Professional Documents

Culture Documents

Risk Assessment - 1059

Risk Assessment - 1059

Uploaded by

Francis Enriquez TanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment - 1059

Risk Assessment - 1059

Uploaded by

Francis Enriquez TanCopyright:

Available Formats

1 of 3

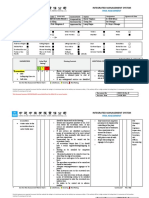

Sie Specific Risk Assemssent

General Notes Site ID - 1059 Scope of work - Telecom Installation

1. drivers shallhave Valid License to drive.

2. Do not access site without the required mandatory PPE (Helmet, Safety Shoes and VIS Jacket).

4. Do not access the site without Safety Induction.

5. Understand the Manual Handling proceedure - to delier by Contractor EHS prior the work

6. Alll driver must summit to the authority and the controls of the site supervisor at all time

7. Pre-Task Briefing Must be done before any work on site, and must include all team members.

Risk Assessment - Installation of Telecom Equipment

RISK ASSESS RISK ASSESS Risk after further action

TASK HAZARD RISK WHO IS EXPOSED? CONTROL MEASURES Further Control

L S RV Risk Level L S RV Level L S RV Risk Level

• Driver must have valid driving license & Defensive Driving Training • Drivers must always avoid any deep

• Vehicle must be fit for the job discussion with passengers to avoid lost of

• Vehicle must be in good working conditions concentration.

• Inspect the vehicle before starting

• Fix the identified problems before moving to site •Vehicle must be fitted with GPS device

• All passengers must fasten the seat belts (front and rear)

• Any load in the vehicle should be properly secured and distributed • Drivers Must be Trained on defensive

Driving • Driving • No material in the front or rear seats of the vehicle driving

•Traffic Hazards

• Fatality

• Passengers • Do not use mobile phone while driving

• Injury, 4 4 16 High • Never over speed • Never drive under the influence of the drugs 3 4 12 Medium 1 4 4 Low

1. Material Mobilization • Collusion • General Public

• Property Damage • Drivers must be very watchfull of other road users during driving

2. Pasenger Mobilization • Weather condition

• Drivers must always keep the volume of the car tape as low as possible if at all to be on.

Site Supervisor to stand By and Monitor the

access.

• Use existing tower ladder to access the tower.

Full body harness, Double Lanyard, Positioning Lanyard, Safety shoes, Climbing Helmets,

Tower Climbing gloves, safety goggles & Slings to be used while doing work at height.

Stability • Tower climbers must inspect the monkey ladder & tower before climbing, In case of

• Broken borns

Fall

Site Access/At height access

Tip over Head

• Injuries • Employee 3 3 9 Medium finding any abnormality do not climb and report to safety department 2 3 6 Medium 1 3 3 Low

Injury

• Property Damage • Always use connectors/carabiners/hooks in verticale position

• Never put double lanyard hooks on the same anchor point. Make sure the persons

working at height are trained by huawei certified third party. Make sure no lone working is

allowed while working at height. Ateendant to be present on the ground at all times.

• Conduct Tool box talk before start of work to clearly elucidate the hazard and its controls • Appropriate PPE must be use such as safety

Manual Handling • Employees should follow safe manual handling and lifting techniques boots and hard hats and gloves.

1. Equipment lifting • Avoid awkward postures always

• Equipment Weight

2. Equipment Off-load • Dimensions

• Back injury • Ensure good house keeping at site • Work Under compitent supervisor

• Sharp Object

• Foot injury

• Employees 3 3 9 Medium

• Keep the walkways clear from any obstruction 2 3 6 Medium 1 3 3 Low

3. Equipment assembly and • Human Eror

• Cut or crush fingers • Placing of heavy equipmnet should required more people (15Kg per one)

• Bone Disorderliness

preparation before Installation • Hit or crush by

• Trip and Fall

Cabling • Pre Trask Briefing to be delivered before the Task commence

• Sharp Object • Injury • PPE Inspection prior use.

