Professional Documents

Culture Documents

2 - REV Method Statement For Electrical Installations of Cable

2 - REV Method Statement For Electrical Installations of Cable

Uploaded by

Ayda JohariCopyright:

Available Formats

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- MBA Project On Employee Welfare MeasuresDocument92 pagesMBA Project On Employee Welfare MeasuresJebin Jacob93% (15)

- Method Statement Pull Out TestDocument7 pagesMethod Statement Pull Out TestAyda JohariNo ratings yet

- Method Statement For Testing and Commissioning of MATVDocument7 pagesMethod Statement For Testing and Commissioning of MATVDong Vanra100% (1)

- Method Statement For MDB & MSBDocument9 pagesMethod Statement For MDB & MSBshareyhouNo ratings yet

- Method Statement For Catv OutletDocument1 pageMethod Statement For Catv OutletBento BoxNo ratings yet

- SCM Book - Part18 - Part1Document2 pagesSCM Book - Part18 - Part1JustNo ratings yet

- Internal Approval of Method StatementsDocument12 pagesInternal Approval of Method Statementsmidhun muraliNo ratings yet

- Method Statement Elect Pipe UndergroundDocument67 pagesMethod Statement Elect Pipe Undergroundمقاول تكييف كهرباء وصحيNo ratings yet

- TEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Document7 pagesTEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Aryaa ArrNo ratings yet

- Distribution Commissioning Work InstructionDocument7 pagesDistribution Commissioning Work InstructionfuatbolatNo ratings yet

- MSS-METHOD STATEMENTS MitendraDocument232 pagesMSS-METHOD STATEMENTS MitendraMitendra Kumar ChauhanNo ratings yet

- 4-Technical Specs - LVDocument29 pages4-Technical Specs - LVtauqeer544gmailcomNo ratings yet

- Appendix H - As-Built Drawing Submission FormDocument1 pageAppendix H - As-Built Drawing Submission FormSyerifaizal Hj. MustaphaNo ratings yet

- Method Statement DSDocument14 pagesMethod Statement DSehteshamNo ratings yet

- Mos For Electrical Work Ad PolyDocument3 pagesMos For Electrical Work Ad PolyCamlock0% (1)

- Appendix G - Shop Drawing Submission FormDocument1 pageAppendix G - Shop Drawing Submission FormSyerifaizal Hj. MustaphaNo ratings yet

- 21 - Low Voltages Electl. Power Conductors and CablesDocument6 pages21 - Low Voltages Electl. Power Conductors and CablesWalid MarhabaNo ratings yet

- Quality Control Inspection Checklist: Project Stonor 3Document1 pageQuality Control Inspection Checklist: Project Stonor 3Syerifaizal Hj. MustaphaNo ratings yet

- Ms For Indoor Ligthing InstallationDocument6 pagesMs For Indoor Ligthing InstallationJoe_AverageNo ratings yet

- MOS Soil Investigation WorksDocument3 pagesMOS Soil Investigation WorksIzza HalimNo ratings yet

- Method Statement For Dressing of Steel PoleDocument3 pagesMethod Statement For Dressing of Steel PoleMary Grace LagundinoNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Method Statement For Re-Testing of LED Strip LightsDocument2 pagesMethod Statement For Re-Testing of LED Strip LightsRyn Rcio100% (1)

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaNo ratings yet

- RFI - 57 Working Pile Concreting and Removal of CasingDocument1 pageRFI - 57 Working Pile Concreting and Removal of CasingJoe PsNo ratings yet

- 01 - PVC Conduits InstallationDocument11 pages01 - PVC Conduits InstallationRaju ManojNo ratings yet

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- Electrical Power System Energization Procedure For Low Voltage EquipmentDocument17 pagesElectrical Power System Energization Procedure For Low Voltage EquipmentMohamed HaleemNo ratings yet

- Method Statment Master List - EDRDocument5 pagesMethod Statment Master List - EDRAltaf KhanNo ratings yet

- 05-ELE - 005 - Implementation of Testing and Adjusting, Commissioning, Handover-ProcedureDocument17 pages05-ELE - 005 - Implementation of Testing and Adjusting, Commissioning, Handover-Procedurehafiz_kdw1111No ratings yet

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 pageCHECKLIST For Installation of Electrical UPVC DuctskevinNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- Method Statement IPBsDocument7 pagesMethod Statement IPBskamil100% (1)

- ExcavationDocument24 pagesExcavationAhmed ImranNo ratings yet

- QM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01Document11 pagesQM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01GaneshNo ratings yet

- Electricity Regulations 1994Document78 pagesElectricity Regulations 1994redwariorNo ratings yet

- All Projects - Snag ListDocument7 pagesAll Projects - Snag ListMohammed Javid HassanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADocument48 pagesM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNo ratings yet

- Method Statement For InstallationDocument5 pagesMethod Statement For InstallationAriel CatapalNo ratings yet

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNo ratings yet

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarNo ratings yet

- Method Statement - MV Cable PullingDocument12 pagesMethod Statement - MV Cable PullingFahd SamiNo ratings yet

- Zeeshan Yasin: AddressDocument8 pagesZeeshan Yasin: AddressZeeshan YasinNo ratings yet

- Submittal Sheet: From: CCDocument2 pagesSubmittal Sheet: From: CCCaberte JohnnyNo ratings yet

