Professional Documents

Culture Documents

RCK13EN

RCK13EN

Uploaded by

Ganesh pawarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCK13EN

RCK13EN

Uploaded by

Ganesh pawarCopyright:

Available Formats

Clamping Elements Type RCK 13

These shaft clamping elements are very compact units capable of

transmitting medium torques. Their design ensures good concentricity

between hubs and shafts, without any other means of location. A slight

axial movement between hub and shaft occurs during clamping. These

units can be installed totally within the hub providing optimum safety, and

Email: sales@crossmorse.com

minimal axial length.

Recommended tolerances for full

torque transmission are:-

Shaft h8

Hub H8

Clamping surfaces to be finished to

Rz ≤ 15 µm.

Fax: +44 121 325 1079

X = Distance required to remove

screws, additional clearance for alan

key may be required.

Dimensions

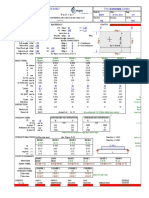

Dimensions mm Torque Axial Surface Pressure Clamping Screws Approx. Min. Hub Dia* mm

Cap. Force Shaft Hub Size Torque Weight

Part No. M F Ps Ph Assy Assy Assy

d D L L1 L2 L3 X Nm kN kg Type A Type B Type C

N/mm 2

N/mm2 Nm

RCK13-18x47 18 47 34 17 22 28 20 350 39 280 120 M6 14 0.27 70 64 59

RCK13-19x47 19 47 34 17 22 28 20 355 37 280 120 M6 14 0.27 70 64 59

RCK13-20x47 20 47 34 17 22 28 20 360 36 280 120 M6 14 0.26 70 64 59

RCK13-22x47 22 47 34 17 22 28 20 400 36 268 123 M6 14 0.25 70 65 59

RCK13-24x50 24 50 34 17 22 28 20 440 37 243 120 M6 14 0.28 74 68 63

RCK13-25x50 25 50 34 17 22 28 20 560 45 280 138 M6 14 0.27 79 72 65

RCK13-28x55 28 55 34 17 22 28 20 625 45 250 128 M6 14 0.32 84 77 70

RCK13-30x55 30 55 34 17 22 28 20 650 43 235 128 M6 14 0.30 84 77 70

RCK13-32x60 32 60 34 17 22 28 20 950 59 290 150 M6 14 0.37 100 89 80

RCK13-35x60 35 60 34 17 22 28 20 1050 60 268 150 M6 14 0.34 100 89 80

RCK13-38x65 38 65 34 17 22 28 20 1140 60 252 146 M6 14 0.41 106 95 86

RCK13-40x65 40 65 34 17 22 28 20 1200 60 232 146 M6 14 0.38 106 95 86

Te l : + 4 4 1 2 1 3 6 0 0 1 5 5

RCK13-45x75 45 75 41 20 25 33 25 2180 97 285 168 M8 35 0.63 134 117 104

RCK13-50x80 50 80 41 20 25 33 25 2430 97 258 158 M8 35 0.68 137 121 109

RCK13-55x85 55 85 41 20 25 33 25 3050 111 268 173 M8 35 0.73 156 135 119

RCK13-60x90 60 90 41 20 25 33 25 3350 112 243 163 M8 35 0.78 158 139 123

RCK13-65x95 65 95 41 20 25 33 25 4080 126 253 173 M8 35 0.83 174 151 133

RCK13-70x110 70 110 50 24 30 40 30 6280 179 278 178 M10 70 1.33 206 177 156

RCK13-75x115 75 115 50 24 30 40 30 6680 178 258 168 M10 70 1.39 206 180 159

RCK13-80x120 80 120 50 24 30 40 30 7130 178 248 168 M10 70 1.48 215 188 166

RCK13-85x125 85 125 50 24 30 40 30 8450 199 258 178 M10 70 1.55 234 202 177

RCK13-90x130 90 130 50 24 30 40 30 9080 202 248 168 M10 70 1.63 233 203 180

RCK13-95x135 95 135 50 24 30 40 30 10580 223 258 178 M10 70 1.70 253 218 191

RCK13-100x145 100 145 56 26 32 44 35 13380 268 268 188 M12 125 2.60 284 241 210

RCK13-110x155 110 155 56 26 32 44 35 14580 265 238 178 M12 125 2.80 290 250 219

RCK13-120x165 120 165 56 26 32 44 35 17880 298 248 178 M12 125 3.00 309 266 233

RCK13-130x180 130 180 64 34 40 52 35 25950 399 238 168 M12 125 4.60 323 282 249

RCK13-140x190 140 190 68 34 40 54 40 26950 385 208 148 M14 190 4.90 313 280 253

