Professional Documents

Culture Documents

Bhel Pipe Thickness Calculation

Bhel Pipe Thickness Calculation

Uploaded by

jose_sebastian_20 ratings0% found this document useful (0 votes)

19 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

19 views2 pagesBhel Pipe Thickness Calculation

Bhel Pipe Thickness Calculation

Uploaded by

jose_sebastian_2Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

CALCULATION FOR THICKNESS OF PIPES AS PER REG. 350 OF iBR 1950

PROJECT: NALCO ANGUL 9&10 , 2X120 MW — GUSTOMER NO : 6578-057-1 4 €879-057-1 PGMA NO : 80-320

ASSY.DRG NO : 1~-80~320-10702/03

1-80-320-12036 /00

PGMA DESCRIPTION: CRH FROM TURBINE TO REHEATER

(p= 2Set-e

« , _—Po i) P= 28282) cg sin oF wR, Hence t= — Pe

= 2SHE2 cm, 91 oF wR, Hence t =P + Go) p= 288-2 cq, ora oF aR, HENCE t =A +o

WHERE, P = MAXIMUM WORKING PRESSURE ~Ka/SaCm (9) T.S.= TENSILE STRENGTH AT 200 ~Kg/Sa.cm

D = OUTSIDE DIAMETER —mm Et = YELD PONT (0.2% PROOF STRESS) AT TEMP —Kg/SaCm

@ = INSIDE DIAMETER —mm es 24 Sr = AVERAGE STRESS TO PRODUCE RUPTURE IN 100,000 hes. AND

eee Dare NALCO 9810 21... ess atecn telco ee oon al le

© = 0.75 mm CUST. No. 6878 & 83“ PRODUCE RUPTURE (AT TEMP) -Kg/Sa.Cm

© = EFFIGENCY FACTOR ‘Sc = AVERAGE STRESS TO PRODUCE AN’ ELONGATION OF 1% CREEP

S = ALLOWABLE STRESS —Kg/Sq.crn

IN 100,000 hrs.(AT TEMP) ~Kg/Sq.cm

FURTHER IN THE TABULATION SELOW |

FS on FL (wmcnever 1s LESS) FOR TEMPLUPTO ANO INL 454° ¢

CR Se (WHCHEER 15 LESS) FOR TEUP ABOVE 454° 6 f= BEND RADU rm

tb = NINE TONES BEFORE BENONG mm

T _ =ve

> Trewe | MATERIAL 5 thm | he [NOMAD THICKNESS

wale] Ne” | USS | waren fe {mm frase | Tolan [PERE SECTS, |

te 825 XMS ge

42.5 | 360 |satoscre(A) | 1138.973|1 |t=

(201138.973x_1)+42'5

42.5 | 360 |SA106GRB(A) | 1138.973)

- 12.5% [1.3 373

te 425 x 558.8

(2x1138.973x_1)+

- 12.5% | 12.55 | 40

- I

NAME SIGNATURE | ~ |

PREPARED: | PRADEEP bey

APPROVED: | APMK Vito, —

DATE: 9609.07 | A.P. Madi ‘"

3608.07 , Ae Madbegmdays oF 4

r — — a — — |

CALCULATION FOR THICKNESS OF PIPES aS PER REG. 350 OF IBR 1950

~ PROJECT:NALCO ANGUL 9810 , 2X120 MW” CUSTOMER NO fans 'S,” 6870-057. PGMA NO : 80-320

ASSY.DRG NO : 1~20-320-10702/03

PGMA DESCRIPTION: CRH FROM TURBINE TO REMEATER 1=80-320-12036/00

ore vance t= 2 gg (r= SES ce oko ee eet aE ag

WERE, P = MAXIMUM WoRKING PRESSURE ~Ka/sa.om tg) 1Si= TENSLE STRENGTH AT 200 ~kg/Sacm

D = OUTSDE DIAMETER “me Et = Yio Pow (oan proor STRESS) MT TEMP —xg/Sqcmn

@ = INSIDE DIAMETER

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GRP Laying and JoiningDocument4 pagesGRP Laying and Joiningjose_sebastian_2No ratings yet

- CPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)Document22 pagesCPM - CPM Terrorists - Murderers in Kerala (Warning - Pictures Are Gruesome)jose_sebastian_2No ratings yet

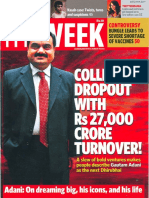

- Adani at WeekDocument8 pagesAdani at Weekjose_sebastian_2No ratings yet

- D N H MundraDocument42 pagesD N H Mundrajose_sebastian_2No ratings yet

- Changlang - Nic.in Stilwell - HTMLDocument5 pagesChanglang - Nic.in Stilwell - HTMLjose_sebastian_2No ratings yet

- The 1965 Indo Pakistan War PreambleDocument64 pagesThe 1965 Indo Pakistan War Preamblejose_sebastian_2No ratings yet

- CW PumpsDocument15 pagesCW Pumpsjose_sebastian_2No ratings yet

- WB III VIDocument1 pageWB III VIjose_sebastian_2No ratings yet

- Pump ErectionDocument2 pagesPump Erectionjose_sebastian_2No ratings yet

- Excel ShortcutsDocument9 pagesExcel Shortcutsjose_sebastian_2No ratings yet

- Dissimilar Materials WeldingDocument2 pagesDissimilar Materials Weldingjose_sebastian_2No ratings yet

- Chineese Materials DinDocument1 pageChineese Materials Dinjose_sebastian_2No ratings yet

- M Tech Part TimeDocument22 pagesM Tech Part Timejose_sebastian_2No ratings yet

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDocument14 pagesCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2No ratings yet

- Arogyamasika May2020 N PDFDocument116 pagesArogyamasika May2020 N PDFjose_sebastian_2No ratings yet

- List of Upcoming Thermal Plants in IndiaDocument11 pagesList of Upcoming Thermal Plants in Indiajose_sebastian_2No ratings yet

- Luni River - Wikipedia, The Free EncyclopediaDocument2 pagesLuni River - Wikipedia, The Free Encyclopediajose_sebastian_2No ratings yet

- Security Clearance Form PDFDocument6 pagesSecurity Clearance Form PDFjose_sebastian_2No ratings yet

- Church BulletinDocument4 pagesChurch Bulletinjose_sebastian_2No ratings yet

- Childcare Application FormDocument8 pagesChildcare Application Formjose_sebastian_2No ratings yet

- Application For Water Service: WWW - Cambridge.caDocument1 pageApplication For Water Service: WWW - Cambridge.cajose_sebastian_2No ratings yet

- Minority Certificate PDFDocument1 pageMinority Certificate PDFjose_sebastian_2No ratings yet

- EPIC Brochure Fall 2017 Ontario Electrical-MechanicalDocument16 pagesEPIC Brochure Fall 2017 Ontario Electrical-Mechanicaljose_sebastian_2No ratings yet

- 4 Squares: This Was Done in World Record Time of 7 SecDocument1 page4 Squares: This Was Done in World Record Time of 7 Secjose_sebastian_2No ratings yet

- A Brief Check List of Labour LawsDocument54 pagesA Brief Check List of Labour Lawsjose_sebastian_2100% (1)

- BooksDocument1 pageBooksManu ChakkingalNo ratings yet