- Metod of Staitment CDP (Pasha Construction)Document7 pagesMetod of Staitment CDP (Pasha Construction)GurbanNo ratings yet

- Elec Foreman CVDocument4 pagesElec Foreman CVhitanshu0% (1)

- Ms Common WorkDocument25 pagesMs Common WorkSahabzada AamirNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)Document39 pagesCgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)diki anggriawanNo ratings yet

- Planning RequirementDocument50 pagesPlanning RequirementLilet P. DalisayNo ratings yet

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDocument23 pages835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911No ratings yet

- Method statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksDocument9 pagesMethod statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksUET MAIN100% (1)

- Work Method StatementDocument6 pagesWork Method StatementbnmqweNo ratings yet

- Method Attempt - Ohtl Search - To Be UsedDocument31 pagesMethod Attempt - Ohtl Search - To Be UsedhaneeneNo ratings yet

- KMTC Advert For September 2021 and March 2022 IntakesDocument2 pagesKMTC Advert For September 2021 and March 2022 IntakesNjoroge MainaNo ratings yet

- Method Statement For Concrete Repair Works.Document9 pagesMethod Statement For Concrete Repair Works.Munaku TafadzwaNo ratings yet

- MS-21 For Fiberglass InsulationDocument9 pagesMS-21 For Fiberglass InsulationAlaa AliNo ratings yet

- Method Statement For Installation of Enclosed Switches IsolatorsDocument10 pagesMethod Statement For Installation of Enclosed Switches IsolatorsADIL AL-AQABYNo ratings yet

- Method Statement-1Document10 pagesMethod Statement-1Kumareswaran Sunthra SakaranNo ratings yet

- O-n-M Manual - Flood Mitigation InfraDocument42 pagesO-n-M Manual - Flood Mitigation InfraKuang Ngang ENo ratings yet

- Materials Inspection Request (MIR)Document8 pagesMaterials Inspection Request (MIR)Anonymous NR3qZ30100% (1)

- Method Statement For Installation of Cable Tray or TrunkingDocument9 pagesMethod Statement For Installation of Cable Tray or TrunkingEmmanuel TamayoNo ratings yet

- Usg Boral TileDocument16 pagesUsg Boral TileAyda JohariNo ratings yet

- 1 Method Statement First Fix Install - ICU HTAR (Autosaved) CompleteDocument7 pages1 Method Statement First Fix Install - ICU HTAR (Autosaved) CompleteAyda JohariNo ratings yet

- Elec - Cirt - JKRDocument4 pagesElec - Cirt - JKRAyda JohariNo ratings yet

- 2 Method Statement - Second Fix Instal - ICU HTAR CompleteDocument4 pages2 Method Statement - Second Fix Instal - ICU HTAR CompleteAyda JohariNo ratings yet

- Aircondit) Oning: Wijaya Sdn. BHDDocument1 pageAircondit) Oning: Wijaya Sdn. BHDAyda JohariNo ratings yet

- 1 - Method Statement For Sika WaterproofingDocument6 pages1 - Method Statement For Sika WaterproofingAyda JohariNo ratings yet

- 1 - REV Method Statement For Generator SetDocument13 pages1 - REV Method Statement For Generator SetAyda JohariNo ratings yet

- Excellent For Small Room: 15cm/6" 15cmDocument1 pageExcellent For Small Room: 15cm/6" 15cmAyda JohariNo ratings yet

- R410A Non Inverter: Ceiling Concealed SeriesDocument2 pagesR410A Non Inverter: Ceiling Concealed SeriesAyda Johari100% (1)

- R410A Non Inverter: High Static Ducted UnitDocument6 pagesR410A Non Inverter: High Static Ducted UnitAyda JohariNo ratings yet

- Hta Av BJM Ow L-001 (r1)Document1 pageHta Av BJM Ow L-001 (r1)Ayda JohariNo ratings yet

- Hta Ac BJM Ow L-002Document1 pageHta Ac BJM Ow L-002Ayda JohariNo ratings yet

- Level5 - Rigging PointDocument1 pageLevel5 - Rigging PointAyda JohariNo ratings yet

- Bealu ThesisDocument56 pagesBealu ThesisTeshaleNo ratings yet

- Full Download Ebook Ebook PDF Managerial Economics in A Global Economy 9th Edition PDFDocument41 pagesFull Download Ebook Ebook PDF Managerial Economics in A Global Economy 9th Edition PDFdaniel.graves434100% (45)

- Guide Questions For Chapter 2Document5 pagesGuide Questions For Chapter 2Kathleen Mangual0% (1)

- Ryan, 2021Document449 pagesRyan, 2021Solav Ezzaaldeen Saeed Dalo100% (2)

- Gender Disparity in Leadership: A Case Study of Belize BanksDocument1 pageGender Disparity in Leadership: A Case Study of Belize BanksJamie Martinez0% (1)

- Consumer Information:: Cibiltusc3Document11 pagesConsumer Information:: Cibiltusc3Ajit KumarNo ratings yet

- GOK Unlock 2.0 OrderDocument9 pagesGOK Unlock 2.0 OrderAbhijith PatelNo ratings yet

- BH Tif08Document24 pagesBH Tif08Andres R. OlguinNo ratings yet

- Ensilo/Fortiedr: Course DescriptionDocument2 pagesEnsilo/Fortiedr: Course DescriptionhoadiNo ratings yet

