Professional Documents

Culture Documents

17.scafold Inspection UNISCO (PF) - 17

17.scafold Inspection UNISCO (PF) - 17

Uploaded by

Benasher Ibrahim0 ratings0% found this document useful (0 votes)

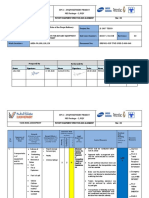

39 views2 pagesThis scaffolding inspection checklist contains 29 items to check for scaffolding safety. It includes checks for proper training of erection crews, use of safety equipment, structural integrity of scaffold components, guard rails and fall protection, ladder safety, and barricading of scaffold areas. Upon completion, the inspector will note any items that require attention and sign off to verify the inspection was performed.

Original Description:

Original Title

17.Scafold Inspection UNISCO[PF]-17

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis scaffolding inspection checklist contains 29 items to check for scaffolding safety. It includes checks for proper training of erection crews, use of safety equipment, structural integrity of scaffold components, guard rails and fall protection, ladder safety, and barricading of scaffold areas. Upon completion, the inspector will note any items that require attention and sign off to verify the inspection was performed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

39 views2 pages17.scafold Inspection UNISCO (PF) - 17

17.scafold Inspection UNISCO (PF) - 17

Uploaded by

Benasher IbrahimThis scaffolding inspection checklist contains 29 items to check for scaffolding safety. It includes checks for proper training of erection crews, use of safety equipment, structural integrity of scaffold components, guard rails and fall protection, ladder safety, and barricading of scaffold areas. Upon completion, the inspector will note any items that require attention and sign off to verify the inspection was performed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

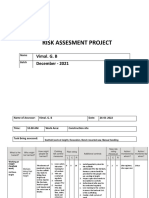

UNITED INDUSTRIAL SERVICES CO.

LLC

SCAFFOLDING INSPECTION CHECKLIST

Location: Date & Time:

Job # & Name:

Inspection done by :-

Sl. Description Yes No NA Remarks

1 Personnel involved in erection and dismantling of scaffolding

trained and experienced in that work.

2 Trained and experienced supervisors provided for the control of

erection and dismantling of scaffolds.

3 Personnel involved in the erection and dismantling of scaffold wear

safety harness, helmet with chinstrap, gloves & shoes.

4 Scoffold erection has taken into consideration the structures,

overhead lines and other activities in the vicinity.

5 Scaffolding materials are of proprietary make, free from defects /

damages and used in accordance with its designed purpose.

6 Standards placed on hard ground, steel, concrete, etc. or suitable sole

plates / base plates provided.

7 Sole plates where provided support at least two standards; either two

adjacent or two opposite standards.

8 Spacing is adequate between the standards with respect to the

intended load.

Type of work Spacing Maximum Load

Access 2.7 M 0.75 KN / M2

Light Duty 2.4 M 1.50 KN / M2

General Purpose 2.1 M 2.00 KN / M2

Heavy Duty 2.0 M 2.50 KN / M2

Special Duty 1.8 M 3.00 KN / M2

9 Ledger joints are staggered and not on the same bay.

10 Transoms spacing suitable to the platform board thickness

Thickness Transoms Spacing

32 mm 0.9 m

40 mm 1.5 m

51 mm 2.5 m

63 mm 3.2 m

11 Intermediate transoms are provided where the transoms spacing

exceeds the limit (every 1.5m for 40 mm thick plank).

12 Ledger (shorter dimension) / façade (longer dimension) bracing

provided from bottom up to top lift.

13 Platform is fully boarded without any gaps between hand rails.

14 The spacing between platform and the structure being worked on does

not exceed 300 mm, without any need for stretching.

15 Work platform is free from projecting nails, bends, cracks, gaps,

overlaps, etc.

16 Planks are securely fastened with clamps.

17 Overhanging of wooden planks of working platforms is restricted

between 50 – 150 mm.

UNISCO[PF]HSE-15 REV-00 15/07/16

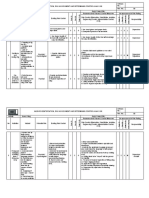

UNITED INDUSTRIAL SERVICES CO.LLC

SCAFFOLDING INSPECTION CHECKLIST

Location: Date & Time:

Job # & Name:

Inspection done by :-

Sl. Description Yes No NA Remarks

18 Work platforms provided with double guard rail (top & middle)

and toe boards.

