Professional Documents

Culture Documents

R0.6 Max.: Section B-B

R0.6 Max.: Section B-B

Uploaded by

Dwarakesh BVOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R0.6 Max.: Section B-B

R0.6 Max.: Section B-B

Uploaded by

Dwarakesh BVCopyright:

Available Formats

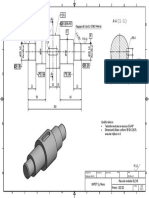

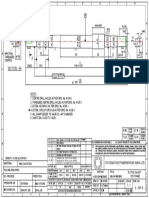

1 2 3 4 5 6 7 8

+0.011

+0.005 25 k5 +0.002

A 15 j5 -0.003 18.025 20.465 20.55 A A

#

-0.2

18 -0.1

$20.65

20.3

20.4

18.000 20.490 27 0.0

A B 22 -0.1

R1

B B

.6

R0 x. R0.6 B

Ma $76(Knurling area) A

11 15 25.5 95.5 27 R0.3 12.5

max.

0.00

163 h10 -0.16 16

202.5

C C

15

+0.12 CC

+0.012

3.35 0.00 * 4 H7 0.000 Thr' CC

1X15 Notes:

0.05 B

# 1.Thease are the turning Dimensions Priore to Knurling

$ 2.Straight Knurling (0.5 to 1.2 Pitch) to be done. Knurling to be raise to 20.55

CC to 20.65

3.Grinding allowance :+0.25mm

0.00

21 -0.13

D +0.1 4.Grinding & Circlip groove as Details as per Drg. No:4-468 (Latest Revision) D

12.2 0.0 5.Centre details as per 4-464 (Latest revision)

0.02 A-A 6.All Sharp edges to have 0.5x45 Chamfer (Where not Mnetioned).

* 7. Drill jig to be used for the holes

B

SECTION B-B

CC Critical to Customer

+0.14

ALL DIMENSIONS ARE IN M.M. ALL SHARP EDGES TO BE CHAMFERED.

E 1.3 0.00 E

DETAIL A C This document, and the information, specifications, drawing, shape, colour, design and the

artwork contained herein is the intellectual property of Rotomag Motors & Controls Pvt. Ltd..

0.5x45

SCALE 2 : 1 CC 24.11.21 13

Shaft material change to EN-19 to

Kriyesh Wasim

It should not be disclosed, copied, reproduced of any item or component or product

manufartured using this information without our written authorization.

eliminate hardning process.

Circlip groove removed,27mm exnded

20.07.20 12 Wasim

from 17mm & 95.5 was 100.5

MATERIAL : EN-19 (Material hardness:23~30 HRC) 23.06.18 11 Process Sequence Added Anil J.C.P ROTOMAG ROTOMAG MOTORS & CONTROLS PVT. LTD.

13

DATE REV. DESCRIPTION DRN BY APPD BY

TOOLING REQUIRED -: DEVIATION(mm) 0.1 0.2 0.3 0.5 0.8 PART NO. TITLE

FROM UP TO

F SP. PROCESS :HARDENING PRESS TOOL & INCLUDING

0.5-6 6-30 30-120 120-315 315-1000 --------- Shaft For SE-30 & SE-40 F

FORMAT ISO A4

DEVIATION ON NON TOLERANCED LINEAR MACHINED DIMENSIONS

DRN BY 08.07.09 SCALE DRG. NO.

PRESSURE DIE PATTERN M/C FIXTURE 25 TO 250 8 TO 25 1.6 TO 8 0.025 TO 1.6 < TO 0.025

1:1

MOULDING DIE DRILL JIG

~ CHD BY 4-1112.13

GRAVITY DIE SURFACE ROUGHNESS IN MICRONS APPD BY

1 2 3 4 5 6 SUPERSEDES NO :SMP-3851.7

-

You might also like

- Full Download Think Social Psychology 2012 Edition 1st Edition Duff Test BankDocument35 pagesFull Download Think Social Psychology 2012 Edition 1st Edition Duff Test Bankremonaplain7421427100% (25)

- Perry Robertson FormulaeDocument5 pagesPerry Robertson FormulaeMehdi KashaniNo ratings yet

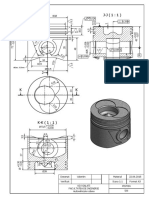

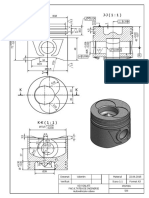

- PistonDocument1 pagePistonBoghian Gabriel MarcelNo ratings yet

- Piston PDFDocument1 pagePiston PDFBoghian Gabriel MarcelNo ratings yet

- PistonDocument1 pagePistonBoghian Gabriel Marcel100% (1)