RCK13-150x200 150 200 68 34 40 54 40 32950 439 228 168 M14 190 5.20 358 313 277

RCK13-160x210 160 210 68 34 40 54 40 38800 485 213 170 M14 190 5.50 380 331 292

RCK13-170x225 170 225 78 44 49 64 50 41300 486 188 130 M14 190 7.70 346 315 289

RCK13-180x235 180 235 78 44 49 64 50 43700 486 178 125 M14 190 8.10 355 325 298

RCK13-190x250 190 250 78 44 49 64 50 57700 607 173 145 M14 190 8.60 408 365 330

RCK13-200x260 200 260 78 44 49 64 50 60700 607 165 140 M14 190 9.00 416 375 340

RCK13-220x285 220 285 88 51 57 72 55 78100 710 180 132 M16 290 12.00 442 402 367

RCK13-240x305 240 305 88 51 57 72 55 106500 848 182 154 M16 290 13.00 515 458 411

RCK13-260x325 260 325 88 51 57 72 55 138500 1017 198 174 M16 290 13.90 598 518 456

RCK13-280x355 280 355 102 60 66 84 65 160300 1094 169 143 M18 400 20.40 574 516 467

RCK13-300x375 300 375 102 60 66 84 65 193200 1230 174 152 M18 400 21.60 629 559 503

2

*Minimum outside diameter of hubs manufactured in medium carbon steels with yield strength ≥ 320 N/mm .

For hub types, and other materials, refer to page 3.

For assembly and disassembly instructions refer to page 24.

INDEX BACK NEXT

You might also like

- Purlin & Sagrod Design (NSCP 2015)Document4 pagesPurlin & Sagrod Design (NSCP 2015)Jake Cortez67% (3)

- Benner's Theory - PPT 2014Document82 pagesBenner's Theory - PPT 2014Mohammed Gazo100% (7)

- Monster Treasure Assortment Set 2 Levels 4 6Document12 pagesMonster Treasure Assortment Set 2 Levels 4 6Nic Trotti100% (5)

- KNDocument42 pagesKNtalibanindonesiaNo ratings yet

- RCK11 12enDocument2 pagesRCK11 12enGanesh pawarNo ratings yet

- H 300x300x10x15 Beam-ColumnDocument2 pagesH 300x300x10x15 Beam-ColumnAngusNo ratings yet

- Beam Design IS800 2007Document10 pagesBeam Design IS800 2007ER Deepak SutharNo ratings yet

- Power and Force Calculations Face Milling1Document1 pagePower and Force Calculations Face Milling1PRAVEEN ENo ratings yet

- H600x200x11x17 Beam ColumnDocument2 pagesH600x200x11x17 Beam ColumnAngusNo ratings yet

- Load Capacity of UB Member Section To BS5950-1:2000-Simplified MethodDocument1 pageLoad Capacity of UB Member Section To BS5950-1:2000-Simplified MethodSara BookerNo ratings yet

- ETABS 19.1.0-Design Details sloofDocument3 pagesETABS 19.1.0-Design Details sloofrobbiNo ratings yet

- Obj9 CompressedDocument2 pagesObj9 Compressedgustavo.paty.diproarqNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- 212 Nadella Rky RKXDocument1 page212 Nadella Rky RKXmanoj_doshi_1No ratings yet

- SDFGGSDG PDFDocument1 pageSDFGGSDG PDFSadhooh NaseerNo ratings yet

- BetonDocument7 pagesBetonBriscan RalucaNo ratings yet

- Column DetailsDocument2 pagesColumn DetailsBevelyn Ginhawa ManaloNo ratings yet

- Weld Stress CalculationsDocument19 pagesWeld Stress CalculationsMichael WaltersNo ratings yet

- Compenstating Type Centralising Type: Large Ball Lock Power Chuck - Suitable For Castings and ForgingsDocument1 pageCompenstating Type Centralising Type: Large Ball Lock Power Chuck - Suitable For Castings and ForgingsmooninjaNo ratings yet

- Steel Equal Angle - Bending (LTB) BS 5950 Simplified Method NSC "Design of Angles"Document3 pagesSteel Equal Angle - Bending (LTB) BS 5950 Simplified Method NSC "Design of Angles"David O'MearaNo ratings yet

