Professional Documents

Culture Documents

Supplier Scorecard Guidelines

Supplier Scorecard Guidelines

Uploaded by

nasernaser741Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supplier Scorecard Guidelines

Supplier Scorecard Guidelines

Uploaded by

nasernaser741Copyright:

Available Formats

Supplier Scorecard Guidelines

Revision Date: 1 September 2004

Approved

(Signature on file)

John Saliture, Director Supplier Quality & Technical Performance Integrated Systems Sector

General Information As part of our efforts to more effectively rate supplier performance, Northrop Grumman Integrated Systems has refined the Supplier Scorecard Process. The Scorecard is used to support our commodity management and strategic sourcing objectives, and is also used as the main criteria for our Platinum Source Certification program. More importantly, we believe the Scorecards facilitate stronger communications between Northrop Grumman and our production supplier team members. Production suppliers who supply material that is ultimately delivered to our customer will receive a Scorecard. Manufacturers and distributors will receive a Scorecard. Special processors, service suppliers, and tooling suppliers will not receive a Scorecard. Supplier Scorecards are posted quarterly on the Northrop Grumman OASIS website located at https://oasis.northgrum.com/ under MyOASIS. Northrop Grumman Team Members Both Quality and Procurement review and have input into your Scorecard. Each supplier has been assigned a Supplier Quality and Technical Performance (SQ&TP) Process Manager. The Process Manager insures accuracy of the Quality Profile and inputs the Process Health/ Lean/ Six Sigma rating. Some suppliers receive purchase orders from multiple sites within the Integrated Systems sector and therefore have various buyers assigned to them. The buyers are responsible to review and correct the Delivery metrics prior to publication. The buyer who has the most open purchase order dollars has been identified as the lead buyer. The lead buyer is responsible for loading the Customer Satisfaction element of the Scorecard. Access to MyOASIS A user ID and password are required to access Supplier Scorecards within MyOASIS. If your company does not have a user ID and password, please contact one of these individuals for help: Suzette Sakazaki Internet Supplier Programs (310) 814-0597 suzette.sakazaki@ngc.com Lisa Terry Integrated Delivery Team (310) 331-1055 lisa.terry@ngc.com Lori New Supplier Quality Administration (310) 332-6689 lori.new@ngc.com

For MyOASIS login problems, please call Suzette Sakazaki.

Scorecard Elements Your Supplier Scorecard is made up of the following elements. These elements have assigned point values and when combined together comprise your Scorecard rating. Objective Elements Quality (ref: Figure 2) Late Delivery o Material received more than 7 days late based on the negotiated purchase order date within the last 6 months. Team Assessment Elements o Customer Satisfaction Responsiveness Responds quickly and thoroughly to requests, written and verbal o Always o Usually, requires an occasional follow up o Seldom, typically requires multiple follow up Able to Accommodate Changes to Requirements with Reasonable Cost and Schedule Impacts o Yes, typically minimal impact o Accommodating but needs follow up and extra effort to define impacts o Accommodates changes, but cost and schedule impacts seem excessive Oversight Oversight Required in the Areas of Quality, Technical and Delivery Requirements o No Oversight Required o Minimal Oversight Required o Regular Oversight Required o Excessive Oversight Required Management Displays Technical and Management Expertise Required to Identify and Implement Innovative Solutions to Issues o Proposed solutions are accurate, concise and insightful, addressing all issues at hand o Average, most solutions are acceptable. Some require further work. o Unable to consistently offer effective solutions o Process Health/ Lean & Six Sigma Process Health Mature Planning and Schedule Management Processes o Supplier has proven Production Control and Planning systems that provides sufficient methods to provide parts to contract reqts o Suppliers Production Control and Planning systems inconsistently provides sufficient methods to provide parts to contract reqts o Supplier has no Production Control system in place or is not used to monitor shop load reqts and the Planning system is non-existent or deficient

Lean & Six Sigma Embraces Continuous Process Improvement with Tools such as Lean and Six Sigma o Employees are Trained and Knowledgeable o Evidence of some Ongoing Activities or Events that Generate Cost Reductions and/or Lead Time Improvements o Aggressively Practiced Throughout the Enterprise. Continuous Improvement of Costs and Lead Times Feedback Any questions regarding your Scorecard should be directed to your Quality Process Manager or your Buyer.