1.Cable routing and arrangement • Cut or Crush • Workers on site

• protruding Object • Property damage

4 2 8 Medium • Proper PPE to be used: ( Gloves, safety shoes, Helmets) 2 2 4 Low Hand Gloves Must be used 1 2 2 Low

2. Working on cable trays • careful while working on sharp edges, and must use gloves

• Awkward Posture • Avoid Awkward posture while working on cable tray

2 of 3

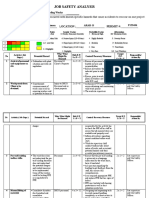

Sie Specific Risk Assemssent

RISK ASSESS RISK ASSESS Risk after further action

TASK HAZARD RISK WHO IS EXPOSED? CONTROL MEASURES Further Control

L S RV Risk Level L S RV Level L S RV Risk Level

• Certified Person on rigging & slinging training should handle the Lifting operation

• All ropes and pulleys should be EN & CE marking and certified

• Manual Lifting Equipment must be certified by third party and have certificate on site

• Drop zone is identified to keep proper distance from lifting area

• Certificates Rigger , Tower Climbers and First Aider are available at site

• Ensure the ropes are in good condition with proper Tag lines

• Ensure the pulley is in good condition • Material Fall Arrest System is properly

• Ensure the pulley is properly attached with the tower installed ( This is a Special device to arrest

Manual Lifting • Trip and fall • Re - check the condition of the pulley attachment in intervals during the work the equipment in the event of any falling)

• Falling of object • Workers on site • No one should be standing under the tower when material is being pulled up

• Material damage • Wind Measuring device ( Anemometer)

1. Knot activities • Weather Condiction

• Injury

• Vodafone Property

3 5 15 High • There should be enough no. of workers to handle the rope with the material 2 5 10 Medium Should available on site to used to 1 5 5 Medium

• Equipment Failure • Property Damage • Public Property • Hold the work in case of adverse weather

2. Pulling material from Ground • Human Error detetrmining the wind speed and apply stop

• Incompitency

lifting when the maximum speed are riched

(=>45 km/hr)

• Work must be carried out under the supervsision of a competent person Continuous monitoring is requried

• Only trained and certified tower climbing & rescue workers will work on tower

• Accessories must be kept in protected bags in order not to fall on the ground • Work on hold in case of strong wind (=>45

• Inspect PPE, Rescue Equipment, Fall Arestor prior use km/hr) or adverse weather ( monitoring)

• Proper PPE to be used:

• EHS officer to monitor the 100% connecting at

Full body harness, Double Lanyard, Positioning Lanyard, Safety shoes, Tower Climbing all time on any height above 2 metters

RRU Installation Helmets, Tower Climbing gloves, safety goggles & Slings

• Tower climbers must inspect the tower before climbing, In case of finding any abnormality

1. Working at height do not climb and report to safety department

• Height • Always use connectors/carabiners/hooks in verticale position

2. Accending from the Tower • Falling Objects • Fatality • Never put double lanyard hooks on the same anchor point

ladder • Weather Condition • Injury Employees 3 5 15 High

• All damaged PPEs must be marked as damaged and removed from site immediately 2 5 10 Medium 1 5 5 Medium

• Incompitency • Property Damage • Never work after sunset or before sunrise

3.RRU Installation • Equipment Weight • All workers on site must be wearing helmets. Material management to be done whicle

installting rectifier. Tandem lifting of the equipment to be done if exceeding 20kg. Site to be

4.Descending from the Tower kept tidy & free from obstructions that could cause slip trips & falls. While working on the

ladder platform, always wear helmet & mind the headspce to avoid colission with the structure.

• Only Qualified electrical engineer will work on electrical installation inside rectifier Job Should be done under compitent supervisor

• Never work with live electricity use lockout tag out system

• Do not wear conductive metal or jewelry (bracelets, chains, rings, etc.)when working on Electrical Enginer Must be third party cerfied in

electricity electric safety training.

Electrical works • Shortcircuit • Use appropriate company insulated tools for the job

• Electocution • Fatality, • LOTO proceedure should be applied

• Workers, • Use Appropriate Electrical PPE during the Batteries installation

1. Rectifier Connection • wrong connection • injury, • Equipments 3 5 15 High 2 5 10 Medium 1 5 12 Medium

• Incompitency • Equipment damage • All Batteries must be cover by Cap immidiately - No neeked head Batteries

• Spark • Proper Electrical signage should be on rectifier to warn un-authorized person .

2. Site Powering

• Be coution of sharp object and protruding object during waste removal.

