Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

53 viewsCW Pumps

CW Pumps

Uploaded by

jose_sebastian_2cw PUMPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WB III VIDocument1 pageWB III VIjose_sebastian_2No ratings yet

- CPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)Document22 pagesCPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)jose_sebastian_2No ratings yet

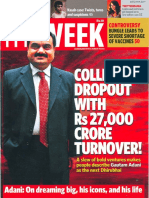

- Adani at WeekDocument8 pagesAdani at Weekjose_sebastian_2No ratings yet

- M Tech Part TimeDocument22 pagesM Tech Part Timejose_sebastian_2No ratings yet

- Changlang - Nic.in Stilwell - HTMLDocument5 pagesChanglang - Nic.in Stilwell - HTMLjose_sebastian_2No ratings yet

- The 1965 Indo Pakistan War PreambleDocument64 pagesThe 1965 Indo Pakistan War Preamblejose_sebastian_2No ratings yet

- Dissimilar Materials WeldingDocument2 pagesDissimilar Materials Weldingjose_sebastian_2No ratings yet

- Bhel Pipe Thickness CalculationDocument2 pagesBhel Pipe Thickness Calculationjose_sebastian_2No ratings yet

- Pump ErectionDocument2 pagesPump Erectionjose_sebastian_2No ratings yet

- Chineese Materials DinDocument1 pageChineese Materials Dinjose_sebastian_2No ratings yet

- D N H MundraDocument42 pagesD N H Mundrajose_sebastian_2No ratings yet

- GRP Laying and JoiningDocument4 pagesGRP Laying and Joiningjose_sebastian_2No ratings yet

- Excel ShortcutsDocument9 pagesExcel Shortcutsjose_sebastian_2No ratings yet

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDocument14 pagesCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2No ratings yet

- Arogyamasika May2020 N PDFDocument116 pagesArogyamasika May2020 N PDFjose_sebastian_2No ratings yet

- List of Upcoming Thermal Plants in IndiaDocument11 pagesList of Upcoming Thermal Plants in Indiajose_sebastian_2No ratings yet

- Luni River - Wikipedia, The Free EncyclopediaDocument2 pagesLuni River - Wikipedia, The Free Encyclopediajose_sebastian_2No ratings yet

- Security Clearance Form PDFDocument6 pagesSecurity Clearance Form PDFjose_sebastian_2No ratings yet

- Church BulletinDocument4 pagesChurch Bulletinjose_sebastian_2No ratings yet

- Childcare Application FormDocument8 pagesChildcare Application Formjose_sebastian_2No ratings yet

- Application For Water Service: WWW - Cambridge.caDocument1 pageApplication For Water Service: WWW - Cambridge.cajose_sebastian_2No ratings yet

- Minority Certificate PDFDocument1 pageMinority Certificate PDFjose_sebastian_2No ratings yet

- EPIC Brochure Fall 2017 Ontario Electrical-MechanicalDocument16 pagesEPIC Brochure Fall 2017 Ontario Electrical-Mechanicaljose_sebastian_2No ratings yet

- 4 Squares: This Was Done in World Record Time of 7 SecDocument1 page4 Squares: This Was Done in World Record Time of 7 Secjose_sebastian_2No ratings yet

- A Brief Check List of Labour LawsDocument54 pagesA Brief Check List of Labour Lawsjose_sebastian_2100% (1)

- BooksDocument1 pageBooksManu ChakkingalNo ratings yet

CW Pumps

CW Pumps

Uploaded by

jose_sebastian_20 ratings0% found this document useful (0 votes)

53 views15 pagescw PUMPS

Original Title

cw pumps

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcw PUMPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

53 views15 pagesCW Pumps

CW Pumps

Uploaded by

jose_sebastian_2cw PUMPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 15

cw? Shee cl Ww

oF f

HL #

FASHION

* 1800HLC-30 22258 (6 FA AHAB

INSTALL&OPERATE SPECIFICATION

LKR SFR J

Shanghai Pump Manufacture Co.,Ltd

1. EE

General.

