Professional Documents

Culture Documents

Electrical Appliance Inspection Method Statement

Electrical Appliance Inspection Method Statement

Uploaded by

Kidesu RamadhaniCopyright:

Available Formats

You might also like

- Trans TemplateDocument2 pagesTrans TemplateMarielle Malabanan100% (1)

- Method of Statement For MV&LV SwitchgearsDocument12 pagesMethod of Statement For MV&LV SwitchgearsUtku Can Kılıç100% (2)

- Pre - Functional Checklist Documentation 9Document5 pagesPre - Functional Checklist Documentation 9renjithv_4No ratings yet

- Method of Statement For Testing & Commissioning of Fire Alarm SystemDocument4 pagesMethod of Statement For Testing & Commissioning of Fire Alarm Systemvin ssNo ratings yet

- Electrical Test ProcedureDocument10 pagesElectrical Test ProcedureJay Anthony MorganNo ratings yet

- Section-02 Testing RequirementDocument24 pagesSection-02 Testing RequirementChaitanya Shakya0% (1)

- Method Statement For Fire Alarm System InstallationDocument4 pagesMethod Statement For Fire Alarm System Installationamg00780% (5)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Bosch Mechanical Gasoline Fuel-Injection System PDFDocument63 pagesBosch Mechanical Gasoline Fuel-Injection System PDFDaniel OliveiraNo ratings yet

- Fire Alarm System Testing & Inspection Scope of WorkDocument8 pagesFire Alarm System Testing & Inspection Scope of Workmarilou garalNo ratings yet

- 36 - Appendix DDocument2 pages36 - Appendix DMahmoud Zakaria BadraNo ratings yet

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- Instrumentation For Equipment PackagesDocument7 pagesInstrumentation For Equipment PackagesaszlizaNo ratings yet

- Testing and Commissioning of Fire Alarm SystemDocument10 pagesTesting and Commissioning of Fire Alarm SystemRobin Oidem CaniedoNo ratings yet

- Inspection and Test ProceduresDocument33 pagesInspection and Test Proceduresmrnoboby0407No ratings yet

- bd16080 FIELDTESTDocument23 pagesbd16080 FIELDTESTBrando Neil SarciaNo ratings yet

- Rev - 11 - Ms - Installation of Fire Alarm SystemDocument9 pagesRev - 11 - Ms - Installation of Fire Alarm Systemanon_534254691No ratings yet

- SWYD - Commissioning ProcedureDocument9 pagesSWYD - Commissioning Procedurekrishna100% (3)

- 16950Document16 pages16950uddinnadeemNo ratings yet

- JW Marriot Abu Dhabi Resort & Spa Otak InternationalDocument15 pagesJW Marriot Abu Dhabi Resort & Spa Otak InternationalPeanut d. DestroyerNo ratings yet

- Switchboard Electrical TestsDocument4 pagesSwitchboard Electrical TestsTTaanNo ratings yet

- Information Sheet l3Document20 pagesInformation Sheet l3Aster Takele OfficialNo ratings yet

- Method Statement For Fire Alarm System InstallationDocument7 pagesMethod Statement For Fire Alarm System InstallationAleen Gamal Al-Dinji100% (1)

- Switch Gear MaintenanceDocument8 pagesSwitch Gear Maintenancedharma_raoNo ratings yet

- WS-Periodic Inspection 9 2008Document10 pagesWS-Periodic Inspection 9 2008NATHANNo ratings yet

- Testing Electrical Equipment 26 08 00Document99 pagesTesting Electrical Equipment 26 08 00Joe GrosirNo ratings yet

- 26 08 00 Electrical Equipment Site Acceptance TestingDocument99 pages26 08 00 Electrical Equipment Site Acceptance TestingArianna IsabelleNo ratings yet

- 5084133-03 IQ - OQ For LRE - PRE 120 - 440 & LFE 110 - 360Document22 pages5084133-03 IQ - OQ For LRE - PRE 120 - 440 & LFE 110 - 360Adamas Bagas SusantoNo ratings yet