• Waste must be stored at designated area, with MSDS been followed for specific

product/waste. • appropriate

and minimum PPE should be used by participants: Safety boot, appropriate hand gloves,

Waste Management • House keeping helmet. and dust masks

• injury • Lifting techniques should also be used for waste that requires been lifted to the

• sharp edges

Site cleanup & waste materials • tripping hazard

• Cut site Workers 3 3 9 Medium appropriate and available vehicle to be used for the exercise. 2 3 6 Medium Review at next opportunity 1 3 3 Low

• Dust • infection

removal

• Workers participating in the waste collecting should be cautious for:

• Sharp objects (glass, nails, metal pieces, etc.)

• obstacles to avoid tripping hazard.

• Proper Gloves should be used always

3 of 3

Sie Specific Risk Assemssent

RISK ASSESS RISK ASSESS Risk after further action

TASK HAZARD RISK WHO IS EXPOSED? CONTROL MEASURES Further Control

L S RV Risk Level L S RV Level L S RV Risk Level

You might also like

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Risk Assessment FOR: Over Head Crane ErectionDocument9 pagesRisk Assessment FOR: Over Head Crane ErectionZameer AhmedNo ratings yet

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument5 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez Tan100% (3)

- AspenTech - Compressor Modeling in Aspen HYSYS DynamicsDocument26 pagesAspenTech - Compressor Modeling in Aspen HYSYS DynamicsTaniadi SuriaNo ratings yet

- 4759 PDFDocument9 pages4759 PDFamitjustamitNo ratings yet

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- JSA For Scaffolding.Document16 pagesJSA For Scaffolding.jeswinimanualNo ratings yet

- Excavation, Trenching & Pot HolingDocument1 pageExcavation, Trenching & Pot HolingHafiz SabriNo ratings yet

- Safe Working at Heights Part 1 - KG - 310519Document15 pagesSafe Working at Heights Part 1 - KG - 310519eugene stevensNo ratings yet

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- Heat Stress Awareness Drill June 2022Document18 pagesHeat Stress Awareness Drill June 2022Subbu AbuNo ratings yet

- Asphalt Paving JsaDocument2 pagesAsphalt Paving Jsanabeel100% (1)

- JSA of Materila Handling ApproviedDocument2 pagesJSA of Materila Handling Approviedsakthi venkatNo ratings yet

- Lifting Operation (JSA)Document4 pagesLifting Operation (JSA)abdullah ashrafNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Rescue Plan To Prevent Suspension Trauma: Ahmed AgbomireDocument8 pagesRescue Plan To Prevent Suspension Trauma: Ahmed AgbomireOsama ShaalanNo ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- Permit To Work Hseprof Com 1691465620Document36 pagesPermit To Work Hseprof Com 1691465620ajidwiyuniarsoNo ratings yet

- Gas Cylinders RADocument5 pagesGas Cylinders RAalla malikNo ratings yet

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Sand FillingDocument1 pageSand FillingSomzworld SomzNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Demolition Risk AssessmentsDocument9 pagesDemolition Risk Assessmentssamar0% (1)

- Safety Observation Formate - 01Document3 pagesSafety Observation Formate - 01Peter LuvisNo ratings yet

- JHA - Excavation, Pile Hacking and Construction of Lean ConcreteDocument13 pagesJHA - Excavation, Pile Hacking and Construction of Lean ConcreteJansen SungaNo ratings yet

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- Hira - Eot CraneDocument4 pagesHira - Eot CraneSantosh SinghNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- Working at Heights Translab and PBDocument1 pageWorking at Heights Translab and PBCIDI Avida Towers VergeNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- 08n Safety Action PlanDocument103 pages08n Safety Action PlanMohammed MinhajNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Lifting Operations Planning Risk Assessment PDFDocument1 pageLifting Operations Planning Risk Assessment PDFulisses costaNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- JSEA FOR EARTH WORK (Alumina Silo Area)Document13 pagesJSEA FOR EARTH WORK (Alumina Silo Area)MD AbdullahNo ratings yet

- QHSEDOCS-Demolition Work Activities Risk AssessmentDocument14 pagesQHSEDOCS-Demolition Work Activities Risk AssessmentLawrence adeleke OmisakinNo ratings yet