2, RRM BIER

Designation.

3. SiMOBERE.

~ FB

Start up, Running and Shut down...

Ty FRE RAE TBR ER TK

Problem, Cause / Remedy.

8. RARBG...

Scope of Supply...

1800HLC-30 Ravi FE HEHE HAR...

1800HLC-30 Pump Performance Chart.

10, 1800HLC-308) 870 INTER...

1800HLC-30 Pump Arrangement Drawing...

11, 1800HLC-30 Revita 3B

1800HLC-30 Pump Sectional Drawing.

12, 1800HLC-30 Aya ie 382 MFR...

1800HLC-30 Pump Hoisting Drawing...

9

*

, LR

1800HLC-30 BIBI FE Ay West RH

TAURI, AF AWD kt

RIOT AH ER, MES I

ABIL SOC, HARA A ARORA. HE

Hea. LA RE, AP

9. HG. MRR. LI. RAE

AE RAKGS HE, HAT AOL

RURK RRM

LRRME ANTE

21 ROSH

RMS: 1800HLC-30

1800 2% mm)

HLGLABRR)

OCT RH)

30(4H#E m)

AER: GOWN, AW

SHUR: $2 SXL, Ait

MR: REL, RK

WRT: ASE

BPSEIIBR: 140mm

BAD 8 ER P(A] Sem.

2.2 Hei.

1 AOA 2 GRHRETN, BaRWIE

FIRRA (WuEAHED

Q712.12m3/s,H=30.8m, 1

n=370rpm

1 AME 1 GRETN, HARK TI

Ca

Q14.455m3/5,H-23.7m, 1

=370rpm

=

882%,

> 62%,

1.General

1800HLC-30 pump is single floor vertical

mixed pump with pull-out design. The pump is

used to transfer clean water or other liquide

with similar physical and chemical properti

of water .The highest temperature of the

transfered liquid can be 50°C. Pump of this

type has higher efficiency, better cavitations

and need small place, it is widely: used in

industry, dock water level control, civil supply

and drainage, chemical papermaking,

agriculture irrigation, circulating water of

power plant and other water conservancy

projects and is better used in the case which

water level always changed and performance

of head is higher.

2,.Designation

2.1 1800 HL C-30

head.

pull-out design

vertical mixed

discharge diameter

Shaft Seal: GFO packing, lubrication by the

medium handed

Guide Bearing: Ceramic SXL, self lubrication

‘Thrust Bearing: Installed in the motor, need

sea water cooling

Couplings: The shafts are connected with dise

couplings

Impeller Clearance: 1.40mm

‘The adjustable nut of pump coupling’s axial

adjust clearance is 4.5mm

2.2 Performance of the pump

‘When two pumps of one group parallel éonnee

-tion operating, every pump's design point:

QH12.12m36,H-30.8m, 1 > 882% ,

0-870:pm_

When one pump of one group operating, every

pump’s design po

Q=14.455m3/s,H=23.7m, 1 > 86.2 % ,

n=370rpm_

2.3 ABMS RA

Lan: BEL CULAR RA

PMB ELIER

‘BIE: OPAL BU AR

WS. YLKS4800-16TH

BURAK. 6600V

WIAA: a-370mpm) 4800KW

Sem: ALA FARR

BAREARAPRMARA: ER 6OT

BARK 80T

3. SAUL

ARATKAR MM SRR, RA

Hib. BLE, FERRE RA bk

HE, RECA MME TEAS.

ARGH (HE) MMAR HF

CS) BSP.

PABBA. PHT.

Be HK I, RR. LAL

Re AFD Eh Sabie. OPE AVE

HE. AA. WRB. RAT, RH

ERP. PME Ore. BAN,

Aaah. PRG. FA. EUR

28. HE. HORA, ePSoME, va

FH.

RH eR St SURE HR SS Set os

URS EAA EE, SARA

aa.