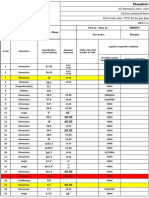

Supplier Scorecard Format (Figure 1)

Quality Profile Rating (See Figure 2)

Actual 100 90 80 77 70 67 57 54 47 44 34 30 20 10 0 Points 50 45 40 39 35 34 29 27 24 22 17 15 10 5 0

Late Delivery

(last 6 months) (PO Date > 7 days) Points Actual 0% 1% 2% 3% 4% 5% 6% 7% 8% 9% > 9% 30 27 24 21 18 15 12 9 6 3 0

Customer Satisfaction

Points 10 9 8 7 6 5 4 3 2 1 0

Process Health/Lean/ Six Sigma

Points 10 9 8 7 6 5 4 3 2 1 0

Supplier Scorecard Rating Blue 91-100 Green 75-90 Yellow 51-74 Red 0-50

Scorecard Formula (Quality Score) + (Late Delivery Score) + (Customer Satisfaction score) + (Process Health Score) = Overall Score

Quality Profile Rating (Figure 2)

Hardware Acceptance Rating (70% wt)

100 99 97 - 98 0 - 96 (70) (47) (24) (0)

QADRRs (30% wt)

0 1 2 3+ (30) (20) (10) (0)

Supplier Quality Profile

100 = 67 to 99 = 35 to 66 = < 35 =

Blue Green Yellow Red

Hardware Acceptance Rating: 1 (Quantity of pieces rejected divided by the quantity of pieces received) x 100 based on previous 12 months of supplier history. QADRRs: Three (3) months of closed QADRRs and all QADRRs with open Corrective Action. Quality System disapproval, appearing in a GIDEP alert or advisory, or a disclosure of nonconforming hardware that has been delivered to a Northrop Grumman customer within the last 12 months will result in an automatic RED Quality Profile rating of a one (1).

Supplier Scorecard

3rd Qtr 2004 Supplier Number: Supplier Name: Mfg./Dist. Address:

123456 XYZ Company 123 South St. Orange, NJ 00000

Buyer Name

ACS: AEW: AGS: Parker, G Quail, P Thomas, C

Process Manager

Williams, B

Platinum Source

Yes

IS Programs

E-2C BQM-34 JSTARS

Scorecard Ratings

Available Pts. Earned Pts.

Quality

Notes: IS - Integrated Systems ACS - Air Combat Systems AEW/EWS - Airborne Early Warning/ Electronic Warfare Systems AGS/ BMS - Airborne Ground Surveillance/ Battle Management Systems

50

27

Late Delivery Customer Satisfaction Process Health/ Lean Total

30

30

10

10

77

10

10

Blue = 91 100; Green = 75 90; Yellow = 51 74; Red = 0 - 50

You might also like

- Principles of Marketing Chapter 5 Managing The Marketing EffortDocument8 pagesPrinciples of Marketing Chapter 5 Managing The Marketing EffortAnghelica Eunice90% (10)

- Motorola Quality ManualDocument12 pagesMotorola Quality ManualHaroon MukhtarNo ratings yet

- SOP-0009 Infrastructure - Production - and Service SupportDocument3 pagesSOP-0009 Infrastructure - Production - and Service Supportkashifbutty2kNo ratings yet

- Process Mapping ChecklistDocument2 pagesProcess Mapping ChecklistCK EspanolNo ratings yet

- GM 1927-30 QSB Audit Master - Final011811Document16 pagesGM 1927-30 QSB Audit Master - Final011811Mohammad GadNo ratings yet