19 Top rail are provided at 950mm above work platform.

20 Toe boards are secured inside the standards and provided around

all open sides.

21 The gap between the toe board and the middle rail does not

exceed 470mm.

22 Ties provided fixing the scaffolding to fixed structures (one tie for every

40 m sq).

23 Scaffold area barricaded to prevent movement of vehicle /

equipment / personnel, in the vicinity.

24 Proper ladder of proprietary make is provided for ascending &

descending and reaching all part of the scaffold (above 1.5 m).

25 Ladder made of timber (timber not painted) or aluminium.

26 Series of ladders with intermediate platforms properly protected with

guard rails and toe boards, are provided, where more than 9 m height

to be climbed.

27 The base to height ratio of ladder maintained as 1 : 4 such that the

angle is 75° from horizontal and 15° from vertical.

28 The ladder is adequately secured with a minimum vertical

protrusion of 1 m above Platform.

29 Scafftag provided in the scaffold indicating its suitability for use.

Comments, if any:

Inspected By :

Name : Signature :

Designation : Date :

Inspection carried out by: Signature with date:

UNISCO[PF]HSE-15 REV-00 15/07/16

You might also like

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- Portable Electrical Equipment InspectorDocument2 pagesPortable Electrical Equipment InspectorAmukelaniNo ratings yet

- Excavation Working in Trenches Swms 10281-6Document17 pagesExcavation Working in Trenches Swms 10281-6JamesNo ratings yet

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- Ehs PR 03.f01 Patos FormDocument2 pagesEhs PR 03.f01 Patos FormClyde Villanueva100% (4)

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- Accident Investigation Form SampleDocument2 pagesAccident Investigation Form Sample811 - 813100% (2)

- Safe Work Method Statement - Part 1: Company DetailsDocument11 pagesSafe Work Method Statement - Part 1: Company DetailsAa YusriantoNo ratings yet

- GP 47.0 Ppe FormDocument1 pageGP 47.0 Ppe FormLarbi BelazizNo ratings yet

- ROAD SAFETY AUDIT (Construction Stage) Case Specific Check List Issue Yes No Comment 1 Traffrc Management Plan (Design and Implementation)Document6 pagesROAD SAFETY AUDIT (Construction Stage) Case Specific Check List Issue Yes No Comment 1 Traffrc Management Plan (Design and Implementation)GANESH MOHITENo ratings yet

- SWP BackfillDocument1 pageSWP BackfillMohamed Zied ChaariNo ratings yet

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Construction Labourer Swms 10556-4Document16 pagesConstruction Labourer Swms 10556-4JamesNo ratings yet

- Stone Cleaning Method Statement and Risk Assessment-1 PDFDocument6 pagesStone Cleaning Method Statement and Risk Assessment-1 PDFحمودي معزNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Checklist For Scaffolding: Construction of Srr2-Construction Management ServicesDocument3 pagesChecklist For Scaffolding: Construction of Srr2-Construction Management ServicesChayank TiwariNo ratings yet

- Stacking & Storage InspectionDocument1 pageStacking & Storage InspectionKiran BhattNo ratings yet

- HSE KPI'sDocument8 pagesHSE KPI'sMahir ShihabNo ratings yet

- Excavation and Trenching Safe Work ProcedureDocument4 pagesExcavation and Trenching Safe Work Proceduresefina mecNo ratings yet

- 14 Fire Mock Drill Report - 17-07-2020Document5 pages14 Fire Mock Drill Report - 17-07-2020Sahadeo ReddyNo ratings yet

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- Job Safety Analysis: Helmet, Shoes, Goggles, Leather Gloves, Noise Mask, Face Shield, Apron EtcDocument3 pagesJob Safety Analysis: Helmet, Shoes, Goggles, Leather Gloves, Noise Mask, Face Shield, Apron Etc123shripadNo ratings yet

- HR HR TEM007 GEN ALL Visitor Induction Rev1.0Document2 pagesHR HR TEM007 GEN ALL Visitor Induction Rev1.0Doni TriatmojoNo ratings yet