- Technical Specifications: 4. General Design and Constructional FeaturesDocument4 pagesTechnical Specifications: 4. General Design and Constructional FeatureskeyurNo ratings yet

- Method of Statement For Addressable Fire Alarm SystemDocument3 pagesMethod of Statement For Addressable Fire Alarm SystemBen Lim80% (5)

- What Is Pat TestingDocument3 pagesWhat Is Pat TestingKrishna JashaNo ratings yet

- FM-200 Clean Agent Fire Suppression System: Engineering SpecificationsDocument17 pagesFM-200 Clean Agent Fire Suppression System: Engineering SpecificationsPanner2009No ratings yet

- Assured Equipment Grounding Conductor ProgramDocument5 pagesAssured Equipment Grounding Conductor ProgramVan SotNo ratings yet

- Abbreviations: OQ Exploration and Production LLCDocument3 pagesAbbreviations: OQ Exploration and Production LLCHamza ShujaNo ratings yet

- Eddy Current SpecificationsDocument7 pagesEddy Current SpecificationsBhavani PrasadNo ratings yet

- CommissioningDocument9 pagesCommissioningIsmael Ochoa JimenezNo ratings yet

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- Method Statement For Fire Alarm System InstallationDocument4 pagesMethod Statement For Fire Alarm System Installationtristan guarino100% (1)

- Electrical Specifications - Division 16 - SECTION 16950 TESTING AND COMMISSIONINGDocument11 pagesElectrical Specifications - Division 16 - SECTION 16950 TESTING AND COMMISSIONINGeng_asayedNo ratings yet

- HS418 Portable Electrical Equipment Inspection Testing and Tagging GuidelineDocument7 pagesHS418 Portable Electrical Equipment Inspection Testing and Tagging GuidelineAmit BhattNo ratings yet

- Elevtrical ELV Spec RevisionDocument4 pagesElevtrical ELV Spec RevisionKapila NayananandaNo ratings yet

- Pre - Functional Checklist Documentation 7Document2 pagesPre - Functional Checklist Documentation 7renjithv_4No ratings yet

- VLF Test Procedure and Partial DownloadsDocument10 pagesVLF Test Procedure and Partial DownloadsScribdTranslationsNo ratings yet

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Click HereDocument3 pagesClick HereHasitha Sri CharindaNo ratings yet

- FACP MethodologyDocument6 pagesFACP MethodologyNobita NobiNo ratings yet

- Commissioning High Voltage EquipmentDocument13 pagesCommissioning High Voltage EquipmentJesus RodriguezNo ratings yet

- Signal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For RailwaysDocument14 pagesSignal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For Railwaysanon_485351313No ratings yet

- Electrical Acceptance TestingDocument23 pagesElectrical Acceptance TestingMarioNo ratings yet

- Fire Alarm SpecificationsDocument13 pagesFire Alarm SpecificationsDyeri FloresNo ratings yet

- SECTION 27 17 00 Testing, Identification and Administration of Balanced Twist Pair InfrastructureDocument9 pagesSECTION 27 17 00 Testing, Identification and Administration of Balanced Twist Pair InfrastructurebillbinghamNo ratings yet

- METHOD STATEMENT - Installation of LV Distribution PanelDocument7 pagesMETHOD STATEMENT - Installation of LV Distribution PanelanishpetercNo ratings yet

- Obvllc Temp Electrical InspectDocument1 pageObvllc Temp Electrical InspectAj OjedaNo ratings yet

- Method Statement For Test and Inspection of An Existing Lightning Protection/Earthing SystemDocument4 pagesMethod Statement For Test and Inspection of An Existing Lightning Protection/Earthing Systemdangtuan27No ratings yet

- Method Statement Ground TestDocument3 pagesMethod Statement Ground Testm.bakrNo ratings yet

- Ansi Neta Ats 2013Document28 pagesAnsi Neta Ats 2013JuniiOrVilkNo ratings yet

- Portable Equp MNT GuideDocument0 pagesPortable Equp MNT GuideashawishNo ratings yet

