Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 viewsGRP Laying and Joining

GRP Laying and Joining

Uploaded by

jose_sebastian_2Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WB III VIDocument1 pageWB III VIjose_sebastian_2No ratings yet

- CPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)Document22 pagesCPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)jose_sebastian_2No ratings yet

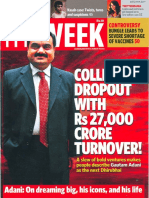

- Adani at WeekDocument8 pagesAdani at Weekjose_sebastian_2No ratings yet

- D N H MundraDocument42 pagesD N H Mundrajose_sebastian_2No ratings yet

- Changlang - Nic.in Stilwell - HTMLDocument5 pagesChanglang - Nic.in Stilwell - HTMLjose_sebastian_2No ratings yet

- The 1965 Indo Pakistan War PreambleDocument64 pagesThe 1965 Indo Pakistan War Preamblejose_sebastian_2No ratings yet

- CW PumpsDocument15 pagesCW Pumpsjose_sebastian_2No ratings yet

- Bhel Pipe Thickness CalculationDocument2 pagesBhel Pipe Thickness Calculationjose_sebastian_2No ratings yet

- Pump ErectionDocument2 pagesPump Erectionjose_sebastian_2No ratings yet

- Excel ShortcutsDocument9 pagesExcel Shortcutsjose_sebastian_2No ratings yet

- Dissimilar Materials WeldingDocument2 pagesDissimilar Materials Weldingjose_sebastian_2No ratings yet

- Chineese Materials DinDocument1 pageChineese Materials Dinjose_sebastian_2No ratings yet

- M Tech Part TimeDocument22 pagesM Tech Part Timejose_sebastian_2No ratings yet

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDocument14 pagesCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2No ratings yet

- Arogyamasika May2020 N PDFDocument116 pagesArogyamasika May2020 N PDFjose_sebastian_2No ratings yet

- List of Upcoming Thermal Plants in IndiaDocument11 pagesList of Upcoming Thermal Plants in Indiajose_sebastian_2No ratings yet

- Luni River - Wikipedia, The Free EncyclopediaDocument2 pagesLuni River - Wikipedia, The Free Encyclopediajose_sebastian_2No ratings yet

- Security Clearance Form PDFDocument6 pagesSecurity Clearance Form PDFjose_sebastian_2No ratings yet

- Church BulletinDocument4 pagesChurch Bulletinjose_sebastian_2No ratings yet

- Childcare Application FormDocument8 pagesChildcare Application Formjose_sebastian_2No ratings yet

- Application For Water Service: WWW - Cambridge.caDocument1 pageApplication For Water Service: WWW - Cambridge.cajose_sebastian_2No ratings yet

- Minority Certificate PDFDocument1 pageMinority Certificate PDFjose_sebastian_2No ratings yet

- EPIC Brochure Fall 2017 Ontario Electrical-MechanicalDocument16 pagesEPIC Brochure Fall 2017 Ontario Electrical-Mechanicaljose_sebastian_2No ratings yet

- 4 Squares: This Was Done in World Record Time of 7 SecDocument1 page4 Squares: This Was Done in World Record Time of 7 Secjose_sebastian_2No ratings yet

- A Brief Check List of Labour LawsDocument54 pagesA Brief Check List of Labour Lawsjose_sebastian_2100% (1)

- BooksDocument1 pageBooksManu ChakkingalNo ratings yet

GRP Laying and Joining

GRP Laying and Joining

Uploaded by

jose_sebastian_20 ratings0% found this document useful (0 votes)

15 views4 pagesOriginal Title

grp laying and joining

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

15 views4 pagesGRP Laying and Joining

GRP Laying and Joining

Uploaded by

jose_sebastian_2Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

6.0 Pipe bedding and foundation

1 brovide finm support for pipe, proper bedding under the pipe must be provided, During the

french excavation, a pipe bedding thickness of at Teast 1S cm must be provided. In case of very

Poor native soils (Silt, clay or mud) an additional 15 em thick foundation is to be excavated ang

provided below the bed. The selected backfill material should be placed in the foundation and

bedding layers and thoroughly compacted by the plate vibrators ot by hand tamping. Wetting of

sand bedding/foundation meteria prior to compaction will improve and facilitate the achievement

of the degree of compaction required,

Pipe laying should always take place in dry trenches. It is not acceptable to lay pipes in flooded

trenches. The contractor should provide the necessary dewatering equipment to enable installation

ta croveed in dry trench, Dewatering equipment should be removed and pumps tumed off only

afer completion of the pipe zone backfilling, and sufficient backfill has been provided to prevent

Pipes from floating if the normal ground water level is above the pipe invert

Fricr to lowering the pipe into the trench, the top 2-3 em of the compacted bedding should be

lightly raked, and small holes should be dug under each joint location so the pipé does not rest on

the joints, The bedding material should provide firm and continuous support over the entire length

of the pipe, excluding the joints areas,

ue contractor should lower the pipe into position after chesking the proper levels and alignment of

the pipeline,

6.1 Inserting the pipe in the coupling

Joints should be made inside the trench following the procedures shown in figures 18 and 19. A

Hee cae with rubber lining must be fixed on the installed pipe at the home line in order to stop

system if they are not removed before the hydrostatic test. Before insertion, the twa pipes should be

Perfectly aligned and leveled to avoid any damage to the rubber rings.