- Desen Arbore de Intrare Reductor PDFDocument1 pageDesen Arbore de Intrare Reductor PDFDan07No ratings yet

- ZC 40243 NATO Picatinny Rail Stanag4694Document1 pageZC 40243 NATO Picatinny Rail Stanag4694Ahmet GençNo ratings yet

- C. Orwin, Stasis-and-Plague PDFDocument18 pagesC. Orwin, Stasis-and-Plague PDFDimitris PanomitrosNo ratings yet

- BaseDocument1 pageBaseAhmad عfiaNo ratings yet

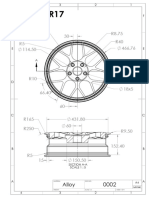

- Dimensions Are in Millimeters Unless Specified Olerances: Linear 0.1mm Angular 0.5Document1 pageDimensions Are in Millimeters Unless Specified Olerances: Linear 0.1mm Angular 0.5Gundhi AsmoroNo ratings yet

- Part1 1Document1 pagePart1 1Nguyên TúNo ratings yet

- Limit - Switch Test1 Sheet1Document1 pageLimit - Switch Test1 Sheet1Kenneth ChawNo ratings yet

- MC Spool 250X144X100X36X182Document1 pageMC Spool 250X144X100X36X182rajiv jainNo ratings yet

- Minus X V2Document4 pagesMinus X V2mmoogii048No ratings yet

- Third ImpressionDocument1 pageThird ImpressionMarco BrunoNo ratings yet

- bản vẽ trục khuỷuDocument1 pagebản vẽ trục khuỷuNgoc NguyenNo ratings yet

- Piston 80 MMDocument1 pagePiston 80 MMNegreteg MarioNo ratings yet

- Dichtkegel: Info@Thesupplier - inDocument1 pageDichtkegel: Info@Thesupplier - insfinhasNo ratings yet

- SLD 02 Plate 430Document1 pageSLD 02 Plate 430Stefan MilojevicNo ratings yet

- Bechelor of Product DesignDocument4 pagesBechelor of Product DesignLazyninjaNo ratings yet

- Proiect 1Document1 pageProiect 1Alin MoldovanNo ratings yet

- Bản vẽ chế tạo chi tiết bánh răng côn-ModelDocument1 pageBản vẽ chế tạo chi tiết bánh răng côn-ModelDuc Nguyen VanNo ratings yet

- REV Zone Description Date Name - : Sleeve Bearing #3Document1 pageREV Zone Description Date Name - : Sleeve Bearing #3Aditya PrajasNo ratings yet

- Poz.5 Izlazno Vratilo Reduktor Model SFSBDocument1 pagePoz.5 Izlazno Vratilo Reduktor Model SFSBJosip BriškiNo ratings yet

- Horn-Ch 14-16-Rev-02Document1 pageHorn-Ch 14-16-Rev-02RV OfficialNo ratings yet

- Detail Struktur Arch Culvert Kemenko (2024.03.21)Document14 pagesDetail Struktur Arch Culvert Kemenko (2024.03.21)andikaNo ratings yet

- Banvechitiet trucIIDocument1 pageBanvechitiet trucIILe HuynhNo ratings yet

- Lê Hải Nhân - 1952371 - Banvechitiet - Tuan15 - NHÂN LÊ HẢIDocument1 pageLê Hải Nhân - 1952371 - Banvechitiet - Tuan15 - NHÂN LÊ HẢITrọng NguyễnNo ratings yet

- Portofolio 1Document2 pagesPortofolio 1Lukman Arsyanto WibowoNo ratings yet

- Flare+Base 2Document1 pageFlare+Base 2MJ DuNo ratings yet

- Steel Panel StiffenerDocument1 pageSteel Panel Stiffenert1welv2eNo ratings yet

- JoontDocument1 pageJoontAhmad عfiaNo ratings yet

- Medidas Del Brazo PDF 1-1Document1 pageMedidas Del Brazo PDF 1-1Luis EscalanteNo ratings yet

- 1 2.2 Cam Parts PLDocument1 page1 2.2 Cam Parts PLSophie CisnerosNo ratings yet

- Casa en San Juan - OburgosDocument6 pagesCasa en San Juan - OburgosRobertoNo ratings yet

- 5 x4 Tehnicki Polirana Povrsina: Cavity - 0420Document2 pages5 x4 Tehnicki Polirana Povrsina: Cavity - 0420Stefan MilojevicNo ratings yet

- Part No.1: 4.252115.X Fixed Roll - LooperDocument1 pagePart No.1: 4.252115.X Fixed Roll - Loopersameh mamdouhNo ratings yet

