Professional Documents

Culture Documents

290BPSWING Gearbox Ass

290BPSWING Gearbox Ass

Uploaded by

Ko ZayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

290BPSWING Gearbox Ass

290BPSWING Gearbox Ass

Uploaded by

Ko ZayCopyright:

Available Formats

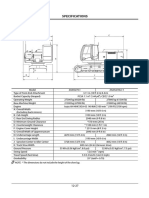

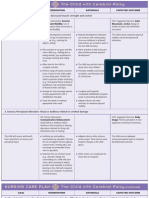

WIN PROGRESS CO.,Ltd.

(Pharkant Branch)

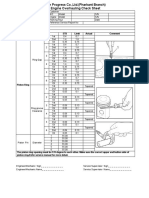

EC290BPrime Swing Gearbox Assemble Check Sheet

Customer Report No.

Machine Model Service date

Machine Serial No. Component Serial No.

Working Hour Cause of Problem

Preparations

Use a torque wrench to tighten the mounting screws to the specified torque.

Clean all parts with cleaning solvent and dry with compressed air.

Rework damaged parts and before assembling, prepare all replacement parts.

Coat the sliding parts, bearings and gears with clean gear oil.

Replace the oil seal.

Tools as follow;

Spanner(18mm,22mm,24mm),Socket wrench(11mm),Eye bolts(10mm,12mm,16mm,

Allen key(5mm,10mm,14mm), Rubber hammer,Screw driver(-),Snap ring pliers(inside,outside),LT-40,LT-165

Torqre Wrench

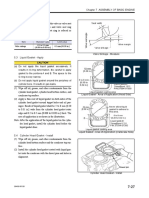

No Description Torque Status Figure

1 Installation, oil seal

Press seal (1) into housing using special tool

Note! Apply grease onto the oil seal lip.

2 Installation,spherical bearing

Install seal(10) collar (9) and nilos ring(8) onto shaft (1)

then install spherical bearing(5).

3 Installation, spherical_bearing

Install shaft (1) assembly into case (4).

Press–fit spherical bearing (3) into hosing

Note! Press–fit both inner and outer race simultaneously.

4 Installation, retaining ring

Install retaining ring (2) onto shaft

5 Install cover (6) and screws (7).

Install retaining ring (2) onto shaft.

6 Installation, cover

Install cover (6) and screws (7). 98.4 ± 9.6 lbf.ft

Note! Apply liquid gasket oncover's face.

Note! Apply loctite onto the threads of screws.

7 Assembly, carrier No.2

Install carrier assembly No.2.

Insert thrust washer (4), bushing (2) and planetary gear

No.2 (3) into carrier (6). Insert pin (1).

Tap spring pin (5) into the pin hole of carrier (6).

After inserting, stake both sides of spring pin (5).

Note! Ensure that gears (3) rotate smoothly.

8 Assembly, carrier No.1

Install under washer(2), gear (5) including bearing (4),

upper washer (2).

Install pins (3) into carrier (6) and install spring pin (1).

After inserting, stake both sides of spring pin(1).

Note! Ensure that gears (5) rotate smoothly.

No Description Torque Status Figure

9 Installation, carrier assembly No.2 into casing

Install ring gear and carrier assembly No.2.

Insert dowel pins (2) at four places on case.

Install ring gear (1) onto case.

Insert carrier assembly No.2 into ring gear (1).

Insert thrust ring(3) into carrier assembly No.2,

then install sun gear (4).

Note! Before installing ring gear, coat the mating surface

of case with liquid gasket loctite.

10 Installation, carrier assembly No.1 and sun gear No.1

Install carrier assembly No.2 (2) into ring gear (1).

Install sun gear No.1 (3).

Note! Confirm that shaft rotates smoothly by turning

the sun gear No.1.

11 Installation, motor

Install retaining ring into motor shaft.