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- Agilet's GSM GPRS ReferenceDocument882 pagesAgilet's GSM GPRS ReferencehilgadNo ratings yet

- 03 Pre-Commissioning and Commissioning 26 08 00 09022022011343Document13 pages03 Pre-Commissioning and Commissioning 26 08 00 09022022011343ibrahimsirpiNo ratings yet

- Earthing and Lightning MaintenanceDocument7 pagesEarthing and Lightning Maintenancetatiana100% (2)

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- 2022.12.01 - DEngWebinar - Updated (2) .pdf-1Document40 pages2022.12.01 - DEngWebinar - Updated (2) .pdf-1Kidesu RamadhaniNo ratings yet

- E6 Electrical Service LoadDocument2 pagesE6 Electrical Service LoadKidesu RamadhaniNo ratings yet

- TechTopic DataCommunication v3 WithRecordingDocument39 pagesTechTopic DataCommunication v3 WithRecordingKidesu RamadhaniNo ratings yet

- Method Statement For Air & Water BalancingDocument7 pagesMethod Statement For Air & Water BalancingKidesu Ramadhani100% (1)

- 2022.06.29 EIT TechnicalWebinar A.Marzoughi WithRecordingDocument30 pages2022.06.29 EIT TechnicalWebinar A.Marzoughi WithRecordingKidesu RamadhaniNo ratings yet

- EIT Intro To Protective Devices Combined WithRecordingDocument47 pagesEIT Intro To Protective Devices Combined WithRecordingKidesu RamadhaniNo ratings yet

- Air Conditioning and Exhaust System SchemeDocument3 pagesAir Conditioning and Exhaust System SchemeKidesu RamadhaniNo ratings yet

- 2022.10.13 Basics of Process Control v2 PDFDocument34 pages2022.10.13 Basics of Process Control v2 PDFKidesu RamadhaniNo ratings yet

- 4 20 Ma Signals 1665634168Document23 pages4 20 Ma Signals 1665634168Kidesu RamadhaniNo ratings yet

- Street Light MS 2Document5 pagesStreet Light MS 2Kidesu RamadhaniNo ratings yet

- Schneider Electric Process Instrumentation Brochure EA 1665557330Document44 pagesSchneider Electric Process Instrumentation Brochure EA 1665557330Kidesu RamadhaniNo ratings yet

- C FB BrochureDocument20 pagesC FB BrochureböhmitNo ratings yet

- PND1000 3 AccessoriesDocument40 pagesPND1000 3 AccessoriesPartsGopher.comNo ratings yet

- Reading Advice Dona WarrenDocument8 pagesReading Advice Dona WarrenVic Annielyn CoronelNo ratings yet

- R30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFDocument219 pagesR30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFdenix49No ratings yet

- English: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDocument25 pagesEnglish: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDorothy Yen Escalaña0% (1)

- Project Muse 42646 PDFDocument27 pagesProject Muse 42646 PDFKaustav RoyNo ratings yet

- Number PatternDocument14 pagesNumber PatternSolehah Roslan100% (1)

- Freedom and Nature in Schelling's Philosophy of Art, Devin ZaneDocument240 pagesFreedom and Nature in Schelling's Philosophy of Art, Devin ZaneTheoria100% (2)

- FiberCable 2 V8 56 Oct20Document288 pagesFiberCable 2 V8 56 Oct20Ronald N Meza CNo ratings yet

- CS 273 Course Notes: Assembly Language Programming With The Atmel AVR MicrocontrollerDocument49 pagesCS 273 Course Notes: Assembly Language Programming With The Atmel AVR MicrocontrollerYassineZklNo ratings yet

- Callisto SPC: Technical SpecificationsDocument3 pagesCallisto SPC: Technical SpecificationsLuis Miguel Figueroa Quiroz “Luis Figueroa”No ratings yet