- Assem1 - Sheet1Document1 pageAssem1 - Sheet1Anwar HariryNo ratings yet

- Assem 2Document1 pageAssem 2Saiful WahyudinNo ratings yet

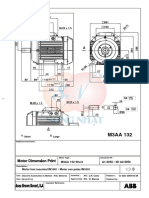

- M3AA 132 Large 3GZE 100 131-005: 2012-07-18 Discrete Automation & Motion - Fáb. MotoresDocument1 pageM3AA 132 Large 3GZE 100 131-005: 2012-07-18 Discrete Automation & Motion - Fáb. MotoresJeanNo ratings yet

- Dik3205-6rrgo 945LC3Document1 pageDik3205-6rrgo 945LC3Madhuri RasalNo ratings yet

- Drawing4 ModelDocument1 pageDrawing4 ModelTasneim SamerrNo ratings yet

- Sec A Sec B: Second Floor PlanDocument1 pageSec A Sec B: Second Floor PlanMohammed Al-HelayelNo ratings yet

- RedactedDocument1 pageRedactedJose PerezNo ratings yet

- Proiect TF A2Document1 pageProiect TF A2Andrieș DamianNo ratings yet

- 302 4 - 013288 - Z Parallel Pinion Gear DRAFTDocument1 page302 4 - 013288 - Z Parallel Pinion Gear DRAFTsamyNo ratings yet

- 72T 2.5M 22ha 30FW 20paDocument1 page72T 2.5M 22ha 30FW 20paaliNo ratings yet

- Skala: 1:1 Satuan: MM Politeknik Negeri Samarinda Solidworks KeteranganDocument1 pageSkala: 1:1 Satuan: MM Politeknik Negeri Samarinda Solidworks KeteranganSerdadu TuaNo ratings yet

- MTP LKSN 2022 FixDocument7 pagesMTP LKSN 2022 FixSuhendri SuhendriNo ratings yet

- Polia Motor Hobby 3PJ Desenho v1Document1 pagePolia Motor Hobby 3PJ Desenho v1Wagner de Oliveira PrestesNo ratings yet

- Ansox Industry: XXX S.S. Jadhav A4 013 8250 00 XDocument1 pageAnsox Industry: XXX S.S. Jadhav A4 013 8250 00 XHimanshu MishraNo ratings yet

- Pg240128a DisplayDocument1 pagePg240128a Displaybancadasol03No ratings yet

- Mobile Dispaly Board Tech DrawingsDocument4 pagesMobile Dispaly Board Tech DrawingsLazyninjaNo ratings yet

- Homogenizer ShaftDocument1 pageHomogenizer ShaftNirbhayNo ratings yet

- A1.5050 Dim - Print.M3AA132E Short IM-B3Document1 pageA1.5050 Dim - Print.M3AA132E Short IM-B3tamphamdinh02No ratings yet

- Rotomag Motors & Controls Pvt. Ltd. Rotomag Motors & Controls Pvt. LTDDocument1 pageRotomag Motors & Controls Pvt. Ltd. Rotomag Motors & Controls Pvt. LTDDwarakesh BVNo ratings yet

- Sigma Vyrobni Program enDocument12 pagesSigma Vyrobni Program enEntropay UserNo ratings yet

- If in Doubt Ask... Do Not Scale The Drawing All Dimensions Are in MM Unless Otherwise Stated Remove All Burrs and Sharp EdgesDocument2 pagesIf in Doubt Ask... Do Not Scale The Drawing All Dimensions Are in MM Unless Otherwise Stated Remove All Burrs and Sharp EdgescparamesNo ratings yet

- Pratical Task 1 1-10Document1 pagePratical Task 1 1-10ishuhaiq7No ratings yet

- Piston of A Petrol Engine: Aluminium Alloy HCS ChlorineDocument1 pagePiston of A Petrol Engine: Aluminium Alloy HCS ChlorineMiki BaneNo ratings yet

- The CAD Album of 100 Parts - 003Document1 pageThe CAD Album of 100 Parts - 003Quang Bach ThomasNo ratings yet

- Plano de CarcasaDocument1 pagePlano de CarcasaRonald Bryan Caqui DurandNo ratings yet

- 4-591.6-63 Frame-Rotor Shaft Receiving MaterialDocument1 page4-591.6-63 Frame-Rotor Shaft Receiving MaterialDwarakesh BVNo ratings yet

- SMP-7686.2 External Pinion For RLGDocument1 pageSMP-7686.2 External Pinion For RLGDwarakesh BVNo ratings yet

- SMP-7622 Rev02 Intermediate GearDocument1 pageSMP-7622 Rev02 Intermediate GearDwarakesh BVNo ratings yet