Install the motor onto ring gear (2) then install screws (1). 263 ± 26lbf.ft

Note! Align match mark (A) of the motor and ring gear (2).

Coat the mating surface of ring gear (2)

with liquid gasket loctite.

Apply loctite onto the threads of screws (1).

12 Installation, pipe

Install pipe (3), gasket copper (5) and valve (4).

Connect pipe (2) onto the motor.

Refill the gear oil through oil filling pipe and

install level gauge (1).

Note! Apply loctite onto pipe (3, 2) before installation.

Amount of oil capacity: 6.1 liter (1.61 gal).

Connect nipple-lubrication to the case. 11 ± 1 lbf.ft

Refill the grease through nipple-lubrication

and connect plug. 11 ± 1 lbf.ft

Note! Amount of grease: 1.2 liter (0.32 gal).

Service Person Sign_ _ _ _ _ _ _ Supervisor Sign_ _ _ _ _ _ _

Service Person Name_ _ _ _ _ _ _ Supervisor Name_ _ _ _ _ _ _

You might also like

- Engine, Assembling: Service InformationDocument29 pagesEngine, Assembling: Service Informationducatiss90074% (23)

- D7EDocument35 pagesD7ERajan Mullappilly71% (21)

- DD15 Detroit DieselDocument10 pagesDD15 Detroit Dieselstarsky100% (4)

- How To Write Your Engineering Experience Record - Professional Engineers ExaDocument3 pagesHow To Write Your Engineering Experience Record - Professional Engineers ExaTherese Araymond67% (3)

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocument17 pagesCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNo ratings yet

- Volvo D6D Shop ArmedDocument45 pagesVolvo D6D Shop ArmedBASILIO JARA HUERTA100% (4)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Sanden SD6V12 Service Manual. Date of Issue May Prepared by Sanden International (Europe) Ltd. For Opel.Document25 pagesSanden SD6V12 Service Manual. Date of Issue May Prepared by Sanden International (Europe) Ltd. For Opel.Luigi TencoNo ratings yet

- Volvo d12d TimingDocument9 pagesVolvo d12d Timingali100% (1)

- 4d94e Shop ManualDocument25 pages4d94e Shop Manualyeudys100% (5)

- Cummins Ism, QSMDocument11 pagesCummins Ism, QSMibnu67% (6)

- Volvo D12Document5 pagesVolvo D12ANH LÊ0% (1)

- Uia UC1901 76146 7Document28 pagesUia UC1901 76146 7That Dude GageNo ratings yet

- Stella 4 Stroke Service Station ManualDocument178 pagesStella 4 Stroke Service Station Manuallcnewt100% (1)

- Track Gearbox, Assembly: Service InformationDocument10 pagesTrack Gearbox, Assembly: Service InformationaungaungoomanualNo ratings yet

- Location of ComponentsDocument103 pagesLocation of ComponentsAstrit Strati100% (1)

- Flow Doc.1 PDFDocument12 pagesFlow Doc.1 PDFJozefNo ratings yet

- Flow Doc 2 PDFDocument18 pagesFlow Doc 2 PDFJozefNo ratings yet

- Final DriveDocument10 pagesFinal DriveaungaungoomanualNo ratings yet

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVONo ratings yet

- TM 5-3805-254-14P-2 Part 5 Ihc F-5070 Dump TruckDocument140 pagesTM 5-3805-254-14P-2 Part 5 Ihc F-5070 Dump TruckAdvocateNo ratings yet

- Unit Injector - Install: Installation ProcedureDocument6 pagesUnit Injector - Install: Installation ProceduredayanaNo ratings yet

- QuickServe Online - (4021531) QSB4.5 and QSB6.7 Operation and Maintenance ManualDocument7 pagesQuickServe Online - (4021531) QSB4.5 and QSB6.7 Operation and Maintenance Manualibrahim salemNo ratings yet