- David SMCC16ge Ppt07Document46 pagesDavid SMCC16ge Ppt07Çağla Kutlu100% (1)

- Fake News Detection Using NLPDocument9 pagesFake News Detection Using NLPIJRASETPublicationsNo ratings yet

- Natural Reader Listening TOEFLDocument22 pagesNatural Reader Listening TOEFLTira Nur FitriaNo ratings yet

- Sony - Micro System - Cmthpz9Document40 pagesSony - Micro System - Cmthpz9SoniaSegerMercedesNo ratings yet

- 03rd MS Seq03 Lis & Do 01Document2 pages03rd MS Seq03 Lis & Do 01Fatima ZohraNo ratings yet

- EditorialReview SylwestrowiczDocument2 pagesEditorialReview SylwestrowiczStefh ZamoraNo ratings yet

- Spur GearDocument3 pagesSpur Gearigualdi53No ratings yet

- Question Set No 3Document77 pagesQuestion Set No 3CuriousNo ratings yet

- MID 039 - CID 0167 - FMI 12: TroubleshootingDocument5 pagesMID 039 - CID 0167 - FMI 12: TroubleshootingNerminTurkenceNo ratings yet

- Negotiating Mobile Identity in The Global Nightscape: Krzysztof Z. JankowskiDocument9 pagesNegotiating Mobile Identity in The Global Nightscape: Krzysztof Z. JankowskiAlex YiuNo ratings yet

- Department of The Interior and Local Government Bureau of Fire ProtectionDocument5 pagesDepartment of The Interior and Local Government Bureau of Fire ProtectionBoy ClementeNo ratings yet

- BUS - 6140 - Module - 5 - Worksheet SaheedDocument6 pagesBUS - 6140 - Module - 5 - Worksheet SaheedAugusta B100% (1)

- DLL in BPP - DIFFERENT BAKED PRODUCTSDocument5 pagesDLL in BPP - DIFFERENT BAKED PRODUCTSAlva Catalina Gamayon-ArmadaNo ratings yet

- Android-Based Classroom Monitoring System For Teacher Using QR Code TechnologyDocument12 pagesAndroid-Based Classroom Monitoring System For Teacher Using QR Code TechnologyAkmad Ali AbdulNo ratings yet

- Parts Catalog: 25 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

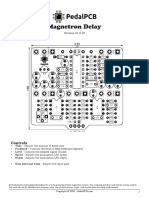

- Magnetron Delay: Revision 10.13.20Document5 pagesMagnetron Delay: Revision 10.13.20manecolooperNo ratings yet

- 1SBN020010R1002 Te5s 120 Electronic TimerDocument4 pages1SBN020010R1002 Te5s 120 Electronic TimermeriemNo ratings yet

Electrical Appliance Inspection Method Statement

Electrical Appliance Inspection Method Statement

Uploaded by

Kidesu RamadhaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Appliance Inspection Method Statement

Electrical Appliance Inspection Method Statement

Uploaded by

Kidesu RamadhaniCopyright:

Available Formats

PAT Cornwall Limited Method Statement for Electrical Appliance Inspection & Testing

1, Client Liaison: The Test Engineer shall make himself known to the person responsible for Health & Safety at the

testing premises. The engineer will liaise with the person or the person nominated as the site contact in all matters

of testing with regard to the schedule of testing on the premises, times appropriate for shutdown of equipment ect.

and advise this person of any appliances that fail testing.

2, Guidelines for Testing: Testing will be carried out under the IEE’s code of Practice for In-Service Inspection and

Testing. This testing includes all electrical equipment of the following types (as detailed in the IEE Code of Practice):

portable appliances, moveable or transportable equipment/appliances, hand-held appliances, stationary

equipment/appliances, fixed appliances, appliances/equipment for building in, IT equipment and extension leads.

