Professional Documents

Culture Documents

BB1 Upgrade

BB1 Upgrade

Uploaded by

PatrickCopyright:

Available Formats

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- David Vizard's How to Build Max Performance Chevy Small Blocks on a BudgetFrom EverandDavid Vizard's How to Build Max Performance Chevy Small Blocks on a BudgetNo ratings yet

- Bba de Lodos Dampener - Instruction - Manual - Rev - DDocument10 pagesBba de Lodos Dampener - Instruction - Manual - Rev - Desteban monterrosa lopez100% (3)

- Recommended Lux LevelsDocument20 pagesRecommended Lux LevelsUNNI VENUGOPAL60% (5)

- Nissan P01 P02 Forklift Trucks Service Manual PDFDocument22 pagesNissan P01 P02 Forklift Trucks Service Manual PDFIvars Frīdbergs40% (5)

- Data File For Students - C08DataDocument46 pagesData File For Students - C08DatarahulNo ratings yet

- Victoria Chemicals PLC (A)Document24 pagesVictoria Chemicals PLC (A)Ade AdeNo ratings yet

- MBa ProjectDocument2 pagesMBa Projectsahil100% (1)

- ThreatMetrix Cybercrime Defender PlatformDocument3 pagesThreatMetrix Cybercrime Defender PlatformJoshua McAfeeNo ratings yet

- Pump Overhaul Prevents Downtime at Amine PlantDocument2 pagesPump Overhaul Prevents Downtime at Amine Plantadamnassir91No ratings yet

- GVVBDocument33 pagesGVVBDeepak KumarNo ratings yet

- Expansion of Water Treatment PlantDocument20 pagesExpansion of Water Treatment PlantRohail AfzalNo ratings yet

- SPBP PemplateDocument2 pagesSPBP PemplateshadabNo ratings yet

- Black Gold Pump y Supply, IncDocument2 pagesBlack Gold Pump y Supply, Inchebert perezNo ratings yet

- SCWS - Service Impact 2022 Sept'22Document36 pagesSCWS - Service Impact 2022 Sept'22Kamal Edlin HusinNo ratings yet

- SAMKUN CENTURY - CatalogDocument28 pagesSAMKUN CENTURY - Catalog韩龙No ratings yet

- ACO Building DrainageDocument8 pagesACO Building DrainagepdfNo ratings yet

- Canned Motor Pump - i-CM: Kirloskar Brothers LimitedDocument8 pagesCanned Motor Pump - i-CM: Kirloskar Brothers Limitedkeeprocking9777No ratings yet

- Canned Motor Pump - i-CM: Kirloskar Brothers LimitedDocument8 pagesCanned Motor Pump - i-CM: Kirloskar Brothers LimitedAmit pumpXpertzNo ratings yet

- Karofi Profile 2024 - NewDocument19 pagesKarofi Profile 2024 - Newtmhung97neuNo ratings yet

- Suggested AnswersDocument5 pagesSuggested AnswersSuhaiziomarNo ratings yet

- COATES INDONESIA - Godwin Presentation BaturajaDocument22 pagesCOATES INDONESIA - Godwin Presentation BaturajaAyu FijriNo ratings yet

- PPP 4Document4 pagesPPP 4semua.urusankuNo ratings yet

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- A Project Report On Manufacturing Auto Parts Using Rubber With Specific Focus On PCK LTDDocument12 pagesA Project Report On Manufacturing Auto Parts Using Rubber With Specific Focus On PCK LTDjijodivaNo ratings yet

- Practise Question Chap 11Document20 pagesPractise Question Chap 11SaadNo ratings yet

- BurusDocument9 pagesBurusDoni AlexaNo ratings yet

- ManataDocument8 pagesManataDoni AlexaNo ratings yet

- Quality Tubing Products: Technical ManualDocument52 pagesQuality Tubing Products: Technical ManualFernando CarvajalNo ratings yet

- Centac C700: Innovation & TraditionDocument2 pagesCentac C700: Innovation & TraditionAbdelhamid BouremmaNo ratings yet

- Wire Certificate 706B12!1!180301Document1 pageWire Certificate 706B12!1!180301mehdiNo ratings yet

- Limestone Test ReportDocument6 pagesLimestone Test ReportFizzi BorhaniNo ratings yet

- Service Letter SL2019-684/JAP: Piston Cleaning RingDocument4 pagesService Letter SL2019-684/JAP: Piston Cleaning RingOctavian DinuNo ratings yet