- Char-Lynn: Series 10 Steering Control Units 001 Disassembly/ReassemblyDocument9 pagesChar-Lynn: Series 10 Steering Control Units 001 Disassembly/ReassemblyIslam ShoukryNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - Installsergio blandon lNo ratings yet

- Final Drive AssemblyDocument118 pagesFinal Drive AssemblyKARTHICKRAJ KANDASAMYNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Install The ATF (Automatic Transaxle Fluid) Oil Cooler Hoses (C) - Page 116 of 138Document15 pagesInstall The ATF (Automatic Transaxle Fluid) Oil Cooler Hoses (C) - Page 116 of 138flash_24014910No ratings yet

- CS 533 ManualDocument9 pagesCS 533 ManualbagoesNo ratings yet

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaNo ratings yet

- Workshop Manual 500R Reversing Drum Mixers Issue 10 2016Document176 pagesWorkshop Manual 500R Reversing Drum Mixers Issue 10 2016ZimChild GAMINGNo ratings yet

- Kbu KBZ4Document5 pagesKbu KBZ4Andrew VNo ratings yet

- This Document Has Been Printed From SPI2. NOT FOR RESALE: Pump To ManifoldDocument1 pageThis Document Has Been Printed From SPI2. NOT FOR RESALE: Pump To Manifoldmoh asalanyNo ratings yet

- Cummins Ism QSM PDFDocument11 pagesCummins Ism QSM PDFEng-AhmedRashadNo ratings yet

- Mshe 112 002 - C4Document18 pagesMshe 112 002 - C4Automan IntertradeNo ratings yet

- VOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFDocument16 pagesVOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFfjjsjekdmme67% (3)

- Slide Cam Pulley: Instructions ManualDocument5 pagesSlide Cam Pulley: Instructions Manualhenrysaputra168No ratings yet

- Install Piston & Conrod 320 GCDocument3 pagesInstall Piston & Conrod 320 GCJebrodNo ratings yet

- Volvo D13H Shop Armed Vol2Document34 pagesVolvo D13H Shop Armed Vol2Juan José AldanaNo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- Service Information EX700BDocument3 pagesService Information EX700BAngelo SolorzanoNo ratings yet

- AC Compressor ServicingDocument28 pagesAC Compressor Servicinggentiles mdqNo ratings yet

- 2006 cbr1000rrDocument162 pages2006 cbr1000rrIsai OchoaNo ratings yet

- Manual XQ29-1.8 Power Tong - MotDocument27 pagesManual XQ29-1.8 Power Tong - MotPedro GilNo ratings yet

- Item Standard Value Limit Value Valve Sinkage - 0.1 To 0.1 MM (-0.004 To 0.004 In.) 0.5 MM (0.020 In.)Document11 pagesItem Standard Value Limit Value Valve Sinkage - 0.1 To 0.1 MM (-0.004 To 0.004 In.) 0.5 MM (0.020 In.)pearl nojokeNo ratings yet

- Removal/installation Recommendations: Identification of NTN-SNR Wheel Bearing KIT R140.77Document7 pagesRemoval/installation Recommendations: Identification of NTN-SNR Wheel Bearing KIT R140.77Ioan PascaNo ratings yet

- YG Cylinder ManualDocument8 pagesYG Cylinder ManualMr NovaNo ratings yet

- Every 500 Hours MaintenanceDocument7 pagesEvery 500 Hours Maintenancerolandaaprian9No ratings yet

- Specifications Systems Operation Testing and Adjusting - CS-531D, CP-533D and CS-533D Vibratory Compactors Vibratory SystemDocument64 pagesSpecifications Systems Operation Testing and Adjusting - CS-531D, CP-533D and CS-533D Vibratory Compactors Vibratory SystemTony Melendez50% (2)

- PV776 TSP161560Document5 pagesPV776 TSP161560Jesús Jaguer MeisterNo ratings yet

- 001-054 Piston and Connecting Rod AssemblyDocument8 pages001-054 Piston and Connecting Rod AssemblyYè WințNo ratings yet

