharges

The over-voltage function monitors the output voltage by

the output voltage. During soft-stop, the low side MOSFET

FB pin. When the FB voltage increases over 125% of the

turns on each cycle to discharge the output voltage.

reference voltage due to the high-side MOSFET failure or

Therefore, the output voltage falls down slowly at the light

for other reasons, the over-voltage protection comparator

load. After the soft-stop interval elapses, the soft-stop pro-

will trigger soft-stop function and shutdown the converter

cess ends and the IC turns off.

output.

Over-Temperature Protection (OTP)

The over-temperature circuit limits the junction tempera- Enable and Shutdown

ture of the APW8804E. When the junction temperature

Driving EN to ground places the APW8804E in shutdown.

exceeds TJ=+160oC, a thermal sensor turns off the both

In shutdown mode, the internal power MOSFETs turn off,

power MOSFETs, allowing the devices to cool. The ther-

all internal circuitry shuts down and the quiescent supply

mal sensor allows the converters to start a start-up pro-

current reduces to less than 1µA.

cess and to regulate the output voltage again after the

junction temperature cools by 50oC. The OTP is designed

Copyright ANPEC Electronics Corp. 11 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Function Description (Cont.)

Powr Good Indicator

POK is actively held low in shutdown and soft-start status.

In the soft-start process, the POK is an open-drain. When

the soft-start is finished, the POK is released. In normal

operation, the POK window is from 85% to 125% of the

converter reference voltage. When the output voltage stays

within this window, POK signal will become high. When

the output voltage outruns 80% or 125% of the target

voltage, POK signal will be pulled low immediately. In

order to prevent false POK drop, capacitors need to paral-

lel at the output to confine the voltage deviation with se-

vere load step transient.

Copyright ANPEC Electronics Corp. 12 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Application Information

Input Capacitor Selection shown in “Typical Application Circuits”. A suggestion of

Because buck converters have a pulsating input current, maximum value of R2 is 200kΩ to keep the minimum

a low ESR input capacitor is required. This results in the current that provides enough noise rejection ability through

best input voltage filtering, minimizing the interference the resistor divider. The output voltage can be calculated

with other circuits caused by high input voltage spikes. as below:

Also, the input capacitor must be sufficiently large to sta- R1 R1

VOUT = VREF ⋅ 1 + = 0.6 ⋅ 1 +

bilize the input voltage during heavy load transients. For R2 R2

good input voltage filtering, usually a 22µF input capacitor

VOUT

is sufficient. It can be increased without any limit for better

input-voltage filtering. Ceramic capacitors show better

R1≤400kΩ

performance because of the low ESR value, and they are

less sensitive against voltage transients and spikes com- FB

pared to tantalum capacitors. Place the input capacitor as APW8804E R2 ≤ 200kΩ

close as possible to the input and GND pin of the device

GND

for better performance.

Inductor Selection

Output Capacitor Selection

For high efficiencies, the inductor should have a low DC

The current-mode control scheme of the APW8804E al-

resistance to minimize conduction losses. Especially at

lows the use of tiny ceramic capacitors. The higher ca-

high-switching frequencies, the core material has a

pacitor value provides the good load transients response.

higher impact on efficiency. When using small chip

Ceramic capacitors with low ESR values have the lowest

inductors, the efficiency is reduced mainly due to higher

output voltage ripple and are recommended. If required,

inductor core losses. This needs to be considered when

tantalum capacitors may be used as well. The output

selecting the appropriate inductor. The inductor value de-

ripple is the sum of the voltages across the ESR and the

termines the inductor ripple current. The larger the induc-

ideal output capacitor.

tor value, the smaller the inductor ripple current and the

lower the conduction losses of the converter. Conversely, V

VOUT ⋅ 1 − OUT

VIN ⋅ ESR + 1

larger inductor values cause a slower load transient ∆VOUT ≅

FSW ⋅ L 8 ⋅ FSW ⋅ COUT

response. A reasonable starting point for setting ripple

current, ∆IL, is 40% of maximum output current. The rec- When choosing the input and output ceramic capacitors,

ommended inductor value can be calculated as below: choose the X5R or X7R dielectric formulations. These

V dielectrics have the best temperature and voltage char-

VOUT 1 − OUT

VIN acteristics of all the ceramics for a given value and size.