- Design of Short Column For Axial Load and MomentDocument5 pagesDesign of Short Column For Axial Load and Momentភារម្យ អេងNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1MRJ287JMT4QHDKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1MRJ287JMT4QHDKBimalBhandariNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- SENSIQ WEIGHBEAM - bvd2453gbDocument8 pagesSENSIQ WEIGHBEAM - bvd2453gbĐào Thanh HoanNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 18YKGXQNC843LKLDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 18YKGXQNC843LKLSES DESIGNNo ratings yet

- Purlins Sample DesignDocument8 pagesPurlins Sample DesignJake CortezNo ratings yet

- 4 - Spur GearsDocument8 pages4 - Spur GearsAnil YildizNo ratings yet

- ETABS Concrete Frame Design: ACI 318-19 Column Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-19 Column Section DesignYaserNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignLulu Danur MayasinNo ratings yet

- Wuxy Trummy CatalogDocument4 pagesWuxy Trummy CatalogMartin RomeroNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.3 Gilang Ramadhan Andaluna License # 1S5LLY67BDQYHLRDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.3 Gilang Ramadhan Andaluna License # 1S5LLY67BDQYHLRbudifreadnoNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Column Section Designheherson juanNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- Orion Design ReportDocument86 pagesOrion Design ReportJiya Titus EmmanuelNo ratings yet

- Track-Type Tractor Track Roller Cap Bolt Torque Procedure and Re-Use Guidelines (4180)Document7 pagesTrack-Type Tractor Track Roller Cap Bolt Torque Procedure and Re-Use Guidelines (4180)juvenalNo ratings yet

- SFH S: TypesDocument8 pagesSFH S: Typeshoward bitasNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document8 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Miguel LuqueNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument6 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- Aci318-08 Moment Shear Torsion DesignDocument7 pagesAci318-08 Moment Shear Torsion DesignMohammed HanafiNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- Columna C1Document2 pagesColumna C1Fredy TzununNo ratings yet

- RCC Pedestal DesignDocument2 pagesRCC Pedestal DesignsivaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BASubandi SihotangNo ratings yet

- Rfqr211351 - Enquiry For DriveDocument34 pagesRfqr211351 - Enquiry For DriveyuwonoNo ratings yet

- LAGOS DORMITORY-BeamDesignDocument147 pagesLAGOS DORMITORY-BeamDesignadetokunbo fapuroNo ratings yet

- ETABS 20.0 Column ReportDocument4 pagesETABS 20.0 Column Reportkheang amgNo ratings yet

- 国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Document30 pages国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Alex MazaNo ratings yet

- ETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BADocument2 pagesETABS 2015 Concrete Frame Design: ETABS 2015 15.2.2 License # 1YTPN38NXMTW9BAjuanda sinagaNo ratings yet

- Etabs 18.1 PDFDocument2 pagesEtabs 18.1 PDFBißék ŚílwàlNo ratings yet

- ETABS 2015 15.1.0-Design DetailsDocument2 pagesETABS 2015 15.1.0-Design DetailsdenyfateNo ratings yet

- Montanari Gearless-MDX26SDocument2 pagesMontanari Gearless-MDX26SAkm AbdullahNo ratings yet

- Calculations Proyect: We Wil Use The d2 and d3 of The Datas Selected (Tr26x3), Not Obtained in The FormulaDocument7 pagesCalculations Proyect: We Wil Use The d2 and d3 of The Datas Selected (Tr26x3), Not Obtained in The FormulamertNo ratings yet

- 2 Way Slab DesignDocument3 pages2 Way Slab DesignAhmedNo ratings yet

- Layout Ducting & Perhitungan Kapasitas BFQ MC-182Document10 pagesLayout Ducting & Perhitungan Kapasitas BFQ MC-182MakhturNo ratings yet

- Axis: 1 Storey: 2: Bending (Top Edge) ..Document21 pagesAxis: 1 Storey: 2: Bending (Top Edge) ..adetokunbo fapuroNo ratings yet

- AgeCare-RCBeamDes (Anish)Document2 pagesAgeCare-RCBeamDes (Anish)Anish PathakNo ratings yet

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- Eadership and AnagementDocument1 pageEadership and AnagementAmol MahajanNo ratings yet