AT OPS SO, RAT bas

SN, GEAR ONE. AR ATK AA HE

MARTEL RATE FAD A ALFERD T

Catt»

ASA SLOT ERR SOHC HE, FE

2.3 Motor Type Deseription

Motor: (details see the documents from shen

yang Electric Machine CO.LTD)

Manufactured by Shen Yang Electric Machine

CO.LTD

‘Type: YLKS4800-16TH

Rated Voltage: 6600V

Rated Power: (n=370rpm) 4800K W_

Direction of rotation: Clockwise as viewed

from motor side

‘The motor bears axial thrust of the pump (the

direction is down): normal 60T and

highest(short time) 80T.

3.Construction

‘This pump is single vertical mixed flow pump

of bellmouth inflow, straight pipe outflow, In

‘order to attain a good inflow performance, an

inlet cone is arranged.

‘The pump's component are the external casing

(fixed) parts, internal casing, and rotor

(pull-out) pats. 7

The main parts of the external casing are

bbellmouth, column pipe (lower), column pipe

(upper) , discharge elbow, base stool, base

plate, motor base stool and so on. The internal

casing contain with diffuser, impeller house,

internal cone, suspension pipe, bearing

support, pump cover (lower), pump cover

(upper) and so on. The main parts of the rotor

‘are impeller, pump shaft, intermediate shaft,

‘middle coupling, pump coupling, motor

coupling, shaft sleeve, shaft nut, impeller mut

and adjustable nut, ete.

‘The radial of pump shaft is supported by two

‘ceramic SXL bearings, which ate respectively

installed in the bearing support and diffuser

bearing; the bearings are self-lubricating.

In order to facilitate the installation and main

tenance, the pump use pull-out construction,

‘The pull-out parts can be pulled out from

‘casing parts without dismantle column pipe

and elbow pipeline and meanwhile, the suction

chamber is dry.

‘The end of the sha’:

ithe impellsr ase

‘Sil 485) WN ALEUf EHRITEIRAA BIER. FR connected by the impeller nut, the pump shaft,

WR ERA MEME A, GUILILAFARAT WGA intermediate shaft and motor shaft are

BER SrHeSONRIRR. connected by disc couplings. The clearance

between impeller and impeller house can be

adjusted by the nut, which is installed in the

pump coupling.

ABAMTABIRH, HUB, 4 This pump use vertical connected motor, when

BRIT) ch ALR. MULGLYEMYEL, SEE the pump is running, the motor bears all axial

FRO A ree. forces, the rotating direction of the motor is

clockwise as viewed from motor side.

4. RHER 4. Main parts weight

Bik wt | mm oe) | [Rane Quaniiy | Weight (kp

ry 1 1400. Ipeter house 7 1400

ahi H 1400 Diftser Hi 1400

FRE 1 3940 Column pipe(lower) 1 3940

my 1 290 ‘Column pipetunper) | __t 3250

fro T 4350 Discharge eltow i 850

4K 2 350x2 | | Guide bearing 2 | 350x3

rer 1 70 Tne coue 1 70

RS 1 500 Bearing support 1 500

RR vi 754 ‘Sting components | _taets_| 754

Re 1 2526 Pump shaft 1 2526

Heath 1 1640 Top shat 1 1640

aE A 4 16X4 Shaft sleeve A 4 16x4

Era) 1 20 Shaf sleeve B 1 20

ELE I 610 Motor coupling 1 610

oe 1 570 Diss coupling) i 70

PRA. T 560 Dis coupting’2) H 360

Raa 1 510 Pump coupiing 1 510

St a 2 20x2 ‘Shaft nut 2 20x2

Ca 1 268 Exports of anti-flange 1 268

wae 1 1295 Suspension pipe 1 195

RRL 1 4215 Pump cover(upper) 1 4215

Rae FR 1 2000 Pump cover(lower) i 2000

Re i 00 Bellmouth 1 1100.

ee i 900 Inlet cone 1 0

aman 1 100 Adjust out 1 106

np seie 1 30 Trapelermit 7 30

ane 1 i330 Impeller T 1330

le H 2830 Base soa 7 2400

ti 1 5100 Base plate 1 5100 |

ny 1 3430 Motor base so! 1 5450

ER) LRPRRARU ER, HRA

SOP, Ret AU RAE TE SEE

EaA—i0M, WMew!