- Leq-Dl-Fk-654-24 Chang Hua Construction Pte LTD (Repair U50-5 71092)Document2 pagesLeq-Dl-Fk-654-24 Chang Hua Construction Pte LTD (Repair U50-5 71092)江宗朋No ratings yet

- Company Profile & Catalogue PDFDocument24 pagesCompany Profile & Catalogue PDFhbookNo ratings yet

- Kki Diaphragm 8500 Actuators CsDocument15 pagesKki Diaphragm 8500 Actuators CsDEFRIZALNo ratings yet

- Indion SBRDocument2 pagesIndion SBRmaksudur4No ratings yet

- Teh Hsin BrochureDocument10 pagesTeh Hsin Brochurelitecounter1111No ratings yet

- Piping & Engineering Piping & Engineering: BJ BJDocument28 pagesPiping & Engineering Piping & Engineering: BJ BJWilson Xavier Orbea BrachoNo ratings yet

- CPI-4601 SeriesDocument2 pagesCPI-4601 SeriesNguyễn ThưNo ratings yet

- Product Information Sheet C890 0625 TIG Foot ControlsDocument1 pageProduct Information Sheet C890 0625 TIG Foot Controlshenrysaputra168No ratings yet

- Amc Hvac VtuDocument2 pagesAmc Hvac VtuDolphin Engineering Services100% (1)

- Fin304 (Mid-Sem Answers 2021)Document9 pagesFin304 (Mid-Sem Answers 2021)sha ve3No ratings yet

- ACO Stainless Steel Gully BrochureDocument68 pagesACO Stainless Steel Gully BrochureLightninWolf32No ratings yet

- Pad Mist EliminatorDocument2 pagesPad Mist EliminatorKapwell LimitedNo ratings yet

- Daichang Catalog 2014 English EditionDocument56 pagesDaichang Catalog 2014 English Edition2021thiennhanNo ratings yet

- Salt Recovery EvaporationDocument2 pagesSalt Recovery EvaporationKapwell LimitedNo ratings yet

- Datasheet PBX 52pdfDocument2 pagesDatasheet PBX 52pdfismaelNo ratings yet

- 30 Year 10% 0%: Q. Use The Present Worth Method To Determine The Total Cost (LCC) of The Three Alternatives BelowDocument13 pages30 Year 10% 0%: Q. Use The Present Worth Method To Determine The Total Cost (LCC) of The Three Alternatives BelowPMPNo ratings yet

- Product Catalogue: Rawlplug LTDDocument154 pagesProduct Catalogue: Rawlplug LTDhemendraengNo ratings yet

- 2020.04.16 - FinalDocument32 pages2020.04.16 - Final韩龙No ratings yet

- External - Celanex PBT 2500-6FC Solution SheetDocument2 pagesExternal - Celanex PBT 2500-6FC Solution Sheetdirk.ziererNo ratings yet

- 2-LCC For VEWDocument30 pages2-LCC For VEWحموده الساميNo ratings yet

- Astm D5890Document2 pagesAstm D5890yuNo ratings yet

- FT - AWWA C900 - Tubería Enterrada C900Document3 pagesFT - AWWA C900 - Tubería Enterrada C900Jimmy Fernández B.No ratings yet

- Aco Rainwater Outlets BrochureDocument40 pagesAco Rainwater Outlets BrochurejotjackNo ratings yet

- ANZ ProposalDocument3 pagesANZ Proposalarif_abdinNo ratings yet

- Koins - Brochure (Eng Ver.) - 2014Document12 pagesKoins - Brochure (Eng Ver.) - 2014Kamal FirmansyahNo ratings yet

- Hydraulic Pump&Motor Spare PartsDocument26 pagesHydraulic Pump&Motor Spare PartsKo Ngelay100% (1)

- Pre Tender CostingDocument580 pagesPre Tender CostingvelarajanNo ratings yet

- cr1 c1 CableDocument3 pagescr1 c1 CableMENo ratings yet

- Beston (Henan) Machinery Co., LTDDocument22 pagesBeston (Henan) Machinery Co., LTDsuratman sastroNo ratings yet

- Pneumatic Actuation: Ahead of The FlowDocument20 pagesPneumatic Actuation: Ahead of The FlowInstratec InstratecNo ratings yet

- Ejemplo Corto IP30Document45 pagesEjemplo Corto IP30eedee3No ratings yet

- Swiftready Label - For Corproates Cash ManagementDocument17 pagesSwiftready Label - For Corproates Cash ManagementFreeman JacksonNo ratings yet