- Person Involved in The Incident Full Name: Designation: Office: Incident Information Date: October 6, 2020 Location of Incident: Incident DescriptionDocument3 pagesPerson Involved in The Incident Full Name: Designation: Office: Incident Information Date: October 6, 2020 Location of Incident: Incident DescriptionLeonardo Jr SultanNo ratings yet

- Ergoselect 150 - Technical Specifi Cations: Product InformationDocument2 pagesErgoselect 150 - Technical Specifi Cations: Product InformationAsep MustopaNo ratings yet

- IEEE Project FormatDocument4 pagesIEEE Project FormatSneha PatilNo ratings yet

- STPDocument18 pagesSTPworldontopNo ratings yet

- CBSE Class 6 Science Chapter 2 Components of Food Important Questions 2023-24Document3 pagesCBSE Class 6 Science Chapter 2 Components of Food Important Questions 2023-24Aiyana PraveshNo ratings yet

- JavaDocument15 pagesJavaMrabet MustaphaNo ratings yet

- The Contemporary World ModuleDocument101 pagesThe Contemporary World ModuleRichard Queman OñateNo ratings yet

- Syllabus Debate PDFDocument5 pagesSyllabus Debate PDFJeicel Ann BarairoNo ratings yet

- Financial Performance Analysis of Nepal Doorsanchar Comapany LimitedDocument23 pagesFinancial Performance Analysis of Nepal Doorsanchar Comapany LimitedLarisha PandeyNo ratings yet

- History of AnatomyDocument21 pagesHistory of AnatomyCatarina SimõesNo ratings yet

- GTB Jeremiah DownloadDocument87 pagesGTB Jeremiah DownloadEdwin PitangaNo ratings yet

- Biofloc Technology (BFT) in Shrimp Farming: Past and Present Shaping The FutureDocument5 pagesBiofloc Technology (BFT) in Shrimp Farming: Past and Present Shaping The FutureMichael LeirvagNo ratings yet

- Methods of Manufacture of Fermented Dairy ProductsDocument25 pagesMethods of Manufacture of Fermented Dairy ProductsRonak RawatNo ratings yet

- VijayawadaDocument62 pagesVijayawadakeerthiNo ratings yet

- SLP Unisa 2014 All CollegesDocument324 pagesSLP Unisa 2014 All CollegesWerner LouwNo ratings yet

- Jan 22 P1R QPDocument36 pagesJan 22 P1R QPAbirNo ratings yet

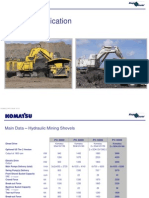

- 11 - PC8000 - 6 ApplDocument37 pages11 - PC8000 - 6 Appljhon jairo trujillo100% (1)

- Brainstorming 2Document14 pagesBrainstorming 2AmierahIzzatiAisyahNo ratings yet

- Outsiders B1 BookletDocument82 pagesOutsiders B1 BookletKakali MallianNo ratings yet

- 3 What Else Can I DoDocument1 page3 What Else Can I DoEnrico Luis BalisalisaNo ratings yet

- The Case For Technology in Music EducationDocument12 pagesThe Case For Technology in Music EducationAndrew T. Garcia93% (15)

- Test-Retest Reliability of The Evaluation Tool of Children's Handwriting-ManuscriptDocument8 pagesTest-Retest Reliability of The Evaluation Tool of Children's Handwriting-Manuscriptvinika ChaudharyNo ratings yet

- TodhunterDocument8 pagesTodhunterHilárioNo ratings yet

- Dinesh Khattar - Quantitative Aptitude For Campus Interview Vol II-Pearson Education (2016)Document434 pagesDinesh Khattar - Quantitative Aptitude For Campus Interview Vol II-Pearson Education (2016)Rough Work100% (1)

- Try It For Yourself: Platform OverviewDocument32 pagesTry It For Yourself: Platform OverviewМаниш НахтвандерерNo ratings yet

- (Download PDF) Soc 6 Introduction To Sociology 6Th Edition Nijole V Benokraitis Full Chapter PDFDocument69 pages(Download PDF) Soc 6 Introduction To Sociology 6Th Edition Nijole V Benokraitis Full Chapter PDFguissabaert100% (6)

- Intrinsic Electric Fields in Two-Dimensional Materials Boost The Solar-to-Hydrogen E Ciency For Photocatalytic Water SplittingDocument6 pagesIntrinsic Electric Fields in Two-Dimensional Materials Boost The Solar-to-Hydrogen E Ciency For Photocatalytic Water SplittingKhaoula El AsameNo ratings yet