S. Be

SL SRT AE

S11 PAAR BUNA, FE

KMAD HH, BARA.

5.12 ARSHRA OER. we,

FR.

5.13 LASSER S

5.1.4 ERM. AE AE: REE

PEGIAP IE RAE SCE, MRE BE

SCHE<0.04mem/m, PTFE ABE F 8 ERR HE

TU, MAR DMAKRA RZ RE

HMR, TRACE MER, SR

SNE E)

S15 eh Titezk ib ie A A

JERE ARE TRAE, RRR

POLAR BMRA, Bbw AER FAL

a

(a) RCA RSME

(b) ARPES SI ERIE AAR

Co) Je RAE —iiek theta, TE

AER

) REAM ETS A,

NMEA AABEL O.3rs htt.

5.2 SER CSILBAEE INERT, A

RED

S21 HRIERRMMT, BK OE

SMT RR.

5.2.2 ORE RET A ARITA

BL ARAMA + 1mm,

PS

5.2.3 MERE. WE, SORES

R, RAAEM. Ire Ae RAP OL

EAMASEM PAR, WAR

HAF £5mm,

Caution! The weights above are design data, which

will possibly increase during producing and casting

progress, Please pay attention to!

5. Installation

5.1 Preparations before installation

5.1.1 Check the pump and the motor to ensure that

they are free of damage. Align the pump shaft and

top shaft if bending occurred.

5.1.2 Eliminate the rust greasy dirt of the parts

surface, and apply anticorrosive paint.

5.1.3 All the necessary tools and cranes should be

available.

5.1.4 Check the base stool, foundation and inlet cone:

‘Check the levelness and foundation strength of the

base stool, the leveiness tolerance of the pump base

stool is less than 0.04mm/m, which can be adjusted

by the adjust bolt under the base stool; the inlet cone

have to in place and finish grouting before the

pump’s installation and make it meets the

requirement of arrangement drawing, (See the

arrangement drawing)

5.1.5 The condition of the pump inflow depend on

the construction of the inlet pool and the arrangement

of the pumps, and it will greatly affect the

performance of the pump. Therefore, please notice

the following point:

(a) the impeller should be submerged to a sufficient

depth

(b) Smooth flow without eddy

(©) No interference among pumps in the same pool

(d) Setting up rubbish screen at the gate of inlet pool,

through which the ideal inlet flow rate should be

below 0.3mis,

5.2 The step of installation (see general drawing,

arrangement drawing and lifting drawing)

5.2.1 Before start installation, the discharge elbow

and column pipe have to preinstall.

5.2.2 Check that whether the foundation level is

equal to the design level, of which the tolerance

should be within + 1mm.

5.2.3 Hoisting into column pipes , discharge

elbow and connecting them tightly to make sure that

there is no leakage among them. The central line of

the discharge elbow should be the seme as tie conta

line of the discharge pipe. The tolerance should be no

more than 5mm.

524 SEE ALTE AR AR) PBR

2 EER. HERA RAI, RE

RAS. RRR TREKS MN ERM,

BRR DATA EAT.

5.2.5 RBM ABMS RRM)

BRR BAGS, RL. PF ARTLOT A

DEREK F 004mm.

5.2.6 SHURA HICH A AST

PAs CESS BR MD BRR LAR TAT IE BT

FIN RER MM CMR, WR

ME MACP AD, PRRRLARE. W

Jatt.

5.2.7 ME AULRERT ALL, CASEI aE

HE, BBL AD LA Ee HEE

eh, PARAL, PR ALS

WE, FERRY bee. Ba

EH A AE LAD BB A HF] OH FD

Ry 4.5402.