- Dewatering Screens: Fax: +61 3 9877 8177 Mobile: 0411 099 989 EmailDocument1 pageDewatering Screens: Fax: +61 3 9877 8177 Mobile: 0411 099 989 Emailkaweesa mosesNo ratings yet

- Contents of FIDIC ContractDocument5 pagesContents of FIDIC ContractDanya T. ReyesNo ratings yet

- IdmDocument327 pagesIdmDipak PrajapatiNo ratings yet

- LP ProblemDocument36 pagesLP ProblemKamal UddinNo ratings yet

- Gereffi Et Al - 2005 - Governance of GVCsDocument27 pagesGereffi Et Al - 2005 - Governance of GVCsFlorinNicolaeBarbuNo ratings yet

- Gis PDFDocument27 pagesGis PDFZaheer AhamedNo ratings yet

- Abcdcr RP 03122013Document162 pagesAbcdcr RP 03122013Kunal RanjaneNo ratings yet

- Claitec PAS Pedestrian Alert System - EN PDFDocument10 pagesClaitec PAS Pedestrian Alert System - EN PDFPranoti JoshiNo ratings yet

- ServiceDocument47 pagesServiceMarko KoširNo ratings yet

- Pune DSR 2016 17Document448 pagesPune DSR 2016 17Er Hemant Patil0% (1)

- 1600 Manual 09 19 06Document22 pages1600 Manual 09 19 06Krzysztof KocmaNo ratings yet

- Ut b-01-04Document62 pagesUt b-01-04Veeraiah AnbuNo ratings yet

- IIP Program For Low-Hazard Industry EmployersDocument58 pagesIIP Program For Low-Hazard Industry EmployersJoseph DeMaria, Ph.D.No ratings yet

- N2+o2 01.03.2023Document83 pagesN2+o2 01.03.2023anNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- ROI: How To Evaluate Your Supply Chain Performance: Dan VessetDocument4 pagesROI: How To Evaluate Your Supply Chain Performance: Dan VessetJeisson Alex MarroquinNo ratings yet

- SZ Sales ProgramDocument28 pagesSZ Sales ProgramrossifrancescoNo ratings yet

- Migrating Oracle To PostgreSQL 892Document34 pagesMigrating Oracle To PostgreSQL 892TrurlScribdNo ratings yet

- Is 513 (PT-1) 2016Document9 pagesIs 513 (PT-1) 2016Gaurav KumarNo ratings yet

- PVC Pipe Manufacturing Unit - CompressDocument5 pagesPVC Pipe Manufacturing Unit - CompressSantosh KumarNo ratings yet

- Value AnalysisDocument19 pagesValue Analysisekta1308No ratings yet

- Best Practices of SQL in SAP HANADocument18 pagesBest Practices of SQL in SAP HANAMythili DuraisamiNo ratings yet

- HM 355S ManualDocument59 pagesHM 355S ManualnicnicnicNo ratings yet

BB1 Upgrade

BB1 Upgrade

Uploaded by

PatrickOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BB1 Upgrade

BB1 Upgrade

Uploaded by

PatrickCopyright:

Available Formats

CASE STUDY

IMPELLER UPGRADE EXTENDS

OPERATIONAL LIFE OF WATER PUMPS

• 50% increase in pump operational life

• 6% increase in performance Industry: Water

Region: Americas

• ROI of 2 years

Category: Site investigation

API Type: BB1

CHALLENGE

The customer was concerned about reduced performance on four Uniglide

pumps that had not received any major maintenance since they were

installed seven years previously. ClydeUnion Pumps, a Celeros Flow

Technology brand, was the original pump manufacturer. We sent our

Aftermarket Services team to the site to conduct a comprehensive health

check of the pumps.

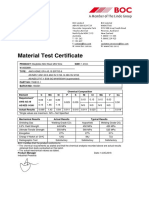

Hole in impeller blade

SOLUTION OUTCOMES

During testing, it became apparent that the performance of the Replacing the impellers complete with new wear rings on the

Uniglide pumps was significantly down on original design Uniglide pumps achieved an immediate 6% increase in

parameters. The top half casing was removed and it was performance. The new aluminium bronze impellers have a

discovered that the impellers were badly damaged and the wear design life in excess of 15 years, more than doubling the Mean

rings were severely worn. Upon investigating the root cause of Time Between Failures (MTBF). Return on investment for this

the damage, we determined that the supply tank often dropped project was calculated to be 2 years.

to a low level and cavitation occurred. This had caused holes to

develop in the impeller’s inlet vanes over time. The client

advised that the low tank levels could not be prevented and

therefore the impellers would have to be replaced every 6 years.