3, Inspection:

a) Flex – the flex will be inspected for any damage ensuring it is free from cuts, fraying or stress.

b) Plug – the plugtop will be opened to ensure that the flexible cable is secure in its anchorage and is correctly

wired, that the fuse is of the correct rating for the appliance and it is free from any sign of overheating and in

physically good condition.

c) The Appliance – the appliance will be inspected to insure that it is in good working order, insuring that it

switches on and off properly and the casing or cabinet has no damage that could result in access to live

parts.

4, Testing:

a) Polarity Test (only carried out on extension cables and supply leads)

b) Earth Continuity Test ( not carried out on Class II appliances that have no earth)

c) Insulation Resistance Test

d) Operational Test (if possible)

e) Earth Leakage Test (if Operational Test carried out)

f) Tests on computer equipment are “soft tests” of 200mA on earth continuity. No operational tests are

carried out on computer CPUs.

5, Labeling:

a) A label will be attached to each appliance that passed testing with the Barcoded appliance ID and Test Date.

This label will be “Mark and Seal”.

b) Appliances that fail testing will be labelled with a “Failed Safety Test” Red label.

6, Documentation: Appliance register, Pass Certificates, Fail certificates (if applicable), Display Certificate will be sent

after the completion of testing on the premises and the data being processed at the office. It is our aim to provide

these within 2 working days of the completion of testing, along with the invoice.

a) Appliance Register – A complete register of all equipment tested on the premises.

b) Pass Certificates – Full details of all test results for appliances that passed testing.

c) Fail Certificates – Appliances that failed testing will be reported on a separate sheet in red showing the

reason and recommendations.

d) Display Certificate – A certificate for display in the staff room, notice board or reception to advise that the

appliances on the premises have been tested for electrical safety.

e) Invoice

You might also like

- Trans TemplateDocument2 pagesTrans TemplateMarielle Malabanan100% (1)

- Method of Statement For MV&LV SwitchgearsDocument12 pagesMethod of Statement For MV&LV SwitchgearsUtku Can Kılıç100% (2)

- Pre - Functional Checklist Documentation 9Document5 pagesPre - Functional Checklist Documentation 9renjithv_4No ratings yet

- Method of Statement For Testing & Commissioning of Fire Alarm SystemDocument4 pagesMethod of Statement For Testing & Commissioning of Fire Alarm Systemvin ssNo ratings yet

- Electrical Test ProcedureDocument10 pagesElectrical Test ProcedureJay Anthony MorganNo ratings yet

- Section-02 Testing RequirementDocument24 pagesSection-02 Testing RequirementChaitanya Shakya0% (1)

- Method Statement For Fire Alarm System InstallationDocument4 pagesMethod Statement For Fire Alarm System Installationamg00780% (5)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Bosch Mechanical Gasoline Fuel-Injection System PDFDocument63 pagesBosch Mechanical Gasoline Fuel-Injection System PDFDaniel OliveiraNo ratings yet

- Fire Alarm System Testing & Inspection Scope of WorkDocument8 pagesFire Alarm System Testing & Inspection Scope of Workmarilou garalNo ratings yet

- 36 - Appendix DDocument2 pages36 - Appendix DMahmoud Zakaria BadraNo ratings yet

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- Instrumentation For Equipment PackagesDocument7 pagesInstrumentation For Equipment PackagesaszlizaNo ratings yet

- Testing and Commissioning of Fire Alarm SystemDocument10 pagesTesting and Commissioning of Fire Alarm SystemRobin Oidem CaniedoNo ratings yet

- Inspection and Test ProceduresDocument33 pagesInspection and Test Proceduresmrnoboby0407No ratings yet

- bd16080 FIELDTESTDocument23 pagesbd16080 FIELDTESTBrando Neil SarciaNo ratings yet

- Rev - 11 - Ms - Installation of Fire Alarm SystemDocument9 pagesRev - 11 - Ms - Installation of Fire Alarm Systemanon_534254691No ratings yet

- SWYD - Commissioning ProcedureDocument9 pagesSWYD - Commissioning Procedurekrishna100% (3)