- 3 RN Sop PDFDocument4 pages3 RN Sop PDFDwitikrushna RoutNo ratings yet

- Environmental Health and Safety Electrical Safety Program and PermitDocument25 pagesEnvironmental Health and Safety Electrical Safety Program and PermitDanielSombeNo ratings yet

- Working Near Utilities: Work Health and Safety ProcedureDocument31 pagesWorking Near Utilities: Work Health and Safety ProcedureVijaya Seharan NairNo ratings yet

- Working On or Adjacent To A Road: Health and Safety ProcedureDocument18 pagesWorking On or Adjacent To A Road: Health and Safety ProcedureEtibar AliyevNo ratings yet

- (JSA) Concreting in FoundationDocument2 pages(JSA) Concreting in FoundationGunjan Sinha AdityaNo ratings yet

- Energized Work PermitDocument1 pageEnergized Work PermithalexNo ratings yet

- Toolboxtalk2 Housekeeping PDFDocument2 pagesToolboxtalk2 Housekeeping PDFSajid HussainNo ratings yet

- SWMS Loading and Unloading Vehicles WHS.127 V002.1Document18 pagesSWMS Loading and Unloading Vehicles WHS.127 V002.1Amit BhattNo ratings yet

- Risk Assessment - Glazing PDFDocument3 pagesRisk Assessment - Glazing PDFAngel GrospeNo ratings yet

- Waste Management PolicyDocument16 pagesWaste Management PolicyImran MahmudNo ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistSalu BahiNo ratings yet

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 pagesCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazNo ratings yet

- Hand and Power Tool Safety 08Document60 pagesHand and Power Tool Safety 08galihNo ratings yet

- RA For Stone Work Rev1Document5 pagesRA For Stone Work Rev1Muhammed yahiyaNo ratings yet

- Emergency Response PlanDocument1 pageEmergency Response PlanArslanSaeedNo ratings yet

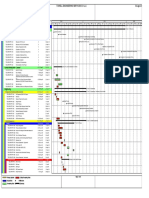

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Emergency Evacuation RouteDocument1 pageEmergency Evacuation Routeabe_seinNo ratings yet

- JD - Occupational Health and Safety OfficerDocument2 pagesJD - Occupational Health and Safety OfficergiovadiNo ratings yet

- 15 Driving Safety and Training ProcedureDocument6 pages15 Driving Safety and Training Procedureihajar9100% (1)

- Coshh Assessment FormDocument6 pagesCoshh Assessment FormAfaan gani InamdarNo ratings yet

- RCCB Testing Format - HSE-CTN-HPP-FMT-001Document1 pageRCCB Testing Format - HSE-CTN-HPP-FMT-001Radha Buildtech100% (1)

- Risk Assessment For Installation, Testing & Commissioning of Fire Pumps SetDocument11 pagesRisk Assessment For Installation, Testing & Commissioning of Fire Pumps SetAmie GTunedNo ratings yet

- Risk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- Risk Assessment of Manual HandlingDocument2 pagesRisk Assessment of Manual HandlingMAB AliNo ratings yet

- Fire Prevention ChecklistDocument1 pageFire Prevention ChecklistJosiahNo ratings yet

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 pagesInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNo ratings yet

- Daily Excavation Safety ChecklistDocument2 pagesDaily Excavation Safety ChecklistfaithablazebNo ratings yet

- 22-RA-Paint WorkDocument2 pages22-RA-Paint Workravindra100% (1)

- Workplace Safety Manual 17 18Document12 pagesWorkplace Safety Manual 17 18Maria Kathleen Evangelio JognoNo ratings yet

- Traning Notes ScafoldingDocument3 pagesTraning Notes ScafoldingibrahimNo ratings yet

- ScaffoldingDocument24 pagesScaffoldingAzrulZamriNo ratings yet

- Intrebari SCaffoldfinalDocument14 pagesIntrebari SCaffoldfinalMadalina FoteaNo ratings yet

- DRP001-PUC-TRL-O94-000-4128 Rev.0Document16 pagesDRP001-PUC-TRL-O94-000-4128 Rev.0Benasher IbrahimNo ratings yet