In order to prolong impeller life and reduce maintenance

frequency, we proposed a material upgrade from cast iron to

aluminium bronze (material BS 1400 AB2), which is more

resistant to cavitation damage. The client accepted this

recommendation. We manufactured new impellers, complete

with new wear rings, for the four pumps.

Cost saving per pump over 15 years

60000

Original material

Upgraded material

50000

40000

Cost (£)

30000

20000

10000

0 5 10 15

Time (Years)

Aberdeen Service Center Calgary Service Center Penistone Service Center

P: +44 1224 756 100 P: +1 800 352 8294 P: +44 1226 763 311

Abu Dhabi Service Center Corpus Christi Center Singapore Service Center

P: +971 02 4081900 P: +1 361 371 6519 P: +65 6513 9276

Annecy Service Center Downey Service Center Zhengzhou Service Center

P: +49 405 220 2401 P: +1 562 622 2371 P: +86 371 8665 2391

Baton Rouge Service Center Glasgow Service Center E: cu.sales@celerosft.com

P: +1 225 778 3310 P: +44 141 637 7141 www.celerosft.com

Battle Creek Service Center Jenks Service Center

P: +1 269 966 4782 P: +1 281 217 6359

Burlington Service Center Odessa Service Center

P: +1 905 315 3813 P: +1 704 808 3780

For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.celerosft.com. Celeros Flow Technology reserves the right to incorporate our latest design and material changes without notice or obligation.

Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmed in writing.

Ref no: CUP_350_04_BB1-UPGRADE_GB Version: 07/2020 COPYRIGHT © 2020 Celeros Flow Technology

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- David Vizard's How to Build Max Performance Chevy Small Blocks on a BudgetFrom EverandDavid Vizard's How to Build Max Performance Chevy Small Blocks on a BudgetNo ratings yet

- Bba de Lodos Dampener - Instruction - Manual - Rev - DDocument10 pagesBba de Lodos Dampener - Instruction - Manual - Rev - Desteban monterrosa lopez100% (3)

- Recommended Lux LevelsDocument20 pagesRecommended Lux LevelsUNNI VENUGOPAL60% (5)

- Nissan P01 P02 Forklift Trucks Service Manual PDFDocument22 pagesNissan P01 P02 Forklift Trucks Service Manual PDFIvars Frīdbergs40% (5)

- Data File For Students - C08DataDocument46 pagesData File For Students - C08DatarahulNo ratings yet

- Victoria Chemicals PLC (A)Document24 pagesVictoria Chemicals PLC (A)Ade AdeNo ratings yet

- MBa ProjectDocument2 pagesMBa Projectsahil100% (1)

- ThreatMetrix Cybercrime Defender PlatformDocument3 pagesThreatMetrix Cybercrime Defender PlatformJoshua McAfeeNo ratings yet

- Pump Overhaul Prevents Downtime at Amine PlantDocument2 pagesPump Overhaul Prevents Downtime at Amine Plantadamnassir91No ratings yet

- GVVBDocument33 pagesGVVBDeepak KumarNo ratings yet

- Expansion of Water Treatment PlantDocument20 pagesExpansion of Water Treatment PlantRohail AfzalNo ratings yet

- SPBP PemplateDocument2 pagesSPBP PemplateshadabNo ratings yet

- Black Gold Pump y Supply, IncDocument2 pagesBlack Gold Pump y Supply, Inchebert perezNo ratings yet

- SCWS - Service Impact 2022 Sept'22Document36 pagesSCWS - Service Impact 2022 Sept'22Kamal Edlin HusinNo ratings yet

- SAMKUN CENTURY - CatalogDocument28 pagesSAMKUN CENTURY - Catalog韩龙No ratings yet

- ACO Building DrainageDocument8 pagesACO Building DrainagepdfNo ratings yet

- Canned Motor Pump - i-CM: Kirloskar Brothers LimitedDocument8 pagesCanned Motor Pump - i-CM: Kirloskar Brothers Limitedkeeprocking9777No ratings yet

- Canned Motor Pump - i-CM: Kirloskar Brothers LimitedDocument8 pagesCanned Motor Pump - i-CM: Kirloskar Brothers LimitedAmit pumpXpertzNo ratings yet

- Karofi Profile 2024 - NewDocument19 pagesKarofi Profile 2024 - Newtmhung97neuNo ratings yet