- Cisco System Managing de Supply ChainDocument7 pagesCisco System Managing de Supply ChainNorberto VarasNo ratings yet

- Comparative Study Auditing Between Profit & Nonprofit OrganizationsDocument52 pagesComparative Study Auditing Between Profit & Nonprofit OrganizationsNael Loay Arandas100% (7)

- Entrepreneurship Project On Gaming Zone in UniversityDocument50 pagesEntrepreneurship Project On Gaming Zone in UniversityArslan Ali Butt89% (19)

- BoeingDocument42 pagesBoeingHarsh SaxenaNo ratings yet

- 06-خطة الإجراءات التصحيحية-Corrective Action PlanDocument11 pages06-خطة الإجراءات التصحيحية-Corrective Action Planحسن ابو فهدNo ratings yet

- Critical To Customer RequirementsDocument29 pagesCritical To Customer RequirementsVaibhav SinghNo ratings yet

- Vendor Evaluation FarmDocument2 pagesVendor Evaluation FarmTrivesh SNo ratings yet

- PFMEA Ranking Table Rating Criteria Action GuidelineDocument10 pagesPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoNo ratings yet

- MMOG - LE Foreword and Intro, V3 2009 PDFDocument26 pagesMMOG - LE Foreword and Intro, V3 2009 PDFwrr190No ratings yet

- 434 MFRDocument10 pages434 MFRHarsh JindalNo ratings yet

- HOTEL CONNISSEUR Python Project (With Code)Document42 pagesHOTEL CONNISSEUR Python Project (With Code)Scary PeepsNo ratings yet

- Sample SopDocument4 pagesSample Sopsandeep sharmaNo ratings yet

- Vendor Supplier Evaluation Audit Form TemplateDocument4 pagesVendor Supplier Evaluation Audit Form TemplateSepti AdeliaNo ratings yet

- Calibration CertificateDocument3 pagesCalibration CertificateMARIBETH AGUBANo ratings yet

- GE ENERGY Quality Manual Oct 2010Document24 pagesGE ENERGY Quality Manual Oct 2010e2ycNo ratings yet

- F02 Project Status Purchased Parts QR83 2011 Version 1-0-01Document3 pagesF02 Project Status Purchased Parts QR83 2011 Version 1-0-01sujay13780No ratings yet

- Existing Supplier Evaluation (R)Document1 pageExisting Supplier Evaluation (R)Lina Mustafa WhiteheadNo ratings yet

- Labour Camp InspectionDocument4 pagesLabour Camp InspectionChandirprakash KrishnamoorthyNo ratings yet

- MaintenanceDocument2 pagesMaintenancepitesoft0% (1)

- Lean Product Development - Redefining The Indian AutomotiveDocument13 pagesLean Product Development - Redefining The Indian AutomotiveTaynan SilvaNo ratings yet

- Process Flowchart - Gadget SamyakDocument9 pagesProcess Flowchart - Gadget SamyakVinay BhandariNo ratings yet

- Job DescriptionDocument2 pagesJob DescriptionPhan Huỳnh Diễm ThảoNo ratings yet

- Audit Report of SRF Date 16.9.11Document6 pagesAudit Report of SRF Date 16.9.11yash272No ratings yet

- Change Management Procedure Approval MatrixDocument2 pagesChange Management Procedure Approval MatrixVijayKrishnaNo ratings yet

- GM 1927-87 Special Nonconforming Material AuditDocument6 pagesGM 1927-87 Special Nonconforming Material AuditMichael HicksNo ratings yet

- Sample Updated IQA Check Sheet.Document16 pagesSample Updated IQA Check Sheet.ashwaniNo ratings yet

- Agile Essentials You Always Wanted To Know: Self Learning ManagementFrom EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementNo ratings yet

- Stellantis Ex PSA Scorecard Quick Reference Guide July 2021Document3 pagesStellantis Ex PSA Scorecard Quick Reference Guide July 2021白子健No ratings yet