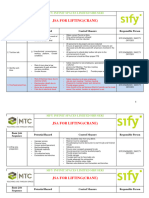

- Jsa For Lifting (Crane) : Sify Infinit Spaces Limited SiruseriDocument6 pagesJsa For Lifting (Crane) : Sify Infinit Spaces Limited SiruseriJISHNU EHSNo ratings yet

- ZFP Sor 2021-6-6Document5 pagesZFP Sor 2021-6-6Muhammad JamshidNo ratings yet

- Monthly Store Inspection ReportDocument1 pageMonthly Store Inspection ReportgkNo ratings yet

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- JSP For Over Head Crane (JSP-HHI-Comm-07)Document4 pagesJSP For Over Head Crane (JSP-HHI-Comm-07)Farooq MohammadNo ratings yet

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- HSE Training ProgramDocument5 pagesHSE Training Programbotahra0% (1)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Emergency Responce Plan and Safety Plan Ram Chandra EnterpriseDocument4 pagesEmergency Responce Plan and Safety Plan Ram Chandra EnterpriseBilal QureshiNo ratings yet

- Boom Placer Safety Inspection ChecklistDocument1 pageBoom Placer Safety Inspection ChecklistMyo LwinNo ratings yet

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- ZFP Sor 2022-12-27Document5 pagesZFP Sor 2022-12-27irfan shafiqueNo ratings yet

- Sand Blasting and Painting Rescue Plan: in The Event of An Emergency in TanksDocument1 pageSand Blasting and Painting Rescue Plan: in The Event of An Emergency in TanksGiorgi KOGOSHVILINo ratings yet

- Risk Assessment For Structural Cabling System Testing and CommissioningDocument5 pagesRisk Assessment For Structural Cabling System Testing and CommissioningInfas YahyaNo ratings yet

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- Unloading Method StatementDocument3 pagesUnloading Method Statementprasanna okNo ratings yet

- Tower Light Inspection ChecklistDocument1 pageTower Light Inspection ChecklistHabib ur rahmanNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- Defensive DrivingDocument54 pagesDefensive DrivingFrancis Enriquez TanNo ratings yet

- Oct-Nov-WSO Newsletter-2022Document18 pagesOct-Nov-WSO Newsletter-2022Francis Enriquez TanNo ratings yet

- Method Statement For Scaffolding WorksDocument17 pagesMethod Statement For Scaffolding WorksFrancis Enriquez TanNo ratings yet

- Cleaning Window Risk AssessmentDocument3 pagesCleaning Window Risk AssessmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - MDDocument2 pages2021.10.2 - Ddab-Hse-Dor-Contraco - MDFrancis Enriquez Tan100% (1)

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Ev04 - Behavioral Based Safety Training SlidesDocument21 pagesEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDocument3 pages2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNo ratings yet

- Additional Guidance Unit 1Document5 pagesAdditional Guidance Unit 1Francis Enriquez TanNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- Heat IndexDocument2 pagesHeat IndexFrancis Enriquez TanNo ratings yet

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Ev01 - Hse Induction Attendance SheetDocument5 pagesEv01 - Hse Induction Attendance SheetFrancis Enriquez TanNo ratings yet

- Table 2 WGBTDocument3 pagesTable 2 WGBTFrancis Enriquez TanNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- Risk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageDocument11 pagesRisk Assessment: Project Name: Se-57, Construction of 10 Villas at Giardino VillageFrancis Enriquez TanNo ratings yet

- RA For Block Works For 10 VillasDocument5 pagesRA For Block Works For 10 VillasFrancis Enriquez TanNo ratings yet

- JSO Slip, Trips & Fall (27 Aug.'07)Document1 pageJSO Slip, Trips & Fall (27 Aug.'07)Francis Enriquez TanNo ratings yet

- JSO Trip & Fall (24 Aug.'07)Document1 pageJSO Trip & Fall (24 Aug.'07)Francis Enriquez TanNo ratings yet

- Al Tronic Ill-Cpu Medium Engines, 2 16 Cylinders Service Instructions FORM Alii-CPU SL 4-91Document8 pagesAl Tronic Ill-Cpu Medium Engines, 2 16 Cylinders Service Instructions FORM Alii-CPU SL 4-91SMcNo ratings yet