BF s212%00 Manual for underground Piping System] Kemoak

8 OW OTN soe. OWE ALON JA0K COKE ow EACH soe)

eee Se SRS [

COUR sip.

—/

Te Shen tae,

HP axa co seit SPEOT Gite 40 oF courenc

ad oe RT iS AB

Figuee 18: Pipe Jointing using a”’come along” jack

0104 sewe asraueo

rai

JOWNG PPE WiTH BLLLDOZER

Figure 29

5.5 Thrust boring and micro-tunneting installations

This method is used when the ground above or around the pipe cannot be disturbed. This isthe case

for crossings under highways, railways, airport runways, rivers etc, This method might be

economical for very deep sewer lines where the cost of opened trench excavations may become

excessive due to the ground conditions where extensive sheet pilings and dewatering might be

required,

‘Two types of pipes are suitable for this kind of application. Special jacking pipe with flush Reka

couplings are available for direct jacking. Also, standard pipes can be provided in short lengths

Suitable for jacking inside a concrete jacket. In this case, the outer conerete pipe takes the jacking

load while the inner pipe provides the corrosion resistance and the required joint tightness. For

typical configurations see the figures below. When pipes are “jacked”, an 18-20 mm thick plywood

or similar compressible material must be placed between the pipe and joint ends to avoid point

loads during the jacking operations.

Figure 12: Thrust boring pipes

a Installation Manual for underground Piping System| Xemrocé

Installation Type

Figures

installation Manual for underground Piping System] Kemrock

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WB III VIDocument1 pageWB III VIjose_sebastian_2No ratings yet

- CPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)Document22 pagesCPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)jose_sebastian_2No ratings yet

- Adani at WeekDocument8 pagesAdani at Weekjose_sebastian_2No ratings yet

- D N H MundraDocument42 pagesD N H Mundrajose_sebastian_2No ratings yet

- Changlang - Nic.in Stilwell - HTMLDocument5 pagesChanglang - Nic.in Stilwell - HTMLjose_sebastian_2No ratings yet

- The 1965 Indo Pakistan War PreambleDocument64 pagesThe 1965 Indo Pakistan War Preamblejose_sebastian_2No ratings yet

- CW PumpsDocument15 pagesCW Pumpsjose_sebastian_2No ratings yet

- Bhel Pipe Thickness CalculationDocument2 pagesBhel Pipe Thickness Calculationjose_sebastian_2No ratings yet

- Pump ErectionDocument2 pagesPump Erectionjose_sebastian_2No ratings yet

- Excel ShortcutsDocument9 pagesExcel Shortcutsjose_sebastian_2No ratings yet

- Dissimilar Materials WeldingDocument2 pagesDissimilar Materials Weldingjose_sebastian_2No ratings yet

- Chineese Materials DinDocument1 pageChineese Materials Dinjose_sebastian_2No ratings yet

- M Tech Part TimeDocument22 pagesM Tech Part Timejose_sebastian_2No ratings yet

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDocument14 pagesCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2No ratings yet

- Arogyamasika May2020 N PDFDocument116 pagesArogyamasika May2020 N PDFjose_sebastian_2No ratings yet

- List of Upcoming Thermal Plants in IndiaDocument11 pagesList of Upcoming Thermal Plants in Indiajose_sebastian_2No ratings yet

- Luni River - Wikipedia, The Free EncyclopediaDocument2 pagesLuni River - Wikipedia, The Free Encyclopediajose_sebastian_2No ratings yet

- Security Clearance Form PDFDocument6 pagesSecurity Clearance Form PDFjose_sebastian_2No ratings yet

- Church BulletinDocument4 pagesChurch Bulletinjose_sebastian_2No ratings yet

- Childcare Application FormDocument8 pagesChildcare Application Formjose_sebastian_2No ratings yet

- Application For Water Service: WWW - Cambridge.caDocument1 pageApplication For Water Service: WWW - Cambridge.cajose_sebastian_2No ratings yet

- Minority Certificate PDFDocument1 pageMinority Certificate PDFjose_sebastian_2No ratings yet

- EPIC Brochure Fall 2017 Ontario Electrical-MechanicalDocument16 pagesEPIC Brochure Fall 2017 Ontario Electrical-Mechanicaljose_sebastian_2No ratings yet

- 4 Squares: This Was Done in World Record Time of 7 SecDocument1 page4 Squares: This Was Done in World Record Time of 7 Secjose_sebastian_2No ratings yet

- A Brief Check List of Labour LawsDocument54 pagesA Brief Check List of Labour Lawsjose_sebastian_2100% (1)

- BooksDocument1 pageBooksManu ChakkingalNo ratings yet