- Windproof Umbrella: Lean Start-Up Management (MGT1022) Slot: TE1 Fall Semester 2019-20Document48 pagesWindproof Umbrella: Lean Start-Up Management (MGT1022) Slot: TE1 Fall Semester 2019-20Samyak Doshi100% (1)

- Delhi Pubic School, Nacharam Accountancy - Xi Question BankDocument9 pagesDelhi Pubic School, Nacharam Accountancy - Xi Question BanklasyaNo ratings yet

- Lecture BPMNDocument15 pagesLecture BPMNAna AlmaNo ratings yet

- BSBHRM415 Assessment 3Document24 pagesBSBHRM415 Assessment 3Michael FelixNo ratings yet

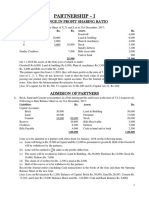

- Partnership - I: Change in Profit Sharing RatioDocument33 pagesPartnership - I: Change in Profit Sharing RatioUjjwal BeriwalNo ratings yet

- March 2020: Facebook Wealth FormulaDocument51 pagesMarch 2020: Facebook Wealth Formulafercho500No ratings yet

- Real Time Vehicle Tracking System Using GSM and GPDocument6 pagesReal Time Vehicle Tracking System Using GSM and GPTheIgor997No ratings yet

- Questions: Download More at WWW - Ebookskenya.co - KeDocument38 pagesQuestions: Download More at WWW - Ebookskenya.co - KeSamielMuhamedOmarNo ratings yet

- 8 - PP V Diaz Conde Digest 1922Document2 pages8 - PP V Diaz Conde Digest 1922Digesting FactsNo ratings yet

- Currency Exchange Rate and International Trade and Capital FlowsDocument39 pagesCurrency Exchange Rate and International Trade and Capital FlowsudNo ratings yet

- Strategic Management Text and Cases 8th Edition Dess Solutions ManualDocument37 pagesStrategic Management Text and Cases 8th Edition Dess Solutions Manualforeliftperiople.ttyox100% (34)

- Bs en 12Document10 pagesBs en 12Alvin BadzNo ratings yet

- Case Study Champions League FinalDocument14 pagesCase Study Champions League FinalRakeem DavidsonNo ratings yet

- Letter From ExporterDocument2 pagesLetter From Exporterdeepak.kadindustriesNo ratings yet

- Doc 20221108 Wa0005.Document12 pagesDoc 20221108 Wa0005.UzmaamehendiartNo ratings yet

- 5ced6438e4b0ef8521f80cbf OriginalDocument101 pages5ced6438e4b0ef8521f80cbf OriginalParth TiwariNo ratings yet

- Push Pull System Spring 2014Document25 pagesPush Pull System Spring 2014Mohammad OkourNo ratings yet

- Leadership and Corporate CultureDocument26 pagesLeadership and Corporate CultureJagdip singh Bhinder100% (1)

- End of Chapter - Activities - Guffey - EBC - 12e - Ch02Document10 pagesEnd of Chapter - Activities - Guffey - EBC - 12e - Ch02k61.2212585011No ratings yet

2 - REV Method Statement For Electrical Installations of Cable

2 - REV Method Statement For Electrical Installations of Cable

Uploaded by

Ayda JohariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 - REV Method Statement For Electrical Installations of Cable

2 - REV Method Statement For Electrical Installations of Cable

Uploaded by

Ayda JohariCopyright:

Available Formats

GOVERNMENT OF MALAYSIA/ KEMENTERIAN KESIHATAN MALAYSIA

KELTRIK ENGINEERING SDN. BHD.

KERJA-KERJA MENAIKTARAF SISTEM GAS PERUBATAN DI

HOSPITAL KUALA KUBU BHARU, SELANGOR

METHOD STATEMENT

ELECTRICAL INSTALLATION OF CABLE,

MDB, SMDB, DB, MCC & CB

Reference No. : KESB / HKKB/ MS/E-02

Rev. No. : 01

Date Issued : 16/08/2022

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

TABLE OF CONTENTS

1. PURPOSE 3

2. SCOPE 3

3. INSTALLATION OF CABLE, MDB’S, SMDB, DB, MCC & CB 3

4. RESPONSIBILITIES

i PROJECT MANAGER (PM) 3

ii CONSTRUCTION MANAGER (CM) 3

iii SITE ENGINEER (SE) 4

iv OFFICER 4

v SUPERVISOR 5

5. EQUIPMENTS & TOOLS 5

6. PROCEDURES OF INSTALLATION SWITCH GEARS 6

7. WORK METHODOLOGY 6

8. HANDLING AND STORAGE 7

9. GENERIC INSTALLATION PROCEDURES 7

10. INSTALLATION METHOD OF MCC 8

11. INSTALLATION OF SMBD & FDB 9

1. PURPOSE

Keltrik Engineering Sdn.Bhd. Page 2 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

The main objective of this method statement (MS) is to define step by step procedures to

implement the equitable practices for Installation of Distribution Boards (DB), Sub Main

Distribution Boards, Motor Control Centre (MCC), Power Distribution Board (PDB) &

Circuit Breaker (CB) through the technical guidelines consist of herein so as to ensure that the

job execution complies with specification and serves the required function to suitable level

where associable in the installation project.