- 16950Document16 pages16950uddinnadeemNo ratings yet

- JW Marriot Abu Dhabi Resort & Spa Otak InternationalDocument15 pagesJW Marriot Abu Dhabi Resort & Spa Otak InternationalPeanut d. DestroyerNo ratings yet

- Switchboard Electrical TestsDocument4 pagesSwitchboard Electrical TestsTTaanNo ratings yet

- Information Sheet l3Document20 pagesInformation Sheet l3Aster Takele OfficialNo ratings yet

- Method Statement For Fire Alarm System InstallationDocument7 pagesMethod Statement For Fire Alarm System InstallationAleen Gamal Al-Dinji100% (1)

- Switch Gear MaintenanceDocument8 pagesSwitch Gear Maintenancedharma_raoNo ratings yet

- WS-Periodic Inspection 9 2008Document10 pagesWS-Periodic Inspection 9 2008NATHANNo ratings yet

- Testing Electrical Equipment 26 08 00Document99 pagesTesting Electrical Equipment 26 08 00Joe GrosirNo ratings yet

- 26 08 00 Electrical Equipment Site Acceptance TestingDocument99 pages26 08 00 Electrical Equipment Site Acceptance TestingArianna IsabelleNo ratings yet

- 5084133-03 IQ - OQ For LRE - PRE 120 - 440 & LFE 110 - 360Document22 pages5084133-03 IQ - OQ For LRE - PRE 120 - 440 & LFE 110 - 360Adamas Bagas SusantoNo ratings yet

- Technical Specifications: 4. General Design and Constructional FeaturesDocument4 pagesTechnical Specifications: 4. General Design and Constructional FeatureskeyurNo ratings yet

- Method of Statement For Addressable Fire Alarm SystemDocument3 pagesMethod of Statement For Addressable Fire Alarm SystemBen Lim80% (5)

- What Is Pat TestingDocument3 pagesWhat Is Pat TestingKrishna JashaNo ratings yet

- FM-200 Clean Agent Fire Suppression System: Engineering SpecificationsDocument17 pagesFM-200 Clean Agent Fire Suppression System: Engineering SpecificationsPanner2009No ratings yet

- Assured Equipment Grounding Conductor ProgramDocument5 pagesAssured Equipment Grounding Conductor ProgramVan SotNo ratings yet

- Abbreviations: OQ Exploration and Production LLCDocument3 pagesAbbreviations: OQ Exploration and Production LLCHamza ShujaNo ratings yet

- Eddy Current SpecificationsDocument7 pagesEddy Current SpecificationsBhavani PrasadNo ratings yet

- CommissioningDocument9 pagesCommissioningIsmael Ochoa JimenezNo ratings yet

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- Method Statement For Fire Alarm System InstallationDocument4 pagesMethod Statement For Fire Alarm System Installationtristan guarino100% (1)

- Electrical Specifications - Division 16 - SECTION 16950 TESTING AND COMMISSIONINGDocument11 pagesElectrical Specifications - Division 16 - SECTION 16950 TESTING AND COMMISSIONINGeng_asayedNo ratings yet

- HS418 Portable Electrical Equipment Inspection Testing and Tagging GuidelineDocument7 pagesHS418 Portable Electrical Equipment Inspection Testing and Tagging GuidelineAmit BhattNo ratings yet

- Elevtrical ELV Spec RevisionDocument4 pagesElevtrical ELV Spec RevisionKapila NayananandaNo ratings yet

- Pre - Functional Checklist Documentation 7Document2 pagesPre - Functional Checklist Documentation 7renjithv_4No ratings yet

- VLF Test Procedure and Partial DownloadsDocument10 pagesVLF Test Procedure and Partial DownloadsScribdTranslationsNo ratings yet

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- Click HereDocument3 pagesClick HereHasitha Sri CharindaNo ratings yet

- FACP MethodologyDocument6 pagesFACP MethodologyNobita NobiNo ratings yet

- Commissioning High Voltage EquipmentDocument13 pagesCommissioning High Voltage EquipmentJesus RodriguezNo ratings yet