- QSD111.00 Corporate Quality Manual PDFDocument22 pagesQSD111.00 Corporate Quality Manual PDFgregory velezNo ratings yet

- Annual ReportDocument240 pagesAnnual Reportappa raoNo ratings yet

- Vendor Evaluation StepsDocument7 pagesVendor Evaluation StepssarmaelectricalNo ratings yet

- BNC-Supplier Audit ProcedureDocument3 pagesBNC-Supplier Audit Procedurekyunjae JetomoNo ratings yet

- 6S Assessment Sheet: Necessary Information Is Not VisibleDocument1 page6S Assessment Sheet: Necessary Information Is Not VisibleMmstevens00No ratings yet

- Calibration Details With Sample Certificate and Website LinksDocument9 pagesCalibration Details With Sample Certificate and Website LinksAkash RajanNo ratings yet

- TE Escalation Matrix-2017Document1 pageTE Escalation Matrix-2017Remo MsaNo ratings yet

- Daily Work MGT Sheet & FormatsDocument5 pagesDaily Work MGT Sheet & FormatsKushagra NagrathNo ratings yet

- Regulatory Risk AnalysisDocument2 pagesRegulatory Risk AnalysisArmand LiviuNo ratings yet

- Primary Roles and ResponsibilitiesDocument3 pagesPrimary Roles and ResponsibilitiesasbishaliniNo ratings yet

- Fmea Chart 70kb PDFDocument1 pageFmea Chart 70kb PDFmike gamerNo ratings yet

- Supplier EvaluationDocument4 pagesSupplier EvaluationAmi Kar100% (1)

- Aspect Impact Hazard Risk Production and InspectionDocument19 pagesAspect Impact Hazard Risk Production and InspectionganrashNo ratings yet

- User Guide: # Y N N/A RYG EvidenceDocument22 pagesUser Guide: # Y N N/A RYG EvidenceLuis RamirezNo ratings yet

- Hatsumono DUCTODocument11 pagesHatsumono DUCTOSerchecko JaureguiNo ratings yet

- Rolled Throughput Yield (Training)Document7 pagesRolled Throughput Yield (Training)Madhavan RamNo ratings yet

- Process Verification Audit ChecklistDocument6 pagesProcess Verification Audit Checklisthmp90No ratings yet

- Process Map - Accounts ReveivableDocument4 pagesProcess Map - Accounts ReveivableOlumide AmbaliNo ratings yet

- Supplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017Document21 pagesSupplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017ilayaraja MKNo ratings yet

- IT Disposal ProposaDocument3 pagesIT Disposal ProposaWale ArewaNo ratings yet

- Skill Matrix MaterialsDocument2 pagesSkill Matrix MaterialsRavikant PandeyNo ratings yet

- Iso 9001 Internal Audit Checklist (EDocFind - Com)Document3 pagesIso 9001 Internal Audit Checklist (EDocFind - Com)anandthoriaNo ratings yet

- KPI For Support Engineer:: Sl. No. Key Result Areas (Kras) Kpi / Target Score ScaleDocument1 pageKPI For Support Engineer:: Sl. No. Key Result Areas (Kras) Kpi / Target Score ScaleSisir KarmakerNo ratings yet

- Change Management ApgDocument12 pagesChange Management ApgChidi OkerekeNo ratings yet

- Lean Thi Nki NG: Single Minute Exchange of Dies: Literature ReviewDocument11 pagesLean Thi Nki NG: Single Minute Exchange of Dies: Literature ReviewBhanuj VermaNo ratings yet

- Quality Manual Template PDFDocument19 pagesQuality Manual Template PDFvarun sainiNo ratings yet

- Garyville AWS Case Study - PDFDocument3 pagesGaryville AWS Case Study - PDFDias M.NNo ratings yet

- (5S Kaizen - Template) Files ManagementDocument7 pages(5S Kaizen - Template) Files ManagementRobert Glen Murrell JrNo ratings yet