- EPCC For Multi Purpose Tank Project (Refloat)Document8 pagesEPCC For Multi Purpose Tank Project (Refloat)Benasher IbrahimNo ratings yet

- Unisco Issue DetailsDocument3 pagesUnisco Issue DetailsBenasher IbrahimNo ratings yet

- Tie in Offsite ValvesDocument8 pagesTie in Offsite ValvesBenasher IbrahimNo ratings yet

- TRA - Rotary Equipment ErectionDocument29 pagesTRA - Rotary Equipment ErectionBenasher IbrahimNo ratings yet

- Code & Specification For PPEs - TESCODocument20 pagesCode & Specification For PPEs - TESCOBenasher IbrahimNo ratings yet

- MS (TP-50002)Document13 pagesMS (TP-50002)Benasher IbrahimNo ratings yet

- Srip TT JS SS PP Sute 0112Document3 pagesSrip TT JS SS PP Sute 0112Benasher IbrahimNo ratings yet

- Life Saving RulesDocument1 pageLife Saving RulesBenasher IbrahimNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- R 1354 001 01 (Datasheet)Document35 pagesR 1354 001 01 (Datasheet)Benasher IbrahimNo ratings yet

- Hs Flash Alert - Reformer - MTCDocument1 pageHs Flash Alert - Reformer - MTCBenasher IbrahimNo ratings yet

- Organization Chart - MPTDocument1 pageOrganization Chart - MPTBenasher IbrahimNo ratings yet

- OIL FILTERATION - TRA - RevDocument21 pagesOIL FILTERATION - TRA - RevBenasher IbrahimNo ratings yet

- Tra-Derrick Module Assembly Below 30 MetersDocument37 pagesTra-Derrick Module Assembly Below 30 MetersBenasher IbrahimNo ratings yet

- Radiation Emergency PlanDocument31 pagesRadiation Emergency PlanBenasher Ibrahim100% (1)

- Aera 0 - Hse Org Chart - Rev 15 - 25.05Document1 pageAera 0 - Hse Org Chart - Rev 15 - 25.05Benasher IbrahimNo ratings yet

- 20 IlluminationDocument1 page20 IlluminationBenasher IbrahimNo ratings yet

- Inspection Unisco (PF) Hse-09Document4 pagesInspection Unisco (PF) Hse-09Benasher IbrahimNo ratings yet

- 25.employee Safety EvaluationDocument1 page25.employee Safety EvaluationBenasher IbrahimNo ratings yet

- 26.lifting Gears UNISCO (PF) HSE-26Document2 pages26.lifting Gears UNISCO (PF) HSE-26Benasher IbrahimNo ratings yet

- 5.default Notice UNISCO (PF) HSE-05Document1 page5.default Notice UNISCO (PF) HSE-05Benasher IbrahimNo ratings yet

- 5.CRASH CART Check ListDocument4 pages5.CRASH CART Check ListBenasher IbrahimNo ratings yet

- 21 WahDocument2 pages21 WahBenasher IbrahimNo ratings yet

- Grauity DetailsDocument2 pagesGrauity DetailsBenasher IbrahimNo ratings yet

- 11.training Attend UNISCO (PF) HSE-11Document1 page11.training Attend UNISCO (PF) HSE-11Benasher IbrahimNo ratings yet

- Demineralized Water or DM WATERDocument3 pagesDemineralized Water or DM WATERBenasher IbrahimNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitBenasher IbrahimNo ratings yet

- Cupboard - One InventoryDocument11 pagesCupboard - One InventoryBenasher IbrahimNo ratings yet

- Medicine Daily ChecklistDocument2 pagesMedicine Daily ChecklistBenasher IbrahimNo ratings yet

- Geotechnical HS StandardsDocument1 pageGeotechnical HS StandardsWhiskoNo ratings yet

- (MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixDocument7 pages(MRDTM 418) : Quantitative Extraction of Asphalt From Asphalt Paving MixBelal AlmokdadNo ratings yet