52.8 ZHU, AUN TIMUR,

SHY R SPRUE LORE.

5.2.9 TAME Ste eZ AE

ME BHER 14£02mm, HAAG,

RSET OMA HE EM TE, Sait,

SOR AL.

5.2.10 BSA MER ERT, Hoe

MERE ER SAAR A se AH ORR

pets. RAH SE HAI ADB FE AL 0.02mm,

REMAN EAEMBET PO, K

RGAE FRIEZE 0.05mm LF.

5.2.4 Connect the fixed external castings (including

discharge pipe) after adjusting. Discharge pipe

should be supported by other bracket and the pump

should be free of pump line stresses. The bracket

will bear not only the weight of discharge pipes but

also the horizontal thrust when the pump runs.

5.2.5 Install the pull-out part (not including impeller

house and pump cover ) and ceramic SXL bearings,

the concentricity of the upper bearing and the lower

bearing should be no more than 0.04mm,

5.2.6 Hoisting the pull-out parts into the extemal

pump casting according to the hoisting drawing,

use concentricity plug at the stuffing box to fix the

pump shaft and correct the central line, at the same

time correct the pump shaft perpendicularity (move

Pump cover, measure the leveling of pump

coupling’s end surface), tighten the fastenings on

the pump cover, then beat the locating pins on.

'$.2.7 Install the motor base stool and motor, as the

datum of pump coupling, ensure the concentricity of

‘motor coupling and pump coupling by moving the

motor and motor base stool, insert reamer bolts,

tighten the fastenings and beat the locating pins on

the two flanges of motor base stool. Make sure that

the axial direction tolerance between motor

coupling and pump coupling is 4.5-:0.2mm by

adjusting the adjusting nut,

5.2.8 Take out the plug use in concentricity, install

stuffing and stuffing cover and tighten fastenings in

the motor and pump coupling.

5.29 The measuring radial tolerance between

ler and impeller house have to meet the design

requirement of 1.4:£0.2mm, and have to be uniform

along the circumferential direction, considering the

rotating droops that beeause of gravity, the tolerance

should be bigger when installing.

5.2.10 Connecting the pump coupling and motor

coupling, then tum the rotating, measure the

clearance and central line of the coupling’s

circumferential direction by using standard plug

gauge, plig ruler and steel ruler. Make sure that

the tolerance is less than 0.02mm, adjust the

rotating central fine’s tolerance less than

0.0Smmaccording to the measurement of couplin:

radial tolerance.

_& ab BS AL

6.1 EAST HARE EAH KE ABER

6.2 RKB, HAAR ES) We

ARB.

63 ERE, MRRAG EM AAAI,

SEDO PLR BE. SURE AAAS BEA BUI ERA

ALOK, BESEENAP BL.

6.4 KEBLE, OCR FACE, Ub

RT URE BS

SEL, AUB AEE RE Bt Dak

6.Start up, Running and Shut down

6.1 Before the pump start up, check the water

level of the pool.(have to meet the requirement).

6.2 After trial operation, each connection part

should be checked so that there is no looseness, no

leakage.

6.3 During the operation, if the pump produced

abnormal vibration or noise, it should be stopped

for inspection immediately. Ifthe water level falls

and is lower than the lowest water level, the pump

must be stopped.

64 When the pump is stopped in freezing

‘conditions, the impeller should not be under water

in case freezing ice damage the pump parts.

6.5 During the running, adjust the tightness of the

packing gland at regularly time to ensure that

there is no spraying but dropping of water.