- Signal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For RailwaysDocument14 pagesSignal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For Railwaysanon_485351313No ratings yet

- Electrical Acceptance TestingDocument23 pagesElectrical Acceptance TestingMarioNo ratings yet

- Fire Alarm SpecificationsDocument13 pagesFire Alarm SpecificationsDyeri FloresNo ratings yet

- SECTION 27 17 00 Testing, Identification and Administration of Balanced Twist Pair InfrastructureDocument9 pagesSECTION 27 17 00 Testing, Identification and Administration of Balanced Twist Pair InfrastructurebillbinghamNo ratings yet

- METHOD STATEMENT - Installation of LV Distribution PanelDocument7 pagesMETHOD STATEMENT - Installation of LV Distribution PanelanishpetercNo ratings yet

- Obvllc Temp Electrical InspectDocument1 pageObvllc Temp Electrical InspectAj OjedaNo ratings yet

- Method Statement For Test and Inspection of An Existing Lightning Protection/Earthing SystemDocument4 pagesMethod Statement For Test and Inspection of An Existing Lightning Protection/Earthing Systemdangtuan27No ratings yet

- Method Statement Ground TestDocument3 pagesMethod Statement Ground Testm.bakrNo ratings yet

- Ansi Neta Ats 2013Document28 pagesAnsi Neta Ats 2013JuniiOrVilkNo ratings yet

- Portable Equp MNT GuideDocument0 pagesPortable Equp MNT GuideashawishNo ratings yet

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- Agilet's GSM GPRS ReferenceDocument882 pagesAgilet's GSM GPRS ReferencehilgadNo ratings yet

- 03 Pre-Commissioning and Commissioning 26 08 00 09022022011343Document13 pages03 Pre-Commissioning and Commissioning 26 08 00 09022022011343ibrahimsirpiNo ratings yet

- Earthing and Lightning MaintenanceDocument7 pagesEarthing and Lightning Maintenancetatiana100% (2)

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- 2022.12.01 - DEngWebinar - Updated (2) .pdf-1Document40 pages2022.12.01 - DEngWebinar - Updated (2) .pdf-1Kidesu RamadhaniNo ratings yet

- E6 Electrical Service LoadDocument2 pagesE6 Electrical Service LoadKidesu RamadhaniNo ratings yet

- TechTopic DataCommunication v3 WithRecordingDocument39 pagesTechTopic DataCommunication v3 WithRecordingKidesu RamadhaniNo ratings yet

- Method Statement For Air & Water BalancingDocument7 pagesMethod Statement For Air & Water BalancingKidesu Ramadhani100% (1)

- 2022.06.29 EIT TechnicalWebinar A.Marzoughi WithRecordingDocument30 pages2022.06.29 EIT TechnicalWebinar A.Marzoughi WithRecordingKidesu RamadhaniNo ratings yet

- EIT Intro To Protective Devices Combined WithRecordingDocument47 pagesEIT Intro To Protective Devices Combined WithRecordingKidesu RamadhaniNo ratings yet

- Air Conditioning and Exhaust System SchemeDocument3 pagesAir Conditioning and Exhaust System SchemeKidesu RamadhaniNo ratings yet

- 2022.10.13 Basics of Process Control v2 PDFDocument34 pages2022.10.13 Basics of Process Control v2 PDFKidesu RamadhaniNo ratings yet

- 4 20 Ma Signals 1665634168Document23 pages4 20 Ma Signals 1665634168Kidesu RamadhaniNo ratings yet

- Street Light MS 2Document5 pagesStreet Light MS 2Kidesu RamadhaniNo ratings yet

- Schneider Electric Process Instrumentation Brochure EA 1665557330Document44 pagesSchneider Electric Process Instrumentation Brochure EA 1665557330Kidesu RamadhaniNo ratings yet

- C FB BrochureDocument20 pagesC FB BrochureböhmitNo ratings yet

- PND1000 3 AccessoriesDocument40 pagesPND1000 3 AccessoriesPartsGopher.comNo ratings yet