L≥

FSW ⋅ ∆IL

IL(MAX) = IOUT(MAX) + 1/2 x ∆IL VIN IIN

To avoid the saturation of the inductor, the inductor should IP-FET

be rated at least for the maximum output current of the IL

IOUT VOUT

converter plus the inductor ripple current. CIN

P-FET

SW

Output Voltage Setting N-FET ESR

In the adjustable version, the output voltage is set by a COUT

resistive divider. The external resistive divider is con-

nected to the output, allowing remote voltage sensing as

Copyright ANPEC Electronics Corp. 13 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Application Information (Cont.)

Output Capacitor Selection (Cont.)

IL CIN

VDD

ILIM

LX

IPEAK

L1

∆IL

IOUT

VOUT

GND

R1

R2

IP-FET

COUT

Via To VOUT

TDFN3x3-10

APW8804E Layout Consideration

ThermalVia diameter

Layout Consideration Ground plane for

12mil X 5 ThermalPAD

For all switching power supplies, the layout is an impor- 0.275

0.75

tant step in the design; especially at high peak currents

0.3

and switching frequencies. If the layout is not carefully

done, the regulator might show noise problems and duty

cycle jitter.

2.70

1. The input capacitor should be placed close to the PVDD

and GND. Connecting the capacitor and PVDD/GND

with short and wide trace without any via holes for good

input voltage filtering. The distance between VIN/GND 0.5

t o c a p a c i t or l e s s t h a n 2m m r e s pe c t i ve ly i s

recommended. 1.75

2. To minimize copper trace connections that can inject TDFN3x3-10

Unit: mm

noise into the system, the inductor should be placed

as close as possible to the LX pin to minimize the APW8804E Recommended Footprint

noise coupling into other circuits.

3. The output capacitor should be place closed to LX and

GND.

4. Since the feedback pin and network is a high imped-

ance circuit the feedback network should be routed

away from the inductor. The feedback pin and feed-

back network should be shielded with a ground plane

or trace to minimize noise coupling into this circuit.

5. A star ground connection or ground plane minimizes

ground shifts and noise is recommended.

Copyright ANPEC Electronics Corp. 14 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Application Information (Cont.)

Input Power Sequence

The APW8804E has three power-on control pins, PVDD,

VDD and EN input pins. It is recommended that the three

inputs should have a standard sequence. The VDD and

PVDD input powers should be present to their respective

pins regardless of input sequence. After VDD and PVDD

powers are ready, the enable signal can be present to

EN pin and the IC will be enabled.

Figure 1 shows the VDD and PVDD comes up before the

VEN. Recommended power on sequence is shown in

Figure1.

VVDD

VPVDD VUV(TH)

VEN VEN(TH)

VOUT

VEN(TH) occurs after

VUV(TH) is reached

Copyright ANPEC Electronics Corp. 15 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Package Information

TDFN3x3-10

D A

b

Pin 1

D2 A1

A3

Pin 1

E2

Corner

L

S TDFN3x3-10

Y

M MILLIMETERS INCHES

B

O

L MIN. MAX. MIN. MAX.

A 0.70 0.80 0.028 0.031

A1 0.00 0.05 0.000 0.002

A3 0.20 REF 0.008 REF

b 0.18 0.30 0.007 0.012

D 2.90 3.10 0.114 0.122

D2 2.20 2.70 0.087 0.106

E 2.90 3.10 0.114 0.122

E2 1.40 1.75 0.055 0.069

e 0.50 BSC 0.020 BSC

L 0.30 0.50 0.012 0.020

K 0.20 0.008

Note : 1. Followed from JEDEC MO-229 VEED-5.