2. SCOPE

This method statement (MS) highlights all proceedings regarding Installation of Distribution

Boards (DB), Sub Main Distribution Boards, Motor Control Centre (MCC), Power

Distribution Board (PDB) & Circuit Breaker (CB) as the following:

3. INSTALLATION OF CABLE, MDB'S, SMDB, DB, MCC & CB.

This installation methodology is to be read in conjunction with the significant (Inspection

Test Plan) ITP highlighting the responsibility and the quality verification to be execute by

several parties.

4. RESPONSIBILITIES

Accountability or Responsibilities for establishing that the steps in this procedure shall be

conducted are particularly at important steps in the procedures.

i. Project Manager (PM)

- complete accountable for the project in terms of work execution, health,

safety, planning & quality. The Project Manager will keep the planning

improvement and proper essential coordination of works.

- The project activities development shall be conducted as per planned

schedule and all the tools, machinery or equipment's required to execute the

works shall be possible easily available and in safe and good condition as

per project planned schedule.

- Proper consideration is paid to all health and safety initiatives and quality

control (QC) in coordination with Safety Engineer/Officer.

ii. Construction Manager (CM)

- accountable/answerable to supervise and control the work on project site.

- Coordinating and accommodating with Engineer and site Team and

foremen for all activities on site.

- Control and sign all Work Inspection Requests (WIR's) prior issuing to

consultant approval.

Keltrik Engineering Sdn.Bhd. Page 3 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

iii. Site Engineer (SE)

- This method statement (MS) to the system shall be implemented as per the

project conditions and approved Shop Drawings (SD).

- Provision of all proper essential information and distribution of

authoritative roles to his Construction team.

- The work development shall be continuously observed and reviewed as per

the planned scheduled program and he will report to his superiors.

- The continual essential and proper coordination with the Safety Engineer or

safety officer or safety representative to make sure that the job tasks are

being conducted in secure & safe working atmosphere.

- The continual essential and proper coordination with the Engineer for any

activity to be accomplished and set up for the appropriate inspection for the

completed works.

- Decisive daily development report shall be gathered for all the tools,

machinery, equipment and workforce.

- Will involve efficiently in the work and observe, inspect and review the

same against the daily report received from the site foremen.

- The passage of all the revised information to the Foremen and ensure that

it's being carried out properly.

iv. Officer

- The duty of Officer works out for the successful, safe and secure

implementation of all occupational safety, health, and environmental (SHE)

initiatives following the HSE plan and that the whole workers are known its

appropriate implementation.

- The proper implementation of occupational HSE safety measures is

suitable to keep a safe and secure working environment on the work

activity.

- Health and Safety Inspection, observations and coordination of all the

worksite/projects activities and HSE training/orientation, personnel in

accident/incidents prevention and its appropriate required reporting to the

Construction Manager and the Project Manager.

- To make inspections to ensure the worksite is maintained in a clean and

tidy manner (housekeeping).

- To ensure that only competent and trained personals shall operate the

machinery, equipment and power tools.

- To implement a strict compliance policy regarding the use of PPE.

Keltrik Engineering Sdn.Bhd. Page 4 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

- To work out for the promotion of positive safety culture at worksite/project.

- Making ensure that high-risk exalted areas are provided with all safety and

health measures such as barricade tape, safety nets, PPE, etc.

- Ensure safe access to a worksite.

v. Supervisor

- All level of supervision will make sure and make strategy in carrying-out of

work and the appropriate distribution of all the available resources in

coordination with the Site Manager/Engineer regularly.

- Will observe and prepare and share daily reports of the activities are

accomplished and coordinated for future strategies with the Site Manager/

Engineer.

- Consolidate all the QA/QC and HSE requirements as asked by the

concerned Manager /Engineer and or consultant.

- Observing all unsafe condition, violence, incident, near miss, or

requirement and reporting immediately to the Site Manager/Engineer.

- responsible for all Store operations ensure the required material delivery to

the worksite and that material storage in safe from any critical damage or

misuse.

- Ensure Proper housekeeping in-store/warehouse and endorse the receiving

of materials at the worksite in coordination with Engineer.

5. EQUIPMENT &TOOLS

All Main Distribution Boards (MDB's), Sub Main Distribution Board (SMDB's),

FDB's, MCC's & Capacitor Bank (CB's) shall be in line with approved material

submittal and as per approved drawings.

Portable Hand Tools (e.g., abrasive wheels, grinders, lawnmowers, powered operated

drills, portable circular saws, portable belt sanding machines, explosive-actuated

fastening tools, and jacks),

Portable Drilling Machine.

Grinding Machine.

Insulation Testing Equipment (ITE).

Digital Multi-meter (VOM (volt-ohm-millimetre, Digital mustimeters (DMM,

DVOM), Measuring Tape.

Ladder/ Scaffolding.

Keltrik Engineering Sdn.Bhd. Page 5 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

Safety PPE’S such as safety shoes, safety helmet, safety glasses, HV flora cent vest,

and multi-role and heavy-duty safety gloves to ensure the maximum ability of safe

work and a dust mask when required.

6. PROCEDURES OF INSTALLATION SWITCH GEARS

Always be ensure that only competent, trained, authorized, licensed professional

workers only shall operate the power tools.

Ensure that temporary live electrical cable management plan shall properly develop

and implement.