7 AE BCE BSI BRR DT RT 7. Problems, Cause/Remedy

ad mw TARA Fault Cause of fault Remedy

eres | mae 7 Tinon & ag | T Reha

wane ree — | genes

creme | 2 rrmmantient | 2. mucenireem | | ove | zune teoed he | 2Rumiag within te

| wea wet teatot | alone peromice | pms nage

‘occa | mgs

ao abr. wotaaesrte | 3. me vivmtin | imei, atin | 3c pe

Eset tna longed | snes

ith esis

4. ob saobearmem | 4. wip srssHeR ‘cna cen | 4A te eam

* oot inger and imple: | between inet ad

sewing impel ing

5 FRAT shat Somer war Joel | 5p te pnp

teobw

Teme fame e) Oo Teo each te som | 1B ews

ame raewsioee Inst | see ‘bates

coosiy sonnet

2 sem 2 moots optic daaged | 2 Ree inpte

2. domes — | 3, ioxuirsrae dite dictape vabe is | 3.0p he dchape

L epee —_| vive coh

= po memara [i wmananze | [i TRowing dreton | VAGhst he roing

ppomAsink No water | wrong. irecion

a. mnmeae | 2 tet panpat | 27h inpatr is ited | 2. Maintenance te

cx | tte mes ater

1 na 1 aR Ww ‘Prckng wearing | Change te pring

snsiies | ac inizaccem | 2, mace acting | 2ockng itt ong | 2. tel ig agin

wexa | sc onnmcaummam | 3. astrmnnin | | anusuily | 21me pecking gland i | 3 Proper erangensnt

a teak roo | so ttt the ites ut

4 Meer 4 ete tat | astanstevewenring | changes steve

8. RN REE 8. Scope of supply

8.1 (ERAF 1800HLC-30 Wh 8.1. CW pump 1800HLC-30 1Ssets

8.2 "BML YLKS4800-16TH Ise 8.2 Motor YLKS4800-16" \Ssets

83 RS EALZ MRS 183 83 °The coupling between pump and motor

15 sets

84 FAME 6 8.4 Anti-flange of export 15 sets

85 VCP RG 15% 85 Pump cathodic protection system

15 sets

8.6 FEA. ata 15% &6Exhaust Valve, Buffer Valve 1Ssets

8.7 BEL ett 8,7 Spare parts

SUL RARER Packing according to order

ona maROs Oring according to order

SHH Beare BR Guide bearing according to order

ae RAR Sleeve according to order

see, ME seerimgtat Bolt, Nut according to onder

88 SATA 8.8 Necessary tools

AORN sear Shaft nut spanner according to order

SYR BARI Plug used in concentricity

according to order

CRRA arose Impeller nut spanner according to order

BARAT eA ‘Motor nut spanner according to order

9, 1800HLC-30 AUB Ht A HERE MHA

1800HLC-30 Pump Performance Chart

SHANGHAI PUMP MANUFACTURE CO., LT

tw AR We AR A a

»

H' PUMP TYPE PERFORMANCE CURVE

IM ge _ 1800HLC-30 he es

8 INR D2A/D2

1 cman

B

@

+

40 en

\

= Pe

25 = KWo

ww 5550

|

} 4880

t 4210

{| ~

t 3540

oF -

80

70

Efficiency

NPSHI

al oa

40 3

3 BS

20 t 20

|

A 5

0 204 6 8 W 12 - 6 18 28 22 24 26 2B 30

a myst

RE Capacity ims} 12412. 14.455 ag Project No.

48 Head In| 308 237 ip Customer

HF Efficiency 1% 88.2 862 ____ eg Revision No.