- 330 D InformacionDocument12 pages330 D InformacionJhonny Frank Paredes CastroNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- Disassembly and AssemblyDocument100 pagesDisassembly and AssemblybagoesNo ratings yet

- 992D Valve Set InstructionsDocument7 pages992D Valve Set InstructionsJohn GrayNo ratings yet

- 24H Engine Valve SetDocument7 pages24H Engine Valve SetJohn GrayNo ratings yet

- Installation Procedure For Vertical Glandless Process PumpDocument22 pagesInstallation Procedure For Vertical Glandless Process PumpYoutube For EducationNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - InstallqwuLzNo ratings yet

- Booster Pump Service ManualDocument11 pagesBooster Pump Service ManualSGI AUTOMOTIVE PVT LTDNo ratings yet

- Pistons and Connecting Rods - InstallDocument3 pagesPistons and Connecting Rods - InstallqwuLzNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Common Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDDocument11 pagesCommon Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDKo ZayNo ratings yet

- Zaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDDocument13 pagesZaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDKo ZayNo ratings yet

- Performance Test For Zx670-3: Unit Actual Value Standard Value RemarkDocument2 pagesPerformance Test For Zx670-3: Unit Actual Value Standard Value RemarkKo ZayNo ratings yet

- ReturnDocument27 pagesReturnKo ZayNo ratings yet

- Upperstructure: Section 2Document193 pagesUpperstructure: Section 2Ko ZayNo ratings yet

- Hydraulic SymbolsDocument15 pagesHydraulic SymbolsKo ZayNo ratings yet

- SpecificationsDocument9 pagesSpecificationsKo ZayNo ratings yet

- SpecificationsDocument5 pagesSpecificationsKo ZayNo ratings yet

- Specifications Zaxis650LcDocument10 pagesSpecifications Zaxis650LcKo ZayNo ratings yet

- Isuzu Parts Catalog 4HK1Document62 pagesIsuzu Parts Catalog 4HK1Ko Zay100% (1)

- SpecificationsDocument4 pagesSpecificationsKo ZayNo ratings yet

- Boom Raise Function SlowDocument1 pageBoom Raise Function SlowKo ZayNo ratings yet

- D12C EngAss, Diss (Piston)Document1 pageD12C EngAss, Diss (Piston)Ko ZayNo ratings yet

- Boom Can't DownDocument1 pageBoom Can't DownKo ZayNo ratings yet

- Boom Cylinder Creeping &driftDocument2 pagesBoom Cylinder Creeping &driftKo ZayNo ratings yet

- Boom Cylinder Can't LiftDocument2 pagesBoom Cylinder Can't LiftKo ZayNo ratings yet

- Electrical Assessment QuestionsDocument24 pagesElectrical Assessment QuestionsKo ZayNo ratings yet

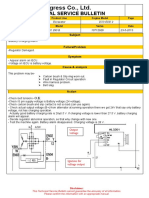

- Win Progress Co., LTD.: Technical Service BulletinDocument3 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- 290BPSWING Gear Box DisassDocument2 pages290BPSWING Gear Box DisassKo ZayNo ratings yet

- D12D Eng Ass and Disass (Piston)Document1 pageD12D Eng Ass and Disass (Piston)Ko ZayNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- Hitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Document71 pagesHitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Ko Zay100% (1)

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Training Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Document18 pagesTraining Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Ko ZayNo ratings yet

- 6.section C - ElectricsDocument225 pages6.section C - ElectricsKo Zay100% (5)

- Engine Oil Pressure Alarm 128 Pid 100 FMI 1Document2 pagesEngine Oil Pressure Alarm 128 Pid 100 FMI 1Ko ZayNo ratings yet

- Damage Crank Shaft BearingDocument2 pagesDamage Crank Shaft BearingKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- FS Curtis FAC 28B 28BC Instruction Manual KubotaDocument69 pagesFS Curtis FAC 28B 28BC Instruction Manual KubotaKo ZayNo ratings yet