Proper required standards compatible with personal protective equipment (PPE) to be

worn while carrying out routine daily activities while working in energized circuits.

To make it possible to provide proper required adequate lighting system in the

working various areas particularly at night shifts.

All Safe lifting operations and shifting of L V switchgear panels and its related

possible critical hazards and risks shall be identifying.

Ensure work activities areas shall be secured and safe with barricade tape, safety nets

and warning signage/posters, proper tagging to be provided (Danger: Low Voltage).

Ensure lockout tag out LOTO) procedure to be followed and implemented during the

execution of work.

Emergency response plan procedure shall be developed as per the worksite/project

condition during the execution of the various activity.

To ensure all material or machinery shift or used by using mechanical aids to avoid

any ergonomics issues.

Always proper permit to work (PTW) to be applied and obtained to start work on the

required area.

Calibrated, certified and tested from third parties’ instruments only to be used.

7. WORK METHODOLOGY

i. All material delivered to worksite should be inspected properly by Engineer and

check if it is stored appropriately as per the manufacturer's recommendations.

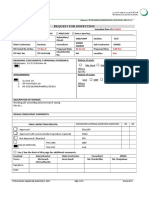

ii. Material Inspection Request (MIR) shall be raised for the inspection of materials

received at the site by Sub-contractor Engineer to the Consultant Engineer.

iii. The strict level of supervision shall be practiced to avoid any incident/accidents or

near misses.

Keltrik Engineering Sdn.Bhd. Page 6 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

iv. Engineer shall coordinate with other contractors and arrange inspection for

installation to the Consultant Engineer.

v. Engineer is accountable for all installation jobs for getting the work inspected and

approved by the Consultant Engineer.

8. HANDLING AND STORAGE

i. After getting of all the all-Main Distribution Boards (MDB's), Sub Main Distribution

Board (SMDB's), and Capacitor Bank, etc. (CB's) and accessories at the site,

necessary precautions shall be taken for unloading, shifting and storage, as below:

ii. Storage of material shall be done in a fully covered and dry space at all the time.

iii. All received materials at worksite shall be inspected as per approved material

submittal.

iv. Any miscalculations, damage and destruction in the material will be notified and

reported for further action.

v. Site Manager/Engineer has to make ensure that all Panel boards used at site are of

free from any damage or deformity of any kind. Any minor damages/malfunction

observed shall be repaired appropriately and in case if the repairs could not be carried

out properly, the panel boards are to be sent to assembler for rectification, after all,

procedures accomplished.

9. GENERIC INSTALLATION PROCEDURE

Make sure that the activates area is tidy, ready and safe to start the installation.

Ensure to take all proper HSE measures to start the installation of MDB's, SMDB's,

FDB's, MCC's, CB's and accessories

Ensure the installation of Main Distribution Boards (MDB's), Sub Main Distribution

Board (SMDB's), and Capacitor Bank, (CB's) and adornments at worksite carried out

by following manufacturer's installation recommendations, the requirement of

applicable standards, regulations and technical guidelines and in accordance.

Before starting the electrical installation, always refer to the approved drawings and

outlines related to the area of installation.

Ensure the materials are stored properly and there is no mark of damage or deformity

of any material from site store all materials and accessories should also be free of dust

and oil etc.

While installation the Main Distribution Boards (MDB's), Sub Main Distribution

Board (SMDB's), and Capacitor Bank, (CB's) Ensure that the issued materials are of

Keltrik Engineering Sdn.Bhd. Page 7 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

approved specifications, submitting and as per the requirement of the area shop

drawings.

10. INSTALLATION METHOD FOR MCC, CB & MDB

Various electrical components such as MCC, CB installation worksite shall be carried

out only concerning approved shop drawings.

All parts of MCC, CB & MDB such as relays, fuses. Current Transformer (CT's),

meters etc. shall be verified against the approved material submittal.

Make sure that the floor surface is prepared properly with base frames grouted to

install the switch gear.

The most important step which is keeping minimum clearance of 1,000mm at the

backside of the panel, so that easy access for termination of cables and other

maintenance works in future can be conducted.

Panel boards shall be installed serially and with Level Vertical following the

Manufacturer’s instructions/endorsements, approved site layout and as per site

specifications.

Closely and carefully examine and heck cabinet interconnections, bus bar

connections, control wire connections between the cubicles after appropriate

alignment of the sections cubical as per manufacturer's drawing, recommendations,

guidance and approved shop drawing.

All knockouts made on the panel covers shall be filed and provided with grommets to

avoid sharp edges injuries and unused knockouts shall be protected.

The connection of bus bar trucking with all panel boards shall be done firmly with

appropriate supports.

The Cables bending radius should be follows the Manufacturer's

instructions/guidelines.

All installing activities such as Cable pulling, termination & crimping shall be

conducted as per cables method of statement.

The completion or termination procedures of installation cables shall be done using

approved material submittal for cable glands and lugs. Glanding and connections

should be carried out only by competent and trained electricians under appointed

supervision of electrical site Engineer.

All distribution panel boards and switch gears shall be provided with proper earthing

connections as per approved shop drawings.

Keltrik Engineering Sdn.Bhd. Page 8 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

Manufacturer instructions are to be adopted for all relay, timer and other breaker

current settings, as per the total connected loads.