- Suggested AnswersDocument5 pagesSuggested AnswersSuhaiziomarNo ratings yet

- COATES INDONESIA - Godwin Presentation BaturajaDocument22 pagesCOATES INDONESIA - Godwin Presentation BaturajaAyu FijriNo ratings yet

- PPP 4Document4 pagesPPP 4semua.urusankuNo ratings yet

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- A Project Report On Manufacturing Auto Parts Using Rubber With Specific Focus On PCK LTDDocument12 pagesA Project Report On Manufacturing Auto Parts Using Rubber With Specific Focus On PCK LTDjijodivaNo ratings yet

- Practise Question Chap 11Document20 pagesPractise Question Chap 11SaadNo ratings yet

- BurusDocument9 pagesBurusDoni AlexaNo ratings yet

- ManataDocument8 pagesManataDoni AlexaNo ratings yet

- Quality Tubing Products: Technical ManualDocument52 pagesQuality Tubing Products: Technical ManualFernando CarvajalNo ratings yet

- Centac C700: Innovation & TraditionDocument2 pagesCentac C700: Innovation & TraditionAbdelhamid BouremmaNo ratings yet

- Wire Certificate 706B12!1!180301Document1 pageWire Certificate 706B12!1!180301mehdiNo ratings yet

- Limestone Test ReportDocument6 pagesLimestone Test ReportFizzi BorhaniNo ratings yet

- Service Letter SL2019-684/JAP: Piston Cleaning RingDocument4 pagesService Letter SL2019-684/JAP: Piston Cleaning RingOctavian DinuNo ratings yet

- Leq-Dl-Fk-654-24 Chang Hua Construction Pte LTD (Repair U50-5 71092)Document2 pagesLeq-Dl-Fk-654-24 Chang Hua Construction Pte LTD (Repair U50-5 71092)江宗朋No ratings yet

- Company Profile & Catalogue PDFDocument24 pagesCompany Profile & Catalogue PDFhbookNo ratings yet

- Kki Diaphragm 8500 Actuators CsDocument15 pagesKki Diaphragm 8500 Actuators CsDEFRIZALNo ratings yet

- Indion SBRDocument2 pagesIndion SBRmaksudur4No ratings yet

- Teh Hsin BrochureDocument10 pagesTeh Hsin Brochurelitecounter1111No ratings yet

- Piping & Engineering Piping & Engineering: BJ BJDocument28 pagesPiping & Engineering Piping & Engineering: BJ BJWilson Xavier Orbea BrachoNo ratings yet

- CPI-4601 SeriesDocument2 pagesCPI-4601 SeriesNguyễn ThưNo ratings yet

- Product Information Sheet C890 0625 TIG Foot ControlsDocument1 pageProduct Information Sheet C890 0625 TIG Foot Controlshenrysaputra168No ratings yet

- Amc Hvac VtuDocument2 pagesAmc Hvac VtuDolphin Engineering Services100% (1)

- Fin304 (Mid-Sem Answers 2021)Document9 pagesFin304 (Mid-Sem Answers 2021)sha ve3No ratings yet

- ACO Stainless Steel Gully BrochureDocument68 pagesACO Stainless Steel Gully BrochureLightninWolf32No ratings yet

- Pad Mist EliminatorDocument2 pagesPad Mist EliminatorKapwell LimitedNo ratings yet

- Daichang Catalog 2014 English EditionDocument56 pagesDaichang Catalog 2014 English Edition2021thiennhanNo ratings yet

- Salt Recovery EvaporationDocument2 pagesSalt Recovery EvaporationKapwell LimitedNo ratings yet

- Datasheet PBX 52pdfDocument2 pagesDatasheet PBX 52pdfismaelNo ratings yet

- 30 Year 10% 0%: Q. Use The Present Worth Method To Determine The Total Cost (LCC) of The Three Alternatives BelowDocument13 pages30 Year 10% 0%: Q. Use The Present Worth Method To Determine The Total Cost (LCC) of The Three Alternatives BelowPMPNo ratings yet

- Product Catalogue: Rawlplug LTDDocument154 pagesProduct Catalogue: Rawlplug LTDhemendraengNo ratings yet

- 2020.04.16 - FinalDocument32 pages2020.04.16 - Final韩龙No ratings yet

- External - Celanex PBT 2500-6FC Solution SheetDocument2 pagesExternal - Celanex PBT 2500-6FC Solution Sheetdirk.ziererNo ratings yet