- SMP-7623 - Rev04 - Output Gear For RLGDocument1 pageSMP-7623 - Rev04 - Output Gear For RLGDwarakesh BVNo ratings yet

- Rotomag Motors & Controls Pvt. Ltd. Rotomag Motors & Controls Pvt. LTDDocument1 pageRotomag Motors & Controls Pvt. Ltd. Rotomag Motors & Controls Pvt. LTDDwarakesh BVNo ratings yet

- Insert A Table of Contents in WordDocument4 pagesInsert A Table of Contents in WordHarvinder SinghNo ratings yet

- 400 3.0 DecouplerDocument12 pages400 3.0 DecouplerRoger AklNo ratings yet

- Ph.D. Qualifying Examination Department of Physics and Astronomy Wayne State UniversityDocument8 pagesPh.D. Qualifying Examination Department of Physics and Astronomy Wayne State UniversityvokalNo ratings yet

- Jason L. Dela Luna: Five9 Virtual Contact CenterDocument7 pagesJason L. Dela Luna: Five9 Virtual Contact CenterdendenbotNo ratings yet

- Development and Validation of A Low Dose Simulation Algorithm For Computed TomographyDocument9 pagesDevelopment and Validation of A Low Dose Simulation Algorithm For Computed TomographyBrankica MitrovicNo ratings yet

- Quantenoptik Vorlesung5 PDFDocument4 pagesQuantenoptik Vorlesung5 PDFErinSuttonNo ratings yet

- Shimamoto Retires, Starts A New Chapter: Tongva Times TimesDocument15 pagesShimamoto Retires, Starts A New Chapter: Tongva Times TimesTongva TimesNo ratings yet

- Lactase Blood GlucoseDocument4 pagesLactase Blood GlucoseMamapoko79No ratings yet

- Cit 726 Computers in Society-2016Document1 pageCit 726 Computers in Society-2016opabalekeNo ratings yet

- Powerpoint Slides Ch05Document62 pagesPowerpoint Slides Ch05Deepak KumarNo ratings yet

- CA Release Automation - 6.5 - ENU - Secure Communications - 20171025Document16 pagesCA Release Automation - 6.5 - ENU - Secure Communications - 20171025Venkateswara Reddy VNo ratings yet

- Asking For Help ActivityDocument5 pagesAsking For Help ActivityMatt LeeNo ratings yet

- Deb Genealogy 10-10-17Document245 pagesDeb Genealogy 10-10-17superm0mof6No ratings yet

- Verilog HDL Synthesis A Practical Primer BhaskerDocument230 pagesVerilog HDL Synthesis A Practical Primer Bhaskermoney_kandan2004100% (4)

- Introduction To Bioinformatics: Course 341 Department of Computing Imperial College, London Moustafa GhanemDocument42 pagesIntroduction To Bioinformatics: Course 341 Department of Computing Imperial College, London Moustafa GhanemCSiti HanifahNo ratings yet

- 2018 19MDModelAssessmentGuidelinesDocument44 pages2018 19MDModelAssessmentGuidelinesEd Praetorian100% (1)

- 3 AVR InterruptsDocument44 pages3 AVR InterruptsZainAsimNo ratings yet

- Vienna AgreementDocument25 pagesVienna Agreementashishpal2k2No ratings yet

- Solution Manual For Art of Public Speaking 12th Edition Lucas 0073523917 9780073523910Document22 pagesSolution Manual For Art of Public Speaking 12th Edition Lucas 0073523917 9780073523910willieNo ratings yet

- Course Outline Phy 193Document9 pagesCourse Outline Phy 193Akemi KeiNo ratings yet

- Group Assignment s1, 2023 Af201Document4 pagesGroup Assignment s1, 2023 Af201miliana vuliNo ratings yet

- Black - Pearl JamDocument1 pageBlack - Pearl JamAnna Carolina Pereira AnninhaNo ratings yet

- Binary SubtractionDocument7 pagesBinary SubtractionBasavraj HarkudNo ratings yet

- A Survey Study of Voting Behavior and Political Participation in ZhejiangDocument26 pagesA Survey Study of Voting Behavior and Political Participation in ZhejianghktmtNo ratings yet

- Assignment 1Document6 pagesAssignment 1FarinFarNo ratings yet

- 2 1 Notes One Step EquationsDocument4 pages2 1 Notes One Step Equationsapi-295637237No ratings yet

- 9xL74SctSQC9qRmfy7Og - CCVSA Online Lab GuideDocument48 pages9xL74SctSQC9qRmfy7Og - CCVSA Online Lab GuideCarlos Eduardo de Souza de SilvaNo ratings yet