Identification labels/posters/tags of approved type shall be attached on all panel

boards.

Co-ordinate and ensure the provision of chequer plates on the open trenches inside

the LV /Electrical rooms.

Be sure that all cable entries and other openings/vents of Electrical/LV Room, walls,

Floor are done with proper recommended and approved sealant.

The manufacturer's representative to verify the worksite installations of MCC, CB &

MDB and provide acceptance of same before Energization/functioning of Panel

boards after getting clearance from Site Manager/Engineer.

11. INSTALLATION METHOD FOR SMDB & FDB

i. Manufacturer’s representative to verify the site installations and provide acceptance

of same before the Energization of electrical Panel boards after getting and receiving

clearance from Site manager/Engineer.

ii. Installation job shall be conducted only by following the approved shop drawings of

the latest editions.

iii. Make sure that all civil and finishing works are accomplished and installation is

released and cleared by civil section to continue with Distribution Board (DB)

installations. Also, ensure that the work area is tidy and secure to commence

activities.

iv. Ensure the wall surface is well prepared to install the Distribution Boards (DB).

v. Height of the Distribution Boards (DB) shall be properly maintained as per

recommended and approved shop drawings so that easy access for termination of

cables and other maintenance works can be accomplished.

vi. Connection of cable trays and cable trucking with all Distribution Boards (DB’s)

shall be done firmly with appropriate supports.

vii. All knockouts work made on the panel covers shall be filed and added with grommets

to avoid sharp edges injures and extra/unutilized knockouts shall be covered. All

cable entries shall be protected and sealed properly.

viii. Termination of cables shall be accomplished using approved cable glands and lugs

glanding and connections should be carried out by only competent technician and

electricians as per the approved/recommended shop drawing. Sub Main Distribution

Board (SMDB's) and FDB's shall be provided with appropriate earthing connections

as per approved shop drawings.

Keltrik Engineering Sdn.Bhd. Page 9 of 10

ELECTRICAL INSTALLATION OF CABLE, MDB, SMDB, DB, MCC & CB

Document No.

Revision No. 01 Rev. Date I 16/08/2022

ix. Doors of Sub Main Distribution Board (SMDB's) and FDB's are to be earthed with

the flexible connection.

x. Identification of approved labels, tagging, and pestering type shall be placed on the

Sub Main Distribution Board (SMDB's) and FDB's.

Keltrik Engineering Sdn.Bhd. Page 10 of 10

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- MBA Project On Employee Welfare MeasuresDocument92 pagesMBA Project On Employee Welfare MeasuresJebin Jacob93% (15)

- Method Statement Pull Out TestDocument7 pagesMethod Statement Pull Out TestAyda JohariNo ratings yet

- Method Statement For Testing and Commissioning of MATVDocument7 pagesMethod Statement For Testing and Commissioning of MATVDong Vanra100% (1)

- Method Statement For MDB & MSBDocument9 pagesMethod Statement For MDB & MSBshareyhouNo ratings yet

- Method Statement For Catv OutletDocument1 pageMethod Statement For Catv OutletBento BoxNo ratings yet

- SCM Book - Part18 - Part1Document2 pagesSCM Book - Part18 - Part1JustNo ratings yet

- Internal Approval of Method StatementsDocument12 pagesInternal Approval of Method Statementsmidhun muraliNo ratings yet

- Method Statement Elect Pipe UndergroundDocument67 pagesMethod Statement Elect Pipe Undergroundمقاول تكييف كهرباء وصحيNo ratings yet

- TEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Document7 pagesTEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Aryaa ArrNo ratings yet

- Distribution Commissioning Work InstructionDocument7 pagesDistribution Commissioning Work InstructionfuatbolatNo ratings yet

- MSS-METHOD STATEMENTS MitendraDocument232 pagesMSS-METHOD STATEMENTS MitendraMitendra Kumar ChauhanNo ratings yet

- 4-Technical Specs - LVDocument29 pages4-Technical Specs - LVtauqeer544gmailcomNo ratings yet

- Appendix H - As-Built Drawing Submission FormDocument1 pageAppendix H - As-Built Drawing Submission FormSyerifaizal Hj. MustaphaNo ratings yet

- Method Statement DSDocument14 pagesMethod Statement DSehteshamNo ratings yet

- Mos For Electrical Work Ad PolyDocument3 pagesMos For Electrical Work Ad PolyCamlock0% (1)

- Appendix G - Shop Drawing Submission FormDocument1 pageAppendix G - Shop Drawing Submission FormSyerifaizal Hj. MustaphaNo ratings yet

- 21 - Low Voltages Electl. Power Conductors and CablesDocument6 pages21 - Low Voltages Electl. Power Conductors and CablesWalid MarhabaNo ratings yet

- Quality Control Inspection Checklist: Project Stonor 3Document1 pageQuality Control Inspection Checklist: Project Stonor 3Syerifaizal Hj. MustaphaNo ratings yet

- Ms For Indoor Ligthing InstallationDocument6 pagesMs For Indoor Ligthing InstallationJoe_AverageNo ratings yet

- MOS Soil Investigation WorksDocument3 pagesMOS Soil Investigation WorksIzza HalimNo ratings yet

- Method Statement For Dressing of Steel PoleDocument3 pagesMethod Statement For Dressing of Steel PoleMary Grace LagundinoNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Method Statement For Re-Testing of LED Strip LightsDocument2 pagesMethod Statement For Re-Testing of LED Strip LightsRyn Rcio100% (1)