Copyright ANPEC Electronics Corp. 16 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Carrier Tape & Reel Dimensions

OD0 P0 P2 P1 A

E1

F

W

B0

K0 A0 A

OD1 B

B

SECTION A-A

T

SECTION B-B

d

H

A

T1

Application A H T1 C d D W E1 F

12.4+2.00 13.0+0.50

330.0±2.00 50 MIN. 1.5 MIN. 20.2 MIN. 12.0±0.30 1.75±0.10 5.5±0.05

-0.00 -0.20

TDFN3x3-10 P0 P1 P2 D0 D1 T A0 B0 K0

1.5+0.10 0.6+0.00

4.0±0.10 8.0±0.10 2.0±0.05 1.5 MIN. 3.30±0.20 3.30±0.20 1.30±0.20

-0.00 -0.40

(mm)

Devices Per Unit

Package Type Unit Quantity

TDFN3x3-10 Tape & Reel 3000

Copyright ANPEC Electronics Corp. 17 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Taping Direction Information

TDFN3x3-10

USER DIRECTION OF FEED

Classification Profile

Copyright ANPEC Electronics Corp. 18 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Classification Reflow Profiles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Preheat & Soak

100 °C 150 °C

Temperature min (Tsmin)

150 °C 200 °C

Temperature max (Tsmax)

60-120 seconds 60-120 seconds

Time (Tsmin to Tsmax) (ts)

Average ramp-up rate

3 °C/second max. 3°C/second max.

(Tsmax to TP)

Liquidous temperature (TL) 183 °C 217 °C

Time at liquidous (tL) 60-150 seconds 60-150 seconds

Peak package body Temperature

See Classification Temp in table 1 See Classification Temp in table 2

(Tp)*

Time (tP)** within 5°C of the specified

20** seconds 30** seconds

classification temperature (Tc)

Average ramp-down rate (Tp to Tsmax) 6 °C/second max. 6 °C/second max.

Time 25°C to peak temperature 6 minutes max. 8 minutes max.

* Tolerance for peak profile Temperature (Tp) is defined as a supplier minimum and a user maximum.

** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum.

Table 1. SnPb Eutectic Process – Classification Temperatures (Tc)

3 3

Package Volume mm Volume mm

Thickness <350 ≥350

<2.5 mm 235 °C 220 °C

≥2.5 mm 220 °C 220 °C

Table 2. Pb-free Process – Classification Temperatures (Tc)

3 3 3

Package Volume mm Volume mm Volume mm

Thickness <350 350-2000 >2000

<1.6 mm 260 °C 260 °C 260 °C

1.6 mm – 2.5 mm 260 °C 250 °C 245 °C

≥2.5 mm 250 °C 245 °C 245 °C

Reliability Test Program

Test item Method Description

SOLDERABILITY JESD-22, B102 5 Sec, 245°C

HOLT JESD-22, A108 1000 Hrs, Bias @ 125°C

PCT JESD-22, A102 168 Hrs, 100%RH, 2atm, 121°C

TCT JESD-22, A104 500 Cycles, -65°C~150°C

HBM MIL-STD-883-3015.7 VHBM≧2KV

MM JESD-22, A115 VMM≧200V

Latch-Up JESD 78 10ms, 1tr≧100mA

Copyright ANPEC Electronics Corp. 19 www.anpec.com.tw

Rev. A.2 - Dec., 2016

APW8804E

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics Corp. 20 www.anpec.com.tw

Rev. A.2 - Dec., 2016

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AeromodellingDocument15 pagesAeromodellingzain ansariNo ratings yet

- DT 900 Pro X: FeaturesDocument1 pageDT 900 Pro X: FeaturestristonNo ratings yet

- Atomic Structure, Bohr Model and IsotopesDocument17 pagesAtomic Structure, Bohr Model and IsotopeskushanNo ratings yet