ANSE NPSH (ml 1.52 12.2 ‘8f Dept

WHE Hydraulic No ®oRE Diameter Imm| 1400 Ke Name ee

fit Speed Irpmi 370 __at# Temperature ("Ci 8 Date 20080718

11, 1800HLC-30 MRR BEA

e

1800HLC-30 Pump Sectional Drawing

eae ato

“polar bose STN 7 — Tree conieg

alti ™ Fant ARE

a erent AE ae NN |_| ing coi

Te oonp cower Ss aay

ak Ste aul He pst al

Wseglotwe Y : Sa

i pace Slt bay

Tounda tion ning Ff > r ie

hy Pe Upper column pipe

or | ate

i fp sak

Tove ap core? rey SS

alan aS

. 3] aaa

peste Toit end at

od

ttt |g

wees le Ri

Inscribed cone pipe Companion Flange

it {

; Fong sat

Hee

oe [Toner column pipe

e wl

wo | ot

‘ |

ipa

[Taper rat

J ia

g Bat roth

kt

Taet cone

1100 j

10. 1800HLC-30 HB vt SEA

eeceaca Pump Arrangement Drawing

1 Teeeeeeer T LC t 5 I g I 7 I z aT

GootH-0&-371H008! motor 4800KW.16P.6.6KV AA

ou

st

seo sate

amomer

Petpet nacre A

cantons Oo

2 goes cre th be ee sds

ow

mu

S.aunraengesataeient et

inuacectiers ok eepoaie fr the ssi ord

Gn oF the bss ee of the pap satan Me.

4 senantaatAK307,

‘nut trepecy ofthe eis mst be

Grser a rats rere 3,

Eee

EEE sat stn

Heme

‘Secieereepacte sm

| on insane L

; SLE oreo a

insect

aaa ete tonto

I SaPEN Tens

i

Y bu

sa

' St

ip wot st

taal me wan 100K

Lititowe ves wos 59850K9

t A a9 Foun ton toot o0ndaKy

D-D te

Ones eee

no aa 1 {0

sss ay

5 es

TARAS TED G

| ___SEPCO MELECTRIC POWER

LRTI

CONSULTANT NORTHWEST ELECTRIC POWER DESIGN INSTITUTE LI

‘APLIPC/NG/Z1N8-1T0

GRAPLRRSXG6IMWRERRHIE 5a al 7

LHAR BAR AA

CONTRACTOR SHANGHAI PUMP MANUFACTURE CO LTD

CARESS

India APL Staion 5 IMO species wt projet PROC

1BITHLC 3h eRBRE

‘8008-31 PUMP GENERAL ARRANGEMENT

ML RBM Tasha

g L T

I

1 2 3 4 5 6 7 8

lloza- 1a¥-0€-371H008) 14050Kg

5840Kg

BEM

ene Installation procedure

User Self provided

— ‘ap SRNL

Demolition procedure

200K (88 Je 8 HL)

5840Kg

The largest Lifting heavy 20000Kg

|

a lft wills | elena [ ebeo [sein [ofan

Fig. 3 ti Hebe a

PE, Z OWNER sation ADANI POWER LIMTED

SERA | furor, LANMEYER INTERNATIONAL INDIA PVT LTD

‘OWNER'S CONSULTANT TERNATIONAL

il @ aan

CONTRACTOR SEPCO B ELECTRIC POWER CONSTRUCTION CORPORATION

a :

DP snicunea|_rxwotherton ere tusin eit [ae aclu

‘TBOOHLC- 30868

Neu von HPve Fe EACS

mis) OR Loeoidtacn [|__woucmnouo | A

1 Z 3 I T o

1 3 4 5 6 7 8

2020" 14¥-08-THO0AL

222

510K9 10Kg

! [ead

ea 22300Kg( Hiab

ean 22300Kg{veight of pullout part)