- DGS MU 204 Rev 1Document19 pagesDGS MU 204 Rev 1JOHN DANIALNo ratings yet

- Progress ReportDocument7 pagesProgress ReportRizki LazuardiNo ratings yet

- Kanowit Progress Report NO.10Document28 pagesKanowit Progress Report NO.10Kevin ChangNo ratings yet

- 3 Bed BungalowDocument1 page3 Bed BungalowMichael KiwingaNo ratings yet

- Flexible Pavement DistressDocument33 pagesFlexible Pavement DistressMohammed Omer KufishahNo ratings yet

- Hoisting Hook Detail: Elevator PlanDocument1 pageHoisting Hook Detail: Elevator Planywb ecsNo ratings yet

- BOQ - Method of Measurement and BOQ PDFDocument176 pagesBOQ - Method of Measurement and BOQ PDFyousef100% (1)

- (L5 - 002) SOLN-SD-DR-MSI-BB623-L5-00391 - D-04.1 (HW-4H.2) at LEVEL 5 0 - B APPROVED WC 0Document1 page(L5 - 002) SOLN-SD-DR-MSI-BB623-L5-00391 - D-04.1 (HW-4H.2) at LEVEL 5 0 - B APPROVED WC 0Michael TugawenNo ratings yet

- DAUB 2021-03 Recommendations For The Selection of Tunnel Boring MachinesDocument55 pagesDAUB 2021-03 Recommendations For The Selection of Tunnel Boring MachinesGeopatarecaNo ratings yet

- Flamex S: Constructive SolutionsDocument4 pagesFlamex S: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Licensed To Arun Kumar Das: (Reaffirmed 2017)Document9 pagesLicensed To Arun Kumar Das: (Reaffirmed 2017)Indira BanerjeeNo ratings yet

- 03 TechnicalDocument33 pages03 Technicalban-mrw CompaniesNo ratings yet

- Infrastructure Works Sewerage Works: All Quantities Marked Provisional Are Subjected To RemeasurementDocument2 pagesInfrastructure Works Sewerage Works: All Quantities Marked Provisional Are Subjected To RemeasurementSyahmi AbdullahNo ratings yet

- Work Method Statement For Earthworks: - Your Project TitleDocument9 pagesWork Method Statement For Earthworks: - Your Project TitleRufahniyah LizhaNo ratings yet

- Grade 7 Module 4 Constructing Pictorial DrawingDocument48 pagesGrade 7 Module 4 Constructing Pictorial DrawingMichael Tico33% (3)

- Project Scope StatementDocument2 pagesProject Scope Statementapi-630184911No ratings yet

- Feb 2017 Buildability SiteDocument21 pagesFeb 2017 Buildability SiteTun Lin OoNo ratings yet

- Retaining Wall & StructureDocument2 pagesRetaining Wall & StructureGreens MacNo ratings yet

- Structural and Crane Load Design CriteriaDocument13 pagesStructural and Crane Load Design CriteriaMontoya SantiagoNo ratings yet

- Method Statement Fo Reinforcement Works BlogDocument8 pagesMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- Precast SystemsDocument13 pagesPrecast Systemsparamarthasom1974No ratings yet

- 1840-1940:genesis of Modern Architecture in Beirut: Robert SalibaDocument12 pages1840-1940:genesis of Modern Architecture in Beirut: Robert SalibaElias AsmarNo ratings yet

- Department of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationDocument7 pagesDepartment of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationKrijan Mali100% (1)

- Building J Renovation-PlansDocument83 pagesBuilding J Renovation-PlansBala Hemanth KumarNo ratings yet

- Euclidean Geometry With Tkz-Euclide: Alain Matthes January 23, 2020Document9 pagesEuclidean Geometry With Tkz-Euclide: Alain Matthes January 23, 2020ruben alejandro TeranNo ratings yet

- Direct Tension in Anchor Bars PDFDocument13 pagesDirect Tension in Anchor Bars PDFvsballaNo ratings yet

- Company Profile: Al Baraq Steel Works L.L.CDocument28 pagesCompany Profile: Al Baraq Steel Works L.L.CEngineering ComillaNo ratings yet

- Chamberlain WhisperDrive 8200CDocument80 pagesChamberlain WhisperDrive 8200CalexologNo ratings yet