- A Proposal On Reusable Sanitary PADSDocument16 pagesA Proposal On Reusable Sanitary PADSMike AbbeyNo ratings yet

- TDS520A User ManualDocument290 pagesTDS520A User Manualplum_brandyNo ratings yet

- My Comments Are Given in Red Below:-: Sajimon.M.KunjuDocument6 pagesMy Comments Are Given in Red Below:-: Sajimon.M.Kunjupdkprabhath_66619207No ratings yet

- MC Condenser Technical ManualDocument35 pagesMC Condenser Technical Manualjuan manuel guerrero florezNo ratings yet

- Tentative Recommendations For Prestressed Concrete-ACI 323 (1958)Document34 pagesTentative Recommendations For Prestressed Concrete-ACI 323 (1958)Alberto Ezequiel León TamayoNo ratings yet

- Template For Submission of Papers To IETE Technical ReviewDocument6 pagesTemplate For Submission of Papers To IETE Technical ReviewTabassum Nawaz BajwaNo ratings yet

- CT Commercial Investment PropertiesDocument25 pagesCT Commercial Investment PropertiesbritalbNo ratings yet

- MDC Monthly Proposal Dec 2019Document2 pagesMDC Monthly Proposal Dec 2019Tushar Prakash ChaudhariNo ratings yet

- Carl Størmer's Auroral Discoveries: Alv Egeland and William J. BurkeDocument9 pagesCarl Størmer's Auroral Discoveries: Alv Egeland and William J. BurkesantiagoNo ratings yet

- Carnot Cycle - Working Principle & Processes With (PV - Ts Diagram)Document8 pagesCarnot Cycle - Working Principle & Processes With (PV - Ts Diagram)Sharif Muhammad HossainNo ratings yet

- Renold TRC Section1 0608Document77 pagesRenold TRC Section1 0608ahexyzNo ratings yet

- Scanfrost Washing Machine ManualDocument5 pagesScanfrost Washing Machine ManualAbdulAzeez ADEBAYONo ratings yet

- Later Middle Ages:: Lord John Alfred Fernandez BsedDocument36 pagesLater Middle Ages:: Lord John Alfred Fernandez BsedJohn Alfred FernandezNo ratings yet

- Road Safety FundamentalsDocument122 pagesRoad Safety Fundamentalssmanoj354100% (3)

- Physics Part 2 Class Xii PDF FreeDocument263 pagesPhysics Part 2 Class Xii PDF FreeibbuarmNo ratings yet

- For HARDBOUNDDocument89 pagesFor HARDBOUNDdelcar vidal100% (1)

- Los Angeles Police OrganizationDocument9 pagesLos Angeles Police OrganizationRylie MatienzoNo ratings yet

- Pueblo Way - Alleged Overdue Utility Bill - RedactedDocument2 pagesPueblo Way - Alleged Overdue Utility Bill - RedactedLas Vegas Review-JournalNo ratings yet

- Aristo Alhakim IndonesiaDocument2 pagesAristo Alhakim Indonesiaaristo anadyaNo ratings yet

- Mock Test - 98 (17 Jan 2023) Rotational DynamicsDocument1 pageMock Test - 98 (17 Jan 2023) Rotational DynamicsparamNo ratings yet

- History G4 Report FinalDocument14 pagesHistory G4 Report FinalElvira MirajulNo ratings yet

- CSR Policy KsfeDocument6 pagesCSR Policy KsfeOhari NikshepamNo ratings yet

- 19vjhg JKJG KJGKJG K GKGK KKK K KDocument4 pages19vjhg JKJG KJGKJG K GKGK KKK K KJatin M PatelNo ratings yet

- Logistics Service AgreementDocument1 pageLogistics Service AgreementBong Tolenada Aled ZurcNo ratings yet

- Mergers Acquisitions and Other Restructuring Activities 7th Edition Depamphilis Test BankDocument19 pagesMergers Acquisitions and Other Restructuring Activities 7th Edition Depamphilis Test Banksinapateprear4k100% (35)

- 0068 NehaDocument1 page0068 Nehang.neha8990No ratings yet

- Bed and Bathroom Linen - 29.12.2020Document2 pagesBed and Bathroom Linen - 29.12.2020Eden Led LightingNo ratings yet