Ah a

ane

12500K9

BENE

j Installation procedure

PREM

Demolition procedure

wi ie | hy | ores oda

cits [iad [athe

ce GS Hee AAR AA

OWNER ADANI POWER LIMITED

eb Ayes, LAHMEYER INTERNATIONAL INDIA PVT LTD

a

OWNER’S CONSULTANT alin cat

Aa @ Ue AR ATER

CONTRACTOR, ‘SEPCO @ ELECTRIC POWER CONSTRUCTION CORPORATION

FF vine] EEE, ols TE al

‘we UMP ‘BOON

ML TE] Pelee [_—worancoar TET

i Hs 2 3 b 7 i

1

E020 1d¥-0€- HOG

47600K9

4586

a

[IL

LJ

STA. AOA 20

a

we as ese ae

ao neeht SOK Installation procedure

PREF

Demolition procedure

F Rly ls BT a Tih Tf Ta T sfn Ts [lf

Fig.7 Fig.8 i Hekenihad

OWNER avagronour ADAN POWER LIMITED

A SE

eee ediaeee weet LAHMEYER INTERNATIONAL INDIA PVT LTD

Ab @ Lea A= A

CONTRACTOR SEPCO a ELECTRIC POWER CONSTRUCTION CORPORA TION

‘iAP COT TS z

Dy vineis|_oowteiedieter msc onc [it gol

. ‘TOOOHLC- 3088

SHAN PRP

UAL 30 POM LIFTING OA MIGS

RUFACTURECo,LT0

LT BT [am wtlacne | wmmcananioms TRAE BY

7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WB III VIDocument1 pageWB III VIjose_sebastian_2No ratings yet

- CPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)Document22 pagesCPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)jose_sebastian_2No ratings yet

- Adani at WeekDocument8 pagesAdani at Weekjose_sebastian_2No ratings yet

- M Tech Part TimeDocument22 pagesM Tech Part Timejose_sebastian_2No ratings yet

- Changlang - Nic.in Stilwell - HTMLDocument5 pagesChanglang - Nic.in Stilwell - HTMLjose_sebastian_2No ratings yet

- The 1965 Indo Pakistan War PreambleDocument64 pagesThe 1965 Indo Pakistan War Preamblejose_sebastian_2No ratings yet

- Dissimilar Materials WeldingDocument2 pagesDissimilar Materials Weldingjose_sebastian_2No ratings yet

- Bhel Pipe Thickness CalculationDocument2 pagesBhel Pipe Thickness Calculationjose_sebastian_2No ratings yet

- Pump ErectionDocument2 pagesPump Erectionjose_sebastian_2No ratings yet

- Chineese Materials DinDocument1 pageChineese Materials Dinjose_sebastian_2No ratings yet

- D N H MundraDocument42 pagesD N H Mundrajose_sebastian_2No ratings yet

- GRP Laying and JoiningDocument4 pagesGRP Laying and Joiningjose_sebastian_2No ratings yet

- Excel ShortcutsDocument9 pagesExcel Shortcutsjose_sebastian_2No ratings yet

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDocument14 pagesCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2No ratings yet

- Arogyamasika May2020 N PDFDocument116 pagesArogyamasika May2020 N PDFjose_sebastian_2No ratings yet

- List of Upcoming Thermal Plants in IndiaDocument11 pagesList of Upcoming Thermal Plants in Indiajose_sebastian_2No ratings yet

- Luni River - Wikipedia, The Free EncyclopediaDocument2 pagesLuni River - Wikipedia, The Free Encyclopediajose_sebastian_2No ratings yet

- Security Clearance Form PDFDocument6 pagesSecurity Clearance Form PDFjose_sebastian_2No ratings yet

- Church BulletinDocument4 pagesChurch Bulletinjose_sebastian_2No ratings yet

- Childcare Application FormDocument8 pagesChildcare Application Formjose_sebastian_2No ratings yet

- Application For Water Service: WWW - Cambridge.caDocument1 pageApplication For Water Service: WWW - Cambridge.cajose_sebastian_2No ratings yet

- Minority Certificate PDFDocument1 pageMinority Certificate PDFjose_sebastian_2No ratings yet

- EPIC Brochure Fall 2017 Ontario Electrical-MechanicalDocument16 pagesEPIC Brochure Fall 2017 Ontario Electrical-Mechanicaljose_sebastian_2No ratings yet

- 4 Squares: This Was Done in World Record Time of 7 SecDocument1 page4 Squares: This Was Done in World Record Time of 7 Secjose_sebastian_2No ratings yet

- A Brief Check List of Labour LawsDocument54 pagesA Brief Check List of Labour Lawsjose_sebastian_2100% (1)

- BooksDocument1 pageBooksManu ChakkingalNo ratings yet