- Reading Advice Dona WarrenDocument8 pagesReading Advice Dona WarrenVic Annielyn CoronelNo ratings yet

- R30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFDocument219 pagesR30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFdenix49No ratings yet

- English: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDocument25 pagesEnglish: Quarter 4 - Module 4: Relative Clause in Making DefinitionsDorothy Yen Escalaña0% (1)

- Project Muse 42646 PDFDocument27 pagesProject Muse 42646 PDFKaustav RoyNo ratings yet

- Number PatternDocument14 pagesNumber PatternSolehah Roslan100% (1)

- Freedom and Nature in Schelling's Philosophy of Art, Devin ZaneDocument240 pagesFreedom and Nature in Schelling's Philosophy of Art, Devin ZaneTheoria100% (2)

- FiberCable 2 V8 56 Oct20Document288 pagesFiberCable 2 V8 56 Oct20Ronald N Meza CNo ratings yet

- CS 273 Course Notes: Assembly Language Programming With The Atmel AVR MicrocontrollerDocument49 pagesCS 273 Course Notes: Assembly Language Programming With The Atmel AVR MicrocontrollerYassineZklNo ratings yet

- Callisto SPC: Technical SpecificationsDocument3 pagesCallisto SPC: Technical SpecificationsLuis Miguel Figueroa Quiroz “Luis Figueroa”No ratings yet

- David SMCC16ge Ppt07Document46 pagesDavid SMCC16ge Ppt07Çağla Kutlu100% (1)

- Fake News Detection Using NLPDocument9 pagesFake News Detection Using NLPIJRASETPublicationsNo ratings yet

- Natural Reader Listening TOEFLDocument22 pagesNatural Reader Listening TOEFLTira Nur FitriaNo ratings yet

- Sony - Micro System - Cmthpz9Document40 pagesSony - Micro System - Cmthpz9SoniaSegerMercedesNo ratings yet

- 03rd MS Seq03 Lis & Do 01Document2 pages03rd MS Seq03 Lis & Do 01Fatima ZohraNo ratings yet

- EditorialReview SylwestrowiczDocument2 pagesEditorialReview SylwestrowiczStefh ZamoraNo ratings yet

- Spur GearDocument3 pagesSpur Gearigualdi53No ratings yet

- Question Set No 3Document77 pagesQuestion Set No 3CuriousNo ratings yet

- MID 039 - CID 0167 - FMI 12: TroubleshootingDocument5 pagesMID 039 - CID 0167 - FMI 12: TroubleshootingNerminTurkenceNo ratings yet

- Negotiating Mobile Identity in The Global Nightscape: Krzysztof Z. JankowskiDocument9 pagesNegotiating Mobile Identity in The Global Nightscape: Krzysztof Z. JankowskiAlex YiuNo ratings yet

- Department of The Interior and Local Government Bureau of Fire ProtectionDocument5 pagesDepartment of The Interior and Local Government Bureau of Fire ProtectionBoy ClementeNo ratings yet

- BUS - 6140 - Module - 5 - Worksheet SaheedDocument6 pagesBUS - 6140 - Module - 5 - Worksheet SaheedAugusta B100% (1)

- DLL in BPP - DIFFERENT BAKED PRODUCTSDocument5 pagesDLL in BPP - DIFFERENT BAKED PRODUCTSAlva Catalina Gamayon-ArmadaNo ratings yet

- Android-Based Classroom Monitoring System For Teacher Using QR Code TechnologyDocument12 pagesAndroid-Based Classroom Monitoring System For Teacher Using QR Code TechnologyAkmad Ali AbdulNo ratings yet

- Parts Catalog: 25 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

- Magnetron Delay: Revision 10.13.20Document5 pagesMagnetron Delay: Revision 10.13.20manecolooperNo ratings yet

- 1SBN020010R1002 Te5s 120 Electronic TimerDocument4 pages1SBN020010R1002 Te5s 120 Electronic TimermeriemNo ratings yet