- NYR (AL) Y 1 X (10-500) MM 0.6/1 KV: Cu / PVC / Awa / PVCDocument5 pagesNYR (AL) Y 1 X (10-500) MM 0.6/1 KV: Cu / PVC / Awa / PVCBagus Arief WibowoNo ratings yet

- 139-WADB AD 2-1 To 2-8Document8 pages139-WADB AD 2-1 To 2-8Danny SupriyadiNo ratings yet

- Smartphone 5G V5Document1 pageSmartphone 5G V5João PedroNo ratings yet

- Copd Drug StudyDocument9 pagesCopd Drug StudyJoegie Ario100% (1)

- Catalog HarfitDocument80 pagesCatalog Harfitfajarsanjaya1992No ratings yet

- Rakesh Bahnewal ResumeDocument3 pagesRakesh Bahnewal ResumeswaroopNo ratings yet

- OB - Hypertensive Disorders in PregnancyDocument6 pagesOB - Hypertensive Disorders in PregnancyM MNo ratings yet

- Autoclaving Glassware CorningDocument2 pagesAutoclaving Glassware CorninghellowinstonNo ratings yet

- Pickerlaza: A Website On Iot Based Garbage Collection SystemDocument20 pagesPickerlaza: A Website On Iot Based Garbage Collection SystemBeckyNo ratings yet

- Brook Comptom Frame Sizes PDFDocument12 pagesBrook Comptom Frame Sizes PDFVictorNo ratings yet

- A Detailed Lesson Plan in Technology and Livelihood Education - Beauty Care (Nail Care)Document4 pagesA Detailed Lesson Plan in Technology and Livelihood Education - Beauty Care (Nail Care)Exequiel Macalisang Ramientos Jr.No ratings yet

- BRKSPM 2012Document92 pagesBRKSPM 2012Mohammad KhorashadizadehNo ratings yet

- Tech Note 14Document2 pagesTech Note 14meteohrNo ratings yet

- DR Geeta Pangi HypertensionDocument6 pagesDR Geeta Pangi HypertensionSheera EiyraaNo ratings yet

- DR Nadia AhmadDocument4 pagesDR Nadia AhmadNadia AhmadNo ratings yet

- Paid Payback (091 120)Document30 pagesPaid Payback (091 120)sabaebrahimii83No ratings yet

- 2 Biostat ProbabilityDocument53 pages2 Biostat ProbabilityNaolShamsuNo ratings yet

- York County Court Schedule For July 17Document26 pagesYork County Court Schedule For July 17York Daily Record/Sunday NewsNo ratings yet

- Publix Coral Springs Inspection ReportDocument5 pagesPublix Coral Springs Inspection ReportAmanda RojasNo ratings yet

- LifeSaver Bottle Instruction Manual 1Document13 pagesLifeSaver Bottle Instruction Manual 1VladimirNo ratings yet

- Steam TableDocument3 pagesSteam TableMUHAMAD SAUKINo ratings yet

- Child - Cerebral PalsyDocument3 pagesChild - Cerebral PalsyJamie Icabandi67% (3)

- Malpresentation and Malposition of The FetusDocument41 pagesMalpresentation and Malposition of The FetusJonielyn LagunaNo ratings yet

- Paper 6 Chemistry General NotesDocument5 pagesPaper 6 Chemistry General NotesMiran El-MaghrabiNo ratings yet

- Hg-Grade 8-Module 5Document23 pagesHg-Grade 8-Module 5Jello PanaguitonNo ratings yet

- Kathon WT 1.5 Percent Biocide PDFDocument14 pagesKathon WT 1.5 Percent Biocide PDFJulia ChouNo ratings yet

- McQuay MWM Technical Manual Eng PDFDocument199 pagesMcQuay MWM Technical Manual Eng PDFBenben CobainNo ratings yet