Professional Documents

Culture Documents

MDI - Group 10 - OM Topic Details - Section C

MDI - Group 10 - OM Topic Details - Section C

Uploaded by

Deependra AroraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDI - Group 10 - OM Topic Details - Section C

MDI - Group 10 - OM Topic Details - Section C

Uploaded by

Deependra AroraCopyright:

Available Formats

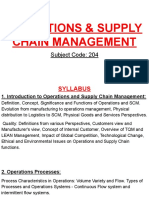

Supply Chain management of Myntra

Introduction: Supply chain management is an interesting subject. Physical shopping will be

lessening in the coming decade. There is a greater need to make the product and service

available to the consumers to their door steps. To make this process a success requires an

intricate design of the supply chain. Before we start we would like to make you aware of the

topics of supply chain that will help to progress further with the paper.

Facility Location:- This involves with the strategic placement of various facility locations.

There are number factors that determines the locations of various facilities like proximity to

the market, business climate, labour etc. the various ways of analysis of optimization of

facility location area.

i. transportation method

ii. Centroidal method.

iii. Cost-volume-profit ratio/ break- even analysis

iv. Factor rating method

Plant Layout:- This involves with arrangement of the facility in order to have the maximum

amount of productivity. There are different types of plant layout structures such as process

layout, product layout group layout etc. various ways that are used to analyse and optimize

are:-

i. systematic layout planning

ii. Block diagram

iii. Assembly line balancing

Aggregate planning:- It deals with the subject of employment and manufacture and

management of the product depending on the on the demand, supply and need of work

force. It basically deals with the optimization of the workforce and product management

based on the demand and supply.

i. Work force level in industries

ii. Subcontracting

iii. Overtime

iv. Hiring and firing

Inventory control:- To meet the demand in the market certain level of stock of the item is

kept. It is classified according to the time it is required to sell off and the availability of the

item. Thus it is classified into fast moving, slow moving, non-moving and scarce, difficult,

easy. There are various EOQ (Economic Order Quantity) models used to calculate the

inventory.

Forecasting:- Inventory management, manufacturing requires an amount of forecasting.

This is done using the data of past experiences. There are two methods of forecasting

quantitative and qualitative methods.

We will discuss above all points in details in our report.

You might also like

- PPC NotesDocument44 pagesPPC Noteshill_me870% (1)

- T 5-6 (A) - JIT, Quality CostsDocument14 pagesT 5-6 (A) - JIT, Quality Costsvipsc201505No ratings yet

- OM End SemDocument16 pagesOM End Semdivya.marathe23No ratings yet

- Unit-6 Final Supply Chain Performance MGMTDocument7 pagesUnit-6 Final Supply Chain Performance MGMTSuMit SoMai THapaNo ratings yet

- Om Assignment: Unit 1Document5 pagesOm Assignment: Unit 1Yashovardhan SinhaNo ratings yet

- MIS in Manufacturing SectorDocument15 pagesMIS in Manufacturing SectorAli Raza100% (1)

- Material Requirement PlanningDocument23 pagesMaterial Requirement Planningsangaleabhi100% (1)

- ASCM NotesDocument4 pagesASCM NotesJanmejai BhargavaNo ratings yet

- PPC Notes PDFDocument36 pagesPPC Notes PDFIbrahim UjjainwalaNo ratings yet

- Finance Manager - AssignmentDocument8 pagesFinance Manager - AssignmentVishal SinghNo ratings yet

- Production Cycle ReportingDocument6 pagesProduction Cycle ReportingAira Jaimee GonzalesNo ratings yet

- MIS in Manufacturing SectorDocument15 pagesMIS in Manufacturing Sectorsagar2go80% (5)

- Raw:/storage/emulated/0/Download/inbound 3081672313263350329Document5 pagesRaw:/storage/emulated/0/Download/inbound 3081672313263350329Marvin Espenocilla EspeñoNo ratings yet

- B.S Anangpuria Institute of Technology and Management FaridabadDocument92 pagesB.S Anangpuria Institute of Technology and Management Faridabadwigivi4421No ratings yet

- Lean Start-Up Management Mgt1022: Digital Assignment - 2Document24 pagesLean Start-Up Management Mgt1022: Digital Assignment - 2PHK. DEEKSHITHNo ratings yet

- Mba Pom Q&aDocument5 pagesMba Pom Q&aRahulNo ratings yet

- Definition and Basic Concepts of Operations ManagementDocument8 pagesDefinition and Basic Concepts of Operations Managementmozakkir589No ratings yet

- Process Strategy Summary - 14 - I Gede Dipta MahesaDocument3 pagesProcess Strategy Summary - 14 - I Gede Dipta Mahesamahesadipta86No ratings yet

- Course Pack - Operations ManagementDocument34 pagesCourse Pack - Operations ManagementSARBIKPAUL CHOWDHURYNo ratings yet

- Role of Operations Management in Corporate Profitability: 1 Product QualityDocument18 pagesRole of Operations Management in Corporate Profitability: 1 Product QualityAmar KoliNo ratings yet