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaNo ratings yet

- RFI - 57 Working Pile Concreting and Removal of CasingDocument1 pageRFI - 57 Working Pile Concreting and Removal of CasingJoe PsNo ratings yet

- 01 - PVC Conduits InstallationDocument11 pages01 - PVC Conduits InstallationRaju ManojNo ratings yet

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- Electrical Power System Energization Procedure For Low Voltage EquipmentDocument17 pagesElectrical Power System Energization Procedure For Low Voltage EquipmentMohamed HaleemNo ratings yet

- Method Statment Master List - EDRDocument5 pagesMethod Statment Master List - EDRAltaf KhanNo ratings yet

- 05-ELE - 005 - Implementation of Testing and Adjusting, Commissioning, Handover-ProcedureDocument17 pages05-ELE - 005 - Implementation of Testing and Adjusting, Commissioning, Handover-Procedurehafiz_kdw1111No ratings yet

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 pageCHECKLIST For Installation of Electrical UPVC DuctskevinNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- Method Statement IPBsDocument7 pagesMethod Statement IPBskamil100% (1)

- ExcavationDocument24 pagesExcavationAhmed ImranNo ratings yet

- QM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01Document11 pagesQM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01GaneshNo ratings yet

- Electricity Regulations 1994Document78 pagesElectricity Regulations 1994redwariorNo ratings yet

- All Projects - Snag ListDocument7 pagesAll Projects - Snag ListMohammed Javid HassanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADocument48 pagesM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNo ratings yet

- Method Statement For InstallationDocument5 pagesMethod Statement For InstallationAriel CatapalNo ratings yet

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNo ratings yet

- Methos of Statement For Startup WorkDocument6 pagesMethos of Statement For Startup WorkMahesh MirajkarNo ratings yet

- Method Statement - MV Cable PullingDocument12 pagesMethod Statement - MV Cable PullingFahd SamiNo ratings yet

- Zeeshan Yasin: AddressDocument8 pagesZeeshan Yasin: AddressZeeshan YasinNo ratings yet

- Submittal Sheet: From: CCDocument2 pagesSubmittal Sheet: From: CCCaberte JohnnyNo ratings yet

- Metod of Staitment CDP (Pasha Construction)Document7 pagesMetod of Staitment CDP (Pasha Construction)GurbanNo ratings yet

- Elec Foreman CVDocument4 pagesElec Foreman CVhitanshu0% (1)

- Ms Common WorkDocument25 pagesMs Common WorkSahabzada AamirNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)Document39 pagesCgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)diki anggriawanNo ratings yet

- Planning RequirementDocument50 pagesPlanning RequirementLilet P. DalisayNo ratings yet

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDocument23 pages835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911No ratings yet

- Method statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksDocument9 pagesMethod statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksUET MAIN100% (1)

- Work Method StatementDocument6 pagesWork Method StatementbnmqweNo ratings yet

- Method Attempt - Ohtl Search - To Be UsedDocument31 pagesMethod Attempt - Ohtl Search - To Be UsedhaneeneNo ratings yet

- KMTC Advert For September 2021 and March 2022 IntakesDocument2 pagesKMTC Advert For September 2021 and March 2022 IntakesNjoroge MainaNo ratings yet

- Method Statement For Concrete Repair Works.Document9 pagesMethod Statement For Concrete Repair Works.Munaku TafadzwaNo ratings yet

- MS-21 For Fiberglass InsulationDocument9 pagesMS-21 For Fiberglass InsulationAlaa AliNo ratings yet

- Method Statement For Installation of Enclosed Switches IsolatorsDocument10 pagesMethod Statement For Installation of Enclosed Switches IsolatorsADIL AL-AQABYNo ratings yet

- Method Statement-1Document10 pagesMethod Statement-1Kumareswaran Sunthra SakaranNo ratings yet

- O-n-M Manual - Flood Mitigation InfraDocument42 pagesO-n-M Manual - Flood Mitigation InfraKuang Ngang ENo ratings yet

- Materials Inspection Request (MIR)Document8 pagesMaterials Inspection Request (MIR)Anonymous NR3qZ30100% (1)

- Method Statement For Installation of Cable Tray or TrunkingDocument9 pagesMethod Statement For Installation of Cable Tray or TrunkingEmmanuel TamayoNo ratings yet

- Usg Boral TileDocument16 pagesUsg Boral TileAyda JohariNo ratings yet

- 1 Method Statement First Fix Install - ICU HTAR (Autosaved) CompleteDocument7 pages1 Method Statement First Fix Install - ICU HTAR (Autosaved) CompleteAyda JohariNo ratings yet

- Elec - Cirt - JKRDocument4 pagesElec - Cirt - JKRAyda JohariNo ratings yet

- 2 Method Statement - Second Fix Instal - ICU HTAR CompleteDocument4 pages2 Method Statement - Second Fix Instal - ICU HTAR CompleteAyda JohariNo ratings yet

- Aircondit) Oning: Wijaya Sdn. BHDDocument1 pageAircondit) Oning: Wijaya Sdn. BHDAyda JohariNo ratings yet

- 1 - Method Statement For Sika WaterproofingDocument6 pages1 - Method Statement For Sika WaterproofingAyda JohariNo ratings yet