- 2-LCC For VEWDocument30 pages2-LCC For VEWحموده الساميNo ratings yet

- Astm D5890Document2 pagesAstm D5890yuNo ratings yet

- FT - AWWA C900 - Tubería Enterrada C900Document3 pagesFT - AWWA C900 - Tubería Enterrada C900Jimmy Fernández B.No ratings yet

- Aco Rainwater Outlets BrochureDocument40 pagesAco Rainwater Outlets BrochurejotjackNo ratings yet

- ANZ ProposalDocument3 pagesANZ Proposalarif_abdinNo ratings yet

- Koins - Brochure (Eng Ver.) - 2014Document12 pagesKoins - Brochure (Eng Ver.) - 2014Kamal FirmansyahNo ratings yet

- Hydraulic Pump&Motor Spare PartsDocument26 pagesHydraulic Pump&Motor Spare PartsKo Ngelay100% (1)

- Pre Tender CostingDocument580 pagesPre Tender CostingvelarajanNo ratings yet

- cr1 c1 CableDocument3 pagescr1 c1 CableMENo ratings yet

- Beston (Henan) Machinery Co., LTDDocument22 pagesBeston (Henan) Machinery Co., LTDsuratman sastroNo ratings yet

- Pneumatic Actuation: Ahead of The FlowDocument20 pagesPneumatic Actuation: Ahead of The FlowInstratec InstratecNo ratings yet

- Ejemplo Corto IP30Document45 pagesEjemplo Corto IP30eedee3No ratings yet

- Swiftready Label - For Corproates Cash ManagementDocument17 pagesSwiftready Label - For Corproates Cash ManagementFreeman JacksonNo ratings yet

- Dewatering Screens: Fax: +61 3 9877 8177 Mobile: 0411 099 989 EmailDocument1 pageDewatering Screens: Fax: +61 3 9877 8177 Mobile: 0411 099 989 Emailkaweesa mosesNo ratings yet

- Contents of FIDIC ContractDocument5 pagesContents of FIDIC ContractDanya T. ReyesNo ratings yet

- IdmDocument327 pagesIdmDipak PrajapatiNo ratings yet

- LP ProblemDocument36 pagesLP ProblemKamal UddinNo ratings yet

- Gereffi Et Al - 2005 - Governance of GVCsDocument27 pagesGereffi Et Al - 2005 - Governance of GVCsFlorinNicolaeBarbuNo ratings yet

- Gis PDFDocument27 pagesGis PDFZaheer AhamedNo ratings yet

- Abcdcr RP 03122013Document162 pagesAbcdcr RP 03122013Kunal RanjaneNo ratings yet

- Claitec PAS Pedestrian Alert System - EN PDFDocument10 pagesClaitec PAS Pedestrian Alert System - EN PDFPranoti JoshiNo ratings yet

- ServiceDocument47 pagesServiceMarko KoširNo ratings yet

- Pune DSR 2016 17Document448 pagesPune DSR 2016 17Er Hemant Patil0% (1)

- 1600 Manual 09 19 06Document22 pages1600 Manual 09 19 06Krzysztof KocmaNo ratings yet

- Ut b-01-04Document62 pagesUt b-01-04Veeraiah AnbuNo ratings yet

- IIP Program For Low-Hazard Industry EmployersDocument58 pagesIIP Program For Low-Hazard Industry EmployersJoseph DeMaria, Ph.D.No ratings yet

- N2+o2 01.03.2023Document83 pagesN2+o2 01.03.2023anNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- ROI: How To Evaluate Your Supply Chain Performance: Dan VessetDocument4 pagesROI: How To Evaluate Your Supply Chain Performance: Dan VessetJeisson Alex MarroquinNo ratings yet

- SZ Sales ProgramDocument28 pagesSZ Sales ProgramrossifrancescoNo ratings yet

- Migrating Oracle To PostgreSQL 892Document34 pagesMigrating Oracle To PostgreSQL 892TrurlScribdNo ratings yet

- Is 513 (PT-1) 2016Document9 pagesIs 513 (PT-1) 2016Gaurav KumarNo ratings yet

- PVC Pipe Manufacturing Unit - CompressDocument5 pagesPVC Pipe Manufacturing Unit - CompressSantosh KumarNo ratings yet

- Value AnalysisDocument19 pagesValue Analysisekta1308No ratings yet

- Best Practices of SQL in SAP HANADocument18 pagesBest Practices of SQL in SAP HANAMythili DuraisamiNo ratings yet

- HM 355S ManualDocument59 pagesHM 355S ManualnicnicnicNo ratings yet