- Transfer CaseDocument6 pagesTransfer CaseTim SmithNo ratings yet

- CS Project MYSQLDocument26 pagesCS Project MYSQLSamir ParmarNo ratings yet

- Supplier Scorecard GuidelinesDocument13 pagesSupplier Scorecard GuidelinesMani Rathinam RajamaniNo ratings yet

- 4.aluminium Company of Malaysia Berhad 2012Document108 pages4.aluminium Company of Malaysia Berhad 2012LeeNo ratings yet

- Spi Report 92758Document9 pagesSpi Report 92758AndyNo ratings yet

- CCD 2 CueDocument103 pagesCCD 2 Cuelaughingboy0No ratings yet

- Naveen BoggavarapuDocument3 pagesNaveen BoggavarapuCA Naveen BoggavarapuNo ratings yet

- Wipro Company ProfileDocument13 pagesWipro Company Profilerush2arthi100% (2)

- Reducing Samples of Aggregate To Testing Size: Standard Practice ForDocument5 pagesReducing Samples of Aggregate To Testing Size: Standard Practice ForAlisúa Másmela ZúñigaNo ratings yet

- SEC FormsDocument5 pagesSEC FormsGoodyNo ratings yet

- Chapter 11 070804Document8 pagesChapter 11 070804Shahid Nasir MalikNo ratings yet

- Merrel Dow Pharmaceuticals Inc. and Anr. v. H.N. Norton Co. Ltd. (1996) R.P.CDocument18 pagesMerrel Dow Pharmaceuticals Inc. and Anr. v. H.N. Norton Co. Ltd. (1996) R.P.Cvivsridhar100% (1)

- Ifcb2009 35Document3,425 pagesIfcb2009 35Anjith AkNo ratings yet

- ISO/TC 176/SC 2 Listing of Approved Interpretations Against ISO 9001:2015Document3 pagesISO/TC 176/SC 2 Listing of Approved Interpretations Against ISO 9001:2015velamirNo ratings yet

- P2P ProcessDocument12 pagesP2P ProcessranganvNo ratings yet

- 19-3-Affidavit of Alex Fisch of Morgan Joseph Tri ArtisanDocument13 pages19-3-Affidavit of Alex Fisch of Morgan Joseph Tri ArtisanDentist The MenaceNo ratings yet

- A1 Profile of ClientDocument2 pagesA1 Profile of ClientAbhiNo ratings yet

- Pizza Hut WaqasDocument30 pagesPizza Hut WaqasNadir Ali0% (2)

- Viral Marketing by Muhammad Iqrash AwanDocument10 pagesViral Marketing by Muhammad Iqrash AwanMuhammad Iqrash AwanNo ratings yet

- What Is The Difference Between Attestation Engagement and Direct Reporting Engagement in AuditingDocument13 pagesWhat Is The Difference Between Attestation Engagement and Direct Reporting Engagement in AuditingJennybabe PetaNo ratings yet

- IPAB Judgement On Payyanoor Ring GIDocument20 pagesIPAB Judgement On Payyanoor Ring GINithin V KumarNo ratings yet

- Q 3 5Document8 pagesQ 3 5DamodarSinghNo ratings yet

- Classic Pen CompanyDocument4 pagesClassic Pen CompanyGaurav Kataria0% (1)

- Account Planning ChecklistDocument1 pageAccount Planning ChecklistGhassan QutobNo ratings yet

- Lindsey A. Lichtscheidl: ObjectiveDocument3 pagesLindsey A. Lichtscheidl: ObjectiveLindsey LichtscheidlNo ratings yet

- Jetstar Airways CaseStudyDocument3 pagesJetstar Airways CaseStudyVenu PrakashNo ratings yet

- Proposal - Bingo NewDocument11 pagesProposal - Bingo NewThejas MurthyNo ratings yet

- Ch1-Intro To Sales ManagementDocument15 pagesCh1-Intro To Sales ManagementJitin GeorgeNo ratings yet