- Nage Waza (Throwing) : HIP THROWS (Koshi Waza)Document5 pagesNage Waza (Throwing) : HIP THROWS (Koshi Waza)Stuart WalshNo ratings yet

- Sample Question Paper - 3: Class - XDocument17 pagesSample Question Paper - 3: Class - XRehan AlamNo ratings yet

- WEF DibiDocument130 pagesWEF DibimanuelNo ratings yet

- Feb 3 Questions Nuclear WasteDocument4 pagesFeb 3 Questions Nuclear WastedcudfhiudfiuNo ratings yet

- The Hamburger Ate Boy Isn't Acceptable (Odd) But The Boy Ate The Hamburger Is Hamburger Doesn't Have This Property and The Noun Boy DoesDocument6 pagesThe Hamburger Ate Boy Isn't Acceptable (Odd) But The Boy Ate The Hamburger Is Hamburger Doesn't Have This Property and The Noun Boy DoesDania SaviraNo ratings yet

- Addition of Green Tea Extract in Fructose Egg Yolk Milk Diluter On The Quality and Antioxidant ContenDocument9 pagesAddition of Green Tea Extract in Fructose Egg Yolk Milk Diluter On The Quality and Antioxidant Conten3129 NashihahNo ratings yet

- CordaDocument7 pagesCordaAlone InNo ratings yet

- 7 QC Tools: Training Module OnDocument38 pages7 QC Tools: Training Module OnKaushik SenguptaNo ratings yet

- Sig Decomp MproxDocument60 pagesSig Decomp MproxOri CarmiNo ratings yet

- EE 413-Engg ElectromagneticsDocument2 pagesEE 413-Engg ElectromagneticsVan GonzalesNo ratings yet

- New Material Seals Better On HVOF CoatingsDocument2 pagesNew Material Seals Better On HVOF Coatingssandbad2100% (2)

- Concha y Toro Company AnalysisDocument23 pagesConcha y Toro Company AnalysisflyawaywiththeseaNo ratings yet

- PPC Researched PointersDocument4 pagesPPC Researched PointershitmonNo ratings yet

- Dip & StrikeDocument20 pagesDip & StrikeSajjad AzizNo ratings yet

- Waqia Karbala Tareekh Ke Aine Me - Urdu BookDocument86 pagesWaqia Karbala Tareekh Ke Aine Me - Urdu BookABBAS ZAIDINo ratings yet

- Hvac Performance Analysis For A Conference Room: Visvesvaraya Technological UniversityDocument27 pagesHvac Performance Analysis For A Conference Room: Visvesvaraya Technological UniversityRohanRayNo ratings yet

- Egg Drop NotesDocument2 pagesEgg Drop Notesapi-365288705No ratings yet

- Module 5 Ge Elec 3Document10 pagesModule 5 Ge Elec 3Crishell Hunahunan AngelesNo ratings yet

- Bodie Investments 12e IM CH27Document3 pagesBodie Investments 12e IM CH27lexon_kbNo ratings yet

- Novice DocumentsDocument100 pagesNovice DocumentsD G Mattichak, Jr100% (3)

- Phy CIA 2mDocument25 pagesPhy CIA 2mA/E5LOGESH AKRNo ratings yet

- Chapter 03-A - 20111108094508Document29 pagesChapter 03-A - 20111108094508Heri YantiNo ratings yet

- Excel Meracik Nutrisi Bandung 11 Feb 2018Document30 pagesExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNo ratings yet

- Sweet Corn and Cheese Samoosa - Google SearchDocument2 pagesSweet Corn and Cheese Samoosa - Google SearchmisslxmasherNo ratings yet

- Hardy ObituaryDocument2 pagesHardy ObituaryNewzjunkyNo ratings yet

- Vertex MaxDocument20 pagesVertex MaxAušra PoderėNo ratings yet

- Instrumentation Cables: Product CatalogueDocument44 pagesInstrumentation Cables: Product Cataloguexinying liuNo ratings yet