- Group 5 Conversion CycleDocument12 pagesGroup 5 Conversion Cycleangeline llasesNo ratings yet

- Examination Preparation Hints EditedDocument13 pagesExamination Preparation Hints EditedMcusine JambaniNo ratings yet

- Project Work On Inventory Management SystemDocument8 pagesProject Work On Inventory Management SystemAndy RuthNo ratings yet

- PMM Notes All UnitsDocument205 pagesPMM Notes All UnitsSwethaNo ratings yet

- Production and Operation Management PPT at BEC DOMS BAGALKOTDocument238 pagesProduction and Operation Management PPT at BEC DOMS BAGALKOTBabasab Patil (Karrisatte)75% (4)

- Bank Operations Manager Manufacturing Operations ManagerDocument6 pagesBank Operations Manager Manufacturing Operations ManagerLauren StuartNo ratings yet

- BSCM 1Document14 pagesBSCM 1Bambang NuryantoNo ratings yet

- Summary - Chapter 1Document3 pagesSummary - Chapter 1RoseJeanAbingosaPernitoNo ratings yet

- Operations ManagmnetDocument6 pagesOperations ManagmnetGorakhpuria MNo ratings yet

- Operations & Supply Chain ManagementDocument35 pagesOperations & Supply Chain ManagementAnimesh kumarNo ratings yet

- MB0044 Assignment Spring 2013Document7 pagesMB0044 Assignment Spring 2013sandy065No ratings yet

- Introduction To Grocery Store and Its Management SystemDocument6 pagesIntroduction To Grocery Store and Its Management SystemAnitha PragasamNo ratings yet

- Production Management (Unit 1,2,3,4)Document8 pagesProduction Management (Unit 1,2,3,4)Amit Vikram OjhaNo ratings yet

- Operation Management NotesDocument30 pagesOperation Management NotesRenato WilsonNo ratings yet

- Ais10 ch12Document105 pagesAis10 ch12Shella FrankeraNo ratings yet

- Chapter 10 Production CycleDocument3 pagesChapter 10 Production CycleZenn Vanrim Lopez100% (1)

- Operation ManagementDocument125 pagesOperation ManagementSarita BhandariNo ratings yet

- Production and Operation Management - SYBBA-IBDocument18 pagesProduction and Operation Management - SYBBA-IBSakuraNo ratings yet

- OMDocument22 pagesOMrishikarathore145No ratings yet

- MRP I (Material Requirements Planning I) : PDFDocument6 pagesMRP I (Material Requirements Planning I) : PDFtjas955No ratings yet

- OSCMDocument43 pagesOSCMSahil BhatNo ratings yet

- BA4204 OPERATIONS MANAGEMENT ALL UNITS 2 MARksDocument16 pagesBA4204 OPERATIONS MANAGEMENT ALL UNITS 2 MARksKrish RavanaNo ratings yet

- ERP ct2Document10 pagesERP ct2kunalsahu10272003No ratings yet

- Production & Operation ManagementDocument42 pagesProduction & Operation ManagementSandeep GhatuaryNo ratings yet

- A SummaryDocument125 pagesA SummarySushil PokhrelNo ratings yet

- Inventory ManagementDocument23 pagesInventory ManagementChanchal GuptaNo ratings yet

- 5th Semester Operation Management BBMDocument125 pages5th Semester Operation Management BBMNeha TimsinaNo ratings yet

- Chapter 5.doc Inventory ManagementDocument7 pagesChapter 5.doc Inventory ManagementAntonio de GuzmanNo ratings yet

- Compendium by OPSIM 24072023Document54 pagesCompendium by OPSIM 24072023abhin pathakNo ratings yet

- POM 5.2 ControllingDocument5 pagesPOM 5.2 Controllingshefaligupta0408No ratings yet

- Question Set For OM Oral Exam.1Document6 pagesQuestion Set For OM Oral Exam.1kalineczka.rausNo ratings yet

- Debanjoy Basak 6Bbah-B 1823136 Production ManagementDocument9 pagesDebanjoy Basak 6Bbah-B 1823136 Production ManagementDEBANJOY BASAK 1823136No ratings yet

- ISCM Assignment 02Document2 pagesISCM Assignment 02Rishabh JainNo ratings yet

- Operations ManagementDocument45 pagesOperations ManagementShilpa N. Lende100% (4)

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Supply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsFrom EverandSupply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsNo ratings yet

- Theory of Accounting Engineering: Reimaging Accounting in the Twenty-First Century for EveryoneFrom EverandTheory of Accounting Engineering: Reimaging Accounting in the Twenty-First Century for EveryoneNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Sustainability in Industry - MC2Document2 pagesSustainability in Industry - MC2Deependra AroraNo ratings yet

- 22P152 - 22P186 - Food and Beverage - MC2Document2 pages22P152 - 22P186 - Food and Beverage - MC2Deependra AroraNo ratings yet

- Blue Modern Technology Business PresentationDocument12 pagesBlue Modern Technology Business PresentationDeependra AroraNo ratings yet

- 22P128 Banking SectionCDocument2 pages22P128 Banking SectionCDeependra AroraNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)