- 1 - REV Method Statement For Generator SetDocument13 pages1 - REV Method Statement For Generator SetAyda JohariNo ratings yet

- Excellent For Small Room: 15cm/6" 15cmDocument1 pageExcellent For Small Room: 15cm/6" 15cmAyda JohariNo ratings yet

- R410A Non Inverter: Ceiling Concealed SeriesDocument2 pagesR410A Non Inverter: Ceiling Concealed SeriesAyda Johari100% (1)

- R410A Non Inverter: High Static Ducted UnitDocument6 pagesR410A Non Inverter: High Static Ducted UnitAyda JohariNo ratings yet

- Hta Av BJM Ow L-001 (r1)Document1 pageHta Av BJM Ow L-001 (r1)Ayda JohariNo ratings yet

- Hta Ac BJM Ow L-002Document1 pageHta Ac BJM Ow L-002Ayda JohariNo ratings yet

- Level5 - Rigging PointDocument1 pageLevel5 - Rigging PointAyda JohariNo ratings yet

- Bealu ThesisDocument56 pagesBealu ThesisTeshaleNo ratings yet

- Full Download Ebook Ebook PDF Managerial Economics in A Global Economy 9th Edition PDFDocument41 pagesFull Download Ebook Ebook PDF Managerial Economics in A Global Economy 9th Edition PDFdaniel.graves434100% (45)

- Guide Questions For Chapter 2Document5 pagesGuide Questions For Chapter 2Kathleen Mangual0% (1)

- Ryan, 2021Document449 pagesRyan, 2021Solav Ezzaaldeen Saeed Dalo100% (2)

- Gender Disparity in Leadership: A Case Study of Belize BanksDocument1 pageGender Disparity in Leadership: A Case Study of Belize BanksJamie Martinez0% (1)

- Consumer Information:: Cibiltusc3Document11 pagesConsumer Information:: Cibiltusc3Ajit KumarNo ratings yet

- GOK Unlock 2.0 OrderDocument9 pagesGOK Unlock 2.0 OrderAbhijith PatelNo ratings yet

- BH Tif08Document24 pagesBH Tif08Andres R. OlguinNo ratings yet

- Ensilo/Fortiedr: Course DescriptionDocument2 pagesEnsilo/Fortiedr: Course DescriptionhoadiNo ratings yet

- Windproof Umbrella: Lean Start-Up Management (MGT1022) Slot: TE1 Fall Semester 2019-20Document48 pagesWindproof Umbrella: Lean Start-Up Management (MGT1022) Slot: TE1 Fall Semester 2019-20Samyak Doshi100% (1)

- Delhi Pubic School, Nacharam Accountancy - Xi Question BankDocument9 pagesDelhi Pubic School, Nacharam Accountancy - Xi Question BanklasyaNo ratings yet

- Lecture BPMNDocument15 pagesLecture BPMNAna AlmaNo ratings yet

- BSBHRM415 Assessment 3Document24 pagesBSBHRM415 Assessment 3Michael FelixNo ratings yet

- Partnership - I: Change in Profit Sharing RatioDocument33 pagesPartnership - I: Change in Profit Sharing RatioUjjwal BeriwalNo ratings yet

- March 2020: Facebook Wealth FormulaDocument51 pagesMarch 2020: Facebook Wealth Formulafercho500No ratings yet

- Real Time Vehicle Tracking System Using GSM and GPDocument6 pagesReal Time Vehicle Tracking System Using GSM and GPTheIgor997No ratings yet

- Questions: Download More at WWW - Ebookskenya.co - KeDocument38 pagesQuestions: Download More at WWW - Ebookskenya.co - KeSamielMuhamedOmarNo ratings yet

- 8 - PP V Diaz Conde Digest 1922Document2 pages8 - PP V Diaz Conde Digest 1922Digesting FactsNo ratings yet

- Currency Exchange Rate and International Trade and Capital FlowsDocument39 pagesCurrency Exchange Rate and International Trade and Capital FlowsudNo ratings yet

- Strategic Management Text and Cases 8th Edition Dess Solutions ManualDocument37 pagesStrategic Management Text and Cases 8th Edition Dess Solutions Manualforeliftperiople.ttyox100% (34)

- Bs en 12Document10 pagesBs en 12Alvin BadzNo ratings yet

- Case Study Champions League FinalDocument14 pagesCase Study Champions League FinalRakeem DavidsonNo ratings yet

- Letter From ExporterDocument2 pagesLetter From Exporterdeepak.kadindustriesNo ratings yet

- Doc 20221108 Wa0005.Document12 pagesDoc 20221108 Wa0005.UzmaamehendiartNo ratings yet

- 5ced6438e4b0ef8521f80cbf OriginalDocument101 pages5ced6438e4b0ef8521f80cbf OriginalParth TiwariNo ratings yet

- Push Pull System Spring 2014Document25 pagesPush Pull System Spring 2014Mohammad OkourNo ratings yet

- Leadership and Corporate CultureDocument26 pagesLeadership and Corporate CultureJagdip singh Bhinder100% (1)

- End of Chapter - Activities - Guffey - EBC - 12e - Ch02Document10 pagesEnd of Chapter - Activities - Guffey - EBC - 12e - Ch02k61.2212585011No ratings yet